Suzuki Grand Vitara JB627. Manual — part 288

7B-68 Air Conditioning System:

CAUTION

!

Be careful not to damage A/C evaporator fins. If A/C evaporator fin is bent, straighten it by using flat

head screwdriver or pair of pliers.

HVAC Unit Removal and Installation

S6JB0B7206008

Removal

WARNING

!

Failure to follow the following procedure and

WARNING may cause air bag deployment,

personal injury, damage to parts, or air bag

being unable to deploy.

• Never rest a steering column assembly on

steering wheel with air bag (inflator)

module face down and column vertical.

• When handling the air bag (inflator)

modules (driver and passenger), be careful

not to drop it or apply an impact to it. If an

excessive impact was applied (e.g.,

dropped from a height of 91.4 cm (3 feet) or

more, never attempt disassembly or repair

but replace it with a new one.

• When grease, cleaning agent. Oil, water,

etc. has got onto air bag (inflator) modules

(driver and passenger), wipe off

immediately with a dry cloth.

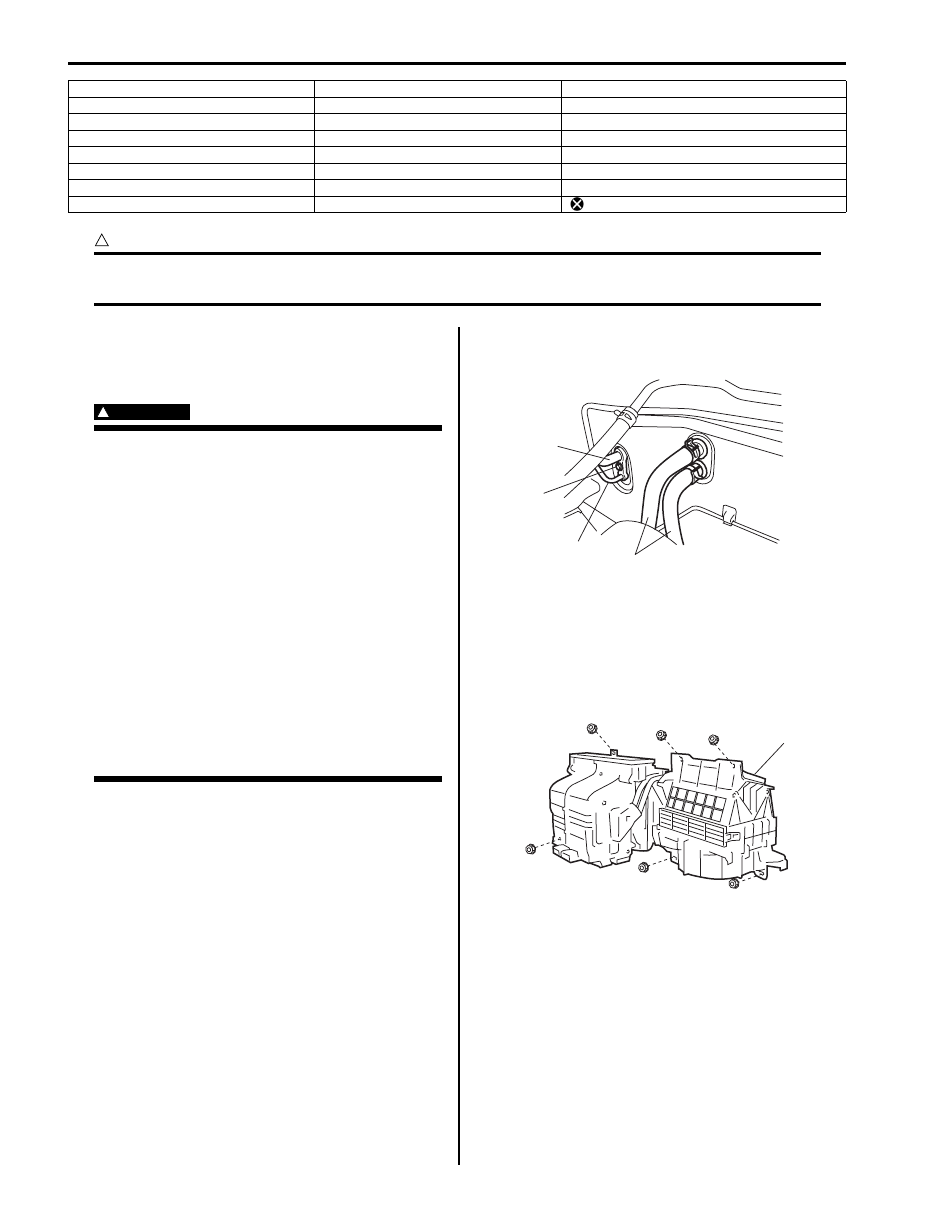

1) Disconnect negative (–) cable at battery.

2) Disable air bag system referring to “Disabling Air

3) Recover refrigerant from A/C system using recovery

and recycling equipment referring to “Recovery” in

“Operation Procedure for Charging A/C with

Refrigerant”.

4) Drain engine coolant and disconnect heater hoses

(1) from HVAC unit.

5) Disconnect suction hose (2) and condenser outlet

hose (3) by removing attaching bolt (4).

6) Remove instrument panel referring to “Instrument

Panel Removal and Installation in Section 9C”.

7) Disconnect rear duct from HVAC unit.

8) Detach wiring, connectors and clamps from HVAC

unit.

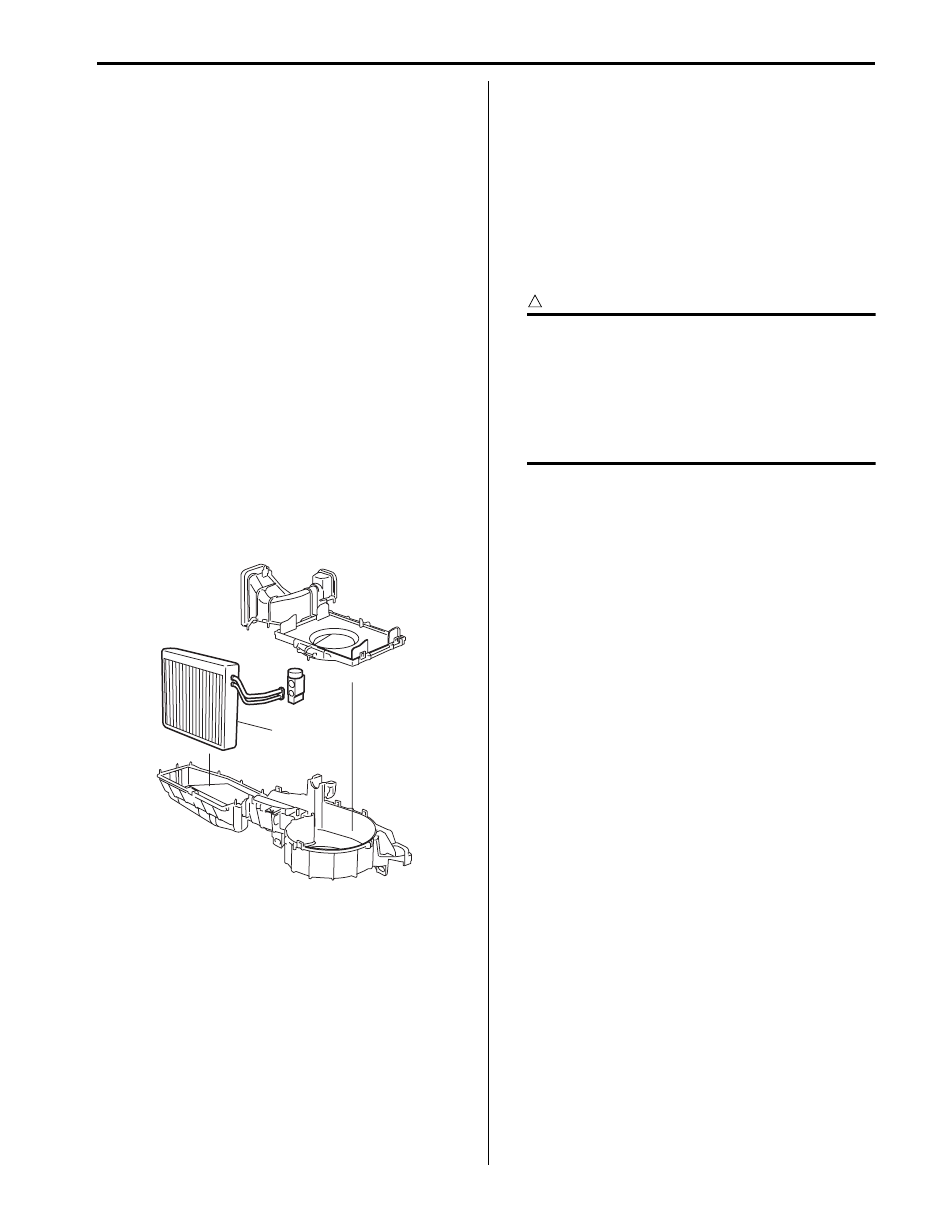

9) Remove HVAC unit (1).

1. Blower upper case

11. Blower motor

21. Inside air temperature sensor

2. Air intake control actuator

12. Blower motor controller

22. Air flow control links

3. Air intake control links

13. Foot duct

23. Air flow control links cover

4. Air filter (if equipped)

14. Aspirator

24. Air flow control actuator

5. Air filter cover

15. Heater core

25. Aspirator hose

6. Air intake control door assembly

16. Heater unit upper case

26. Packing

7. Expansion valve

17. Temperature control door assembly

27. O-ring

8. Evaporator

18. Air flow control door assembly

: Do not reuse.

1

3

2

4

I5JB0A720043-01

1

I5JB0A720044-01

Air Conditioning System: 7B-69

Installation

1) Install HVAC unit by reversing removal procedure,

noting the following items.

• When installing each part, be careful not to catch

any wiring harness.

• Replenish specified amount of compressor oil to

compressor suction side referring to “Precautions

on Replenishing Compressor Oil”.

• Install the padding (1) to the installation hole

uniformly.

• Fill engine coolant to radiator.

• Enable air bag system referring to “Enabling Air

• Evacuate and charge system. Refer to “Operation

Procedure for Charging A/C with Refrigerant”.

A/C Evaporator Removal and Installation

S6JB0B7206009

Removal

1) Remove HVAC unit referring to “HVAC Unit Removal

2) Remove evaporator (1) from HVAC unit by

disassembling HVAC unit.

3) Remove evaporator temperature sensor from

evaporator.

Installation

Reverse removal procedure to install A/C evaporator

nothing the following instructions.

• Install evaporator temperature sensor onto evaporator

referring to “A/C Evaporator Temperature Sensor

Removal and Installation”.

A/C Evaporator Inspection

S6JB0B7206010

1) Check evaporator fins for blockage. If found clogged,

use compressed air to clean the fins.

CAUTION

!

• Do not use water for cleaning of

evaporator.

• Be careful not to damage evaporator fins.

If evaporator fin is bent, straighten it by

using a screwdriver or pair of pliers. If any

leakage is found from fitting or tube, repair

or replace evaporator.

2) Check inlet and outlet fittings for crack or scratch.

Repair them as required.

1

I5JB0A720045-02

7B-70 Air Conditioning System:

A/C Evaporator Temperature Sensor Removal

and Installation

S6JB0B7206011

Removal

1) Remove A/C evaporator (1) referring to “A/C

Evaporator Removal and Installation”.

2) Remove A/C evaporator temperature sensor (2)

from evaporator.

Installation

1) Identify evaporator by the following tables.

NOTE

As for Evaporator, there are 4 varieties

depending on the internal structure.

2) Install evaporator temperature sensor onto

evaporator in a correct position as shown in figure.

CAUTION

!

Mis-position causes insufficiency cooling

and damaged of A/C system.

Evaporator

type

Selection condition

A

LH steering vehicle

Evaporator with

protection rubber (1)

B

Evaporator without

protection rubber (2)

C

RH steering vehicle

Evaporator with

protection rubber

D

Evaporator without

protection rubber

3. Protection rubber

1

2

I5JB0A720046-01

1

2

3

I5GEB4720001-01

[A]: Evaporator type A

5. Holding part fixed to fin of 6th

line from the left-side edge

[B]: Evaporator type B

6. Sensor part fixed to fin of 5th line

from the left-side edge

[C]: Evaporator type C

7. Holding part fixed to fin of 3rd

line from the left-side edge

[D]: Evaporator type D

8. Sensor part fixed to fin of 8th line

from the right-side edge

1. Evaporator temperature

sensor

9. Holding part fixed to fin of 6th

line from the right-side edge

2. Evaporator

10. Sensor part fixed to fin of 5th line

from the right-side edge

3. 34.5 mm (1.36 in.)

11. Holding part fixed to fin of 3rd

line from the right-side edge

4. Sensor part fixed to fin of 8th

line from the left-side edge

4

2

5

6

7

9

8

11

10

3

[A]

[B]

2

3

2

3

[C]

[D]

2

3

1

1

1

1

I5GEB4720002-03

Air Conditioning System: 7B-71

A/C Evaporator Temperature Sensor Inspection

S6JB0B7206012

Check resistance between A/C evaporator temperature

sensor terminals. If check result is not in specification,

replace A/C evaporator temperature sensor with the new

one.

A/C evaporator temperature sensor resistance

11.2 – 11.5 k

Ω at 0 °C (32 °F)

3.8 – 3.9 k

Ω at 25 °C (77 °F)

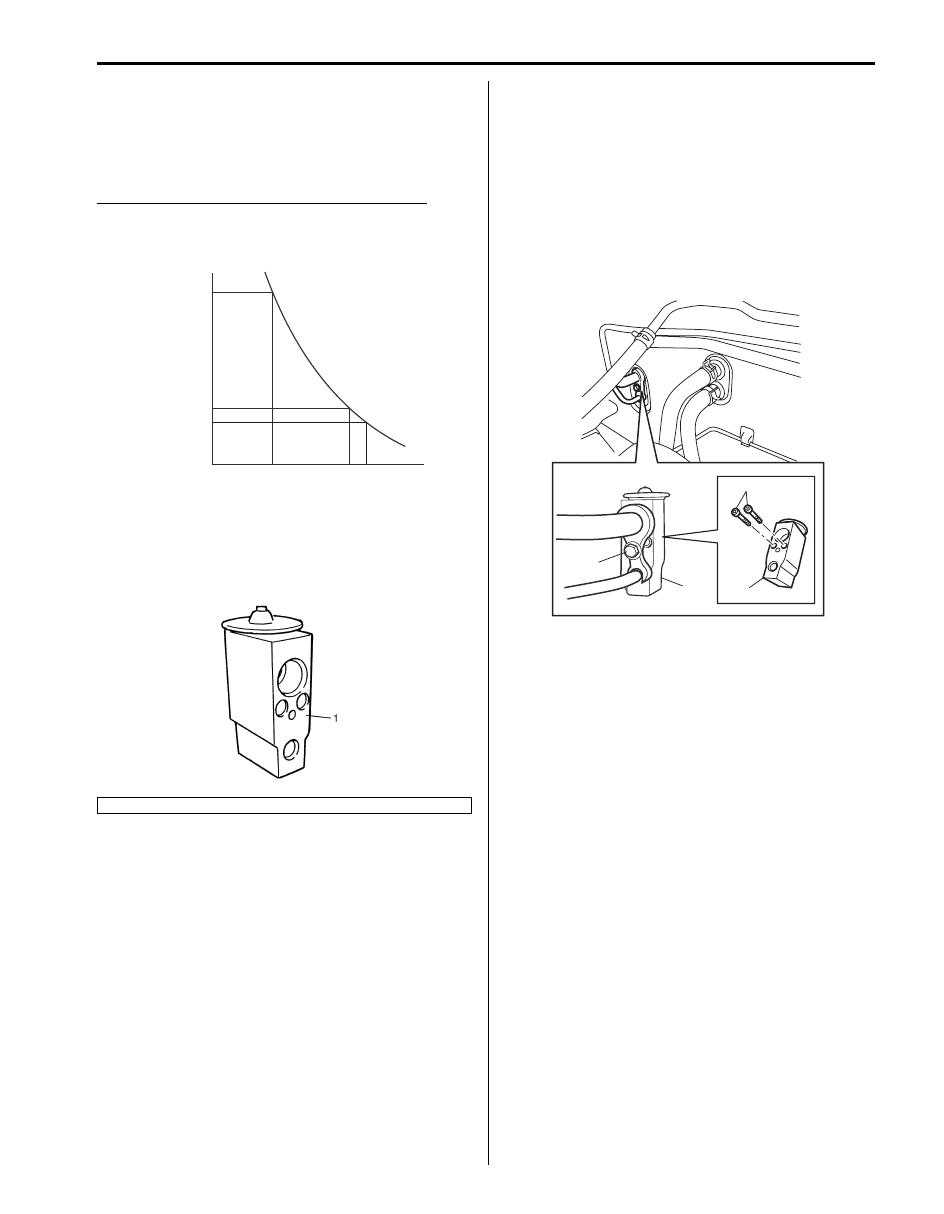

Expansion Valve On-Vehicle Inspection

S6JB0B7206013

Refer to “A/C System Performance Inspection”.

Expansion Valve Removal and Installation

S6JB0B7206014

Removal

1) Recover refrigerant from the A/C system with

recovery and recycling equipment referring to

“Recovery” in “Operation Procedure for Charging A/

C with Refrigerant”.

2) Loosen a bolt (1) and remove pipes from expansion

valve (2).

3) Loosen bolts (3) and remove expansion valve.

Installation

1) Reverse removal nothing the following instructions.

• Apply compressor oil to O-ring of expansion valve

and pipes.

2) Evacuate and charge system according to

“Operation Procedure for Charging A/C with

Refrigerant”.

1. Expansion valve

(k

Ω

)

11.4

3.9

3.3

0

32

25

77

30

86

(˚C)

(˚F)

Resistance

Temperature

I5JB0A720090-03

IYSQ01720049-01

3

1

2

2

I5JB0A720048-02

Нет комментариевНе стесняйтесь поделиться с нами вашим ценным мнением.

Текст