Suzuki Grand Vitara JB627. Manual — part 165

3C-64 Transfer:

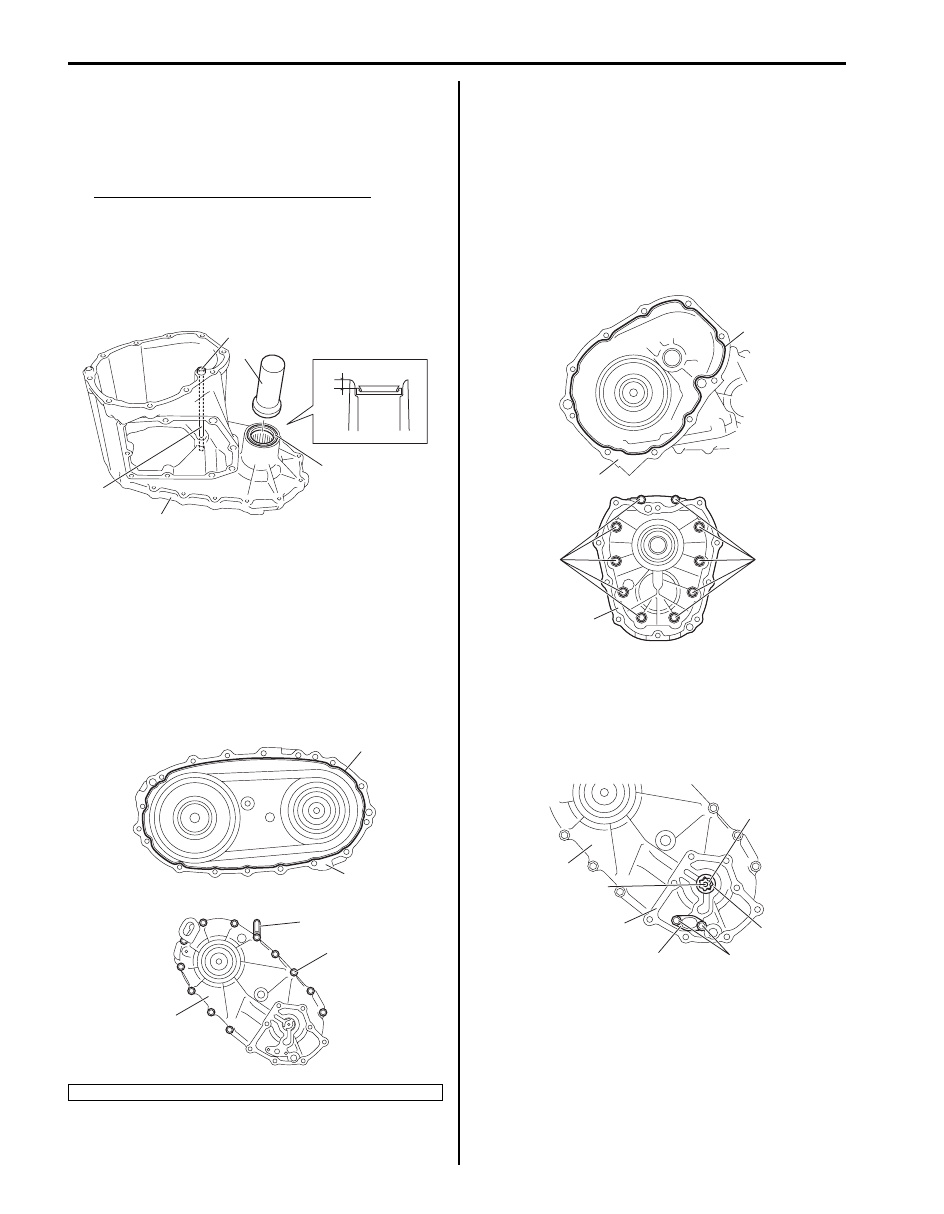

15) Install oil pipe (1) and knock pin (2) into center case

(3).

16) Install new front oil seal No.1 (4) into center case

using special tool as shown in figure, and then apply

grease to oil seal lip.

Distance between case and oil seal “a”

: 3.5 – 4.5 mm (0.138 – 0.177 in.)

“A”: Grease 99000–25010 (SUZUKI Super

Grease A)

Special tool

(A): 09913–70123

17) Clean mating surface of both center case and rear

case (1), apply sealant to rear case as shown in

figure by such amount that its section is 1.2 mm

(0.047 in.) in diameter, mate center case with rear

case and then tighten bolts (2) to specified torque.

“A”: Sealant 99000–31260 (SUZUKI Bond

No.1217G)

Tightening torque

Rear case bolt (a): 23 N·m (2.3 kgf-m, 17.0 lb-ft)

18) Clean mating surface of both center case (1) and

front case, apply sealant to center case as shown in

figure by such amount that its section is 1.2 mm

(0.047 in.) in diameter, mate front case (3) with

center case and then tighten bolts (2) to specified

torque.

“A”: Sealant 99000–31260 (SUZUKI Bond

No.1217G)

Tightening torque

Rear case bolt (a): 23 N·m (2.3 kgf-m, 17.0 lb-ft)

19) Install oil strainer (1) to rear case (2).

Tightening torque

Strainer bolt (a): 10 N·m (1.0 kgf-m, 7.5 lb-ft)

20) Install oil pump inner rotor (3), outer rotor (4) and

drive pin (5) to rear case (6).

3. Clamp

2

1

3

(A)

4, “A”

“a”

I5JB0A331046-03

“A”

1

3

1

2, (a)

I5JB0A331047-02

“A”

1

2, (a)

2, (a)

3

I5JB0A331048-03

2

5

6

1

(a)

4

3

I5JB0A331050-01

Transfer: 3C-65

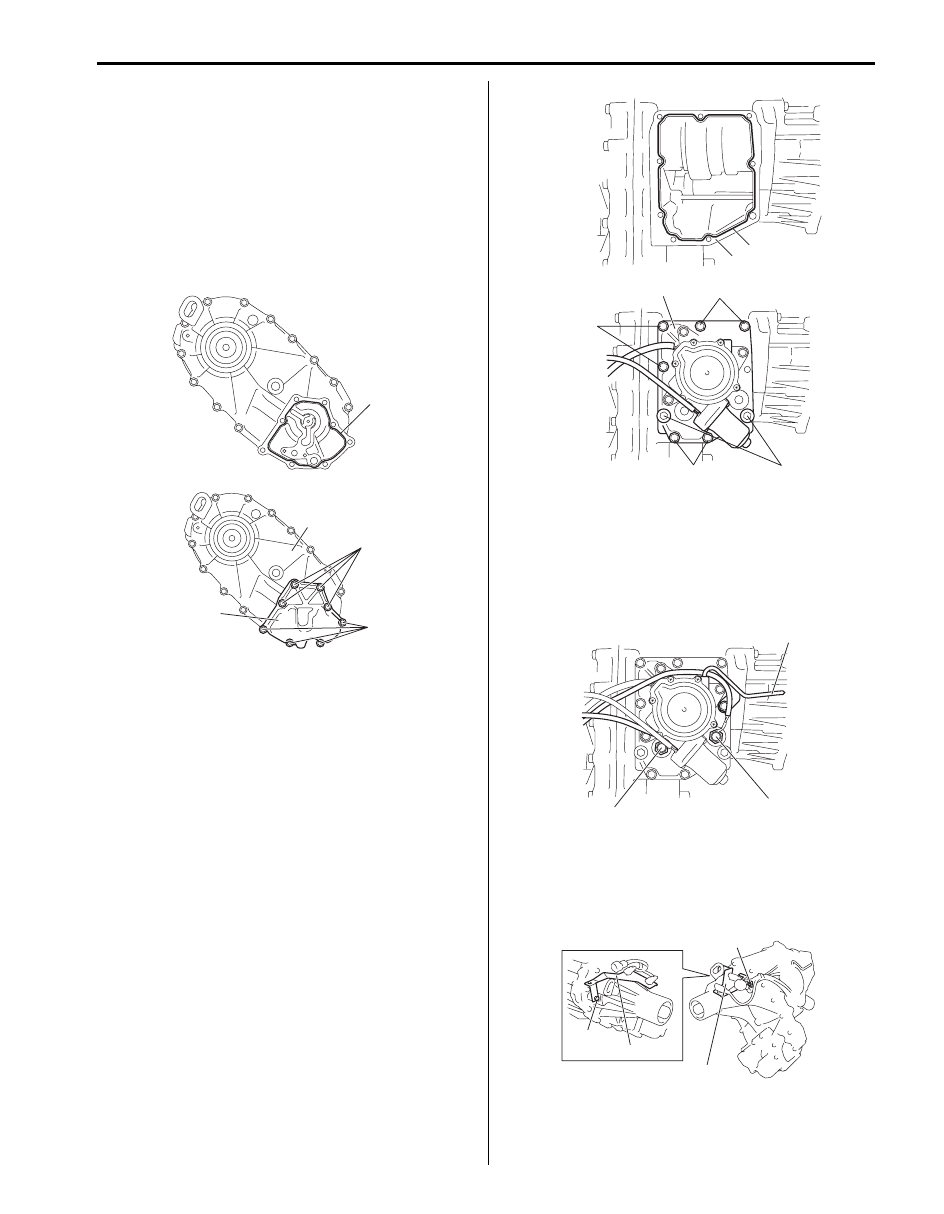

21) Clean mating surface of oil pump cover (1) and rear

case (2), apply sealant to rear case as shown in

figure by such amount that its section is 1.2 mm

(0.047 in.) in diameter, mate oil pump cover with rear

case and then tighten bolts (3) to specified torque.

“A”: Sealant 99000–31260 (SUZUKI Bond

No.1217G)

Tightening torque

Oil pump cover bolt (a): 23 N·m (2.3 kgf-m, 17.0

lb-ft)

22) Clean mating surface of control cover (1) and center

case (2), apply sealant to center case as shown in

figure by such amount that its section is 1.2 mm

(0.047 in.) in diameter, confirm the each fork of

control cover is in groove of the sleeve, mate control

cover with center case and then tighten control cover

bolts (3) to which thread lock cement has been

applied and control cover dowel bolts (4) to specified

torque.

“A”: Sealant 99000–31260 (SUZUKI Bond

No.1217G)

“B”: Thread lock cement 99000–32110 (Thread

Lock Cement Super 1322)

Tightening torque

Control cover bolt (a): 23 N·m (2.3 kgf-m, 17.0 lb-

ft)

Control cover dowel bolt (b): 23 N·m (2.3 kgf-m,

17.0 lb-ft)

23) Install center differential lock switch (1), 4L/N switch

(2) and breather pipe (3).

Tightening torque

Center differential lock switch (a): 20 N·m (2.0

kgf-m, 14.5 lb-ft)

4L/N switch (b): 20 N·m (2.0 kgf-m, 14.5 lb-ft)

24) Install harness bracket (1).

Tightening torque

Harness bracket bolt (a): 10 N·m (1.0 kgf-m, 7.5

lb-ft)

“A”

3, (a)

3, (a)

1

2

I5JB0A331049-02

“A”

2

1

3, “B”, (a)

3, “B”, (a)

3, “B”, (a)

4, “B”, (b)

I5JB0A331051-04

3

2, (b)

1, (a)

I5JB0A331052-02

(a)

(a)

1

1

I5JB0A331053-01

3C-66 Transfer:

Transfer Assembly Inspection

S6JB0B3306010

• Check needle bearing and bearing contacting surface

for damage. Replace as required.

• Check gear tooth surface and shift mechanism in the

same manner as with transmission. Correct or replace

as necessary.

• Check drive chain and sprockets for abnormal wear or

damage. Replace as required.

• Check transfer control cover assembly for abnormal

wear or damage. Replace control cover assembly.

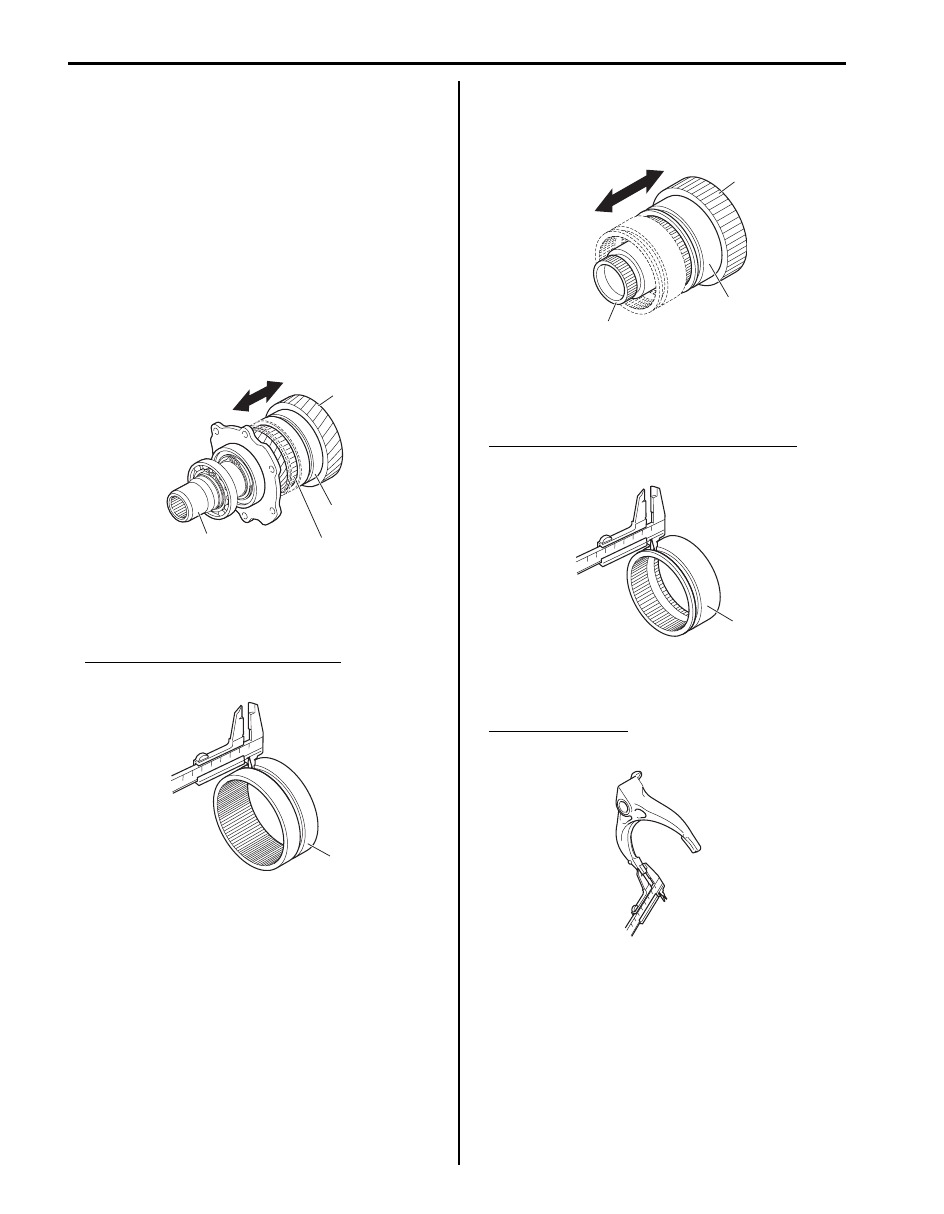

• Assemble input gear assembly (1), center differential

assembly (2), low gear (3) and reduction shift sleeve

(4), check whether reduction shift sleeve moves

smoothly, and replace it if defect is found.

• Measure the width of groove part of reduction shift

sleeve (1).

If measured value is out of specification, replace

reduction sleeve.

Reduction shift sleeve groove width

: 6.9 – 7.1 mm (0.272 – 0.280 in.)

• Assemble front drive shaft (1), front drive sprocket (2)

and differential lock clutch sleeve (3), check whether

differential lock clutch sleeve moves smoothly, and

replace it if defect is found.

• Measure the width of groove part of differential lock

clutch sleeve (1).

If measured value is out of specification, replace

reduction sleeve.

Differential lock clutch sleeve groove width

: 6.9 – 7.1 mm (0.272 – 0.280 in.)

• Measure thickness of shift fork. If thickness of shift

fork is out of specification, replace control cover

assembly.

Shift fork thickness

: 6.5 – 6.8 mm (0.256 – 0.268 in.)

3

4

2

1

I5JB0A331054-01

1

I5JB0A331055-01

2

3

1

I5JB0A331056-01

1

I5JB0A331057-01

I5JB0A331082-01

Transfer: 3C-67

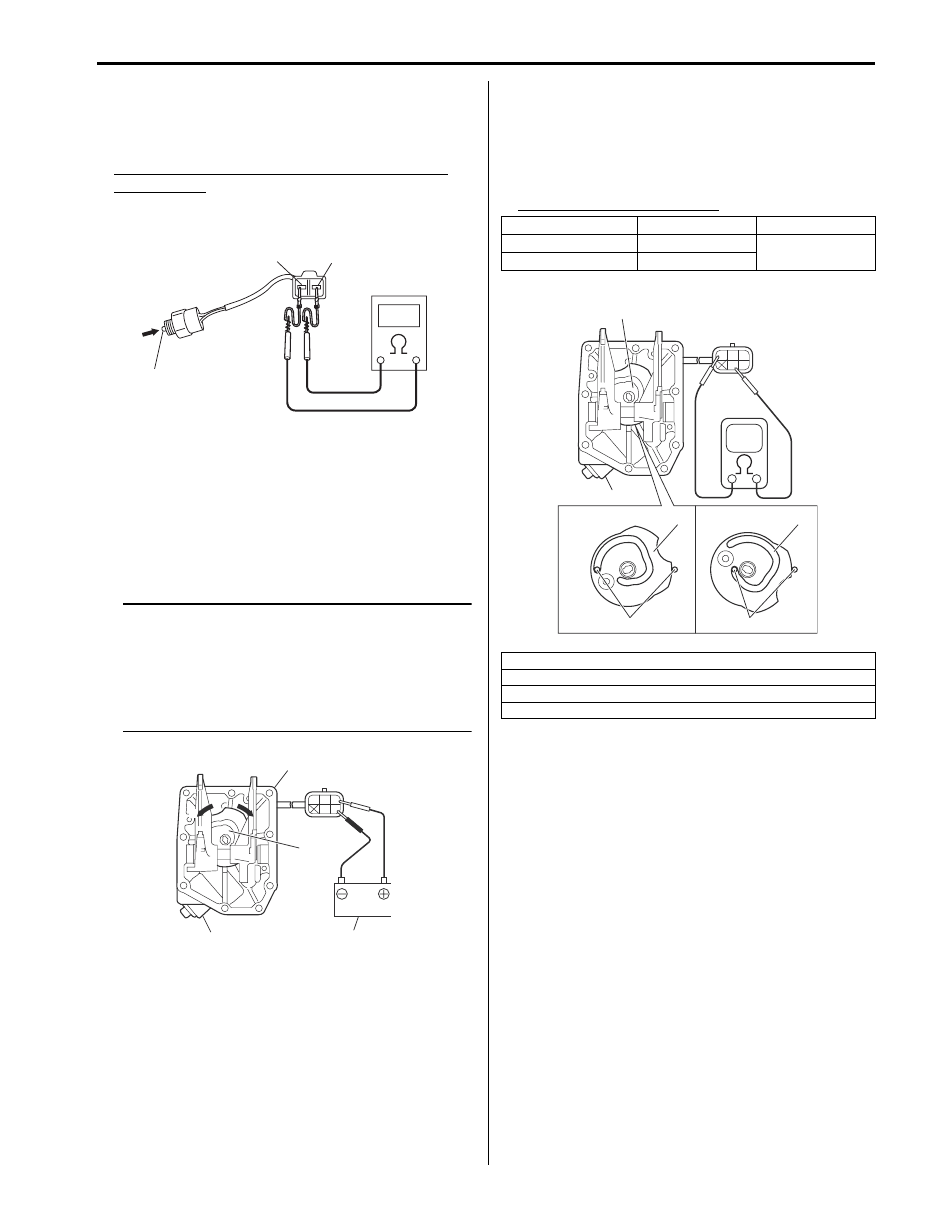

• Check 4L/N switch and center differential lock switch

for continuity between “a” and “b” terminals of switch.

If check result is not as specified below, replace

switch.

4L/N switch and center differential lock switch

specification

Switch button (1) released: Continuity

Switch button (1) kept pushing: No continuity

• Connect terminal “1” of transfer actuator (3) to the

positive of battery (4) and terminal “2” to the negative,

and confirm cam (2) rotates in the direction of A. At

the same time, connect terminal “2” of transfer

actuator (3) to the positive and terminal “1” to the

negative, and confirm it rotates in the direction of B. If

it doesn’t operate correctly, replace transfer actuator

assembly.

NOTE

• Do not rotate transfer actuator applying

voltage, while transfer actuator removed

from transfer control cover assembly (1).

• Do not apply voltage of the battery in the

direction of rotation limit at rotation limit

position of transfer actuator.

• Operate the motor, and measure the resistance

between following terminals of transfer actuator when

matching transfer actuator (1) to 4H-lock position and

4L-lock position.

If measured value is out of specification, replace

transfer actuator.

Transfer actuator resistance

1

“a”

“b”

I5JB0A331058-01

1

2

1

3

5

4 2

4

3

A

B

I5JB0A331059-01

Transfer position

Terminal

Resistance

4H-lock

4 – 5

385 – 400

Ω

4L-lock

3 – 4

[A]: 4H-lock position

[B]: 4L-lock position

2. Cam

3. Shift fork pin

[A]

[B]

3

3

2

2

1

2

1

2

3

5

4

I5JB0A331060-02

Нет комментариевНе стесняйтесь поделиться с нами вашим ценным мнением.

Текст