Suzuki Grand Vitara JB627. Manual — part 124

2B-10 Front Suspension:

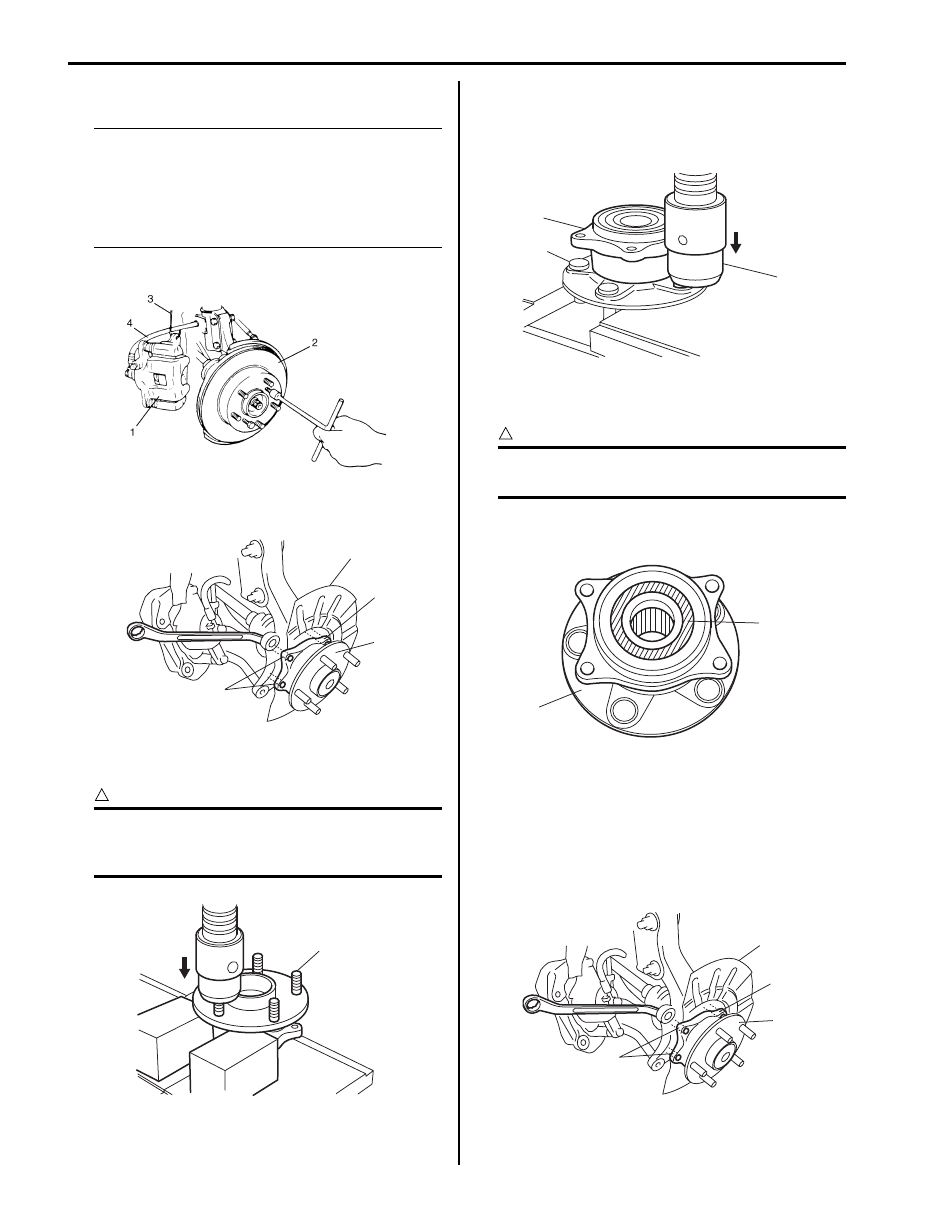

4) Remove caliper (1) with carrier.

NOTE

Hang removed caliper with a wire hook or the

like (3) so as to prevent brake hose (4) from

bending, twisting or tension.Do not depress

brake pedal during pads removal.

Do not operate brake pedal with pads

removed.

5) Pull brake disc (2) off by using two 8 mm bolts.

6) Remove wheel hub housing bolts (3), and then

remove wheel hub assembly (1) and dust cover (2).

7) Remove hub bolts (1) with copper hammer or

hydraulic press.

CAUTION

!

Never remove bolt unless replacement is

necessary.

Be sure to use a new bolt for replacement.

Installation

1) Insert new hub bolt (1) in hub hole. Rotate hub bolt

slowly to assure that serrations are aligned with

those made by original bolt.

2) Apply grease to end face of inner ring (2) before front

wheel nub (1) installation.

CAUTION

!

Do not apply the grease to the encoder

section to avoid the encoder malfunction.

“A”: Grease 99000–25010 (SUZUKI Super

Grease A)

3) Install wheel hub (1) and dust cover (2) to steering

knuckle.

4) Tighten wheel hub housing bolts (3) to specified

torque

Tightening torque

Wheel hub housing bolt (a): 50 N·m (5.0 kgf-m,

36.5 lb-ft)

I5JB0A220014-01

1

2

3

3

I5JB0A220015-01

1

I5JB0A220016-01

1

I5JB0A220017-01

1

2, "A"

I5JB0A220018-01

3,(a)

3,(a)

2

1

I5JB0A220019-01

Front Suspension: 2B-11

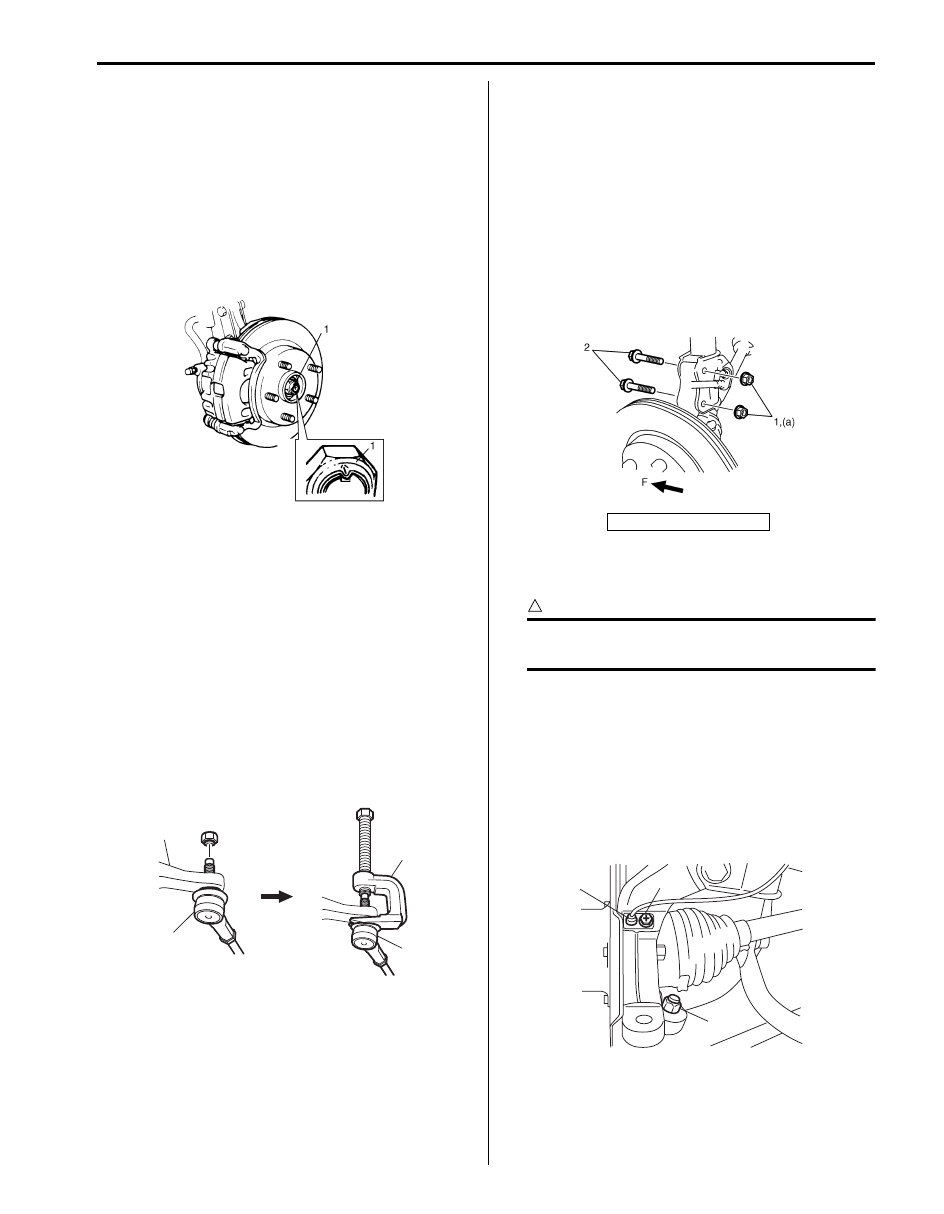

5) Install brake disk and brake caliper.

6) Tighten caliper carrier bolt to specified torque.

Tightening torque

Caliper carrier bolt: 85 N·m (8.5 kgf-m, 61.5 lb-ft)

7) Depress foot brake pedal and hold it there. Tighten

new drive shaft nut (1) to specified torque.

Tightening torque

Drive shaft nut: 220 N·m (22.0 kgf-m, 159.5 lb-ft)

8) Caulk drive shaft nut (1) as shown.

9) Tightening wheel nuts to specified torque.

Tightening torque

Wheel nut: 100 N·m (10.0 kgf-m, 72.5 lb-ft)

Steering Knuckle Removal and Installation

S6JB0B2206008

Removal

1) Hoist vehicle and remove wheel.

2) Remove Front wheel hub assembly referring to

“Front Wheel Hub Assembly Removal and

Installation”.

3) Disconnect tie-rod end (1) from steering knuckle (2)

with puller (3).

4) Disconnect front height sensor (if equipped) from

suspension control arm for left side referring to

“Height Sensor Removal and Installation (If

Equipped) in Section 9B”.

5) Remove wheel speed sensor from knuckle.

6) Remove steering knuckle ball joint nut then remove

strut bracket bolts and nut.

7) Disconnect ball joint from steering knuckle with

puller and then remove steering knuckle.

Installation

For installation, reverse removal procedure, noting the

following instructions.

1) Connect steering knuckle to suspension arm.

2) Install strut bracket bolts (2) and nuts (1).

3) Tighten strut bracket nuts (1) to specified torque.

Tightening torque

Strut bracket nut (a): 135 N·m (13.5 kgf-m, 98.0

lb-ft)

4) Tighten new suspension arm ball joint nut (1) to

specified torque.

CAUTION

!

Never reuse the removed suspension arm

ball joint nut.

Tightening torque

Suspension arm ball joint nut (a): 55 N·m (5.5

kgf-m, 40.0 lb-ft)

5) Install wheel speed sensor (2) and tighten wheel

speed sensor bolt (3).

Tightening torque

Wheel speed sensor bolt (b): 11 N·m (1.1 kgf-m,

8.0 lb-ft)

I5JB0A220021-01

2

1

3

1

I5JB0A220020-01

F: Vehicle forward

I5JB0A220025-01

2

3,(b)

1,(a)

I5JB0A220026-01

2B-12 Front Suspension:

6) Connect front height sensor (if equipped) to

suspension control arm for left side referring to

“Height Sensor Removal and Installation (If

Equipped) in Section 9B”.

7) Connect tie-rod end (1) to steering knuckle (2),

tighten new nut (3) to specified torque.

Tightening torque

Tie-rod end nut (a): 45 N·m (4.5 kgf-m, 32.5 lb-ft)

8) Install front wheel hub assembly and dust cover to

steering knuckle referring to “Front Wheel Hub

Assembly Removal and Installation”.

9) Check front wheel alignment adjust it as necessary.

For check and adjustment procedures, refer to

“Front Wheel Alignment Inspection and Adjustment”.

10) Adjust headlight auto leveling system (if equipped),

refer to “Initialization of Auto Leveling Headlight

System in Section 9B”.

Front Wheel Hub, Disc, Nut and Bearing Check

S6JB0B2206009

• Inspect each wheel disc for dents, distortion and

cracks.

A disc in badly damaged condition must be replaced.

• Check rust of installation face inside of wheel disc.

As rust affects adversely, remove it thoroughly.

• Check tightness of wheel nuts and, if necessary,

retighten them to specified torque.

Tightening torque

Wheel nut (a): 100 N·m (10.0 kgf-m, 72.5 lb-ft)

• Check wear of wheel bearing. When measuring thrust

play, apply a dial gauge to wheel hub as shown in

figure.

Front wheel bearing thrust play

Limit: 0.1 mm (0.004 in.)

• Check wheel bearing noise and smooth wheel rotation

by rotating wheel in figure.

If defective, replace bearing.

2

3,(a)

1

I5JB0A220028-01

(a)

I5JB0A220029-01

I3RM0A220034-01

I2RH01220011-01

Front Suspension: 2B-13

Suspension Control Arm Removal and

Installation

S6JB0B2206010

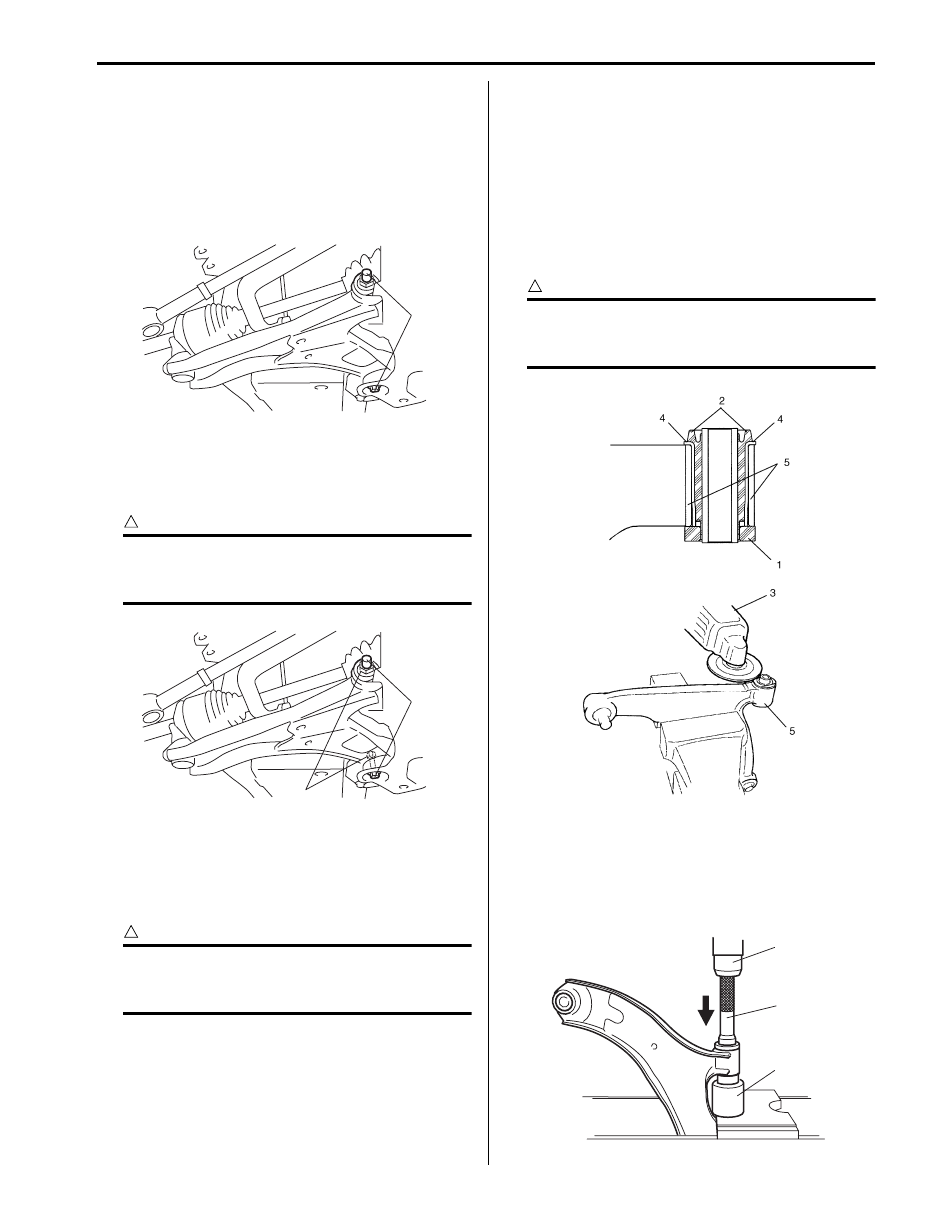

Removal

1) Remove steering knuckle from suspension control

arm referring to “Steering Knuckle Removal and

Installation”.

2) Remove suspension control arm bolts (1).

Installation

1) Install suspension control arm bolts (1) and tighten

suspension control arm nuts (2) temporarily by hand.

CAUTION

!

If suspension control arm nut is reused,

apply engine oil to thread, bearing and trunk

surface.

2) Connect steering knuckle to suspension control arm

referring to “Steering Knuckle Removal and

Installation”.

3) Tighten suspension control arm nuts to specified

torque with vehicle weight on suspension.

CAUTION

!

It is the most desirable to have vehicle off

hoist and in non-loaded condition when

tightening them.

Tightening torque

Suspension control arm nut: 135 N·m (13.5 kgf-

m, 98.0 lb-ft)

Suspension Control Arm / Bushing

Disassembly and Assembly

S6JB0B2206011

Disassembly

1) Remove rubber stopper (1).

2) Cut rubber (2) of flange of suspension control arm

front bushing.

3) Using grinder (3), grind off flange (4) of front

bushing.

CAUTION

!

Be careful not to damage suspension control

arm (5) when grinding flange (4) of front

bushing with grinder.

4) Push out bushing by using hydraulic press (2) and

special tools.

Special tool

(A): 09945–55410

(B): 09913–75821

1

I5JB0A220031-01

1

2

I5JB0A220033-01

I5JB0A220027-02

1

(A)

(B)

I5JB0A220035-01

Нет комментариевНе стесняйтесь поделиться с нами вашим ценным мнением.

Текст