Suzuki Grand Vitara JB627. Manual — part 173

4A-11 Brake Control System and Diagnosis:

Booster Operation Check

S6JB0B4106010

There are two ways to perform this inspection, with and

without a tester. Ordinarily, it is possible to roughly

determine its condition without using a tester.

NOTE

For this check, make sure that no air is in

hydraulic line.

Inspection without Tester

Check air tightness

1) Start engine.

2) Stop engine after running for 1 to 2 minutes.

3) Depress brake pedal several times with the same

load as in ordinary braking and observe pedal travel.

If pedal goes down deep the first time but its travel

decreases as it is depressed the second and more

times, air tightness is obtained.

4) If pedal travel doesn’t change, air tightness isn’t

obtained.

NOTE

If defective, inspect vacuum lines and sealing

parts, and replace any faulty part.

When this has been done, repeat the entire

test.

Check operation

1) With engine stopped, depress brake pedal several

times with the same load and make sure that pedal

travel doesn’t change.

2) Start engine while depressing brake pedal. If pedal

travel increases a little, operation is satisfactory. But

no change in pedal travel indicates malfunction.

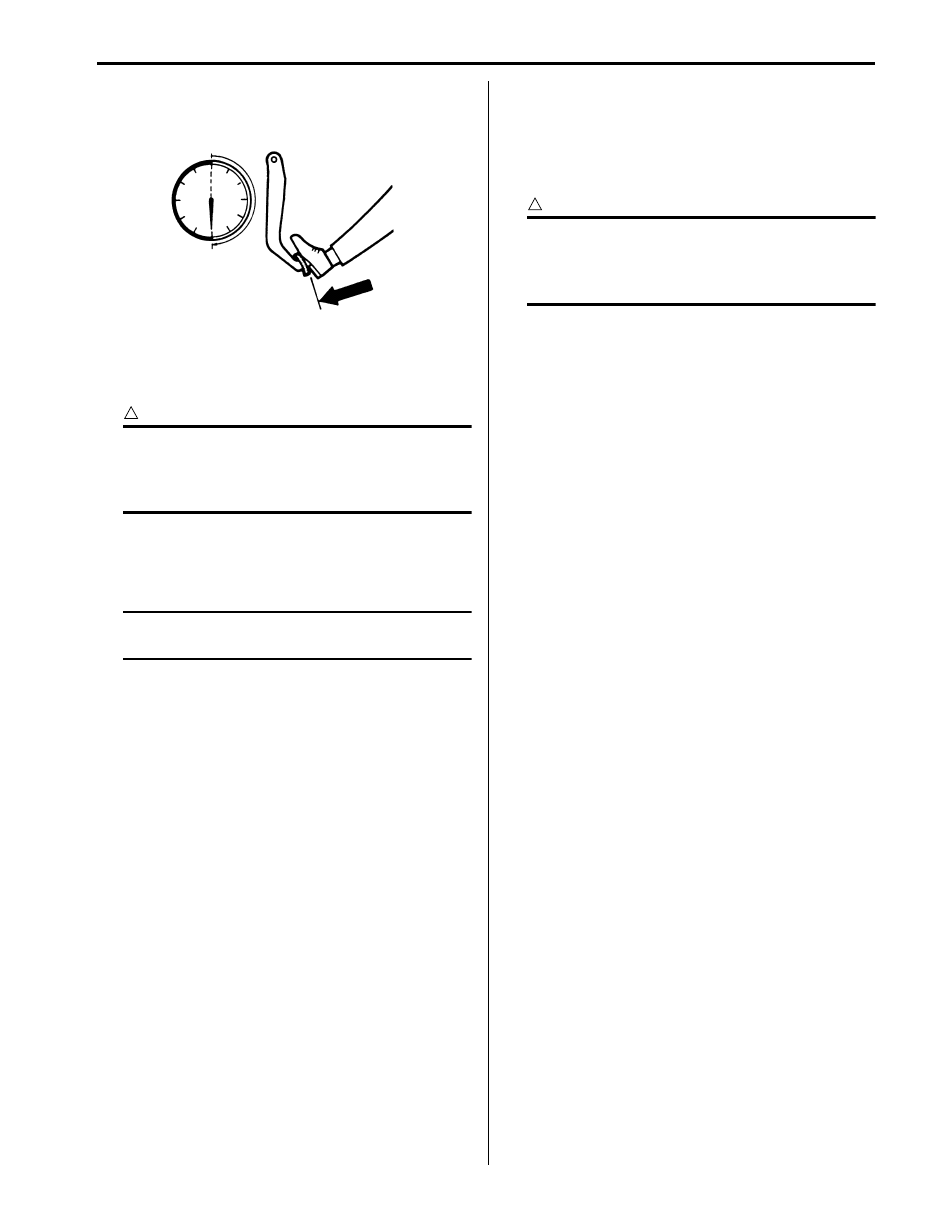

Check air tightness under load

1) With engine running, depress brake pedal. Then

stop engine while holding brake pedal depressed.

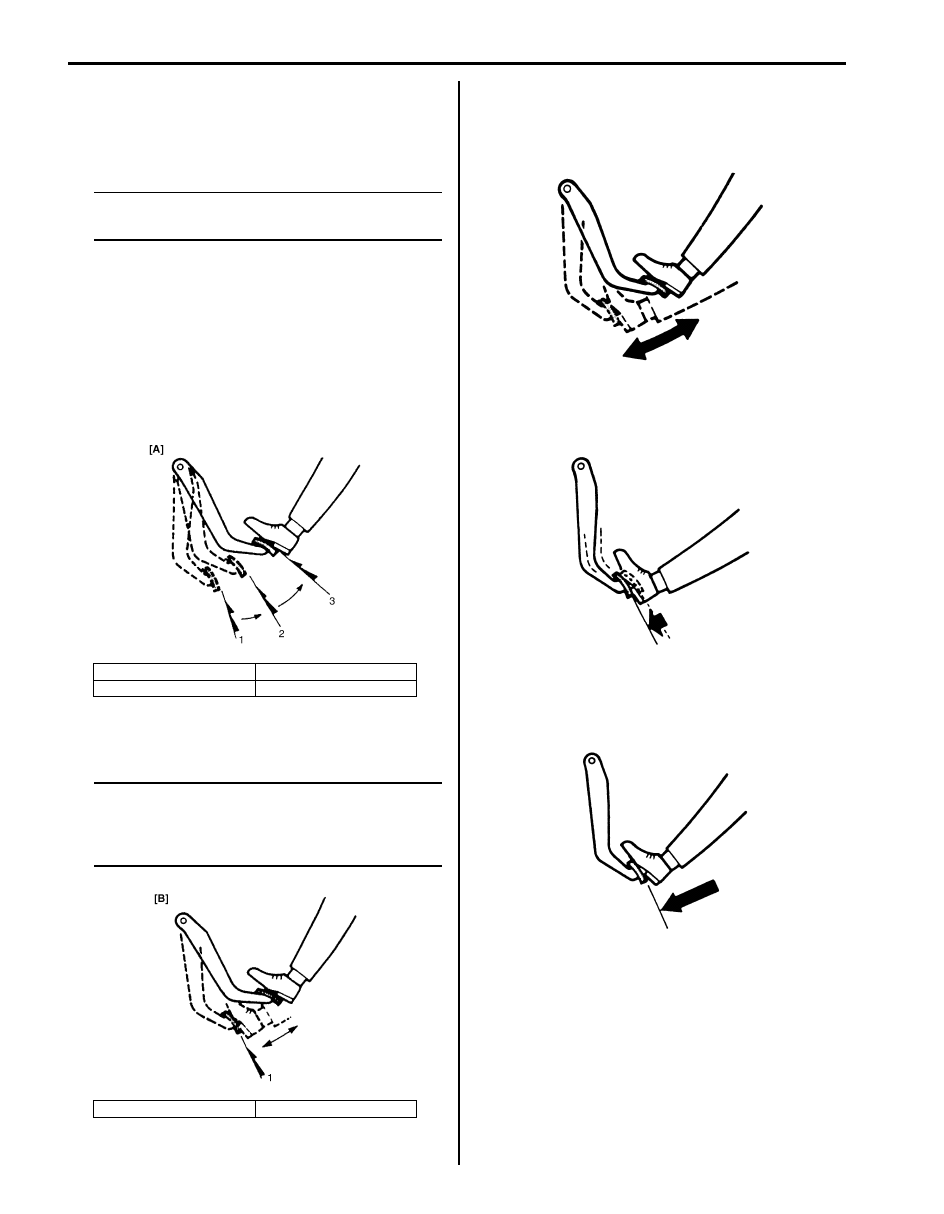

[A]: Good

2. 2nd

1. 1st

3. 3rd

[B]: No Good

1. 1st, 2nd, 3rd

I5JB0A410008-01

I5JB0A410009-01

IYSQ01410018-01

IYSQ01410019-01

IYSQ01410020-01

Brake Control System and Diagnosis: 4A-12

2) Hold brake pedal depressed for 30 seconds. If pedal

height does not change, condition is good. But it isn’t

if pedal rises.

Front Brake Hose / Pipe Removal and

Installation

S6JB0B4106011

CAUTION

!

Do not allow brake fluid to get on painted

surfaces. Painted surfaces will be damaged

by brake fluid, flush it with water immediately

if any fluid is spilled.

Removal

1) Raise and support vehicle properly. Remove tire and

wheel.

NOTE

This operation is not necessary when

removing pipes connecting master cylinder.

2) Clean dirt and foreign material from both flexible

hose end and pipe end fittings.

3) Drain brake fluid in reservoir.

4) Remove brake flexible hose or pipe.

Installation

Reverse brake flexible hose removal procedure, noting

the following.

• Tighten brake pipe flare nut to specified torque.

Tightening torque

Brake pipe flare nut (M10): 16 N·m (1.6 kgf-m,

12.0 lb-ft)

Brake pipe flare nut (M12): 19 N·m (1.9 kgf-m,

14.0 lb-ft)

• Make sure that steering wheel is in straight-forward

position and flexible hose has not twist or kink.

• Check to make sure that flexible hose doesn’t contact

any part of suspension, both in extreme right and

extreme left turn conditions.

If it does at any point, remove and correct. Fill and

maintain brake fluid level in reservoir.

• Bleed brake system. Refer to “Air Bleeding of Brake

• Perform brake test and check installed part for fluid

leakage.

Rear Brake Hose / Pipe Removal and

Installation

S6JB0B4106012

CAUTION

!

Do not allow brake fluid to get on painted

surfaces. Painted surfaces will be damaged

by brake fluid, flush it with water immediately

if any fluid is spilled.

Removal

1) Raise and support vehicle properly. Remove tire and

wheel.

2) Clean dirt and foreign material from both flexible

hose end and pipe end fittings.

3) Drain brake fluid in reservoir.

4) Remove brake flexible hose or pipe.

Installation

Reverse brake flexible hose removal procedure, noting

the following.

• Fill and maintain brake fluid level in reservoir.

• Bleed brake system. Refer to “Air Bleeding of Brake

• Perform brake test and check each installed part for

fluid leakage.

• Install clamps properly referring to the figure and

tighten bolts.

• When installing hose, make sure that it has no twist or

kink.

IYSQ01410021-01

4A-13 Brake Control System and Diagnosis:

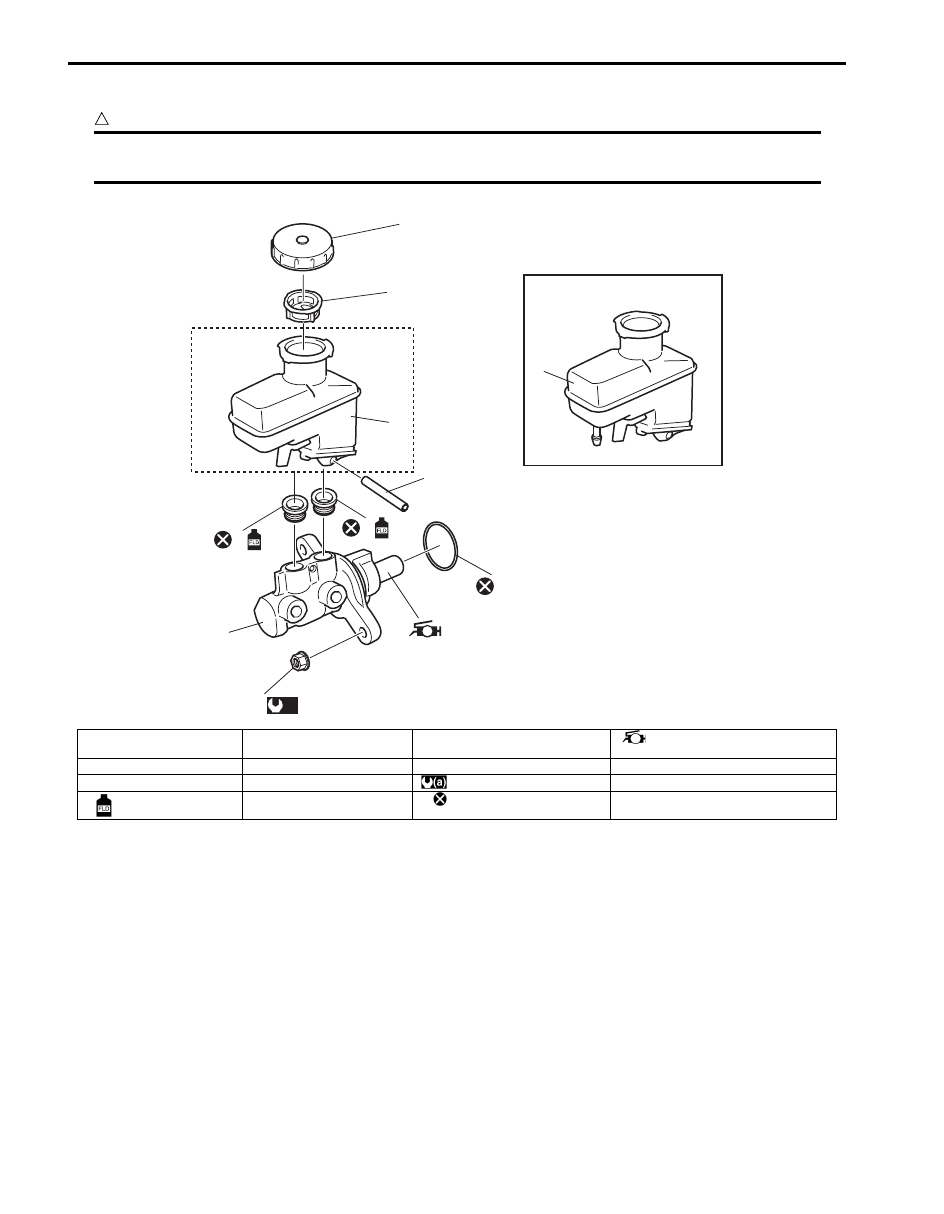

Master Cylinder Components

S6JB0B4106013

CAUTION

!

Never disassemble master cylinder. Disassembly will spoil its original function. If faulty condition is

found, replace it with new one as an assembly.

[A]

[B]

4

5

3

3

2

2

1

7

6

8

(a)

I6JB0B410002-01

[A]: A/T model

3. Reservoir

7. O-ring

: Apply grease to piston rod

(Grease included in spare parts)

[B]: M/T model

4. Reservoir cap

8. Master cylinder fixing nut

1. Master cylinder body

5. Filter

: 18 N

⋅m (1.8 kgf-m, 13.0 lb-ft)

2. Grommet

: Apply brake fluid.

6. Reservoir connector pin

: Do not reuse.

Brake Control System and Diagnosis: 4A-14

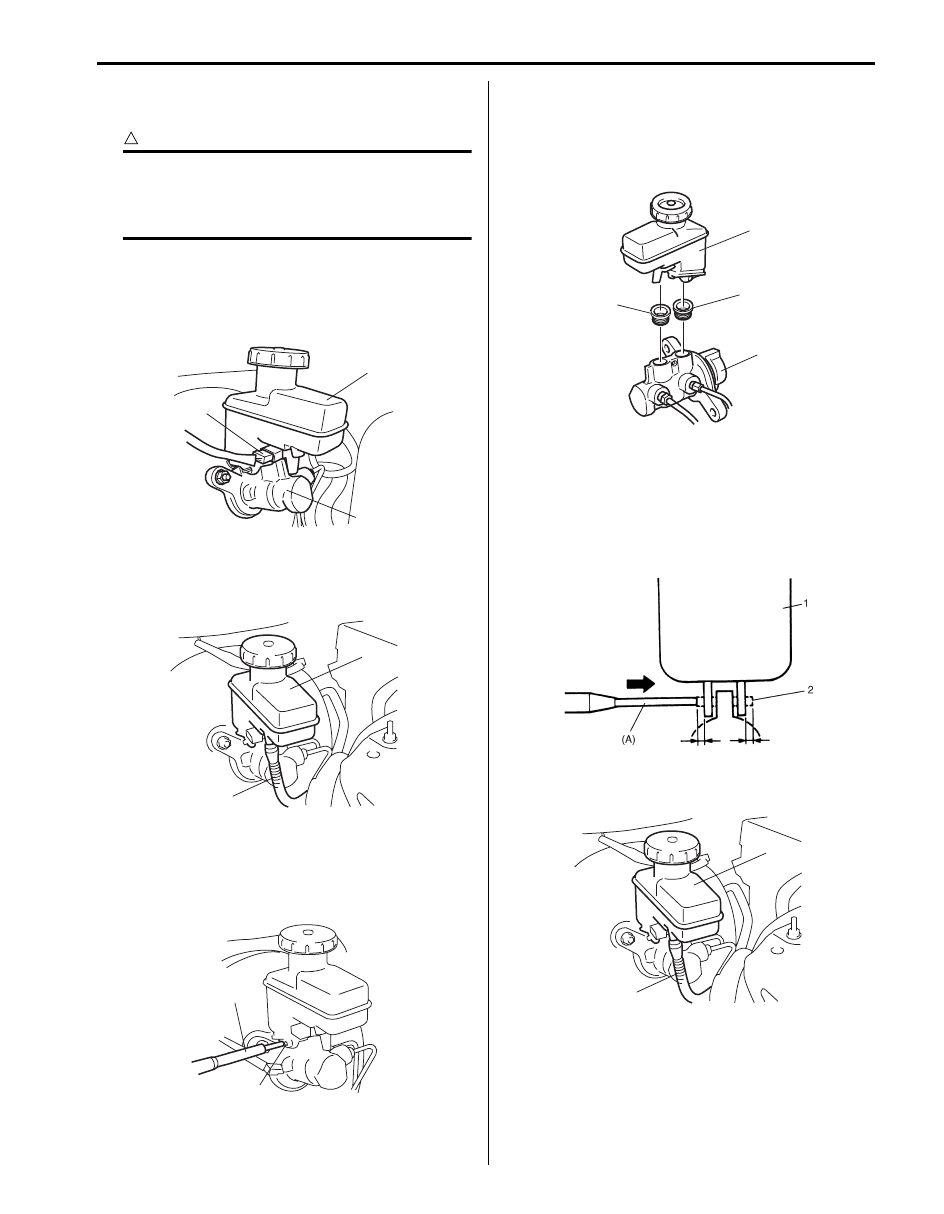

Master Cylinder Reservoir Removal and

Installation

S6JB0B4106014

CAUTION

!

Do not allow brake fluid to get on painted

surfaces. Painted surfaces will be damaged

by brake fluid, flush it with water immediately

if any fluid is spilled.

Removal

1) Disconnect reservoir lead wire at coupler (1).

2) Clean outside of reservoir (2) and master cylinder

(3).

3) Take out fluid with syringe or such.

4) Disconnect clutch reservoir hose (1) from reservoir

(2) (M/T model).

5) Remove reservoir connector pin (1) by using special

tool and then reservoir.

Special tool

(A): 09916–44310

Installation

1) When using new grommets (3), lubricate them with

the same fluid as the one to fill reservoir (1) with.

Then press-fit grommets (3) to master cylinder (2).

Grommets (3) must be seated in place.

2) Install reservoir (1) and drive in reservoir connector

pin (2) by using special tool (A). till both of its ends at

the right and left of reservoir becomes the same

length.

Special tool

(A): 09916–44310

3) Connect clutch reservoir hose (1) to reservoir (2) (M/

T model).

3

2

1

I5JB0A410011-02

2

1

I5JB0A410012-02

1

(A)

I5JB0A410013-02

1

2

3

3

I5JB0A410014-01

I5JB0A410015-01

2

1

I5JB0A410012-02

Нет комментариевНе стесняйтесь поделиться с нами вашим ценным мнением.

Текст