Suzuki Grand Vitara JB627. Manual — part 168

3D-3 Propeller Shaft:

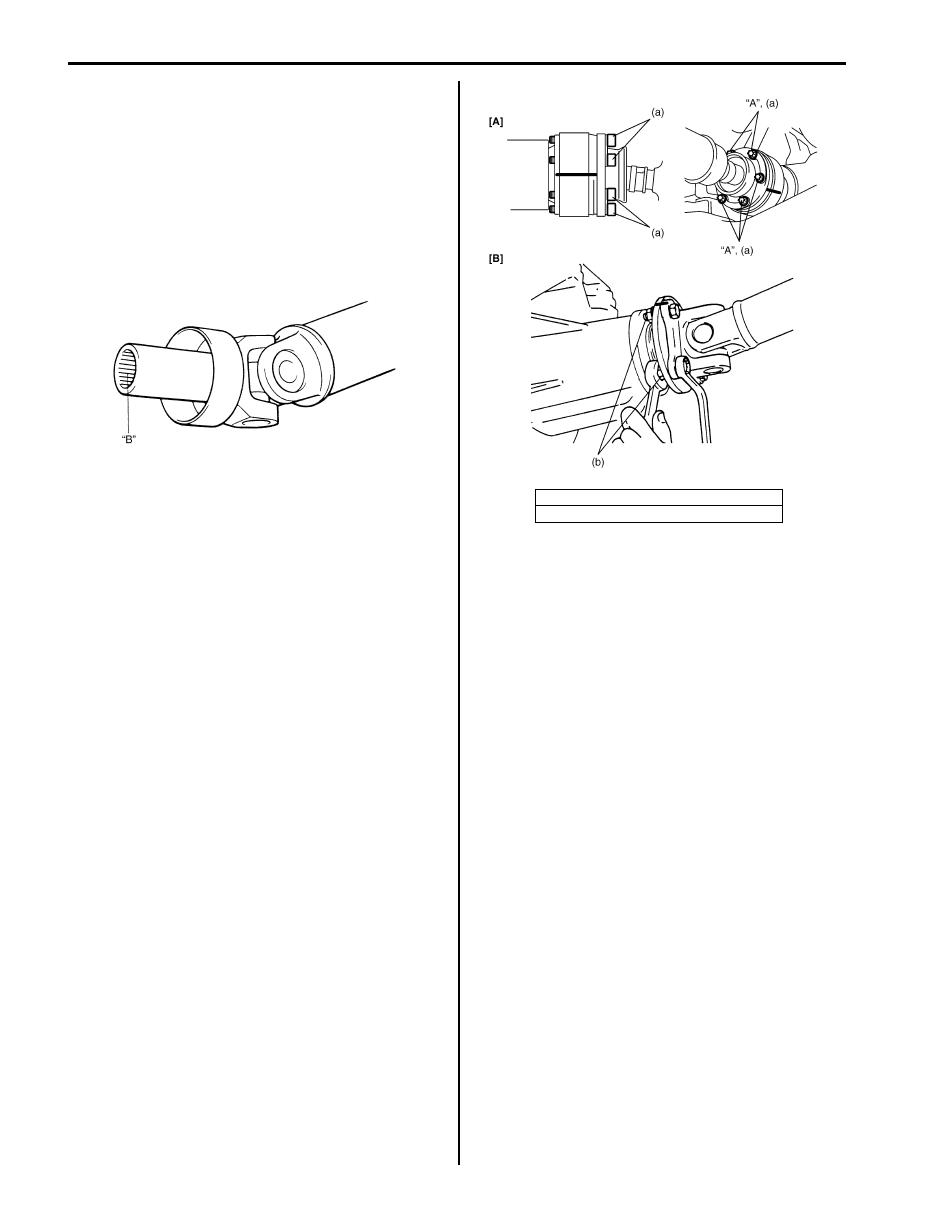

Installation

Reverse removal procedure to install propeller shaft

noting the following points.

• Clean and inspect sliding portion of propeller shaft

end (where oil seal contacts) before installation and if

even small dent or scratch exists, correct end clean it

again.

Then apply grease inside splines of propeller shaft.

“B”: Grease 99000–25010 (SUZUKI Super Grease

A)

• Install propeller shaft aligning match marks.

Otherwise, vibration may occur during driving.

• Use the following specification to torque universal joint

flange nuts and bolts. For front propeller shaft flange

bolt (front differential side), apply thread lock cement

to thread part of bolts if reused.

• Fill transfer oil, if removed front propeller shaft

referring to “Transfer Oil Change in Section 3C”.

“A”: Thread lock cement 99000–32110 (Thread

Lock Cement Super 1322)

Tightening torque

Front propeller shaft flange bolt (a): 30 N·m (3.0

kgf-m, 22.0 lb-ft)

Rear propeller shaft flange nut (b): 85 N·m (8.5

kgf-m, 61.5 lb-ft)

IYSQ01521009-01

[A]: Front propeller shaft

[B]: Rear propeller shaft

I5JB0A340004-01

Propeller Shaft: 3D-4

Propeller Shaft Disassembly and Assembly

S6JB0B3406003

CAUTION

!

Never disassemble each joint.

Performing this prohibited service will affect

its original performance.

Disassembly

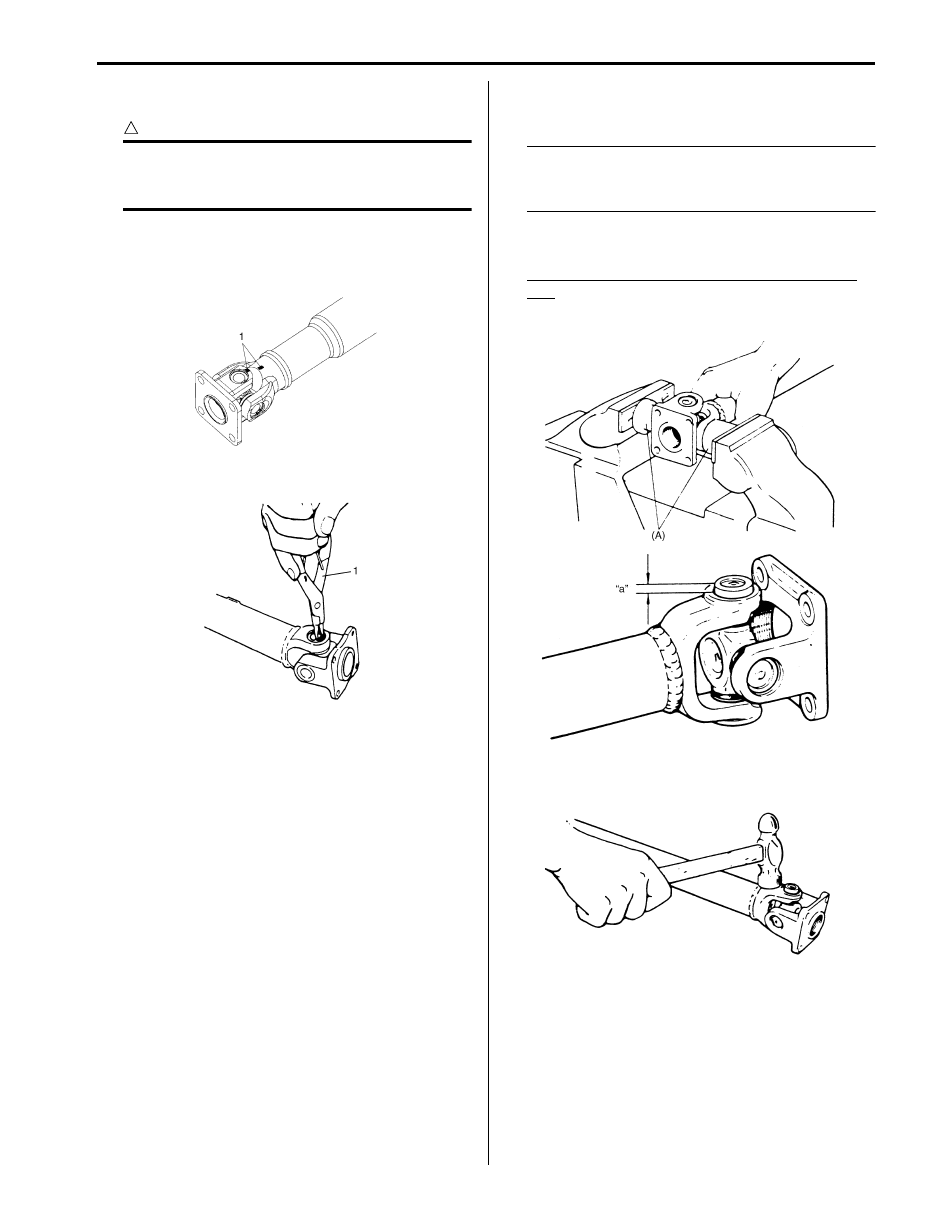

1) Give match marks (1) on flange yoke and shaft as

shown in the figure.

2) Using snap ring plier (1), remove 2 circlips.

3) Using special tool, push spider bearing race out 3 –

4 mm (0.12 – 0.16 in.) from shaft yoke race.

NOTE

Before pushing it out, apply penetrate

lubricant between bearing race (1) and yoke

race (2).

Special tool

(A): 09926-48010

Spider bearing race installing position (length

“a”)

“a”: 3 – 4 mm (0.12 – 0.16 in.)

4) Tapping yoke with a hammer, completely remove

bearing race.

I5JB0A340007-01

I5JB0A340005-02

I5JB0A340006-01

IYSQ01340007-01

3D-5 Propeller Shaft:

5) Take out bearing race on the other side in the same

way as in Step 3) and 4).

6) Push out bearing race on flange yoke side as

described in Step 2) and 3), and then, holding

bearing race in a vise (1), tap flange yoke and take

out race. (Refer to the figure.)

Remove bearing race on the opposite side in the

same way.

NOTE

• Take care not to lose rollers in spider

bearing race when removing it.

• Fit removed bearings temporarily in spider

so that they can be reinstalled in their

original positions.

Assembly

NOTE

Make sure that rollers inside spider bearing

race are all in place.

CAUTION

!

In assembly, be sure to use new circlips,

spider (1) and bearings (2). Reuse of circlips,

spider (1) and bearings (2) once assembled is

prohibited.

1) Make sure to apply grease to spider bearing race.

“A”: Grease 99000–25030 (SUZUKI Super

Grease C)

2) Insert bearing race into yoke, using press, until it is

flush with yoke face. When doing this, insert spider

into bearing race to prevent rollers in bearing race

from coming out.

3) Aligning match marks (1) and insert the other

bearing race on the opposite side into yoke, using

press until it is flush with yoke face.

4) Insert bearing races on the flange yoke side in the

same way as described in Step 1) and 2).

5) Securely fit 4 circlips to shaft and flange yoke.

NOTE

• Make sure that each circlip is fitted in

groove securely.

6) After assembly, check to ensure that both shaft yoke

and flange yoke move smoothly.

IYSQ01340008-01

IYSQ01340010-01

IYSQ01340009-01

I5JB0A340007-01

Propeller Shaft: 3D-6

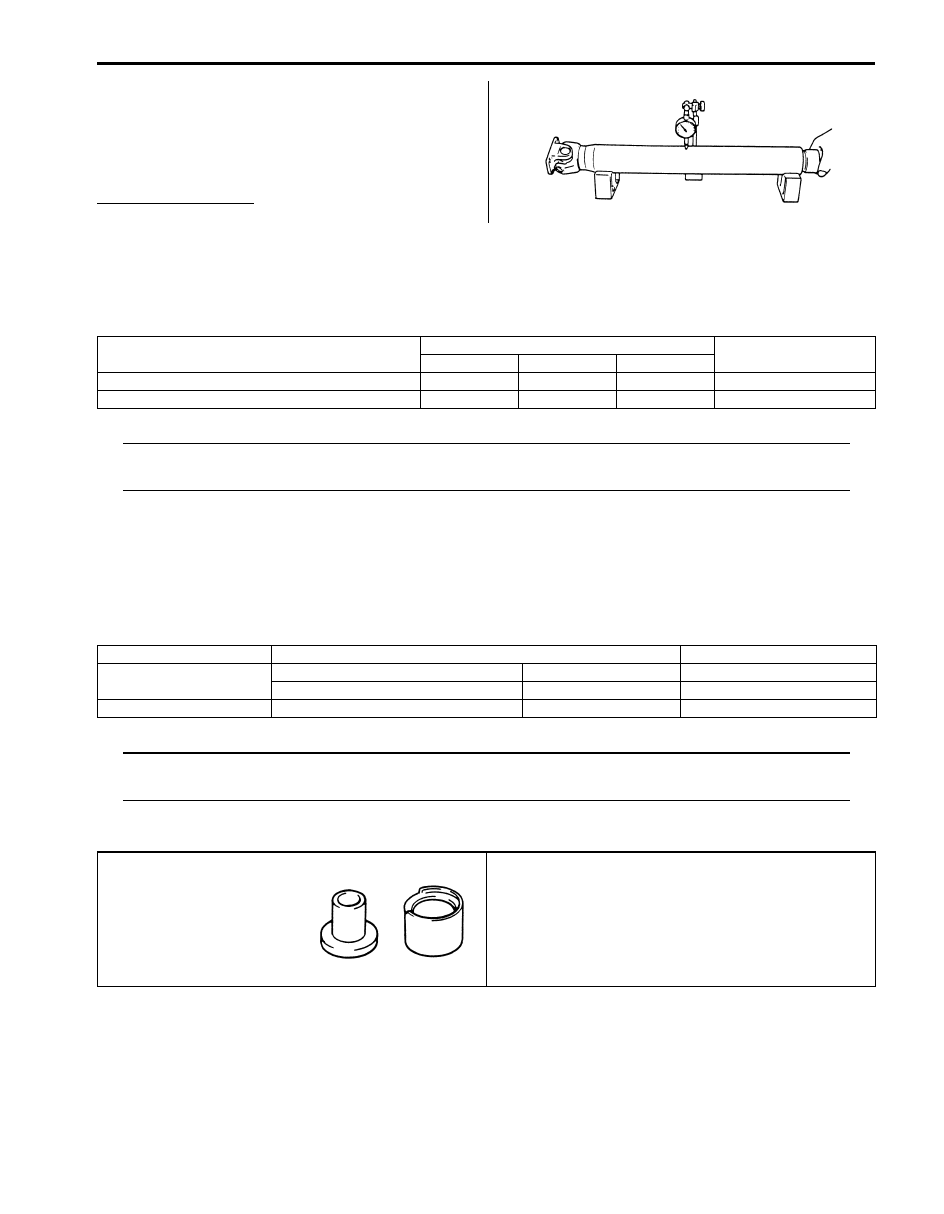

Propeller Shaft Inspection

S6JB0B3406004

Inspect propeller shaft, universal joint and ball joint for

damage, and propeller shaft for runout.

If damage is found or shaft runout exceeds its limit,

replace.

Propeller shaft runout

Limit: 0.8 mm (0.031 in.)

Specifications

Tightening Torque Specifications

S6JB0B3407001

NOTE

The specified tightening torque is also described in the following.

“Propeller Shaft Construction”

Reference:

For the tightening torque of fastener not specified in this section, refer to “Fastener Information in Section 0A”.

Special Tools and Equipment

Recommended Service Material

S6JB0B3408001

NOTE

Required service material is also described in the following.

“Propeller Shaft Construction”

Special Tool

S6JB0B3408002

IYSQ01340013-01

Fastening part

Tightening torque

Note

N

⋅m

kgf-m

lb-ft

Front propeller shaft flange bolt

30

3.0

22.0

Rear propeller shaft flange nut

85

8.5

61.5

Material

SUZUKI recommended product or Specification

Note

Grease

SUZUKI Super Grease A

P/No.: 99000–25010

SUZUKI Super Grease C

P/No.: 99000–25030

Thread lock cement

Thread Lock Cement Super 1322

P/No.: 99000–32110

09926–48010

Universal joint assembling

tool

)

Нет комментариевНе стесняйтесь поделиться с нами вашим ценным мнением.

Текст