Suzuki Grand Vitara JB627. Manual — part 112

1I-2 Starting System:

Diagnostic Information and Procedures

Cranking System Symptom Diagnosis

S6JB0B1904001

Possible symptoms due to starting system trouble would be as follows:

• Starting motor does not run (or runs slowly)

• Starting motor runs but fails to crank engine

• Abnormal noise is heard

Proper diagnosis must be made to determine exactly where the cause of each trouble lies. .in battery, wiring harness,

(including starting motor switch), starting motor or engine.

Do not remove motor just because starting motor does not run. Check the following items and narrow down scope of

possible causes.

1) Condition of trouble

2) Tightness of battery terminals (including ground cable connection on engine side) and starting motor terminals

3) Discharge of battery

4) Mounting of starting motor

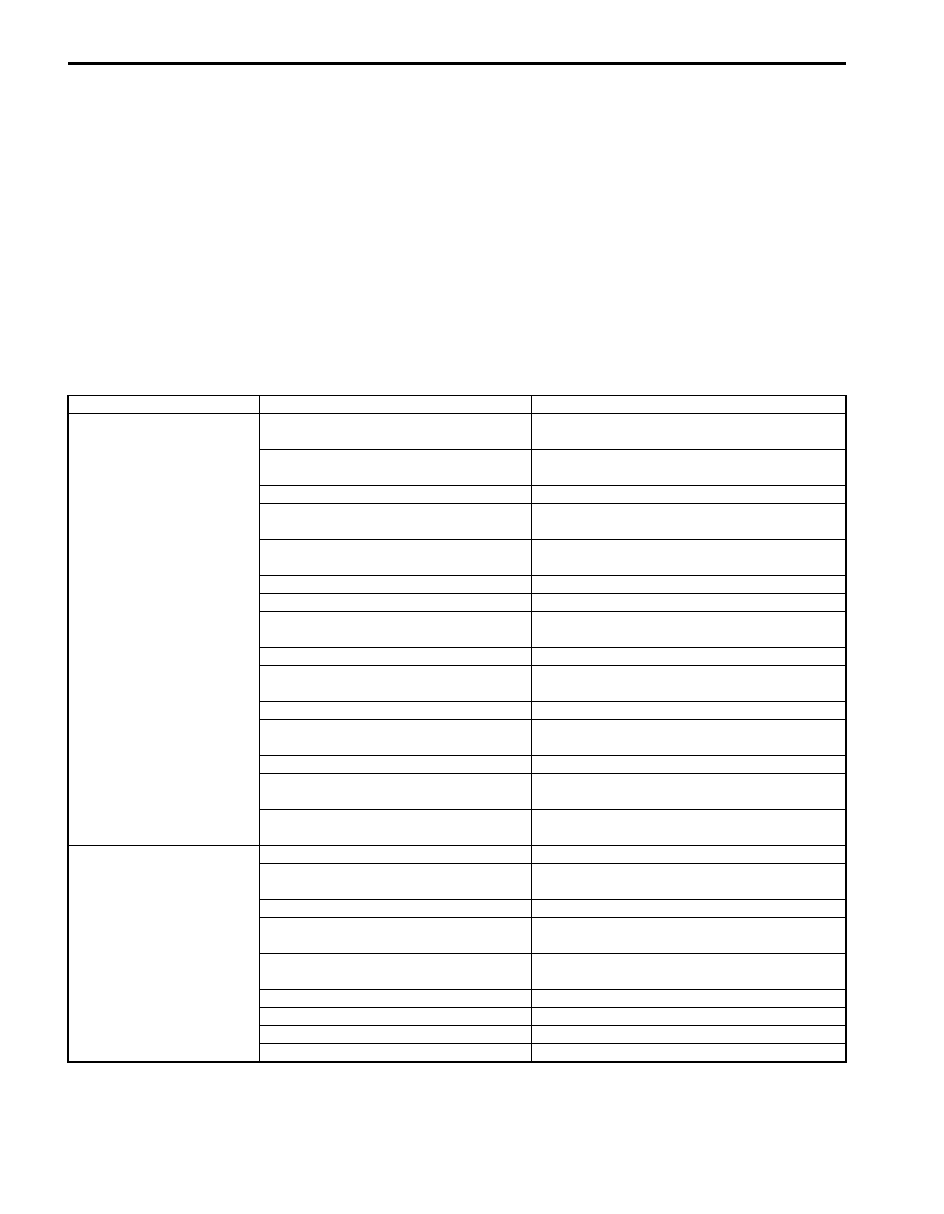

Condition

Possible cause

Correction / Reference Item

Motor not running – No

operating sound of

magnetic switch

Shift lever switch is not in P or N, or not

adjusted (A/T)

Shift in P or N, or adjust switch.

Malfunction of clutch pedal position

switch (M/T)

Adjust or replace.

Battery run down

Recharge battery.

Battery voltage too low due to battery

deterioration

Replace battery.

Poor contact in battery terminal

connection

Retighten or replace.

Loose grounding cable connection

Retighten.

Fuse set loose or blown off

Tighten or replace.

Poor contacting action of ignition switch

and magnetic switch

Replace.

Lead wire coupler loose in place

Retighten.

Open-circuit between ignition switch and

magnetic switch

Repair.

Open-circuit in pull-in coil

Replace magnetic switch.

Brushes are seating poorly or worn

down

Repair or replace.

Poor sliding or plunger and/or pinion

Repair.

Faulty starting motor control relay

“Engine and Emission Control System Relay

Inspection in Section 1C”.

Faulty ECM and its circuit

“Inspection of ECM and Its Circuits in Section

1A”.

Motor not running –

Operating sound of

magnetic switch heard

Battery run down

Recharge battery.

Battery voltage too low due to battery

deterioration

Replace battery.

Loose battery cable connections

Retighten.

Burnt main contact point, or poor

contacting action of magnetic switch

Replace magnetic switch.

Brushes are seating poorly or worn

down

Repair or replace.

Weakened brush spring

Replace.

Burnt commutator

Replace armature.

Layer short-circuit of armature

Replace.

Crankshaft rotation obstructed

Repair.

Starting System: 1I-3

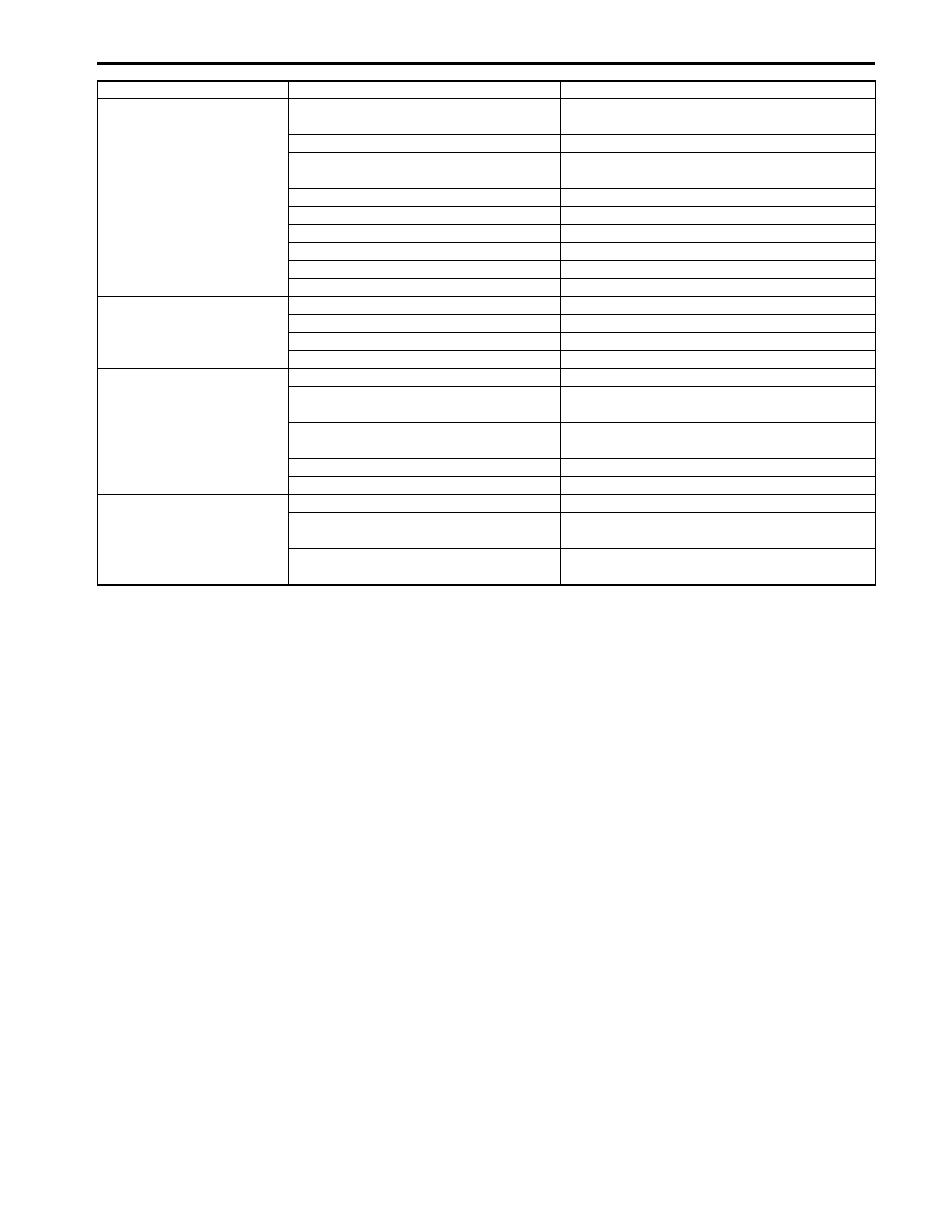

Starting motor running,

but too slow (small

torque) – Battery and

wiring are satisfactory

Insufficient contact of magnetic switch

main contacts

Replace magnetic switch.

Layer short-circuit of armature

Replace.

Disconnected, burnt or worn

commutator

Repair commutator or replace armature.

Worn brushes

Replace brush.

Weakened brush springs

Replace brush assembly.

Burnt or abnormally worn end bush

Replace front housing.

Burnt commutator

Replace armature.

Layer short-circuit of armature

Replace.

Crankshaft rotation obstructed

Repair.

Starting motor running,

but not cranking engine

Worn pinion tip

Replace over-running clutch.

Poor sliding of over-running clutch

Repair.

Over-running clutch slipping

Replace over-running clutch.

Worn teeth of ring gear

Replace flywheel (M/T) or drive plate (A/T).

Noise

Abnormally worn bush

Replace front housing.

Worn pinion or worn teeth of ring gear

Replace over-running clutch, flywheel (M/T) or

drive plate (A/T).

Poor sliding of pinion (failure in return

movement)

Repair or replace.

Worn internal or planetary gear teeth

Replace.

Lack of oil in each part

Lubricate.

Starting motor does not

stop running

Fused contact points of magnetic switch Replace magnetic switch.

Short-circuit between turns of magnetic

switch coil (layer short-circuit)

Replace magnetic switch.

Failure of returning action in ignition

switch

Replace.

Condition

Possible cause

Correction / Reference Item

1I-4 Starting System:

Starting Motor Performance Test

S6JB0B1904002

CAUTION

!

Each test must be performed within 3 – 5

seconds to avoid coil from burning.

Pull-In Test

1) Connect battery to magnetic switch as shown.

2) Check that plunger and pinion move outward. If

plunger and pinion don’t move, replace magnetic

switch.

NOTE

Before testing, disconnect lead wire from

terminal “M”.

Hold-In Test

1) While connected as above with plunger out,

disconnect negative lead (2) from terminal “M” (1).

2) Check that plunger and pinion remain out. If plunger

and pinion return inward, replace magnetic switch.

Plunger and Pinion Return Test

1) Disconnect negative lead (1) from switch body (2).

2) Check that plunger and pinion return inward. If

plunger and pinion don’t return, disassemble and

inspect starting motor.

No-Load Performance Test

1) Connect battery and ammeter to starter as shown.

2) Check that starter rotates smoothly and steadily with

pinion moving out. Check that ammeter indicates

specified current.

Specified current (no-load performance test)

90 A MAX. at 11 V

NOTE

Use wires as thick as possible and tighten

each terminal fully.

1. Terminal “S”

2. Terminal “M”

3. Lead wire (switch to motor)

1

3

2

I6JB01190001-02

1

2

I6JB01190002-02

1

2

I6JB01190003-02

A

I6JB01190004-01

Starting System: 1I-5

Repair Instructions

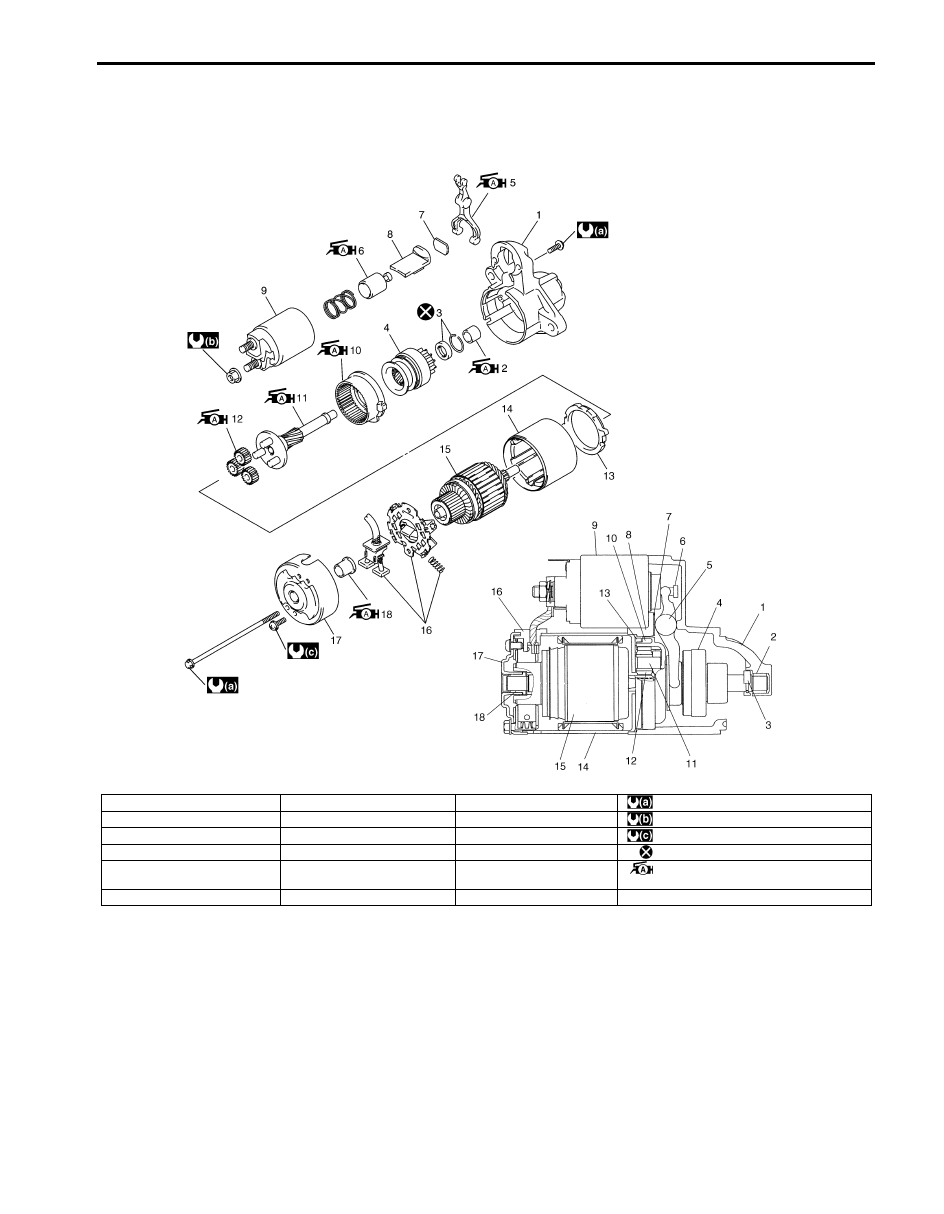

Starting Motor Components

S6JB0B1906001

I6JB01190005-02

1. Front housing

7. Plate

13. Packing

: 6 N

⋅m (0.6 kgf-m, 4.5 lb-ft)

2. Bush

8. Seal rubber

14. Yoke

: 10 N

⋅m (1.0 kgf-m, 7.5 lb-ft)

3. Pinion stop ring

9. Magnetic switch

15. Armature

: 3 N

⋅m (0.3 kgf-m, 2.5 lb-ft)

4. Over-running clutch

10. Internal gear

16. Brush assembly

: Do not reuse.

5. Lever

11. Planetary carrier shaft

17. Rear bracket

: Apply grease 99000-25010 to sliding

surface of each part.

6. Plunger

12. Planetary gear

18. Rear bush

Нет комментариевНе стесняйтесь поделиться с нами вашим ценным мнением.

Текст