Suzuki Grand Vitara JB627. Manual — part 167

3C-72 Transfer:

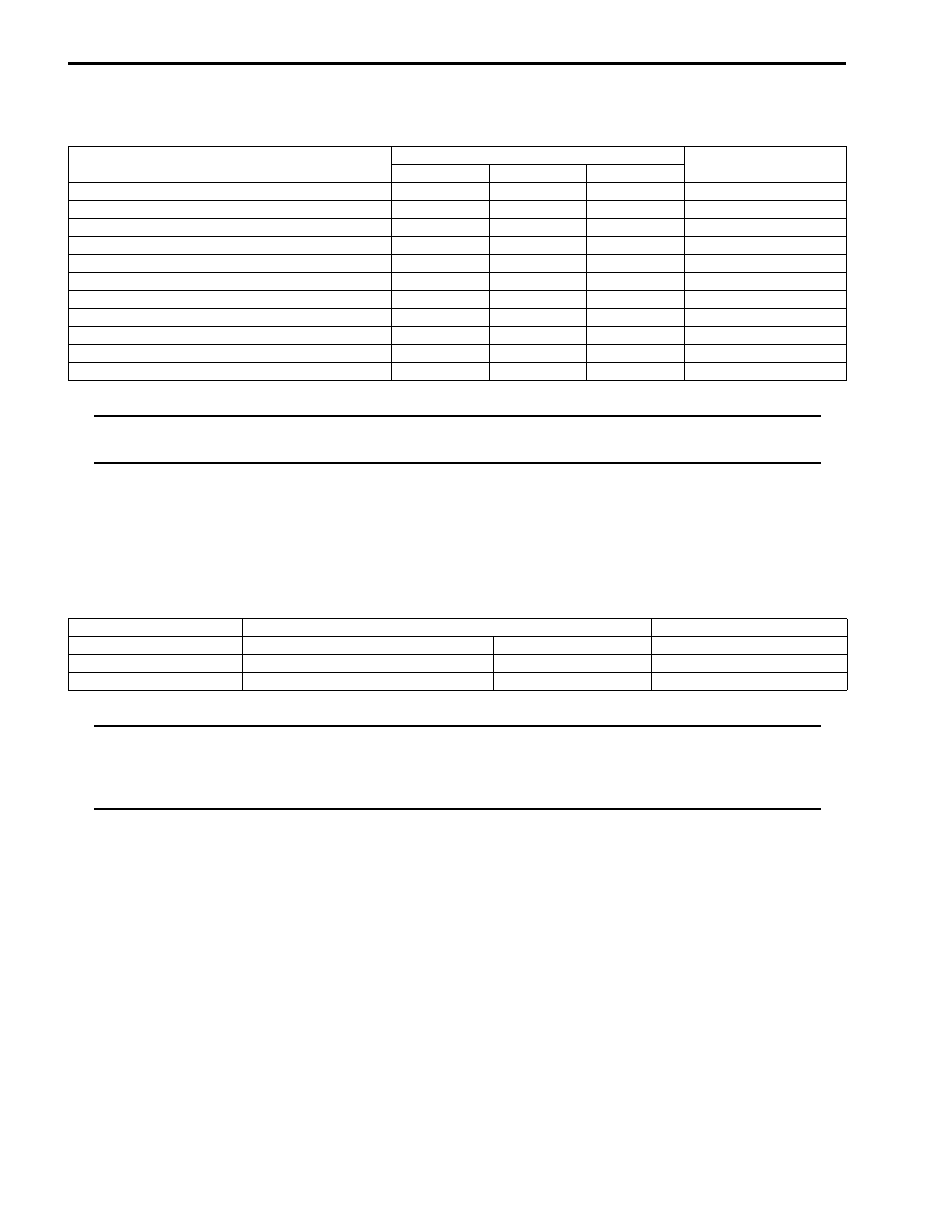

Specifications

Tightening Torque Specifications

S6JB0B3307001

NOTE

The specified tightening torque is also described in the following.

“Transfer Assembly Components”

Reference:

For the tightening torque of fastener not specified in this section, refer to “Fastener Information in Section 0A”.

Special Tools and Equipment

Recommended Service Material

S6JB0B3308001

NOTE

Required service material is also described in the following.

“Transfer Assembly Components”

“Input Gear Assembly, Counter Gear Assembly, Front Output Shaft Assembly and Rear Output Shaft

Assembly Components”

Fastening part

Tightening torque

Note

N

⋅m

kgf-m

lb-ft

Transfer oil level / filler plug

23

2.3

17.0

Transfer oil drain plug

23

2.3

17.0

Input gear plate bolt

23

2.3

17.0

Rear case bolt

23

2.3

17.0

Strainer bolt

10

1.0

7.5

Oil pump cover bolt

23

2.3

17.0

Control cover bolt

23

2.3

17.0

Control cover dowel bolt

23

2.3

17.0

Center differential lock switch

20

2.0

14.5

4L/N switch

20

2.0

14.5

Harness bracket bolt

10

1.0

7.5

Material

SUZUKI recommended product or Specification

Note

Grease

SUZUKI Super Grease A

P/No.: 99000–25010

Sealant

SUZUKI Bond No.1217G

P/No.: 99000–31260

Thread lock cement

Thread Lock Cement Super 1322

P/No.: 99000–32110

Transfer: 3C-73

Special Tool

S6JB0B3308002

09912–34510

09913–70123

Case separator

Bearing installing tool

09913–76010

09913–80113

Bearing installer

Bearing installer

09913–84510

09913–85210

Bearing installer

Bearing installer

09925–98210

09925–98221

Input shaft bearing installer

Bearing installer

09928–36510

09940–54910

Transfer cap

Front fork oil seal install

driver

SUZUKI scan tool

—

This kit includes following

items. 1. Tech 2, 2. PCMCIA

card, 3. DLC cable, 4. SAE

16/19 adapter, 5. Cigarette

cable, 6. DLC loop back

adapter, 7. Battery power

cable, 8. RS232 cable, 9.

RS232 adapter, 10. RS232

loop back connector, 11.

Storage case, 12. ) / )

3D-1 Propeller Shaft:

Driveline / Axle

Propeller Shaft

Precautions

Propeller Shaft Caution

S6JB0B3400001

CAUTION

!

• All propeller shaft fasteners are an important attaching part in that it could affect the performance of

vital parts and systems, and/or could result in major repair expense. They must be replaced with one

of the same part number or with an equivalent part if replacement becomes necessary. Do not use a

replacement part of lesser quality or substitute design. Torque values must be used as specified

during reassembly to assure proper retention of this part.

• Never attempt to heat, quench or straighten any propeller shaft part. Replace it with a new part, or

damage to the part may result.

General Description

Propeller Shaft Construction

S6JB0B3401001

Most universal joints and ball joints require no maintenance. They are lubricated for life and can not be lubricated on

the vehicle. If a universal joint becomes noisy or worn, it must be replaced.

The propeller shaft is a balanced unit. Handle it carefully so that balance can be maintained.

I5JB0A340001-02

[A]: Front propeller shaft

4. Spider joint assembly

: Apply grease (99000-25030) to spider bearing race.

[B]: Rear propeller shaft

5. Circlip

1. Front propeller shaft flange bolt

: Apply thread lock 99000-32110 to bolt thread.

: 85 N

⋅m (8.5 kgf-m, 61.5 lb-ft)

2. Rear propeller shaft flange nut

: 30 N

⋅m (3.0 kgf-m, 22.0 lb-ft)

3. Support washer

: Do not reuse.

Propeller Shaft: 3D-2

Diagnostic Information and Procedures

Propeller Shaft Symptom Diagnosis

S6JB0B3404001

Repair Instructions

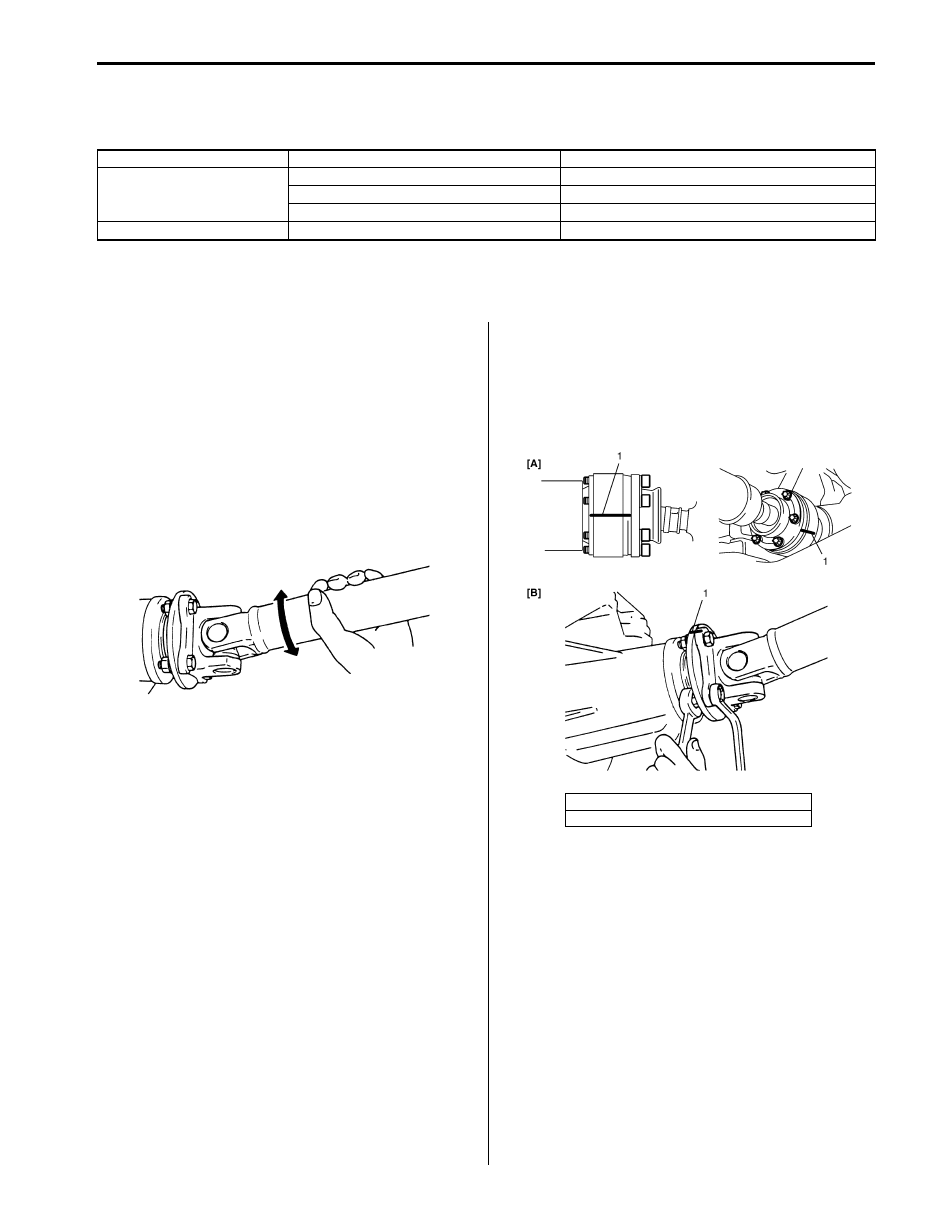

Propeller Shaft Joint Check

S6JB0B3406001

If universal joints and ball joints are suspected of

producing chattering or rattling noise, inspect them for

wear. For universal joint, check to see if cross spider

rattles in yokes or if splines are worn down and replace

defective propeller shaft assembly with new one.

Noise coming from universal joint and ball joint can be

easily distinguished from other noises because rhythm

of chattering or rattling is in step with cruising speed.

Noise is pronounced particularly on standing start or in

coasting condition (when braking effect of engine is

showing in the drive line).

Propeller Shaft Removal and Installation

S6JB0B3406002

Removal

1) Hoist vehicle.

2) Give match marks (1) on joint flange and propeller

shaft as shown in the figure.

3) Remove rear propeller shaft.

4) Drain transfer oil when removed front propeller shaft

from transfer.

Condition

Possible cause

Correction / Reference Item

Abnormal noise

Loose propeller shaft flange bolt and nut Tighten propeller shaft flange bolt and nut.

Spider bearing worn out or stuck

Replace.

Wear spider

Replace propeller shaft.

Vibration

Deformed propeller shaft

Replace.

I5JB0A340003-01

[A]: Front propeller shaft

[B]: Rear propeller shaft

I5JB0A340002-02

Нет комментариевНе стесняйтесь поделиться с нами вашим ценным мнением.

Текст