Suzuki Grand Vitara JB627. Manual — part 116

1J-5 Charging System:

Generator Test (Undercharged Battery Check)

S6JB0B1A04003

This condition, as evidenced by slow cranking or

indicator clear with red dot can be caused by one or

more of the following conditions even though indicator

lamp may be operating normal.

The following procedure also applies to cars with

voltmeter and ammeter.

1) Make sure that undercharged condition has not been

caused by accessories left on for extended period of

time.

2) Check drive belt for proper tension.

3) If battery defect is suspected, refer to “Battery

4) Inspect wiring for defects. Check all connections for

tightness and cleanliness, battery cable connections

at battery, starting motor and ignition ground cable.

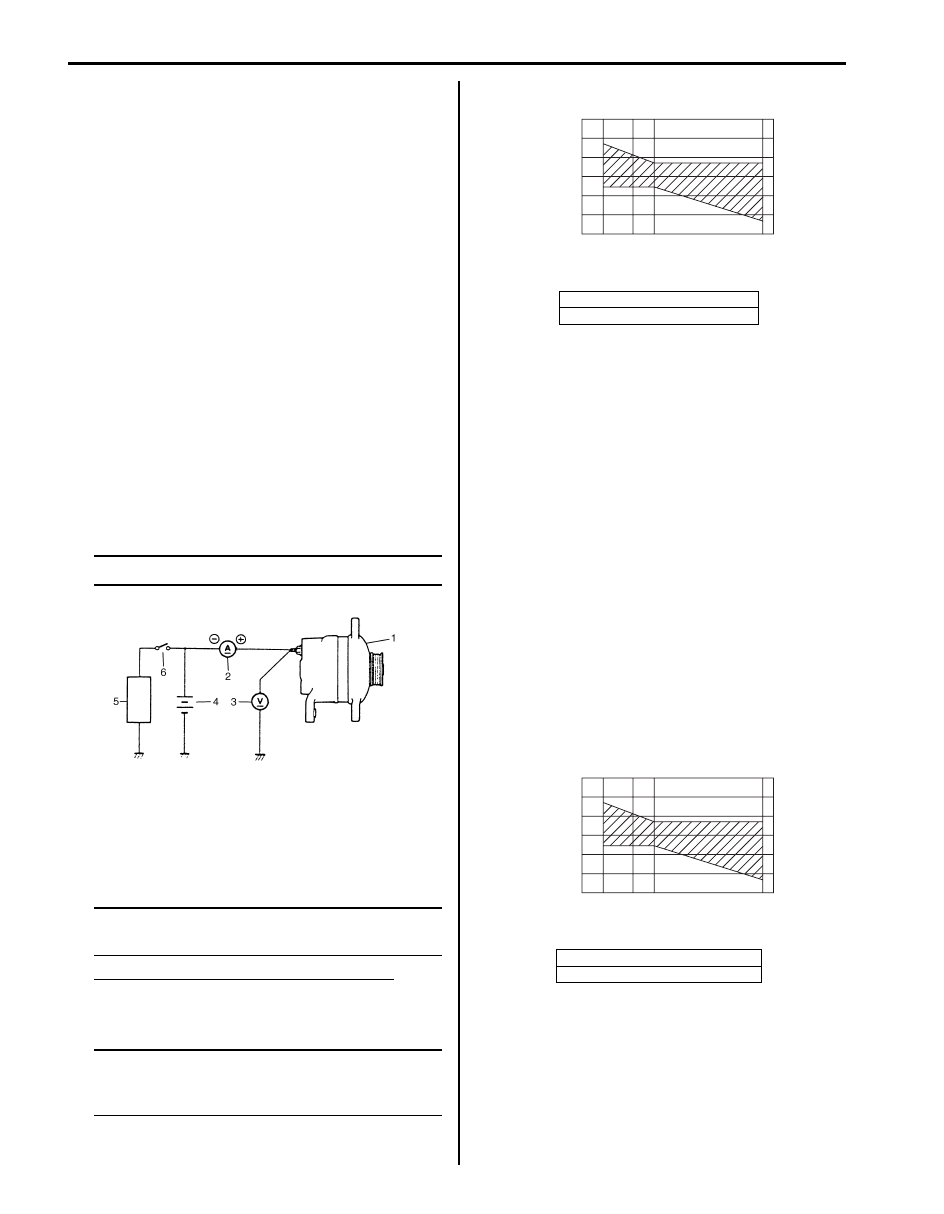

5) Connect switch (6), load (5), battery (4), voltmeter

(3) and ammeter (2) to generator (1) as shown in

figure.

Voltmeter: Set between generator “B” terminal

and ground.

Ammeter: Set between generator “B” terminal

and battery (+) terminal.

NOTE

Use fully charged battery.

6) Measure current and voltage.

No-Load Check

1) Run engine from idling up to 2000 rpm and read

meters.

NOTE

Turn off switches of all accessories (wiper,

heater etc.).

Specification for undercharged inspection

Current: 10 A

Voltage (at 20

°C (68 °F)): 14.2 – 14.8 V

NOTE

Consideration should be taken that voltage

will differ somewhat with regulator case

temperature as shown in the figure.

• If voltage is higher than standard value

If voltage is higher than standard value, check ground

of brushes.

If brushes are not grounded, replace IC regulator.

• If voltage is lower than standard value

If voltage is lower than standard value, check rotor

and stator, rectifier, brushes, regulator.

Load Check

1) Run engine at 2000 rpm and turn on head light and

heater motor.

2) Measure current and if it is less than 30 A repair or

replace generator.

Generator Test (Overcharged Battery Check)

S6JB0B1A04004

1) To determine battery condition, refer to “Battery

2) If obvious overcharge condition exists as evidenced

by excessive spewing of electrolyte, measure

generator “B” terminal voltage at engine 2000 rpm.

3) If measured voltage is higher than upper limit value,

proceed to “Generator Disassembly and Assembly”.

4) Check ground of brushes. If brushes are not

grounded, replace IC regulator. Then check field coil

for grounds and shorts, referring to “Generator

Inspection”.

IYSQ011A0007-01

[A]: Regulated voltage (V)

[B]: Heat sink temperature (

°C)

[A]: Regulated voltage (V)

[B]: Heat sink temperature (

°C)

16.0

15.5

14.3

15.2

14.8

14.2

13.3

14.6

15.0

14.5

14.0

13.5

13.0

-30

0

20

[A]

[B]

68

22

120 (˚C)

248 (˚F)

(V)

I5JB0A1A0006-02

16.0

15.5

14.3

15.2

14.8

14.2

13.3

14.6

15.0

14.5

14.0

13.5

13.0

-30

0

20

[A]

[B]

68

22

120 (˚C)

248 (˚F)

(V)

I5JB0A1A0006-02

Charging System: 1J-6

Repair Instructions

Jump Starting in Case of Emergency

S6JB0B1A06001

With Auxiliary (Booster) Battery

CAUTION

!

Do not push or tow vehicle to start. Damage

to emission system and/or to other parts of

vehicle may result.

Both booster and discharged battery should be treated

carefully when using jumper cables. Follow procedure

outlined below, being careful not to cause sparks.

WARNING

!

• Departure from these conditions or

procedure described below could result in:

a. Serious personal injury (particularly to

eyes) or property damage from such

causes as battery explosion, battery

acid, or electrical burns.

b. Damage to electronic components of

either vehicle.

• Never expose battery to open flame or

electric spark. Batteries generate gas

which is flammable and explosive.

• Remove rings, watches, and other jewelry.

Wear approved eye protection.

• Do not allow battery fluid to contact eyes,

skin, fabrics, or painted surface as fluid is

a corrosive acid. Flush any contacted area

with water immediately and thoroughly.

• Be careful so that metal tools or jumper

cables do not contact positive battery

terminal (or metal in contact with it) and

any other metal on vehicle, because a

short circuit could occur.

• Batteries should always be kept out of

reach of children.

1) Set parking brake and place automatic transmission

in PARK (NEUTRAL on manual transmission).

2) Turn OFF ignition switch, turn OFF lights and all

other electrical loads.

3) Check built-in indicator (if equipped). If it is clear or

light yellow, replace the battery.

4) Attach end of one jumper cable to positive terminal

of booster battery and the other end of the same

cable to positive terminal of discharged battery. (Use

12-volt battery only to jump start engine).

5) Attach one end of the remaining negative cable to

negative terminal of booster battery, and the other

end to a solid engine ground (such as exhaust

manifold) at least 45 cm (18 in.) away from battery of

vehicle being started.

WARNING

!

Do not connect negative cable directly to

negative terminal of dead battery.

6) Start engine of vehicle that is providing jump start

and turn off electrical accessories. Then Start engine

of the vehicle with discharged battery.

7) Reverse connecting procedure exactly when

disconnecting jumper cable. Negative cable must be

disconnected from engine that was jump started first.

With Charging Equipment

CAUTION

!

When jump starting engine with charging

equipment, be sure equipment used is 12-

volt and negative ground. Do not use 24-volt

charging equipment. Using such equipment

can cause serious damage to electrical

system or electronic parts.

1J-7 Charging System:

Battery Dismounting and Remounting

S6JB0B1A06002

WARNING

!

When handling battery, following safety

precautions should be followed:

• Hydrogen gas is produced by battery. A

flame or spark near battery may cause the

gas to ignite.

• Battery fluid is highly acidic. Avoid spilling

on clothing or other fabric. Any spilled

electrolyte should be flushed with large

quantity of water and cleaned immediately.

Dismounting

1) Disconnect negative cable.

2) Disconnect positive cable.

3) Remove retainer.

4) Remove battery.

Handling

When handling battery, the following safety precautions

should be followed:

• Hydrogen gas is produced by battery. A flame or

spark near battery may cause the gas to ignite.

• Battery fluid is highly acidic. Avoid spilling on clothing

or other fabric. Any spilled electrolyte should be

flushed with large quantity of water and cleaned

immediately.

Remounting

1) Reverse removal procedure.

2) Torque battery cables securely.

NOTE

Check to be sure that ground cable has

enough clearance to hood panel by terminal.

Generator Dismounting and Remounting

S6JB0B1A06003

Dismounting

1) Disconnect negative (–) cable at battery.

2) Remove air cleaner case and hose.

3) Disconnect generator lead wire (“B” terminal wire)

and coupler from generator.

4) Remove water pump and generator drive belt. Refer

to “Water Pump and Generator Drive Belt Removal

and Installation”.

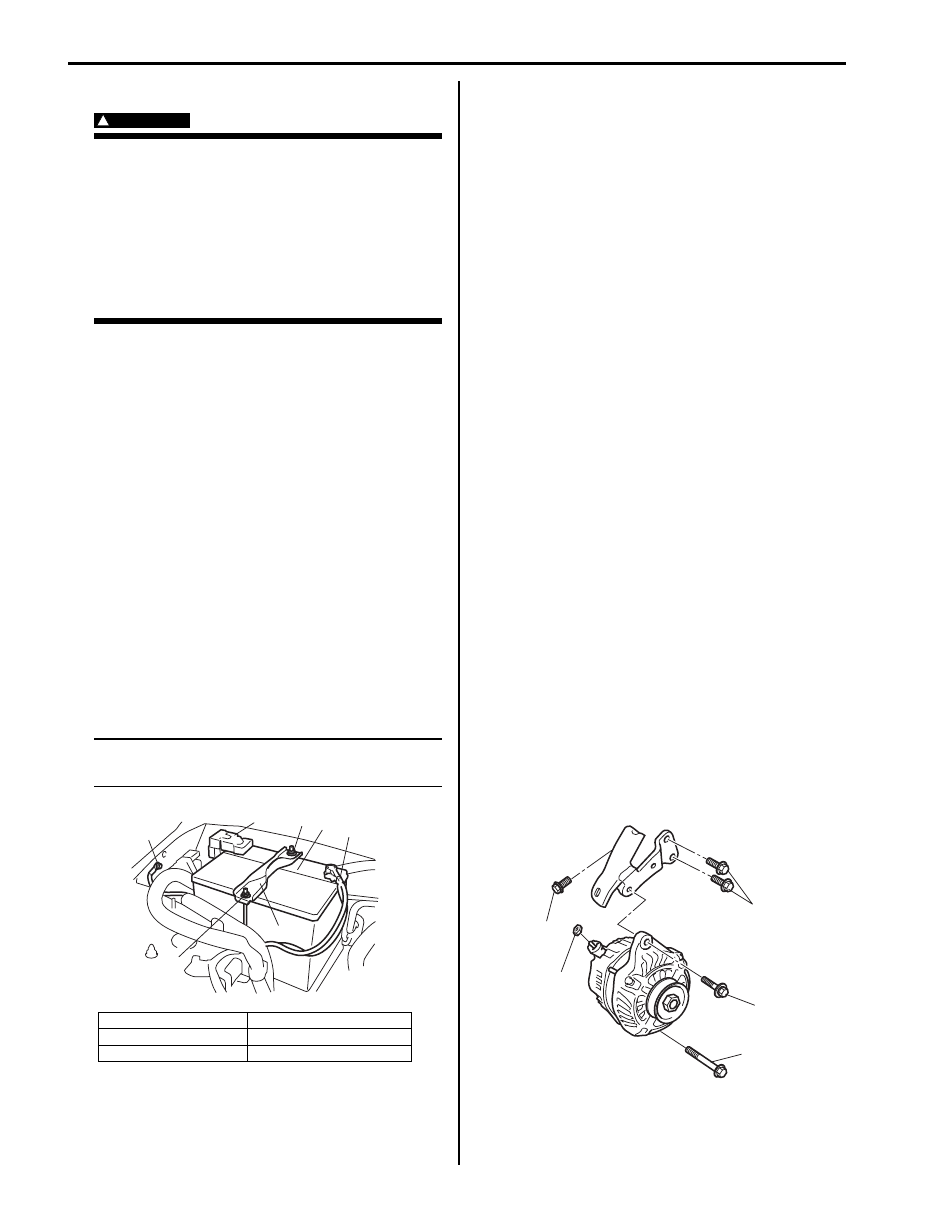

5) Remove generator bracket bolt and then remove

bracket.

6) Remove generator mounting bolt.

7) Remove generator.

Remounting

1) Install bracket and then tighten generator bracket

bolt (3) to specified torque.

Tightening torque

Generator bracket bolt (c): 45 N·m (4.5 kgf-m,

32.5 lb-ft)

2) Mount generator on the generator bracket.

3) Tighten generator mounting bolt (upper bolt (short)

(1), lower bolt (long) (2)).

Tightening torque

Generator mounting upper bolt (a): 25 N·m (2.5

kgf-m, 18.0 lb-ft)

Generator mounting lower bolt (b): 45 N·m (4.5

kgf-m, 32.5 lb-ft)

4) Install water pump and generator drive belt. Refer to

“Water Pump and Generator Drive Belt Removal and

Installation”.

5) Connect “B” terminal wire and coupler to generator.

Tightening torque

“B” terminal outer nut (d): 7 N·m (0.7 kgf-m, 5.0

lb-ft)

6) Install air cleaner case and hose.

7) Connect negative (–) cable at battery.

1. Battery

4. Body ground bolt

2. Positive cable

5. Retainer

3. Negative cable

6. Nut

4

2

6

5

3

1

6

I6JB011A0003-01

1,(a)

2,(b)

3,(c)

3,(c)

(d)

I6JB011A0004-01

Charging System: 1J-8

Generator Components

S6JB0B1A06004

7

8

2

1

3

4

5

6

9

10

11

12

13

15

16

14

(a)

(c)

(b)

(b)

(b)

I6JB011A0005-02

1. Pulley nut

6. Driver end bearing

11. Rear housing

16. “B” terminal nut

2. Pulley

7. Bearing retainer

12. Rectifier

: 118 N

⋅m (11.8 kgf-m, 85.5 lb-ft)

3. Front housing

8. Rotor

13. Regulator assembly

: 4 N

⋅m (0.4 kgf-m, 3.0 lb-ft)

4. Stator

9. Rear end bearing

14. Generator stay bushing

: 9 N

⋅m (0.9 kgf-m, 7.0 lb-ft)

5. Frame bolt

10. Retainer screw

15. “B” terminal

Нет комментариевНе стесняйтесь поделиться с нами вашим ценным мнением.

Текст