Suzuki Grand Vitara JB627. Manual — part 286

7B-60 Air Conditioning System:

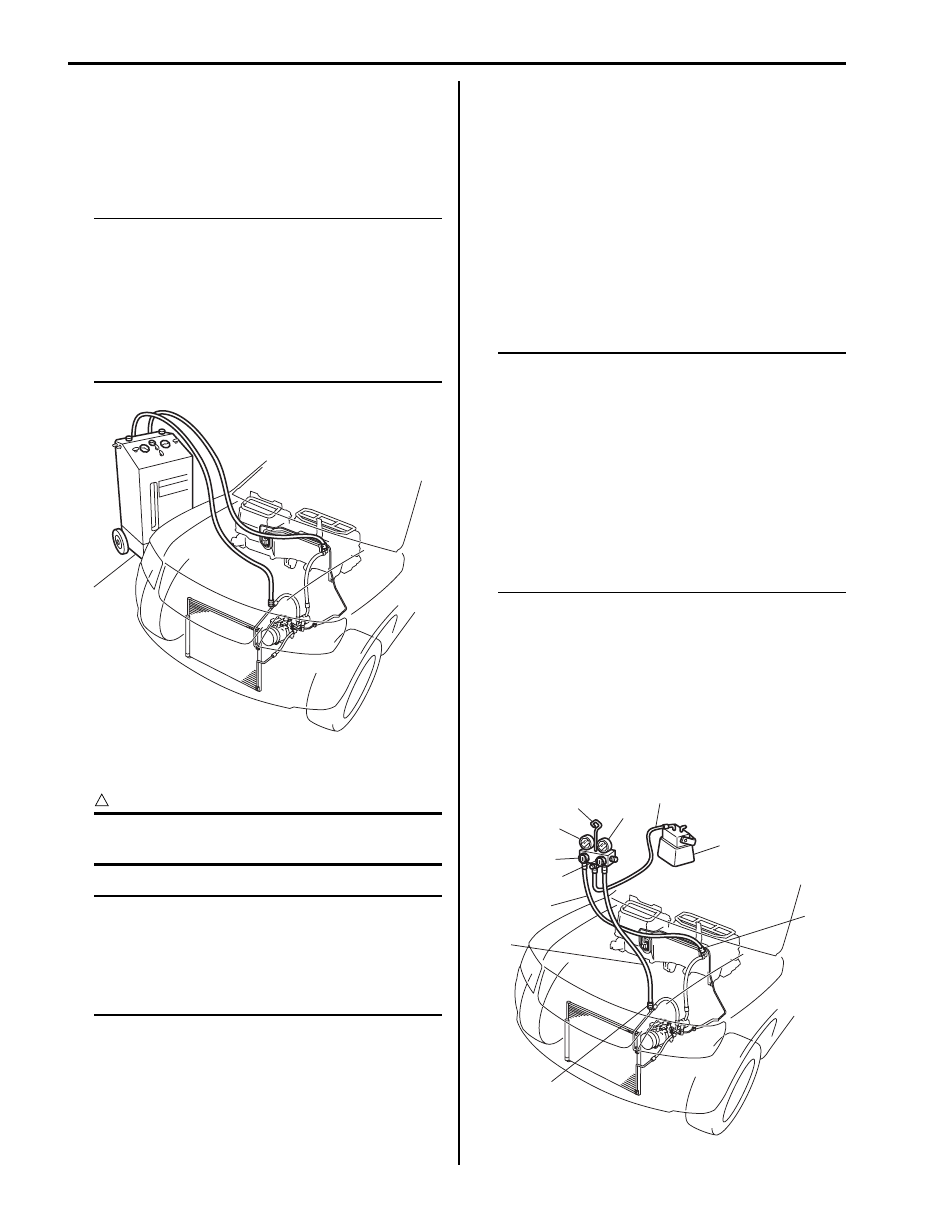

Recovery

When discharging refrigerant out of A/C system, always

recover it by using refrigerant recovery and recycling

equipment (1). Discharging refrigerant HFC-134a

(R134a) into atmosphere would cause adverse effect to

environments.

NOTE

• After recovering refrigerant from system

the amount of removed compressor oil

must be measured for replenishing

compressor oil. Refer to “Precautions on

Replenishing Compressor Oil”.

• When handling recovery and recycling

equipment, be sure to follow the

instruction manual for the equipment.

Evacuation

CAUTION

!

Do not evacuate before recovering

refrigerant in system.

NOTE

Once A/C system circuit is opened (exposed

to atmospheric air) air conditioning system

must be evacuated by using a vacuum pump.

The A/C system should be attached with a

manifold gauge set, and should be evacuated

for approx. 20 minutes.

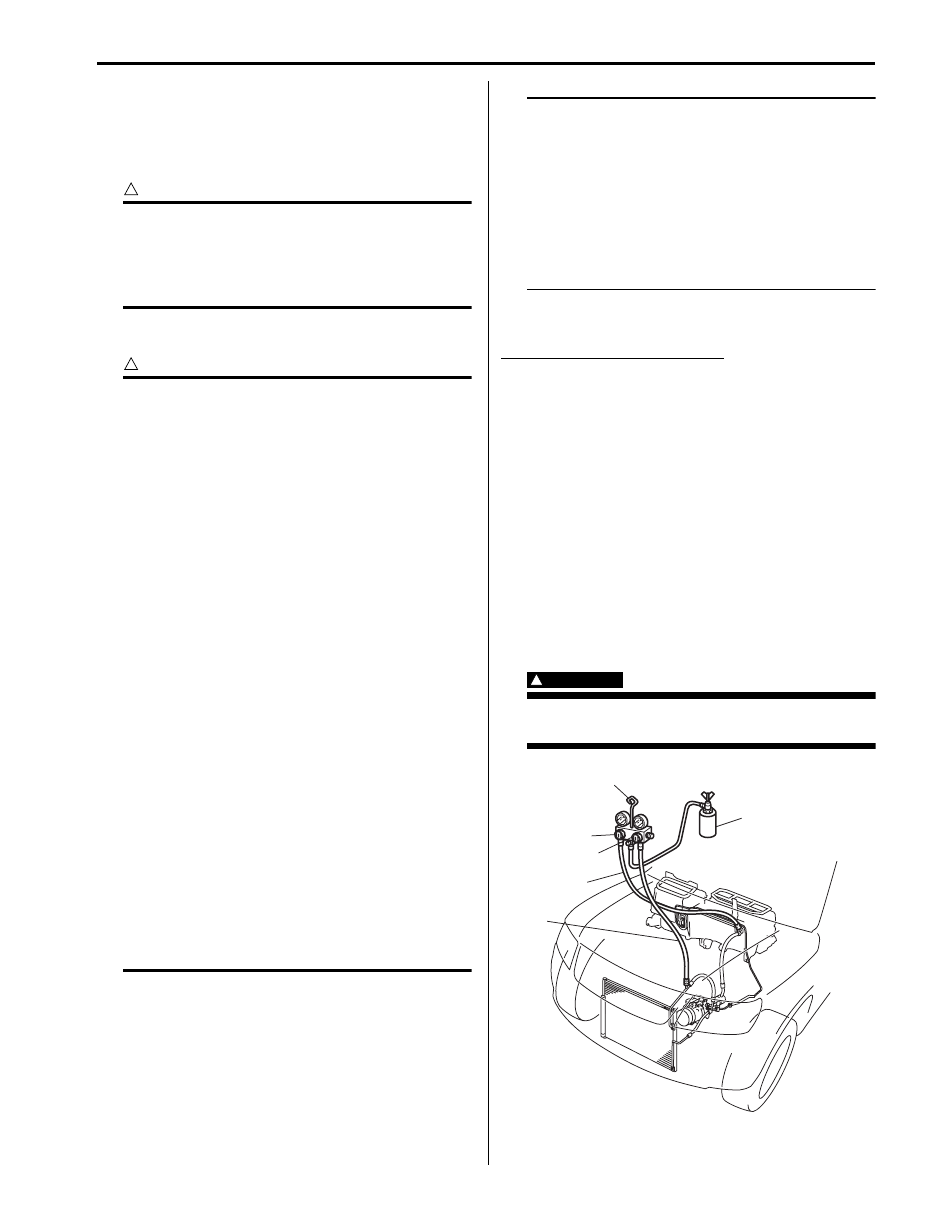

1) Connect high charging hose (1) and low charging

hose (2) of manifold gauge set (3) respectively as

follows:

High charging hose (1)

→ High pressure charging

valve (4) on discharge hose

Low charging hose (2)

→ Low pressure charging

valve (5) on suction pipe

2) Attach center charging hose (6) of manifold gauge

set (3) to vacuum pump (7).

3) Operate vacuum pump (7), and then open

discharge-side valve (9) (Hi) of manifold gauge set

(3).

If there is no blockage in the system, there will be an

indication on high pressure gauge (10).

In this case, open the other-side valve (8) (Lo) of the

set and repair the system.

4) Approx. 10 minutes later, low pressure gauge (11)

should show a vacuum lower than –100 kPa (–1.0

kg/cm

2

, –760 mmHg, –14.2 psi) providing no

leakage exists.

NOTE

• If the system does not show a vacuum

below –100 kPa (–1.0 kg/cm

2

, –760 mmHg,

–14.2 psi), close both valves, stop vacuum

pump and watch movement of low

pressure gauge.

• Increase in the gauge reading suggests

existence of leakage. In this case, repair

the system before continuing its

evacuation.

• If the gauge shows a stable reading

(suggesting no leakage), continue

evacuation.

5) Evacuation should be carried out for a total of at

least 20 minutes.

6) Continue evacuation until low pressure gauge

indicates a vacuum less than –100 kPa (–1.0 kg/cm

2

,

–760 mmHg, –14.2 psi), and then close both valves

(8), (9).

7) Stop vacuum pump (7). Disconnect center charging

hose (6) from pump inlet. Now, the system is ready

for charging refrigerant.

1

I5JB0A720032-01

8

9

2

1

4

5

11

3

10

6

7

I5JB0A720033-01

Air Conditioning System: 7B-61

Checking of A/C System for Pressure Leaks

After completing the evacuation, close manifold gauge

high pressure valve (Hi) and low-pressure valve (Lo) and

wait 10 minutes. Verify that low-pressure gauge reading

has not changed.

CAUTION

!

If the gauge reading moves closer to “0”,

there is a leak somewhere. Inspect the tubing

connections, make necessary corrections.

And then evacuate system once again and

make sure that there are no leaks.

Charge

CAUTION

!

• Because the sight glass is not used for this

A/C system, do not perform an additional

charge to the A/C system. To charge the

proper amount of refrigerant, recover and

evacuate the A/C system first. And then,

charge the proper amount of refrigerant

into the A/C system.

• Always charge through low pressure-side

of A/C system at after the initial charging is

performed from the high-pressure side

with the engine stopped.

• Never charge to high pressure-side of A/C

system with engine running.

• Do not charge while compressor is hot.

• When installing tap valve to refrigerant

container to make a hole there through,

carefully follow directions given by

manufacturer.

• A pressure gauge should always be used

before and during charging.

• The refrigerant container should be

emptied of refrigerant when discarding it.

• The refrigerant container should not be

heated up to 40

°C (104 °F) or over.

• Refrigerant container should not be

reversed in direction during charging.

Reversing in direction causes liquid

refrigerant to enter compressor, causing

troubles, such as compression of liquid

refrigerant and the like.

NOTE

The A/C system contains HFC-134a (R-134a).

Described here is a method to charge the A/C

system with refrigerant from the refrigerant

service container.

When charging refrigerant recovered by

using the refrigerant and recycling

equipment (when recycling refrigerant),

follow the procedure described in the

equipment manufacturer’s instruction

manual.

Charge proper amount of refrigerant accurately in

accordance with the following procedure.

Specified amount of refrigerant

570

± 30 g (20.1 ± 1.0 oz)

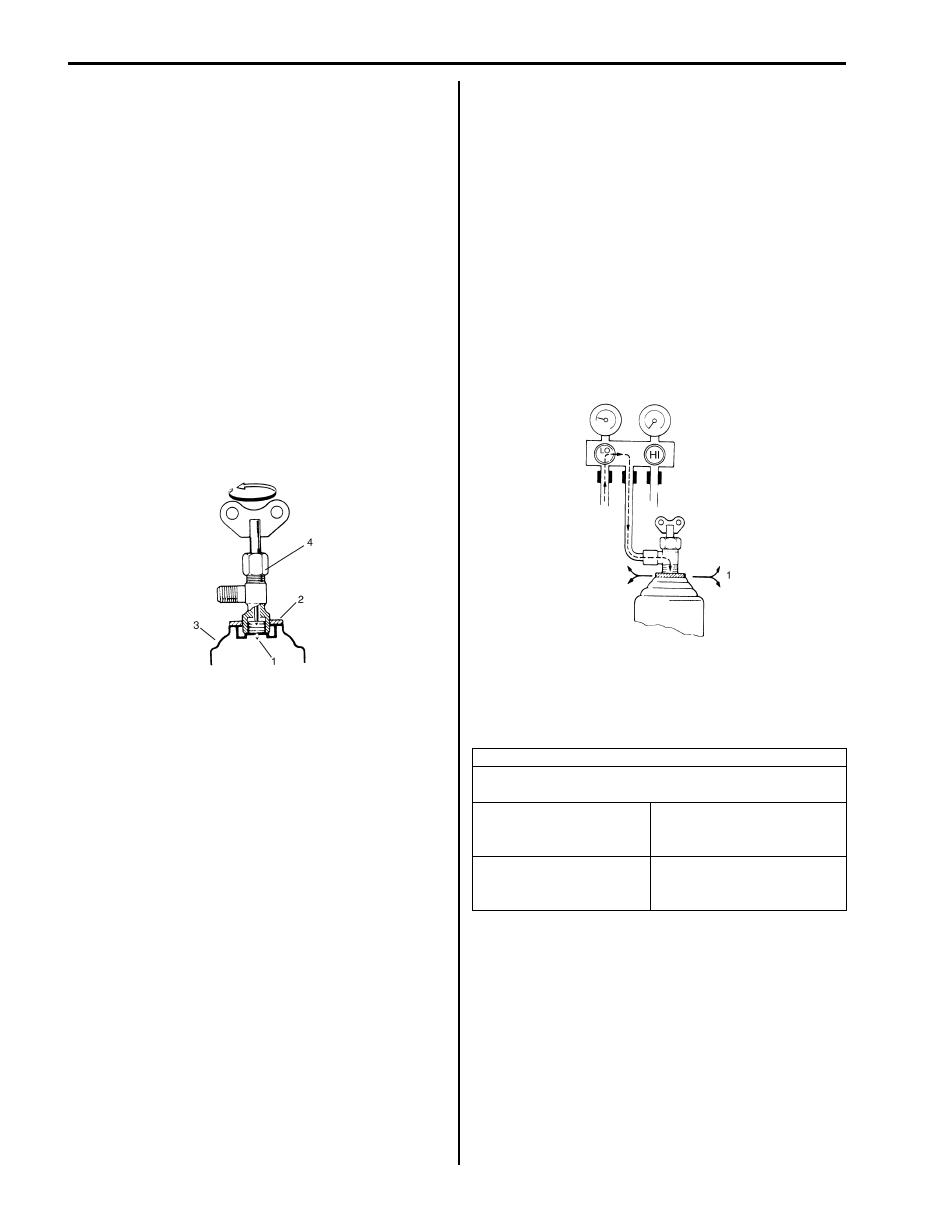

The initial charging of the A/C system is performed from

the high-pressure side with the engine stopped.

And next, this method must be followed by charging from

the low-pressure side with the engine running.

1) Check to make sure that hoses are routed properly

after evacuating the system.

2) Connect low charging hose (1) and high charging

hose (2) of the manifold gauge set (3) in position.

Thus open refrigerant container valve (4) to purge

the charging line.

3) Open the high-pressure side valve (6) and charge

refrigerant to system.

4) After a while, open the low-pressure side valve (5)

and close the high-pressure side valve (6).

WARNING

!

Make sure that high pressure-side valve is

closed securely.

5

6

1

2

3

4

I5JB0A720034-01

7B-62 Air Conditioning System:

5) Start engine and keep engine speed at 1,500 rpm.

Then, operate A/C system.

6) Charge A/C system with refrigerant in vapor state. At

this time, refrigerant container should be held

upright.

7) When refrigerant container (3) is emptied, the use

following procedure to replace it with a new

refrigerant container (3).

a) Close low pressure valve.

b) Replace empty container (3) with a refrigerant

container which has been charged with

refrigerant. When using refrigerant container tap

valve (4), use the following procedure for

replacement.

i)

Retract needle (1) and remove refrigerant

container tap valve (4) by loosening its plate

nut (2).

ii) Install previously-removed refrigerant

container tap valve (4) to a new refrigerant

container (3).

c) Purge any air existing in center charging hose.

When using refrigerant container tap valve, use

the following procedure to purge air.

i)

Once fully tighten refrigerant container tap

valve and then loosen (open) plate nut

slightly.

ii) Open low pressure valve of manifold gauge

set a little.

iii) As soon as refrigerant comes out with a

“hiss” (1) through a clearance between

refrigerant container and tap valve, tighten

plate nut as well as manifold gauge set low

pressure valve.

iv) Turn handle of tap valve clockwise so that its

needle is screwed into the new container to

make a hole for refrigerant flow.

8) After the system has been charged with specified

amount (570

± 30 g) of refrigerant or when low

pressure gauge and high pressure gauge have

indicated the following specified value, close low

pressure side valve on manifold gauge set.

IYSQ01720015-01

Low side and high side pressure example

Gauges should read as follows when ambient

temperature is 30

°C (86 °F)

Pressure

on high pressure gauge

1340 – 1670 kPa

13.4 – 16.7 kg/cm

2

191 – 237 psi

Pressure

on low pressure gauge

280 – 390 kPa

2.8 – 3.9 kg/cm

2

40 – 55 psi

IYSQ01720016-01

Air Conditioning System: 7B-63

Removal of Manifold Gauge Set

WARNING

!

High pressure side is under high pressure.

Therefore, be careful not to get injured

especially on your eyes and skin.

For the A/C system charged with the specified amount of

refrigerant, remove manifold gauge set as follows:

1) Close low pressure side valve of manifold gauge set.

(The high pressure side valve is closed continuously

during the process of charging.)

2) Close refrigerant container valve.

3) Stop engine.

4) Using shop rag, remove charging hoses from service

valves. This operation must be performed quickly.

5) Put caps on service valves.

Check A/C System for Refrigerant Leaks

Whenever a refrigerant leak is suspected in the system

or any service operation has been performed which may

result in malfunction lines and/or connections, it is

advisable to check for leaks.

Common sense should be used in performing any

refrigerant leak test, since the need and extent of any

such test will, in general, depend upon the nature of a

complaint and the type of a service performed on the

system.

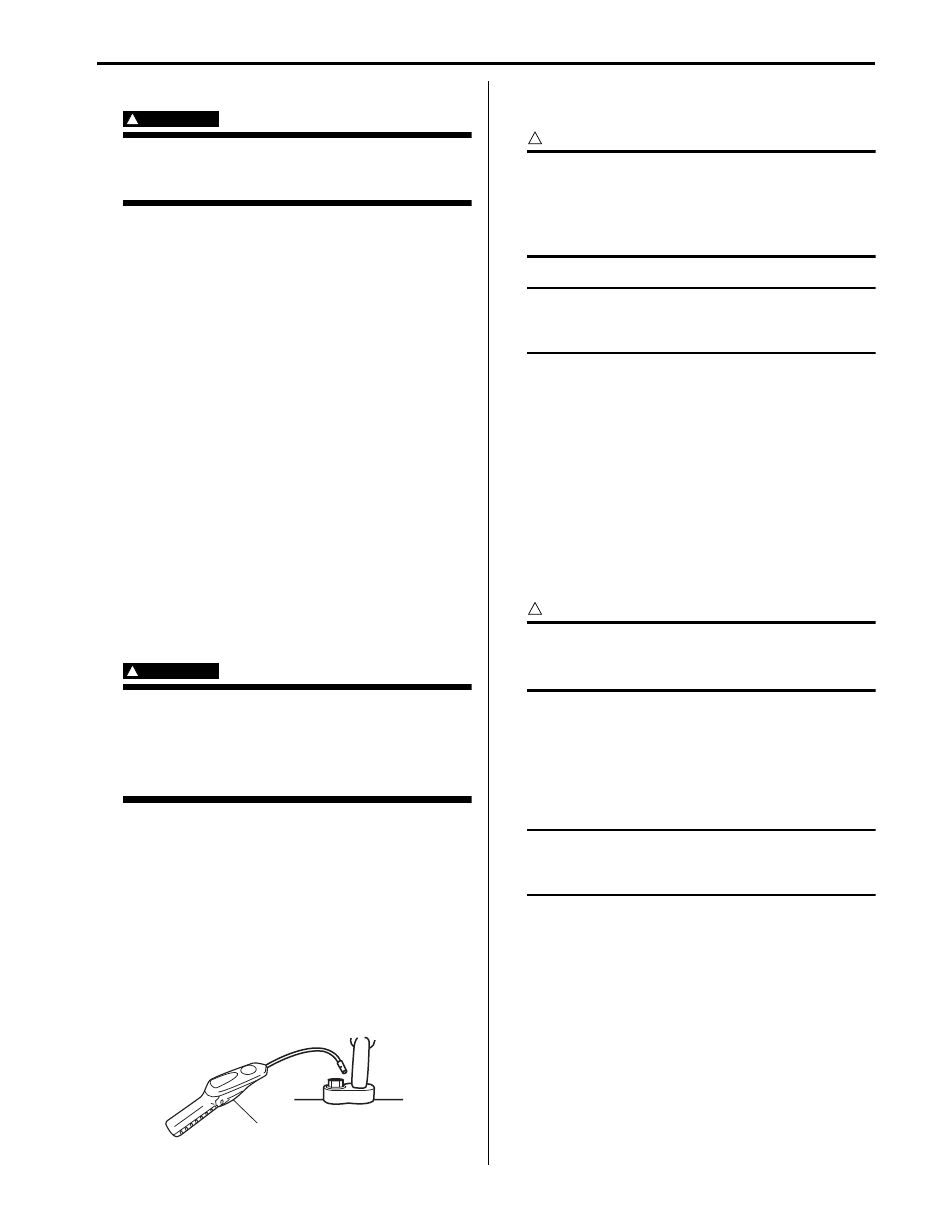

Liquid leak detector

WARNING

!

• To prevent explosions or fires, make sure

that there are no flammables in the vicinity.

• When exposed to fire, the refrigerant turns

into a poisonous gas (phosgene). Do not

inhale this gas.

There are a number of fittings and places throughout the

air conditioning system where a liquid leak detector

solution may be used to pinpoint refrigerant leaks.

By merely applying the solution to the area in question

with a swab, such as attached to the bubbles will form

within seconds if there is a leak.

For confined areas, such as sections of the evaporator

and condenser, an electronic (gas) leak detector (1) is

more practical for determining leaks.

Special tool

(A): 09990–86012

A/C Condenser Assembly On-Vehicle

Inspection

S6JB0B7206002

CAUTION

!

Be careful not to damage condenser fins. If

condenser fin is bent, straighten it by using a

screwdriver or pair of pliers. If any leakage is

found from fitting or tube, repair or replace

condenser.

NOTE

Clogged condenser fins should be washed

with water, and should be dried with

compressed air.

Check the followings.

• Clog of condenser fins.

If any clog is found, condenser fins should be washed

with water and should be dried with compressed air.

• Condenser fins for leakage and breakage If any

defects are found, repair or replace condenser.

• Condenser fittings for leakage. If any defects are

found, repair or replace condenser.

A/C Condenser Assembly Removal and

Installation

S6JB0B7206003

CAUTION

!

Do not damage condenser fins. If condenser

fin is bent, straighten it by using flat head

screwdriver or pair of pliers.

Removal

1) Disconnect negative (–) cable at battery.

2) Recover refrigerant from A/C system referring to

“Operation Procedure for Charging A/C with

Refrigerant”.

NOTE

The amount of removed compressor oil must

be measured for replenishing compressor

oil.

1, (A)

I5JB0C720002-01

Нет комментариевНе стесняйтесь поделиться с нами вашим ценным мнением.

Текст