Suzuki Grand Vitara JB627. Manual — part 85

1D-21 Engine Mechanical:

• Use new exhaust manifold gasket.

• Tighten exhaust manifold mounting bolts and nuts to

specified torque referring to “Exhaust Manifold

Removal and Installation in Section 1K”.

• Refill coolant referring to “Cooling System Flush and

• Finally, start engine and check for engine coolant

leaks and exhaust gas leakage.

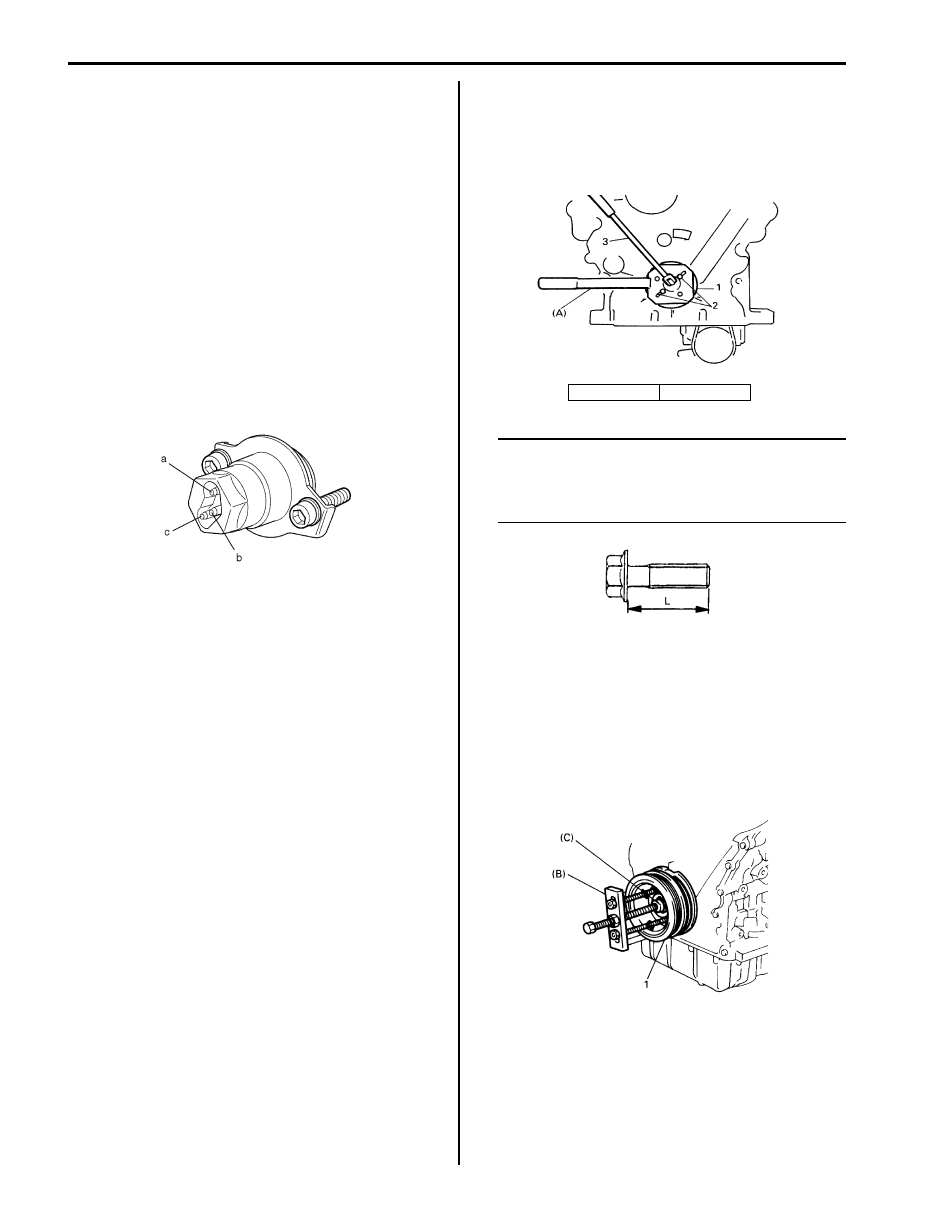

Engine Block Heater (If Equipped) Inspection

S6JB0B1406015

• Check continuity between terminal “a” and “c”. If there

is no continuity, replace it.

• Check that there is no continuity between terminal “a”

or “b” and “c”. If there is continuity, replace it.

• Check continuity between terminal “c” and engine

block heater body. If there is no continuity, replace it.

Timing Chain Cover Removal and Installation

S6JB0B1406016

Removal

1) Remove engine assembly from vehicle. Refer to

“Engine Assembly Removal and Installation”.

2) Remove electric throttle body assembly with intake

collector and intake manifold. Refer to “Intake

Collector and Intake Manifold Removal and

Installation” and “Electric Throttle Body Assembly

Removal and Installation”.

3) Remove cylinder head covers. Refer to “Cylinder

Head Covers Removal and Installation”.

4) Remove P/S pump and A/C compressor (if

equipped) drive belt referring to “P/S Pump and A/C

Compressor (If Equipped) Drive Belt Removal and

Installation in Section 6C”.

5) Remove water pump and generator drive belt. Refer

to “Water Pump and Generator Drive Belt Removal

and Installation in Section 1J”.

6) Remove water pump pulley.

7) Remove thermostat cap. Refer to “Thermostat

Removal and Installation in Section 1F”.

8) Remove P/S pump bracket. Refer to “P/S Hose /

Pipe Components in Section 6C”.

9) Remove oil pans. Refer to “Oil Pan and Oil Pump

Strainer Removal and Installation in Section 1E”.

10) Remove crankshaft pulley bolt (1). To lock crankshaft

pulley, use special tool (camshaft pulley holder) as

shown in figure.

Special tool

(A): 09917–68221

NOTE

Be sure to use the following bolt for fixing

special tool to crankshaft pulley.

Bolt size: M8, P1.25 L=45 mm

Strength: 7T

11) Remove crankshaft pulley (1).

If it is hard to remove, use special tools (Steering

wheel remover, Bearing puller attachment) as shown

in figure.

If bolts of steering wheel remover are too long,

replace them with those of suitable length.

Special tool

(A): 09944–36011

(B): 09926–58010

12) Remove timing chain cover.

I1SQ01162003-01

2. Bolt

3. Wrench

IYSQ01143031-01

IYSQ01143032-01

I6JB01140038-01

Engine Mechanical: 1D-22

Installation

Reverse removal sequence to install timing chain cover

noting the following points.

• Clean sealing surface on timing chain cover,

crankcase, cylinder block and cylinder heads.

Remove oil, old sealant, and dust from sealing

surface.

• Apply sealant “A” to timing chain cover sealing

surface area as shown in figure.

“A”: Sealant 99000–31260 (SUZUKI Bond

No.1217G)

• Apply sealant “B” to mating surfaces of cylinder head

and cylinder block as shown in figure.

“B”: Water tight sealant 99000–31140 (SUZUKI

Bond No.1207B)

• Apply engine oil to new oil seal lip and water pump O-

ring. Using special tool (bearing installer), install new

oil seal (2) with its surface is flash with edge of timing

chain cover (1).

Special tool

(D): 09913–75510

• Install timing chain cover.

Tightening torque

Timing chain cover bolt: 11 N·m (1.1 kgf-m, 8.0 lb-

ft)

• Install CMP sensor to timing chain cover referring to

“Camshaft Position (CMP) Sensor Removal and

Installation in Section 1C”.

• Install crankshaft pulley (1).

To lock crankshaft pulley, use special tool (camshaft

pulley holder) with it at shown in figure.

Special tool

(A): 09917–68221

Tightening torque

Crankshaft pulley bolt (a): 150 N·m (15 kgf-m,

108.5 lb-ft)

“a”: 2 mm (0.08 in.)

1. Timing chain cover

“b”: 3 mm (0.11 in)

2. Sealant “A”

[A]: View A

“a”: 7 mm (0.28 in.)

1. Cylinder head

“b”: 67 mm (2.64 in.)

2. Cylinder block

“c”: 17 mm (0.67 in.)

3. Cylinder head gasket

“d”: 18 mm (0.71 in.)

4. Rub into

“e”: 10 mm (0.39 in.)

5. Jig

“f”: 34 mm (1.34 in.)

“g”: 50 mm (1.97 in)

I6JB01140114-01

"a"

"b"

"d"

"f"

"e"

"c"

"a"

"g"

2

"B"

1

1

A

A

A

[A]

"B"

1

3

2

4

5

I5JA01140005-02

2. Bolt

3. Wrench

IYSQ01143037-01

I6JB01140108-01

1D-23 Engine Mechanical:

NOTE

Be sure to use the following bolt for fixing

special tool to crank pulley.

Bolt size: M8, P1.25 L=45 mm

Strength: 7T

Timing Chain Cover Inspection

S6JB0B1406017

Check oil seal lip for damage or deterioration. Replace

as necessary.

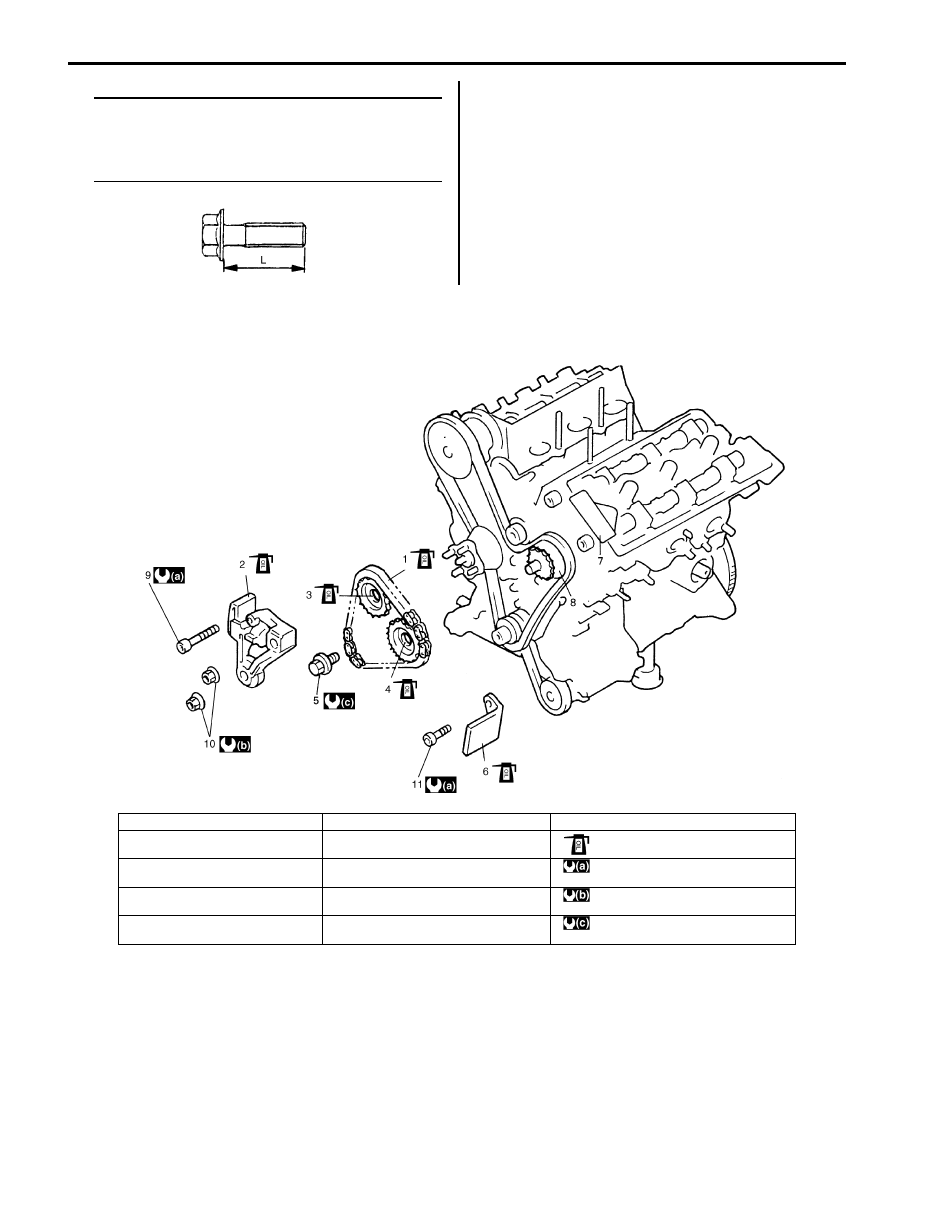

LH (No.1) Bank 2nd Timing Chain and Chain Tensioner Components

S6JB0B1406018

IYSQ01143032-01

I6JB01140039-01

1. LH (No.1) bank 2nd timing chain

6. Timing chain guide No.4

11. Timing chain guide No. 4 bolt

2. Timing chain tensioner adjuster No.3

7. Timing chain guide No.5

: Apply engine oil to sliding surface of

each point.

3. LH (No.1) bank intake camshaft

sprocket

8. Idler sprocket No.2

: 11 N

⋅m (1.1 kgf-m, 8.0 lb-ft)

4. LH (No.1) bank exhaust camshaft

sprocket

9. Timing chain tensioner adjuster No. 3 bolt

: Tighten 45 N

⋅m (4.5 kgf-m, 32.5 lb-ft) by

the specified procedure.

5. Camshaft sprocket bolt

10. Timing chain tensioner adjuster No. 3 nut

: Tighten 80 N

⋅m (8.0 kgf-m, 58.0 lb-ft) by

the specified procedure.

Engine Mechanical: 1D-24

LH (No.1) Bank 2nd Timing Chain and Chain

Tensioner Removal and Installation

S6JB0B1406019

Removal

1) Remove engine assembly from vehicle. Refer to

“Engine Assembly Removal and Installation”.

2) Remove timing chain cover. Refer to “Timing Chain

Cover Removal and Installation”.

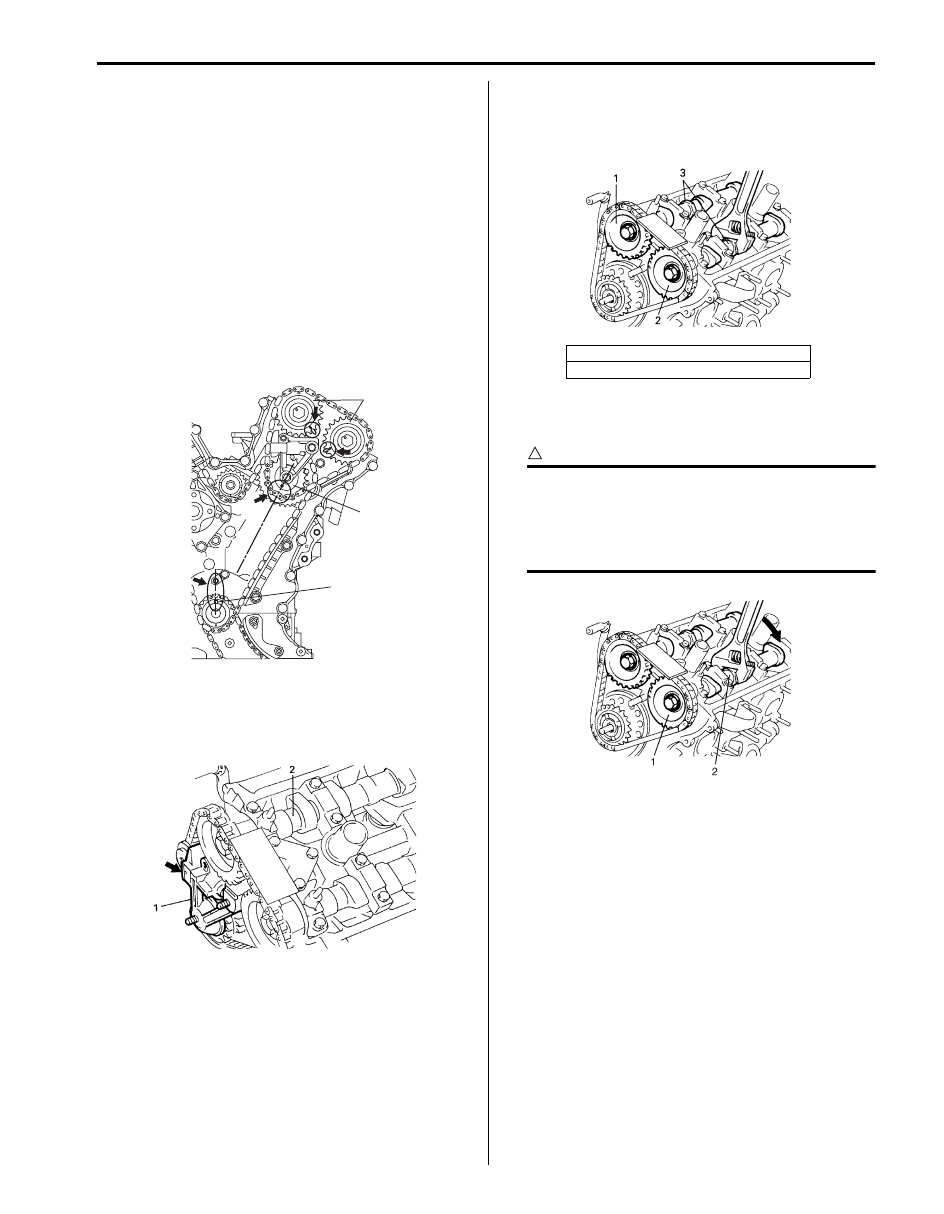

3) Turn crankshaft to meet the following condition.

• Key (1) on crankshaft positions as shown.

• Mark on idler sprocket No.2 (2) points the center

of crankshaft.

• The marks on sprockets (3) match with marks on

cylinder head.

4) Remove timing chain tensioner adjuster No.3 (1).

To remove it, slacken LH (No.1) bank 2nd timing

chain by turning intake camshaft (2)

counterclockwise a little while pushing back pad.

5) Remove LH (No.1) bank intake and exhaust

camshaft sprocket bolts.

To remove it, fit a spanner to hexagonal part (3) at

the center of camshaft to hold it stationary.

6) Remove LH (No.1) bank exhaust camshaft sprocket

(1).

CAUTION

!

Removing sprocket (1) from camshaft (2) may

cause cam to turn, resulting in damage to

valve and piston. To prevent this, when

removing sprocket, hold camshaft stationary

by using a spanner at its hexagonal part.

7) Remove LH (No.1) bank intake camshaft sprocket.

8) Remove LH (No.1) bank 2nd timing chain.

1

2

3

I6JB01140040-01

I6JB01140041-01

1. LH (No.1) bank intake camshaft sprocket

2. LH (No.1) bank exhaust camshaft sprocket

I6JB01140042-01

I6JB01140043-01

Нет комментариевНе стесняйтесь поделиться с нами вашим ценным мнением.

Текст