Suzuki Grand Vitara JB627. Manual — part 289

7B-72 Air Conditioning System:

A/C Refrigerant Pressure Sensor and Its Circuit

Inspection

S6JB0B7206015

1) Disconnect A/C refrigerant pressure sensor

connector.

2) Turn ignition switch to ON position.

3) Check if voltage between “GRY/RED” wire terminal

and “GRY/GRN” wire terminal of A/C refrigerant

pressure sensor connector is 4.75 V to 5.25 V.

If not, check A/C refrigerant pressure sensor circuit.

4) Connect A/C refrigerant pressure sensor connector

with ignition switch turned OFF.

5) Connect manifold gauge set to the charging valves.

6) Check A/C refrigerant pressure sensor voltage of

ECM connector referring to “A/C System Inspection

at ECM”.

If voltage is not as specified below, replace A/C

refrigerant pressure sensor.

A/C refrigerant pressure sensor voltage

specifications (A/C refrigerant pressure measured

by manifold gauge)

0.8 MPa (8.0 kg/cm

2

, 116 psi): Approx. 1.46 – 1.71 V

1.4 MPa (14 kg/cm

2

, 203 psi): Approx. 2.28 – 2.53 V

1.6 MPa (16 kg/cm

2

, 232 psi): Approx. 2.55 – 2.80 V

1.8 MPa (18 kg/cm

2

, 261 psi): Approx. 2.82 – 3.03 V

A/C Refrigerant Pressure Sensor Removal and

Installation

S6JB0B7206016

Removal

1) Recover refrigerant from the A/C system with the

recovery and recycling equipment referring to

“Recovery” in “Operation Procedure for Charging A/

C with Refrigerant”.

2) Disconnect negative (–) cable from battery.

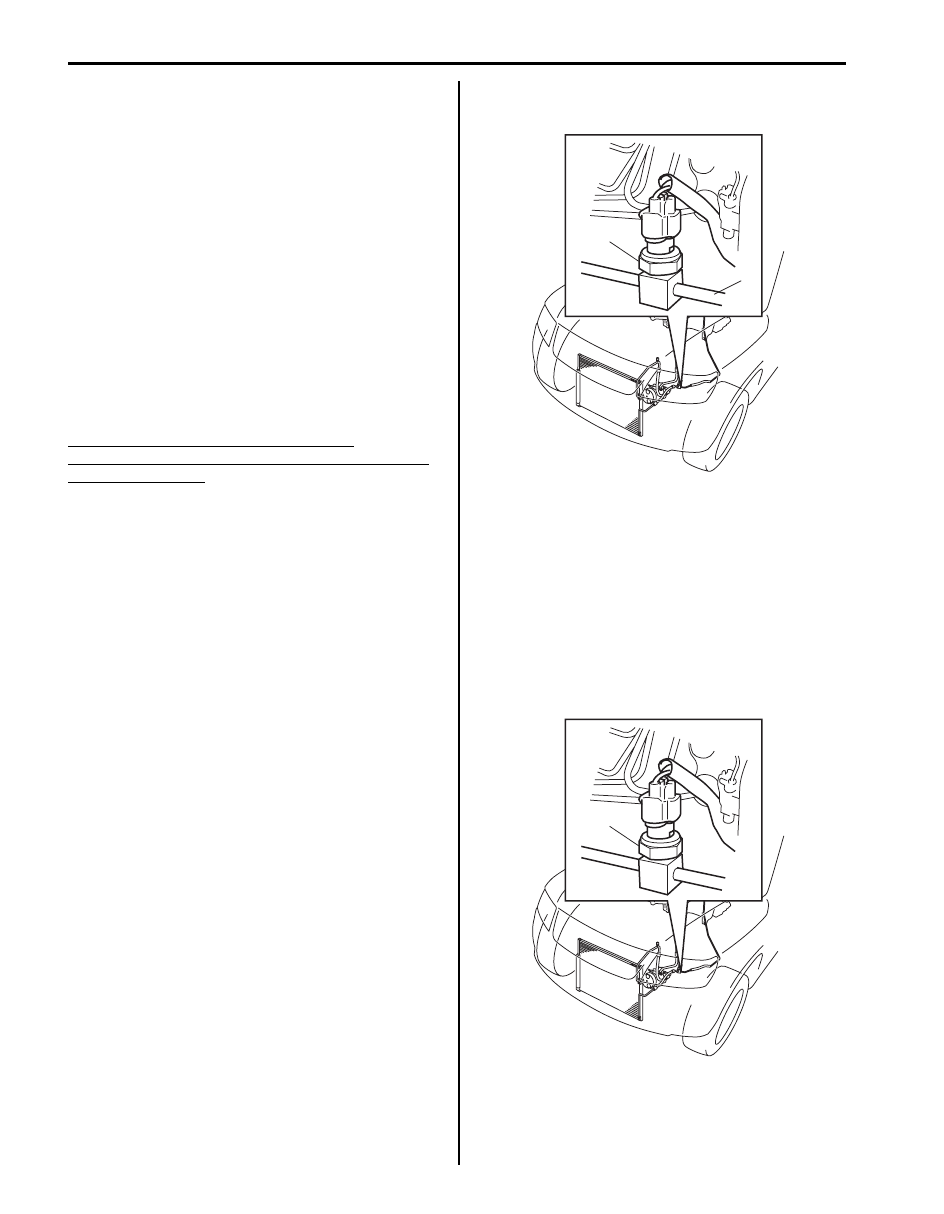

3) Disconnect A/C refrigerant pressure sensor

connector.

4) Remove A/C refrigerant pressure sensor (1) from

liquid pipe (2).

Installation

Reverse removal procedure noting the following

instructions.

• Apply compressor oil to O-ring of A/C refrigerant

pressure sensor.

• Tighten A/C refrigerant pressure sensor (1) to

specified torque.

Tightening torque

A/C refrigerant pressure sensor (a): 11 N·m (1.1

kgf-m, 8.0 lb-ft)

• Evacuate and charge the A/C system referring to

“Evacuation” and “Charge” in “Operation Procedure

for Charging A/C with Refrigerant”.

1

2

I5JB0A720049-03

1, (a)

I5JB0A720050-03

Air Conditioning System: 7B-73

Sunload Sensor Removal and Installation

S6JB0B7206017

Removal

1) Disconnect negative (–) cable at battery.

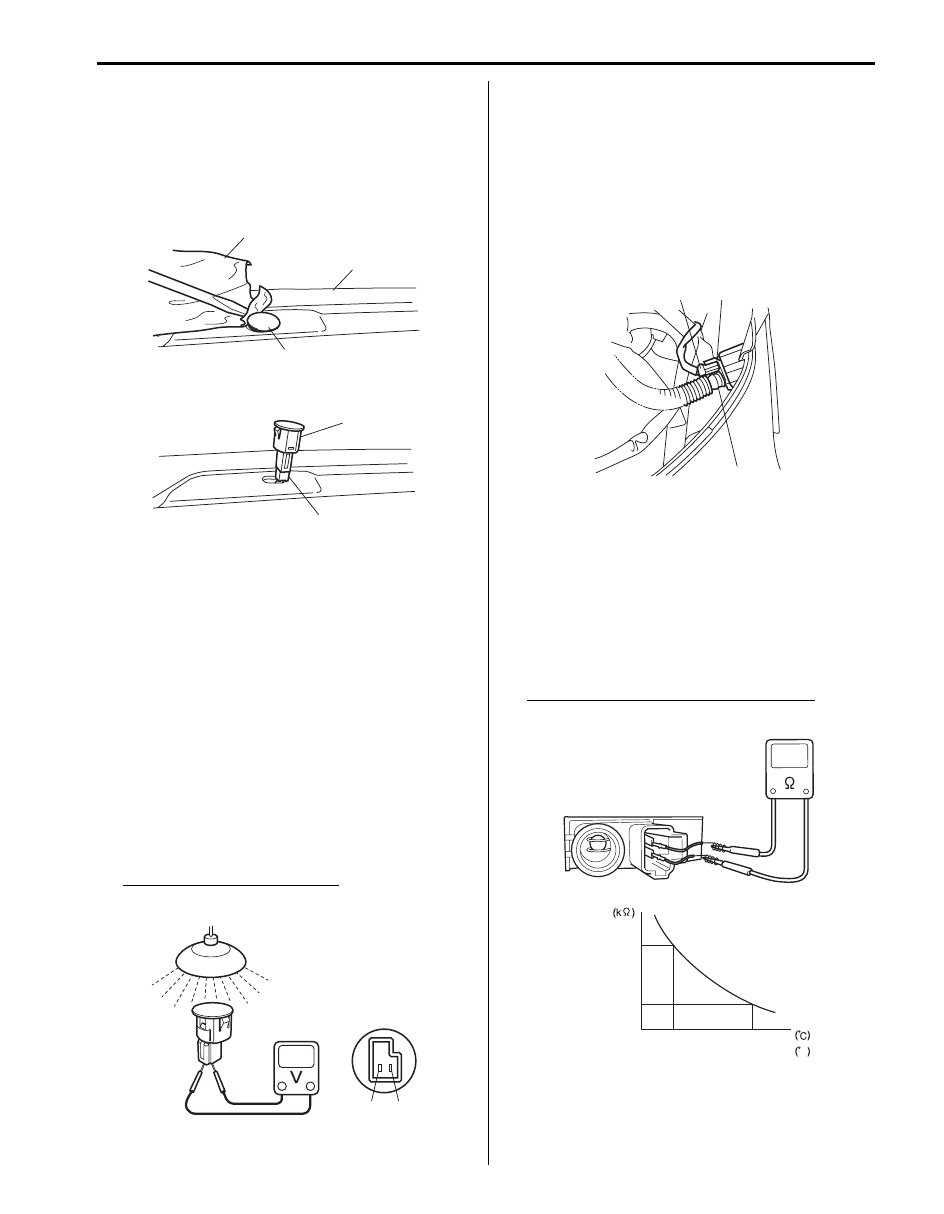

2) Detach sunload sensor (1) located on the driver side

of the dashboard (3). Be careful not to damage the

sensor and dashboard by using rag (2).

3) Disconnect connector (1) from sunload sensor (2).

Installation

Reverse removal procedure.

Sunload Sensor Inspection

S6JB0B7206018

1) Remove sunload sensor. Refer to “Sunload Sensor

2) Light over the sensor vertically with an incandescent

light of approximately 100 watt.

3) The distance between the sensor and the light

should be approximately 100 mm (3.94 in.).

4) Measure the voltage between the terminals with the

(+) probe on the terminal “a” and the (–) probe on the

terminal “b”.

5) Make sure if the voltage is approximately 0.38 – 0.42

V. If not, replace the sensor with the new one.

Sunload sensor specifications

“a” – “b”: Approx. 0.38 – 0.42 V

Inside Air Temperature Sensor Removal and

Installation

S6JB0B7206019

Removal

1) Disconnect negative cable (–) at battery.

2) Remove steering column hole cover.

3) Disconnect inside air temperature sensor connector

(1) and aspirator hose (2).

4) Remove inside air temperature sensor (3) from

vehicle.

Installation

Reverse removal procedure.

Inside Air Temperature Sensor Inspection

S6JB0B7206020

1) Remove Inside air temperature sensor referring to

“Inside Air Temperature Sensor Removal and

Installation”.

2) Check resistance between terminals.

Inside air temperature sensor resistance

Approx. 1.7 k

Ω ± 85 Ω at 25 °C (77 °F)

2

1

3

I5JB0A720051-01

1

2

I5JB0A720052-01

“b”

“a”

I5JB0A720053-01

2

3

1

I5JB0A720054-01

Temperature

Resistance

1.7

0

32

25

77

F

5.5

I5JB0A720055-01

7B-74 Air Conditioning System:

Outside Air Temperature Sensor Removal and

Installation

S6JB0B7206021

Refer to “Outside Air Temperature Sensor Removal and

Installation (If Equipped) in Section 9C”.

Outside Air Temperature Sensor Inspection

S6JB0B7206022

Refer to “Outside Air Temperature Sensor Inspection (If

Equipped) in Section 9C”.

Air Flow Control Actuator Removal and

Installation

S6JB0B7206023

Refer to “Air Flow Control Actuator Removal and

Installation in Section 7A”.

Air Flow Control Actuator Inspection

S6JB0B7206024

Refer to “Air Flow Control Actuator Inspection in Section

7A”.

Air Intake Control Actuator Removal and

Installation

S6JB0B7206025

Refer to “Air Intake Control Actuator Removal and

Installation in Section 7A”.

Air Intake Control Actuator Inspection

S6JB0B7206026

Refer to “Air Intake Control Actuator Inspection in

Section 7A”.

Temperature Control Actuator Removal and

Installation

S6JB0B7206027

Refer to “Temperature Control Actuator Removal and

Installation in Section 7A”.

Temperature Control Actuator Inspection

S6JB0B7206028

Refer to “Temperature Control Actuator Inspection in

Section 7A”.

HVAC Control Module Removal and Installation

S6JB0B7206029

Refer to “HVAC Control Module Removal and Installation

in Section 7A”.

A/C Compressor Drive Belt Inspection and

Adjustment

S6JB0B7206030

Refer to “P/S Pump and A/C Compressor (If Equipped)

Drive Belt Inspection and Adjustment in Section 6C”.

A/C Compressor Drive Belt Removal and

Installation

S6JB0B7206031

Refer to “P/S Pump and A/C Compressor (If Equipped)

Drive Belt Removal and Installation in Section 6C”.

A/C Compressor Relay Inspection

S6JB0B7206032

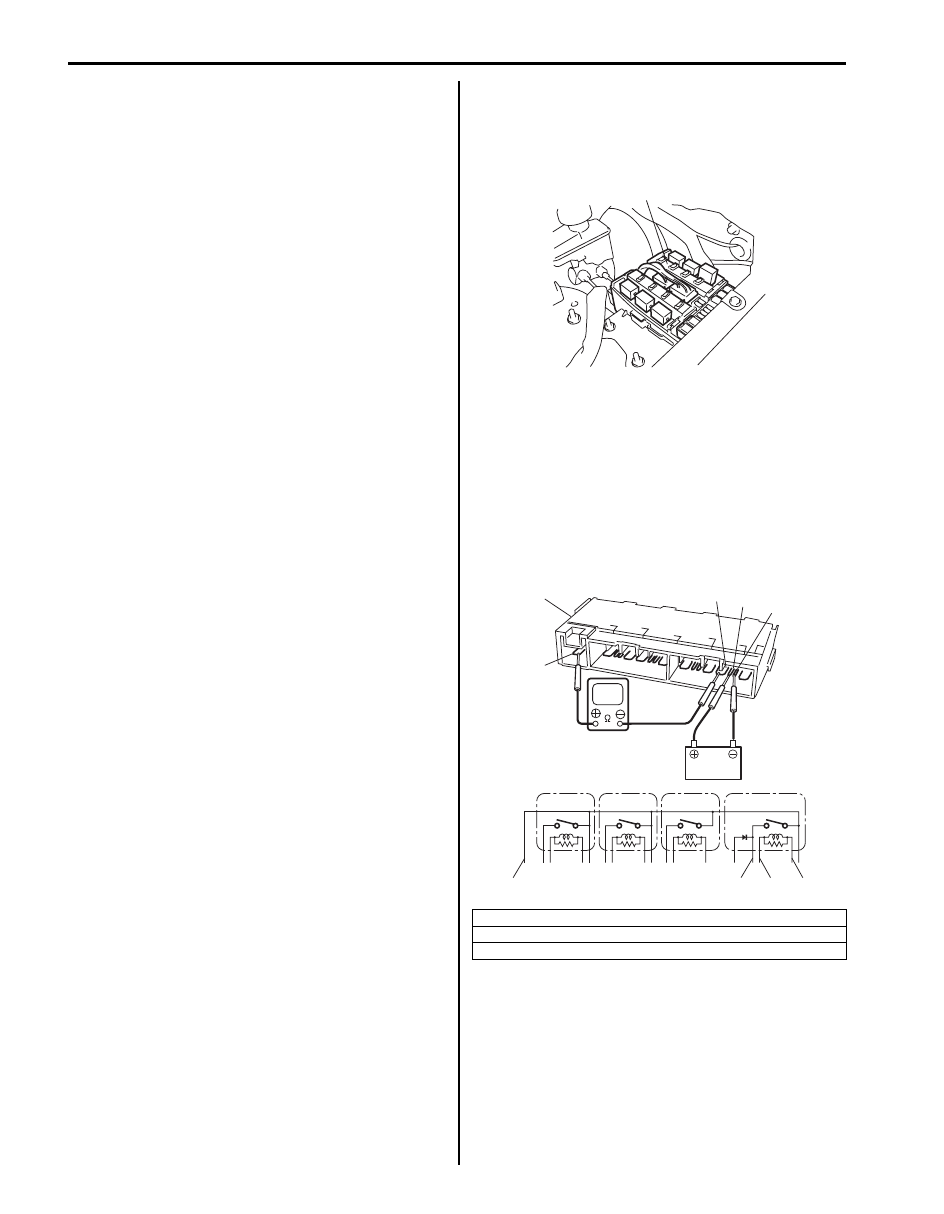

1) Disconnect negative (–) cable at battery.

2) Remove included in integration relay No.2 (1) from

vehicle.

3) Check that there is no continuity between terminals

“C” and “D”.

If there is continuity, replace integration relay No.2

(1).

4) Connect battery positive (+) terminal to terminal “B”

of relay. Connect battery negative (–) terminal to

terminal “A” of relay. Check for continuity between

terminal “C” and “D”. If there is no continuity when

relay is connected to the battery, replace integration

relay No.2 (1).

[A]: A/T relay

[B]: HO2S heater relay

[C]: Compressor relay

1

I5JB0A720057-01

“D”

“C”

[A]

[B]

[C]

1

“B”

“A”

“C”

“D”

“B”

“A”

I6JB01720008-01

Air Conditioning System: 7B-75

Compressor Assembly On-Vehicle Inspection

S6JB0B7206033

1) Install manifold gauge set (1) as shown in the figure.

2) Close Hi (4) and Lo (5) side valves.

3) Run engine at fast idle.

4) Check compressor for the following items.

If any of the checks indicated a defect, repair

compressor.

• High pressure gauge reading is not low and low

pressure gauge reading is not higher than normal.

• Metallic sound

• Leakage from compressor

Compressor Assembly Removal and

Installation

S6JB0B7206034

Removal

1) Run engine at idle with A/C ON for 10 minutes.

2) Disconnect negative (–) cable at battery.

3) Recover refrigerant from the A/C system using

recovery and recycling equipment referring to

“Recovery” in “Operation Procedure for Charging A/

C with Refrigerant”.

NOTE

The amount of compressor oil at removed

must be measured and the same amount

must be poured when installing the

compressor.

4) Drain engine coolant.

5) Remove radiator inside hose and outside hose from

vehicle.

6) Remove radiator cooling fan assembly referring to

“Radiator Cooling Fan Assembly Removal and

Installation in Section 1F”.

7) Remove drive belt referring to “P/S Pump and A/C

Compressor (If Equipped) Drive Belt Removal and

Installation in Section 6C”.

8) Disconnect magnet clutch connector.

9) Disconnect suction hose and discharge hose from

compressor.

NOTE

Cap open fitting immediately to keep

moisture out of system.

10) Remove compressor from its mount.

Installation

CAUTION

!

Be sure to use HFC-134a (R-134a)

compressor oil.

Reverse removal procedure noting the following

instructions.

• If compressor is replaced, pour new compressor oil

referring to “Precautions on Replenishing Compressor

Oil”.

• Install drive belt referring to “P/S Pump and A/C

Compressor (If Equipped) Drive Belt Removal and

Installation in Section 6C”.

• Install radiator cooling fan assembly referring to

“Radiator Cooling Fan Assembly Removal and

Installation in Section 1F”.

• Fill engine coolant to radiator.

• Evacuate and charge system referring to “Evacuation”

and “Charge” in “Operation Procedure for Charging A/

C with Refrigerant”.

Tightening torque

Compressor mounting bolt: 25 N·m (2.5 kgf-m,

18.0 lb-ft)

2. High pressure side (Delivery side hose)

3. Low pressure side (Suction side pipe)

1

5

3

4

2

I5JB0A720059-01

Нет комментариевНе стесняйтесь поделиться с нами вашим ценным мнением.

Текст