Suzuki Grand Vitara JB627. Manual — part 9

0B-6 Maintenance and Lubrication:

Fuel Lines and Connections Inspection

S6JB0B0206010

Visually inspect fuel lines and connections for evidence

of fuel leakage, hose cracking and damage. Make sure

all clamps are secure.

Repair leaky joints, if any.

Replace hoses that are suspected of being cracked.

Fuel Filter Replacement

S6JB0B0206011

Fuel filter is installed in fuel pump assembly in fuel tank.

Replace fuel filter or fuel pump assembly with new one,

referring to “Fuel Pump Assembly Removal and

Installation in Section 1G”.

Fuel Tank Inspection

S6JB0B0206012

Check fuel tank for damage, cracks, fuel leakage,

corrosion and tank bolts looseness.

If a problem is found, repair or replace.

Crankcase Ventilation Hoses and Connections

Inspection (Vehicle without A/F Sensor)

S6JB0B0206013

Check crankcase ventilation hose and connections for

leaks, cracks or clog. Repair or replace if necessary.

PCV Valve Inspection

S6JB0B0206014

Check crankcase ventilation hose and PCV hose for

leaks, cracks or clog, and PCV valve for stick or clog.

Refer to “PCV Valve Inspection in Section 1B” for PCV

valve checking procedure.

Fuel Evaporative Emission Control System

Inspection

S6JB0B0206015

1) Visually inspect hoses for cracks, damage, or

excessive bends. Inspect all clamps for damage and

proper position.

2) Check EVAP canister for operation and clog,

referring to “EVAP Canister Inspection in Section

1B”.

If a malfunction is found, repair or replace.

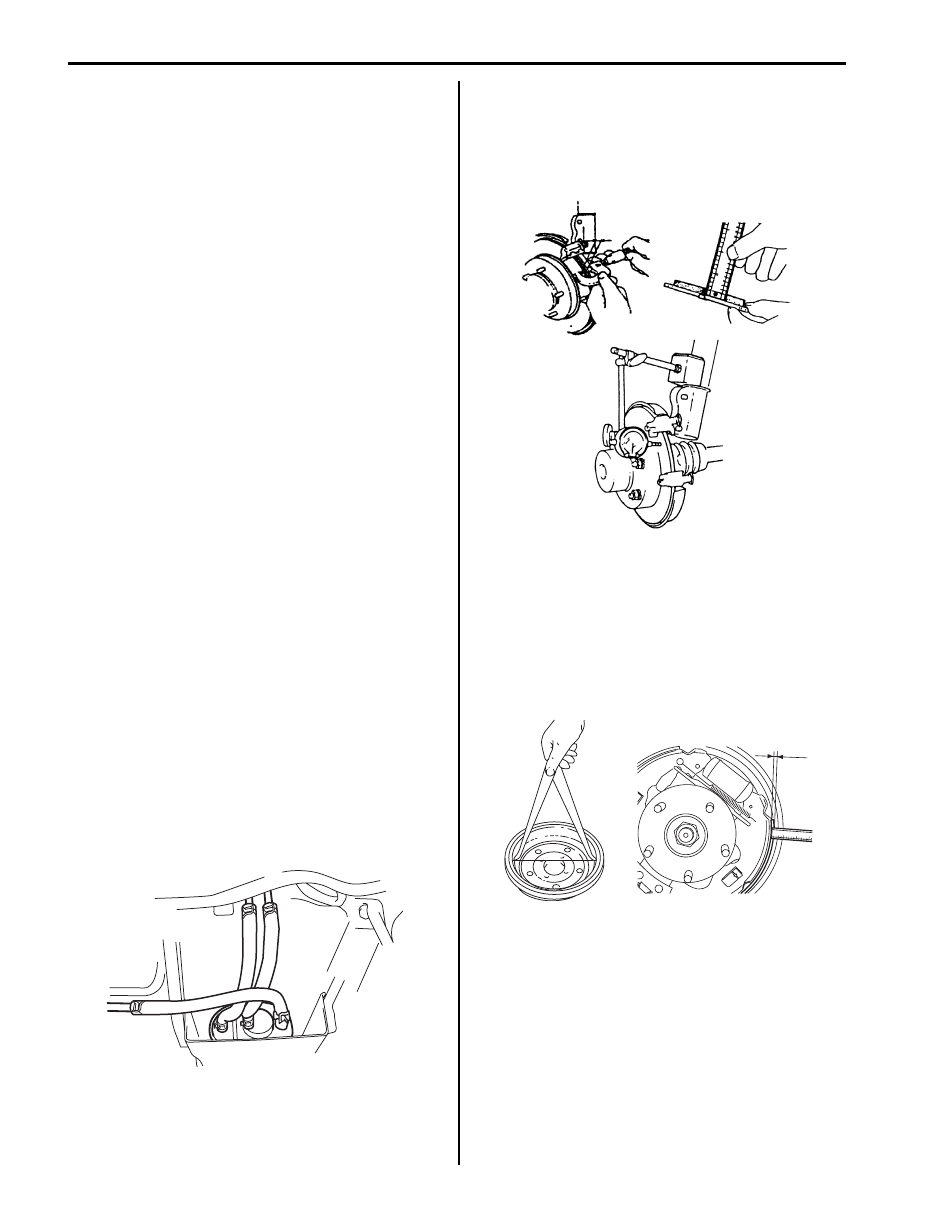

Brake Discs and Pads Inspection

S6JB0B0206016

Check front disc brake pads and discs for excessive

wear, damage and deflection. Replace parts as

necessary. For details, refer to “Front Brake Disc and

Pad Inspection in Section 4B”.

Brake Drums and Shoes Inspection

S6JB0B0206017

Check rear brake drums and brake linings for excessive

wear and damage, while wheels and drums are

removed. At the same time, check wheel cylinders for

leaks. Replace these parts as necessary.

For details, refer to “Rear Brake Drum and Shoe

Inspection in Section 4C”.

I5JB0A020005-01

I5JB0A020006-01

I5JB0A020007-02

Maintenance and Lubrication: 0B-7

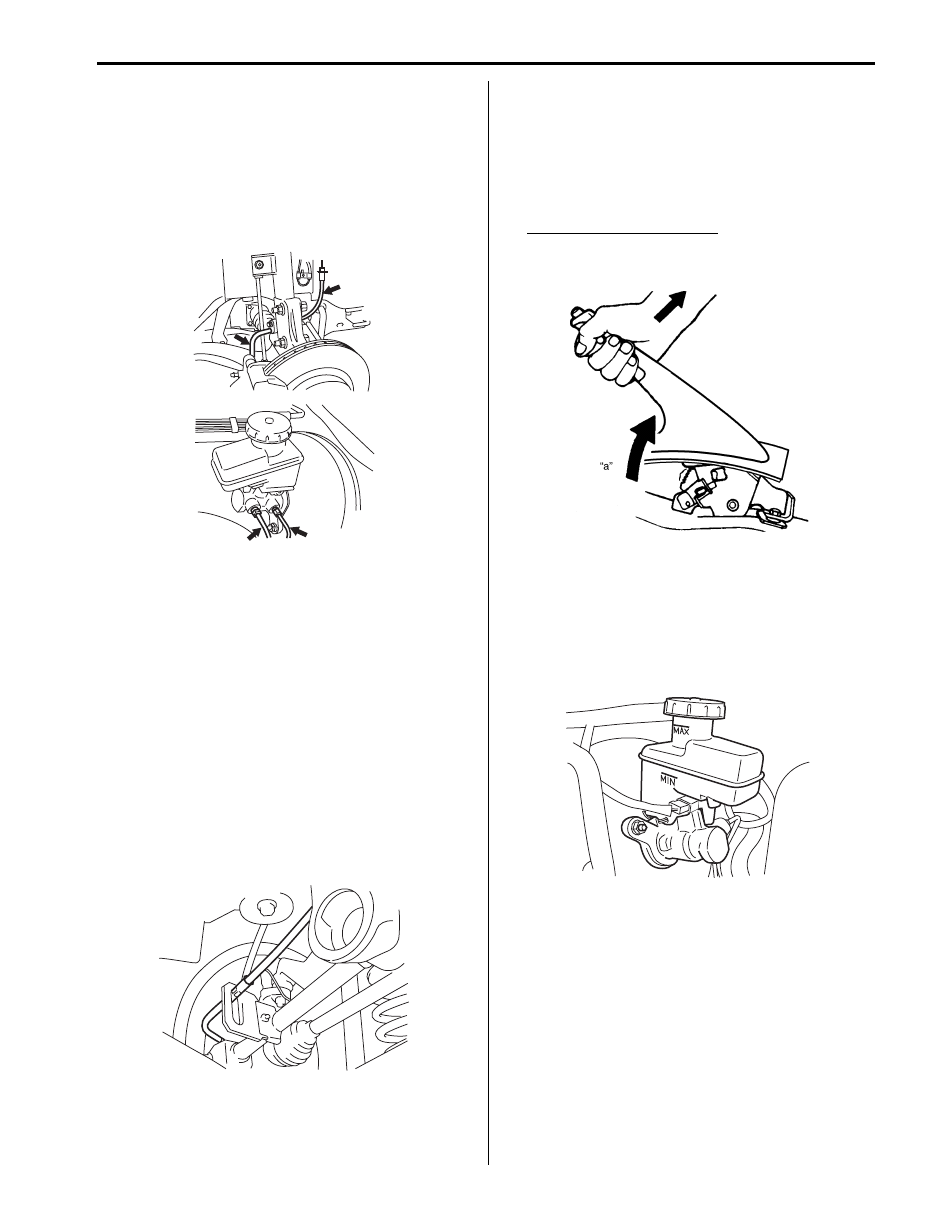

Brake Hoses and Pipes Inspection

S6JB0B0206018

Perform this inspection where there is enough light and

use a mirror as necessary.

Check brake hoses and pipes for proper hookup, leaks,

cracks, chafing and other damage.

Check that hoses and pipes are clear of sharp edges

and moving parts.

Repair or replace any of these parts as necessary.

Brake Fluid Change

S6JB0B0206019

Change brake fluid as follows.

1) Drain existing fluid from brake system completely.

2) Fill reservoir with specified brake fluid indicated on

reservoir cap. For the details, refer to

“Brake Fluid Level Check in Section 4A”.

3) Carry out air purge operation, referring to “Air

Bleeding of Brake System in Section 4A”.

Parking Brake Lever and Cable Inspection

S6JB0B0206020

1) Inspect brake cable for damage and smooth

movement.

Replace cable if it is in deteriorated condition.

2) Check tooth tip of each notch for damage or wear. If

any damage or wear is found, replace parking lever.

3) Check parking brake lever for proper operation and

stroke, and adjust it if necessary.

For checking and adjusting procedures referring to

“Parking Brake Check and Adjustment in Section

4D”.

Parking brake lever stroke

“a”: 5 – 7 notches (with 200 N (20 kg, 44 lbs) of

pull pressure)

Clutch Fluid Inspection

S6JB0B0206021

1) Check system for evidence of fluid leakage.

Repair leaky point if any.

2) Check reservoir for fluid level referring to “Clutch

Fluid Inspection in Section 5C”.

I5JB0A020008-01

I5JB0A020023-01

I5JB0A020024-01

I5JB0A410005-01

0B-8 Maintenance and Lubrication:

Tire / Wheel Inspection and Rotation

S6JB0B0206022

1) Check tires for uneven or excessive wear, or

damage.

If defective, replace. Refer to “Irregular and/or

Premature Wear Description in Section 2D” and

“Wear Indicators Description in Section 2D”for

details.

2) Check inflating pressure of each tire and adjust

pressure to specification as necessary. Refer to

“Tires Description in Section 2D” for details.

NOTE

• Tire inflation pressure should be checked

when tires are cool.

• Specified tire inflation pressure should be

found on tire placard or in owner’s manual

which came with the vehicle.

3) Rotate tires. For details, refer to “Tire Rotation in

Wheel Discs Inspection

S6JB0B0206023

Inspect each wheel disc for dents, distortion and cracks.

A disc in badly damaged condition must be replaced.

Wheel Bearing Inspection

S6JB0B0206024

1) Check front wheel bearing for wear, damage,

abnormal noise or rattles.

For details, refer to “Front Wheel Hub, Disc, Nut and

Bearing Check in Section 2B”.

2) Check rear wheel bearing for wear, damage,

abnormal noise or rattles.

For details, refer to “Rear Wheel Disc, Nut and

Bearing Check in Section 2C”.

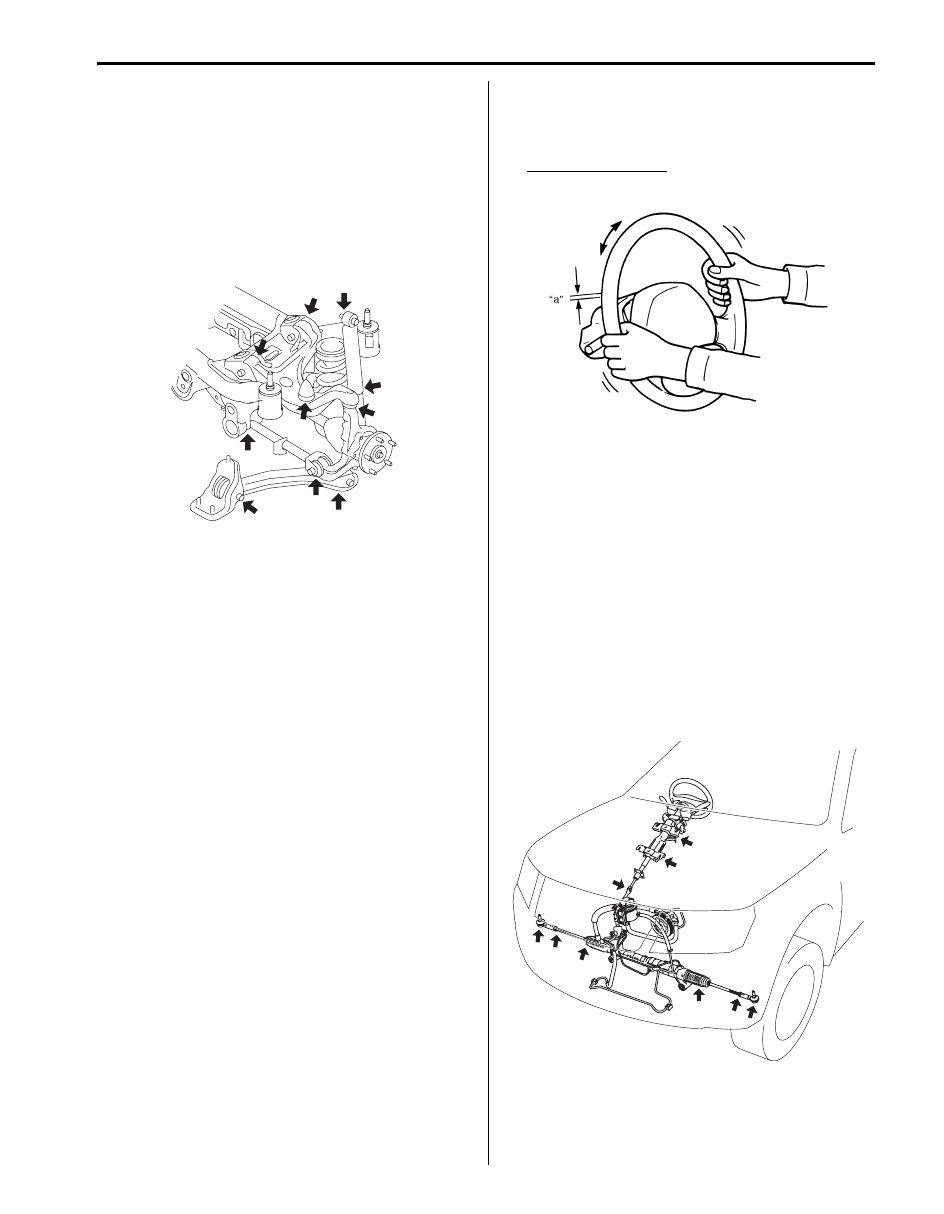

Suspension System Inspection

S6JB0B0206025

Check suspension bolts and nuts painted with yellow for

tightness and retighten them as necessary.

Repair or replace defective parts, if any.

Front

• - Check stabilizer bushing for damage, wear or

deformation.

- Check stabilizer bar and joints for damage or

deformation.

• - Inspect strut for damage, deformation, oil leakage

and operation. If strut is found faulty, replace it as an

assembly unit, because it can not be disassembled.

Refer to “Front Strut Assembly Check in Section 2B”

for operation check.

- Inspect strut dust cover for damage or crack.

• - Check ball joint stud dust seal (boot) for leaks,

detachment, tear or other damage.

- Check suspension control arm bushing for damage,

wear or deterioration.

• Check other suspension parts for damage, loose or

missing parts; also for parts showing signs of wear or

lack of lubrication. Replace any parts found defective.

1. Wear indicator

I2RH01240005-01

I5JB0A020009-01

Maintenance and Lubrication: 0B-9

Rear

• - Check shock absorber for damage, deformation, oil

leakage and operation.

• - Check coil spring, upper arm, lower arm, control rod

and trailing rod for deformation and damage.

- Check bushings of each suspension part for wear,

damage and deterioration.

- Check bump stopper for damage and deterioration

- Check ball joint stud dust seal (boot) for leaks,

detachment, tear or other damage.

• Check other suspension parts for damage, loose or

missing parts; also for parts showing signs of wear or

lack of lubrication. Replace any parts found defective.

Steering System Inspection

S6JB0B0206026

1) Check steering wheel for play and rattle, holding

vehicle in straight forward condition on the ground.

Steering wheel play

“a”: 0 – 30 mm (0 – 1.2 in.)

2) Check universal joints of steering shaft for rattle and

damage. If rattle or damage is found, replace

defective part with a new one.

3) Check steering linkage for looseness and damage.

Repair or replace defective part, if any.

4) Check bolts and nuts for tightness and retighten

them as necessary.

Repair or replace defective parts, if any.

5) Check boots of steering linkage for damage (leaks,

detachment, tear, dent, etc.). If damage is found,

replace it with new one.

If any dent is found on steering rack boots, correct it

to original shape by turning steering wheel to the

right or left as far as it stops and holding it for a few

seconds.

6) Check wheel alignment referring to “Front Wheel

Alignment Inspection and Adjustment in Section 2B”.

I5JB0A020010-01

I5JB0A630004-02

I5JB0C020001-01

Нет комментариевНе стесняйтесь поделиться с нами вашим ценным мнением.

Текст