Suzuki Grand Vitara JB627. Manual — part 10

0B-10 Maintenance and Lubrication:

Propeller Shafts and Drive Shafts Inspection

S6JB0B0206027

Propeller Shafts Inspection

1) Check universal joint and spline of propeller shaft for

rattle. If rattle is found, replace defective part with a

new one.

2) Check propeller shaft (front and rear) flange yoke

bolts for tightness, and retighten them as necessary.

Refer to “Tightening Torque Specifications in Section

3D”.

Drive Shafts Inspection

Check drive axle boots (wheel side and differential side)

(1) for leaks, detachment, tear or other damage.

Replace boot as necessary.

Manual Transmission Oil Inspection

S6JB0B0206028

1) Inspect transmission case for evidence of oil

leakage. Repair leaky point if any.

2) Make sure that vehicle is placed level for oil level

check.

3) Remove level / filler plug (1) of transmission.

4) Check oil level.

Oil level can be checked roughly by means of level

plug hole. That is, if oil flows out of level plug hole or

if oil level is found up to hole when level / filler plug is

removed, oil is properly filled.

If oil is found insufficient, pour specified amount of

specified oil.

5) Tighten level / filler plug to specified torque referring

to “Manual Transmission Oil Change in Section 5B”.

Manual Transmission Oil Change

S6JB0B0206029

Change transmission oil with new specified oil referring

to “Manual Transmission Oil Change in Section 5B”.

Automatic Transmission Fluid Inspection

S6JB0B0206030

1) Inspect transmission case for evidence of fluid

leakage. Repair leaky point, if any.

2) Make sure that vehicle is placed level for fluid level

check.

3) Check fluid level referring to “A/T Fluid Level Check

in Section 5A”. If fluid level is low, replenish specified

fluid.

Automatic Transmission Fluid Change

S6JB0B0206031

1) Inspect transmission case for evidence of fluid

leakage. Repair leaky point, if any.

2) Make sure that vehicle is placed level.

3) Change fluid referring to “A/T Fluid Change in

I5JB0A020019-02

1

I5JB0A020012-01

2. Drain plug

1

2

I5JB0A020013-01

Maintenance and Lubrication: 0B-11

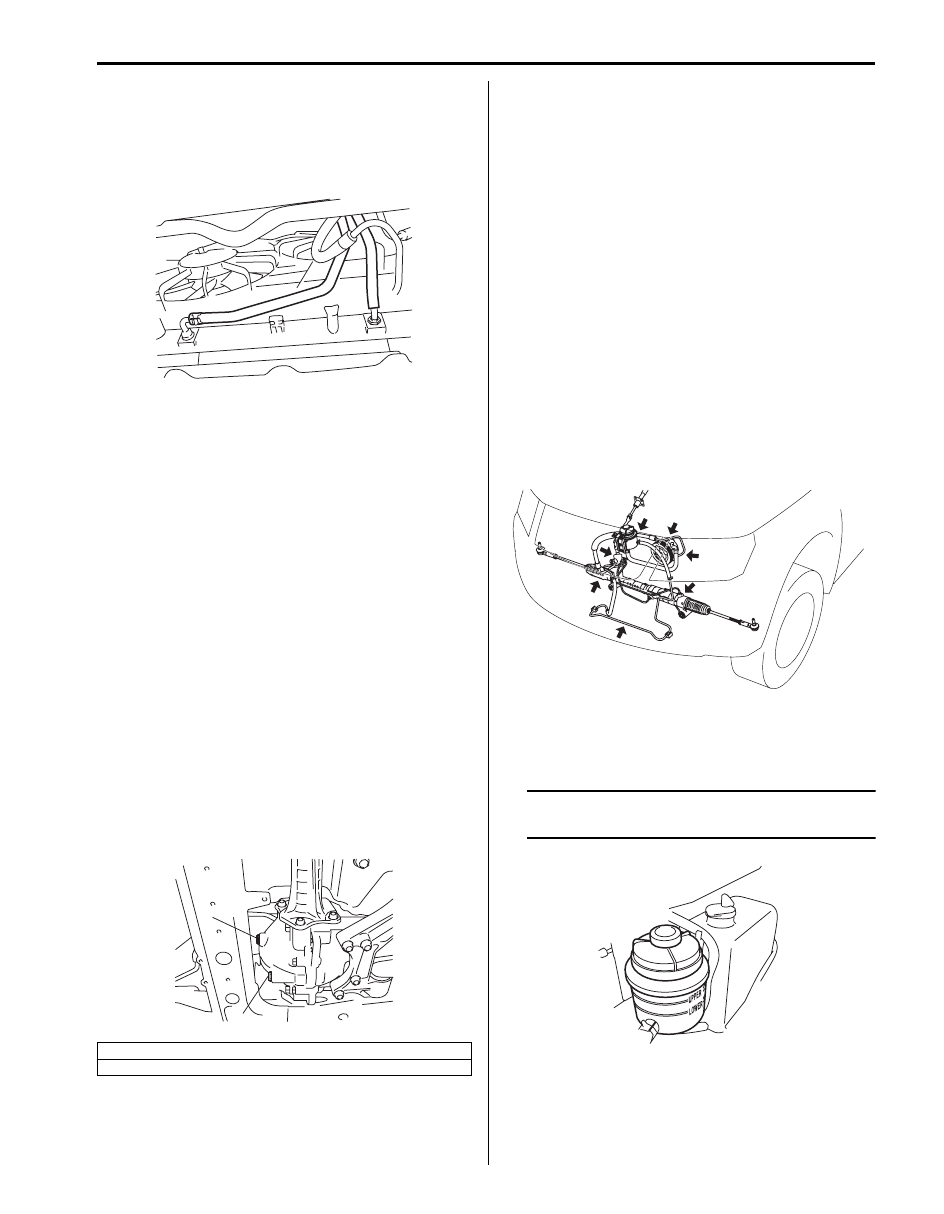

Automatic Transmission Fluid Cooler Hose

Inspection

S6JB0B0206032

Check automatic transmission fluid cooler hose for fluid

leakage, cracks, damage and deterioration. Replace

hose and/or clamp if any faulty condition is found.

Transfer Oil Inspection (If Equipped)

S6JB0B0206033

1) Check transfer case for evidence of oil leakage.

Repair leaky point if any.

2) Make sure that vehicle is placed level for oil level

check.

3) Check oil level referring to “Transfer Oil Level Check

Differential Oil Inspection

S6JB0B0206034

1) Check differential for evidence of oil leakage.

Repair leaky point if any.

2) Make sure that vehicle is placed level for oil level

check.

3) Remove level / filler plug of differentials (front and/or

rear) and check oil level.

Oil level can be checked roughly by means of level

plug hole. That is, if oil flows out of level plug hole or

if oil level is found up to hole when level / filler plug is

removed, oil is properly filled.

If oil is found insufficient, pour specified amount of

specified oil.

4) Tighten level plug to specified torque.

For front differential, refer to “Front Differential Oil

Change: Front in Section 3B”.

For rear differential, refer to “Rear Differential Oil

Change: Rear in Section 3B”.

Transfer (If Equipped) or Differential Oil Change

S6JB0B0206035

Change transfer oil or differential oil (front and rear) with

new specified oil respectively.

For transfer, refer to “Transfer Oil Change in Section

3C”.

For front differential, refer to “Front Differential Oil

Change: Front in Section 3B”.

For rear differential, refer to “Rear Differential Oil

Change: Rear in Section 3B”.

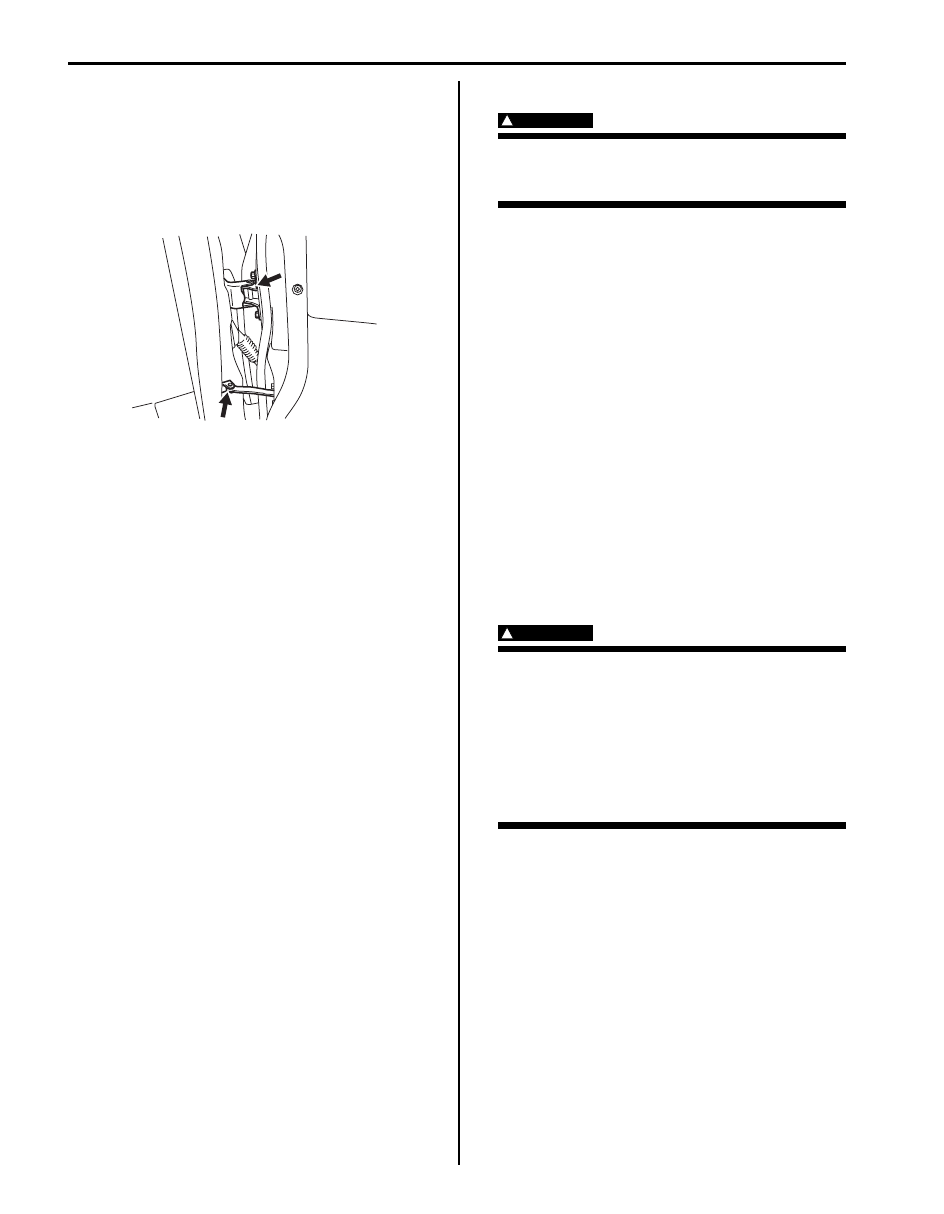

Power Steering (P/S) System Inspection

S6JB0B0206036

1) Visually check power steering system for fluid

leakage and hose for damage and deterioration.

Repair or replace defective parts, if any.

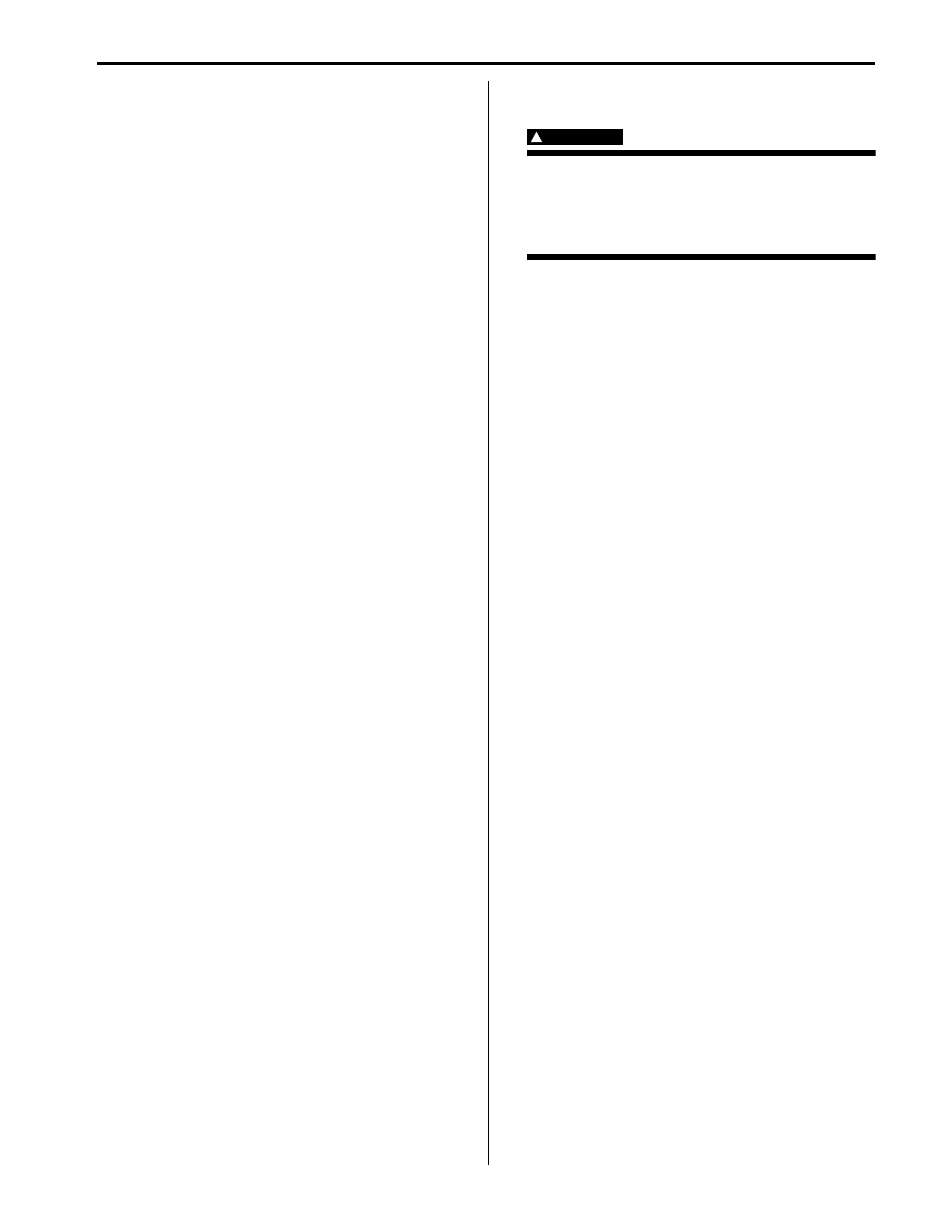

2) Check fluid level with engine stopped. If it is lower

than LOWER level line, fill fluid up to UPPER level

line.

NOTE

Fluid level should be checked when fluid is

cool.

3) Visually check pump drive belt for cracks and wear

and tension, referring to “P/S Pump and A/C

Compressor (If Equipped) Drive Belt Inspection and

Adjustment in Section 6C”.

If necessary, Adjust or replace it.

1. Oil level / filler plug (Apply sealant.)

2. Drain plug (Apply sealant.)

I5JB0A020025-02

1

2

I5JB0A020015-03

I5JB0C020002-01

I6JB01020010-02

0B-12 Maintenance and Lubrication:

All Hinges, Latches and Locks Inspection

S6JB0B0206037

Doors

Check that each door of front, rear and back (rear end)

doors opens and closes smoothly and locks securely

when closed.

If any malfunction is found, lubricate hinge and latch or

repair door lock system.

Engine Hood

Check that secondary latch operates properly (check

that secondary latch keeps hood from opening all the

way even when pulling hood release handle inside

vehicle.) Also check that hood opens and closes

smoothly and properly and hood locks securely when

closed.

If any malfunction is found, lubricate hinge and latch, or

repair hood lock system.

HVAC Air Filter Inspection (If Equipped)

S6JB0B0206038

Check air filter for dirt and damage. Clean or replace if

necessary referring to “HVAC Air Filter Inspection in

Section 7B”.

HVAC Air Filter Replacement (If Equipped)

S6JB0B0206039

Replace air filter with new one referring to “HVAC Air

Filter Removal and Installation in Section 7B”.

Final Inspection for Maintenance Service

S6JB0B0206040

WARNING

!

When carrying out road tests, select a safe

place where no man or no running vehicle is

seen so as to prevent any accident.

Seats

Check that seat slides smoothly and locks securely at

any position. Also check that reclining mechanism of

front seat back allows it to be locked at any angle.

Seat Belt

Inspect belt system including webbing, buckles, latch

plates, retractors and anchors for damage or wear.

Check that seat belt is securely locked.

Battery Check

Check battery for damage, terminal corrosion and

condition.

If battery is equipped with built-in indicator, check battery

condition by the indicator.

Accelerator Pedal Operation

Check that pedal operates smoothly without getting

caught or interfered by any other part.

Engine Start

Check engine start for readiness.

WARNING

!

Before performing the following check, be

sure to have enough room around the

vehicle. Then, firmly apply both the parking

brake and the regular brakes. Do not use the

accelerator pedal. If the engine starts, be

ready to turn off the ignition promptly. Take

these precautions because the vehicle could

move without warning and possibly cause

personal injury or property damage.

On A/T vehicles, try to start the engine in each select

lever position. The starting motor should crank only in

“P” (Park) or “N” (Neutral).

On M/T vehicles, place the shift lever in “Neutral,”

depress clutch pedal fully and try to start.

I5JB0A020026-01

Maintenance and Lubrication: 0B-13

Exhaust System Check

Check for leakage, cracks or loose supports.

Clutch (for Manual Transmission)

Check for the following.

• Clutch is completely released when depressing clutch

pedal,

• No slipping clutch occurs when releasing pedal and

accelerating.

• Clutch itself is free from any abnormal condition.

Gearshift or Select Lever (Transmission)

Check gear shift or select lever for smooth shifting to all

positions and for good performance of transmission in

any position.

With A/T vehicle, also check that shift indicator indicates

properly according to which position select lever is

shifted to.

With A/T vehicle, make sure that vehicle is at complete

stop when shifting select lever to “P” range position and

release all brakes.

Transfer (Motor-shift type)

Check that transfer position indicator on instrument

cluster turns on properly according to transfer switch

position.

Brake

Foot brake

Check the following:

• that brake pedal has proper travel,

• that brake works properly,

• that it is free from noise,

• that vehicle does not pull to one side when brake is

applied,

• and that brake do not drag.

Parking brake

Check that lever has proper travel.

WARNING

!

With vehicle parked on a fairly steep slope,

make sure nothing is in the way downhill to

avoid any personal injury or property

damage. Be prepared to apply regular brake

quickly even if vehicle should start to move.

Check to ensure that parking brake is fully effective

when the vehicle is stopped on the safe slope and brake

lever is pulled all the way.

Steering

• Check to ensure that steering wheel is free from

instability, or abnormally heavy feeling.

• Check that the vehicle does not wander or pull to one

side.

Engine

• Check that engine responds readily at all speeds.

• Check that engine is free from abnormal noise and

abnormal vibration.

Body, Wheels and Power Transmitting System

Check that body, wheels and power transmitting system

are free from abnormal noise and abnormal vibration or

any other abnormal condition.

Meters and Gauge

Check that speedometer, odometer, fuel meter,

temperature gauge, etc. are operating accurately.

Lights

Check that all lights operate properly.

Windshield Defroster

Periodically check that air comes out from defroster

outlet when operating heater or air conditioning.

Set fan switch lever to max speed position for this check.

Нет комментариевНе стесняйтесь поделиться с нами вашим ценным мнением.

Текст