Suzuki Grand Vitara JB627. Manual — part 153

3C-16 Transfer:

Detail of 4WD Control System Check

Step 1: Customer complaint analysis

Record details of the problem (failure, complaint) and how it occurred as described by the customer.

For this purpose, use of such a questionnaire form as shown in the following will facilitate collecting information to the

point required for proper analysis and diagnosis.

Customer questionnaire (Example)

NOTE

The form is a standard sample. It should be modified according to conditions characteristic of each

market.

Customer’s name:

Model:

VIN:

Problem Symptoms

Frequency of Occurrence

Conditions for

Occurrence of Ploblem

Environmental Condition

Diagnostic Trouble Code

Date of Reg:

Transfer position indicator abnormal: fails to turn on / fails to turn off /

flashes

Abnormal noise while vehicle running: from transfer, from actuator,

other

No shifted to “4H” position

No shifted to “4H-lock” position

No shifted to “4L-lock” position

No shifted to “N” position

When starting: at initial start only / at every start / other

Vehicle speed: while accelerating / while decelerating / at stop /

while turning / while running at constant speed /

other

Road surface condition: Paved road / rough road / snow-covered road /

other

Wheather: fine / cloudy / rain / snow / other

Temperature: ( )

First check: Normal code / malfunction code ( )

Second check after test drive: Normal code / malfunction code ( )

Continuous / Intermittent ( times a day, a month) /

other

Date of problem:

Mileage:

Date of issue:

I5JB0A332011-02

Transfer: 3C-17

Step 2. DTC / freeze frame data check, record and

clearance

First, referring to “DTC Check”, check DTC and pending

DTC. If DTC exists, print or write down DTC and freeze

frame data and then clear malfunction DTC(s) by

referring to “DTC Clearance”. Malfunction DTC indicates

malfunction in the system but it is not possible to know

from it whether the malfunction is occurring now or it

occurred in the past and normal condition has been

restored. In order to know that, check symptom in

question according to Step 5 and then recheck DTC

according to Step 6.

Diagnosing a trouble based on the DTC in this step only

or failure to clear the DTC in this step may result in an

faulty diagnosis, trouble diagnosis of a normal circuit or

difficulty in troubleshooting which is otherwise

unnecessary.

Step 3 and 4. Visual inspection

As a preliminary step, be sure to perform visual check of

the items that support proper function of the 4WD control

system referring to “Visual Inspection”.

Step 5. Trouble symptom confirmation

Check trouble symptoms based on information obtained

in “Step 1: Customer complaint analysis: ” and “Step 2.

DTC / freeze frame data check, record and clearance: ”.

Also, reconfirm DTC according to “DTC Confirmation

Procedure” described in each DTC flow.

Step 6 and 7. Rechecking and record of DTC and

freeze frame data

Refer to “DTC Check” for checking procedure.

Step 8. 4WD control symptom diagnosis

Check the parts of the system suspected as a possible

cause referring to “4WD Control Symptom Diagnosis”.

Step 9. Troubleshooting for DTC

Based on the DTC indicated in Step 6 / 7 and referring to

“applicable DTC flow”, locate the cause of the trouble,

namely in a sensor, switch, wire harness, connector,

actuator, 4WD control module or other part and repair or

replace faulty parts.

Step 10. Check for intermittent problem

Check parts where an intermittent trouble is easy to

occur (e.g. wire harness, connector, etc.), referring to

“Intermittent and Poor Connection Inspection in Section

00” and related circuit of DTC recorded in Step 2.

Step 11. Final confirmation test

Confirm that the problem symptom has gone and the

vehicle is free from any abnormal conditions. If what has

been repaired is related to the malfunction DTC, clear

the DTC once and check to ensure that no malfunction

DTC is indicated.

Transfer Position Indicator Operation Check

S6JB0B3304002

1) Turn ignition switch to OFF position.

2) Check that transfer position indicators turn on for

about 2 seconds and then turns off.

If any faulty condition is found, proceed to “Transfer

Position Indicator Does Not Come ON at Ignition

Switch ON but Engine Stops” or “Transfer Position

Indicator Remains ON Steady at Ignition Switch ON”.

4WD Control System Operation Inspection

S6JB0B3304003

NOTE

• If it is difficult to shift between “4H” and

“4H-lock” while vehicle is moving, stop

vehicle and operate Transfer switch.

• When ABS operates while shifting from

“4H” to “4H-lock” (“4H-lock” to “4H”), it

becomes to disagreement of transfer

switch and transfer position. End of the

ABS operation, and then transfer shifting

from “4H” to “4H-lock” (“4H-lock” to “4H”).

• Transfer position indicator blinks during

shifting process.

• Transfer position indicator blinks and

warning buzzer sounds during “N”

position at intervals of 3 seconds.

• When shifting to “N” or “4L-lock” does not

shifts, try the following procedure.

– For M/T model, shift transmission to N

(Neutral) position, turn ignition switch to

ON position, depress clutch pedal and

brake pedal while engine is running, and

then try shifting again.

– For A/T model, turn ignition switch to

ON position, move vehicles lowly back

or forth a few feet, depress brake pedal,

and then try shifting again.

1) Inspect shift operation from 4H to 4H-lock as follows.

a) Start engine.

b) Position front wheels straight ahead.

c) Confirm that vehicle is under following

conditions.

• Transfer shift position is 4H.

• Vehicle speed is less than 100 km/h (60 mph).

d) Turn transfer switch to “4H-lock” position.

e) Check that differential lock indicator blinks, and

then comes ON steady.

3C-18 Transfer:

2) Inspect shift operation from 4H-lock to 4L-lock as

follows.

a) Stop vehicle completely with engine running.

b) Position front wheels straight ahead.

c) Confirm that vehicle is under following

conditions.

• Transfer shift position is 4H-lock.

• Transmission shift lever is at “N” position. (for

A/T model)

• Clutch pedal is depressed fully. (for M/T

model)

• Brake pedal is depressed.

d) Push and turn transfer switch to “4L-lock”

position.

e) Check that 4L indicator blink, and then

differential lock indicator and 4L indicator comes

ON steady.

3) Inspect shift operation from 4L-lock to 4H-lock as

follows.

a) Stop vehicle completely with engine running.

b) Position front wheels straight ahead.

c) Confirm that vehicle is under following

conditions.

• Transfer shift position is 4L-lock.

• Transmission shift lever is at “N” position. (for

A/T model)

• Clutch pedal is depressed fully. (for M/T

model)

• Brake pedal is depressed.

d) Push and turn transfer switch to “4H-lock”

position.

e) Check that 4L indicator blink, and then

differential lock indicator comes ON steady and

4L indicator not come ON.

4) Inspect shift operation from 4H-lock to 4H as follows.

a) Start engine.

b) Position front wheels straight ahead.

c) Confirm that vehicle is under following

conditions.

• Transfer shift position is 4H-lock.

• Vehicle speed is less than 100 km/h (60 mph).

d) Turn transfer switch to “4H” position.

e) Check that differential lock indicator blinks, and

then not comes ON.

5) Inspect shift operation from 4H to N as follows.

a) Stop vehicle completely with engine running.

b) Position front wheels straight ahead.

c) Confirm that vehicle is under following

conditions.

• Transfer shift position is 4H.

• Transmission shift lever is at “N” position. (for

A/T model)

• Clutch pedal is depressed fully. (for M/T

model)

• Brake pedal is depressed.

d) Turn transfer switch to “” position (1), keep it

there for about 10 seconds, and then turn it to

“N” position after N indicator blinks.

e) Check that N indicator blinks and warning buzzer

sounds, and then N indicator comes ON steady.

Visual Inspection

S6JB0B3304004

Check the following parts and systems visually.

1

I5JB0A332002-01

Inspection Item

Referring

• Front differential oil ---- level, leakage

“Front Differential Oil Change: Front in Section 3B”

• Rear differential oil ---- level, leakage

“Rear Differential Oil Change: Rear in Section 3B”

• Transfer gear oil ---- level, leakage

• Manual transmission oil ---- level, leakage

“Manual Transmission Oil Change in Section 5B”

• A/T fluid ---- level, leakage

“A/T Fluid Level Check in Section 5A”

• Transfer mounting(s) ---- wear and looseness

• Fuses ---- burning

• Battery ---- fluid level, corrosion of terminal

“Battery Inspection in Section 1J”

• Connectors of electric wire harness ---- disconnection,

friction

“Intermittent and Poor Connection Inspection in Section

00”

• Other parts that can be checked visually

Transfer: 3C-19

DTC Check

S6JB0B3304005

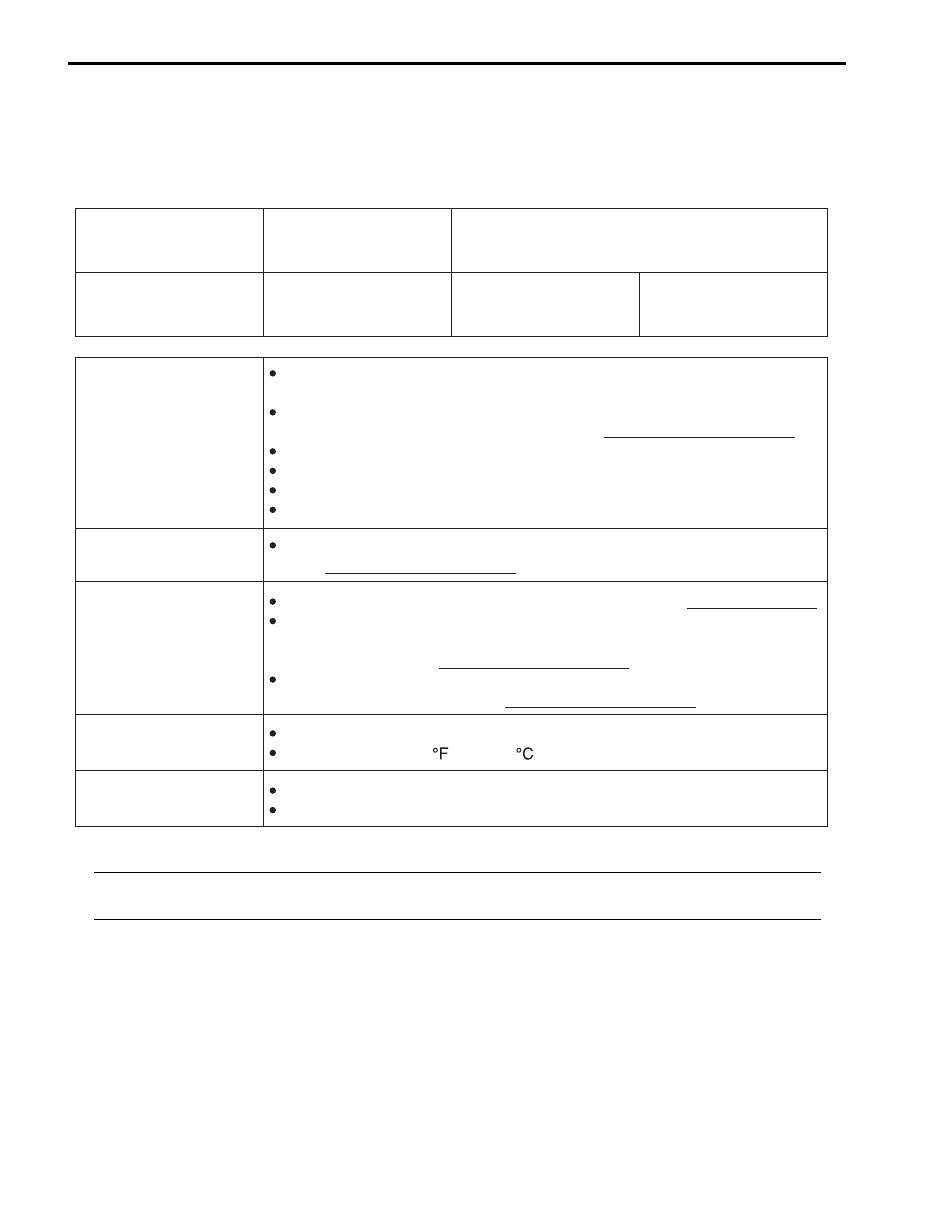

Using SUZUKI Scan Tool

1) Turn ignition switch to OFF position.

2) Connect SUZUKI scan tool to data link connector

(DLC) (1) located on underside of instrument panel.

Special tool

(A): SUZUKI scan tool

3) Turn ignition switch to ON position.

4) Read DTC according to instructions displayed on

SUZUKI scan tool and print it or write it down. Refer

to SUZUKI scan tool operator’s manual for further

details.

If communication between SUZUKI scan tool and

4WD control module is not possible, check if

SUZUKI scan tool is communicable by connecting it

to 4WD control module in another vehicle. If

communication is possible in this case, SUZUKI

scan tool is in good condition. Then check data link

connector and serial data line (circuit) in the vehicle

with which communication was not possible.

5) After completing the check, turn ignition switch OFF

and disconnect SUZUKI scan tool from data link

connector (DLC).

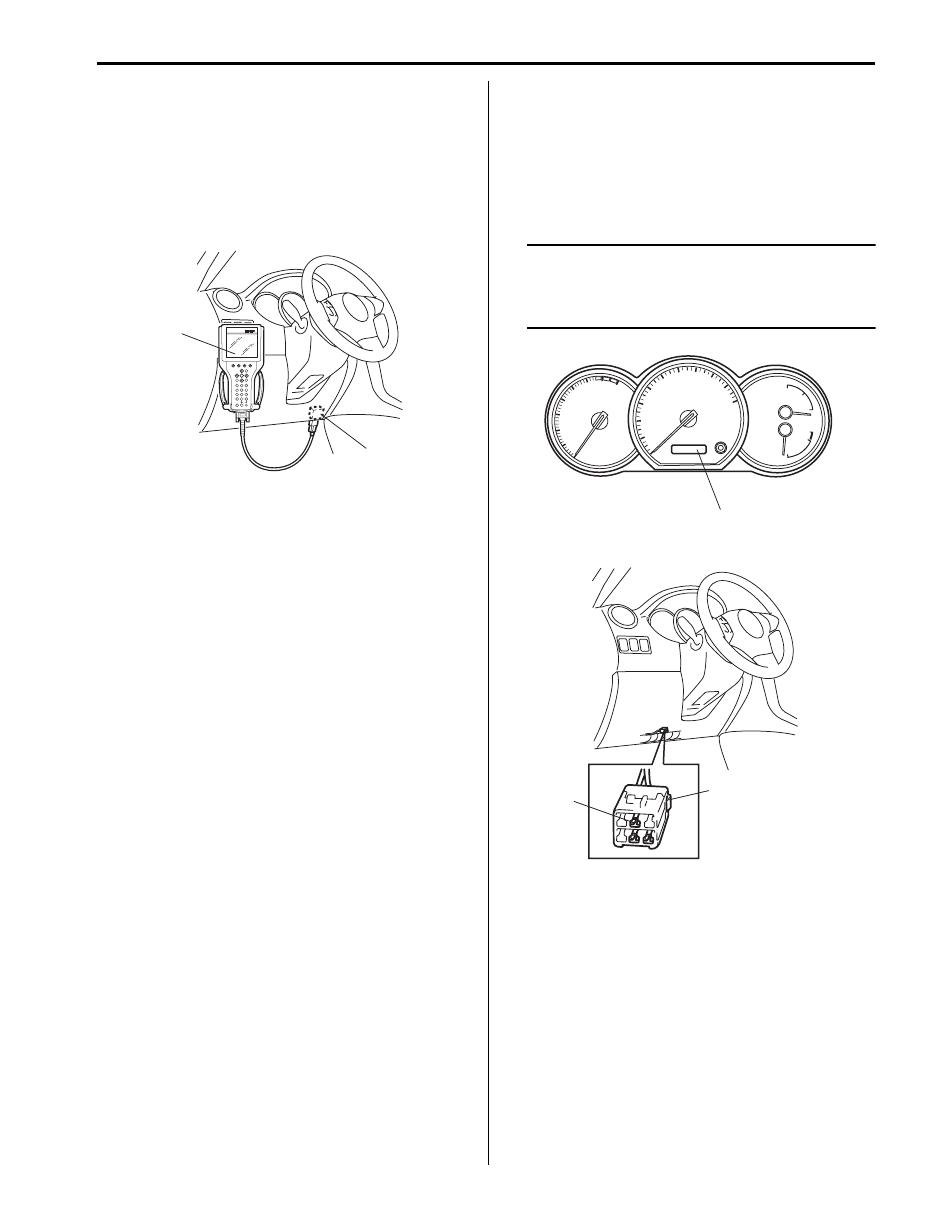

Using Diagnosis Connector

1) With ignition switch OFF position, using service wire

short diagnosis switch terminal (1) of diagnosis

connector (2) and body ground.

2) With ignition switch ON position and leaving engine

OFF, read DTC displayed on digital display odometer

(3) of combination meter referring to “DTC Table”.

NOTE

When more than 2 DTCs are stored in

memory, flashing for each DTC is repeated

three times starting with the smallest DTC

number in increasing order.

3) After completing the check, turn ignition switch OFF,

disconnect service wire from diagnosis connector.

(A)

1

I5JB0A332012-01

1

2

3

I5JB0A332013-01

Нет комментариевНе стесняйтесь поделиться с нами вашим ценным мнением.

Текст