Suzuki Grand Vitara JB627. Manual — part 101

1E-8 Engine Lubrication System:

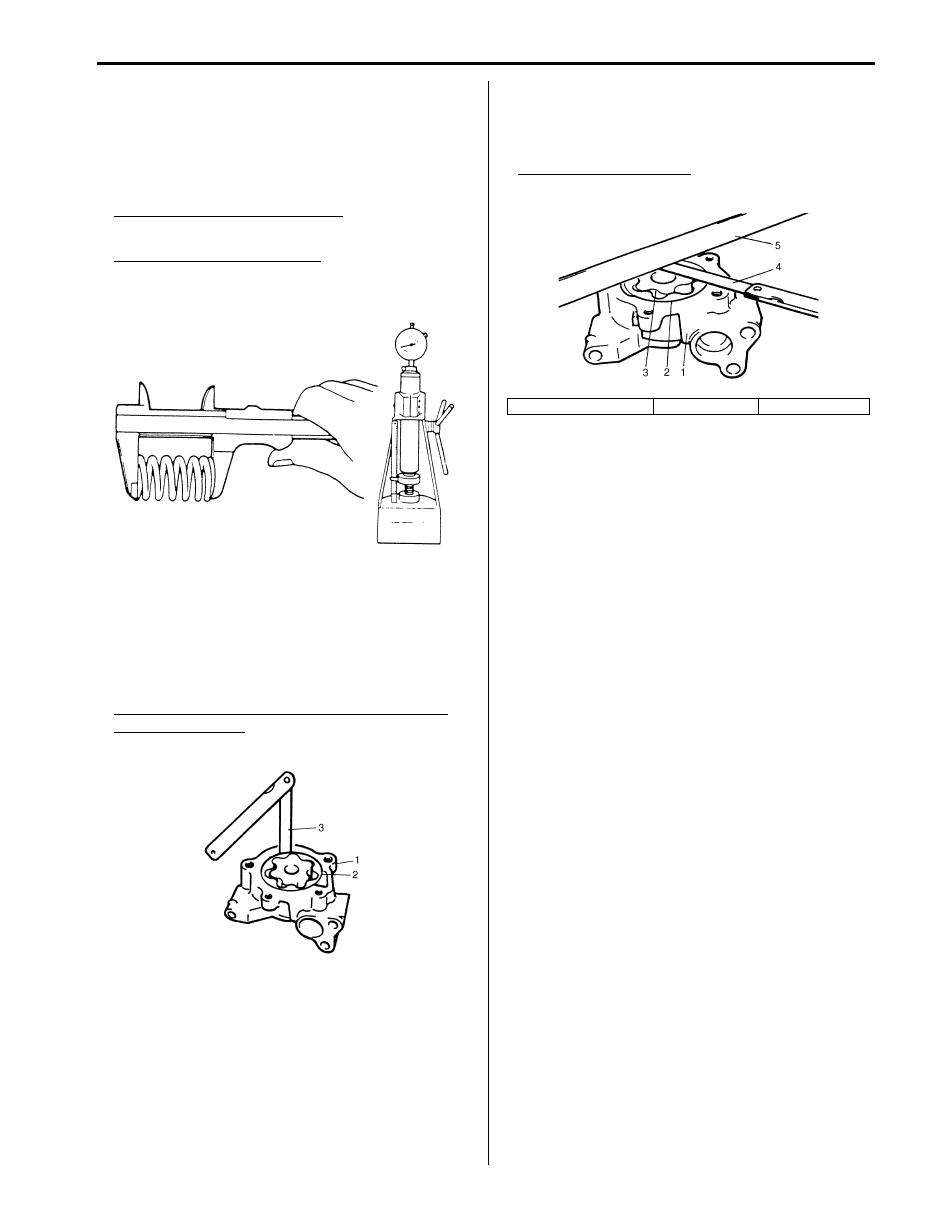

Oil Pump and Oil Pump Chain Inspection

S6JB0B1506006

Oil Pump Chain Guide

Check shoe (1) for wear or damage.

Oil Pump Drive Sprocket

Check teeth of sprocket for wear or damage.

Oil Pump Sprocket

Check teeth of sprocket for wear or damage.

Oil Pump Chain

Check oil pump chain for wear or damage.

Oil Pump Disassembly and Reassembly

S6JB0B1506007

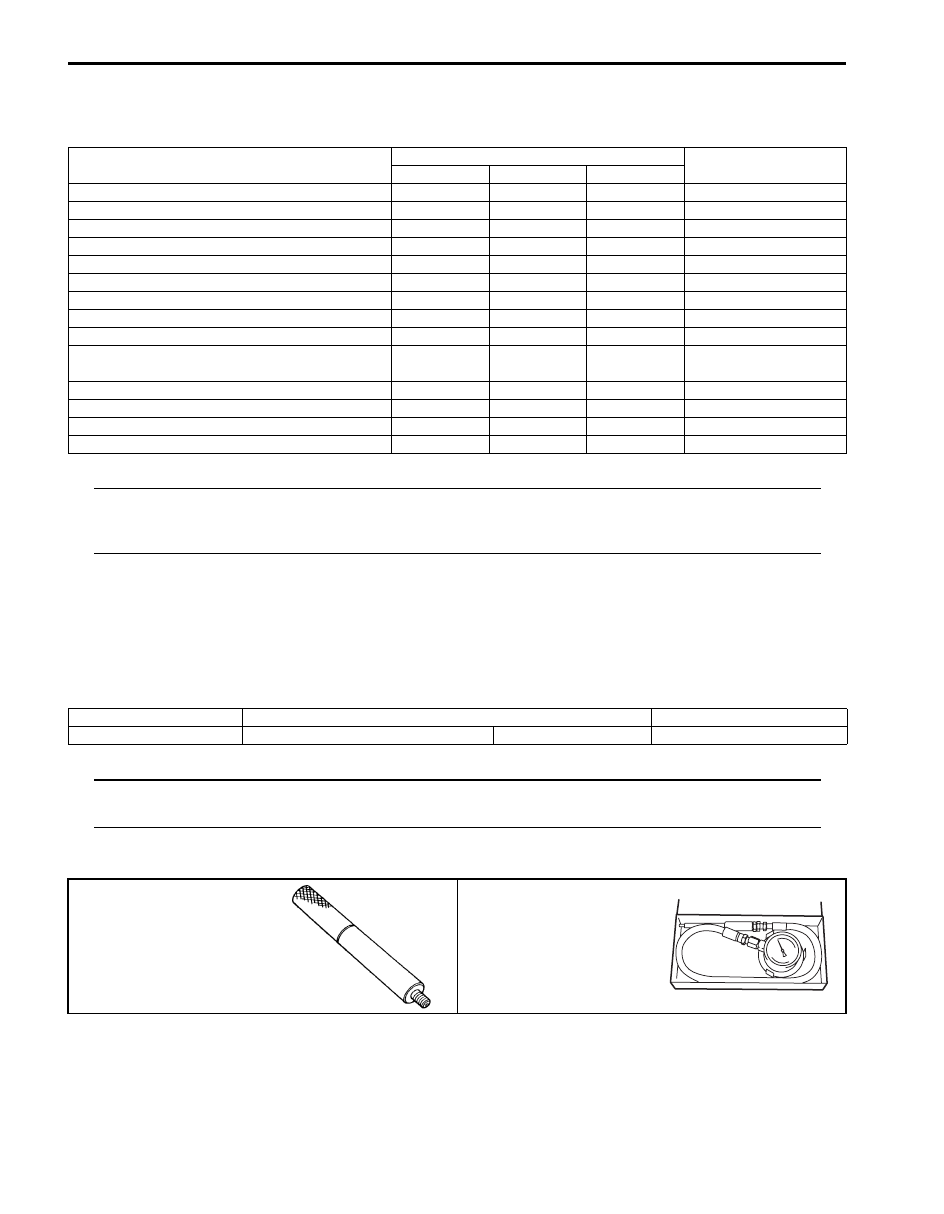

Disassembly

Disassemble oil pump referring to “Oil Pump and Oil

Pump Chain Components”.

CAUTION

!

Do not remove oil pump sprocket or bolt.

Otherwise, oil pump sprocket and/or oil

pump rotor shaft might be damaged.

Reassembly

1) Wash, clean and then dry all disassembled parts.

2) Apply thin coat of engine oil to inner and outer rotors,

and inside surfaces of oil pump case.

3) Reassemble oil pump. After reassembling oil pump,

check to be sure that rotor turns smoothly by hand.

Tightening torque

Oil pump bolt (a): 12 N·m (1.2 kgf-m, 9.0 lb-ft)

IYSQ01153026-01

IYSQ01153027-01

IYSQ01153028-01

IYSQ01153029-01

IYSQ01153019-01

Engine Lubrication System: 1E-9

Oil Pump Inspection

S6JB0B1506008

• Check outer rotor, inner rotor and oil pump cases for

excessive wear or damage.

• Check relief valve for excessive wear or damage.

• Measure free length and tension of oil relief spring.

Spring (for oil pump) free length

63.47 mm (2.49 in.)

Spring (for oil pump) preload

80.38 – 88.22 N (8.04 – 8.82 kg, 58.14 – 63.80 lb) for

52.0 mm (2.05 in.)

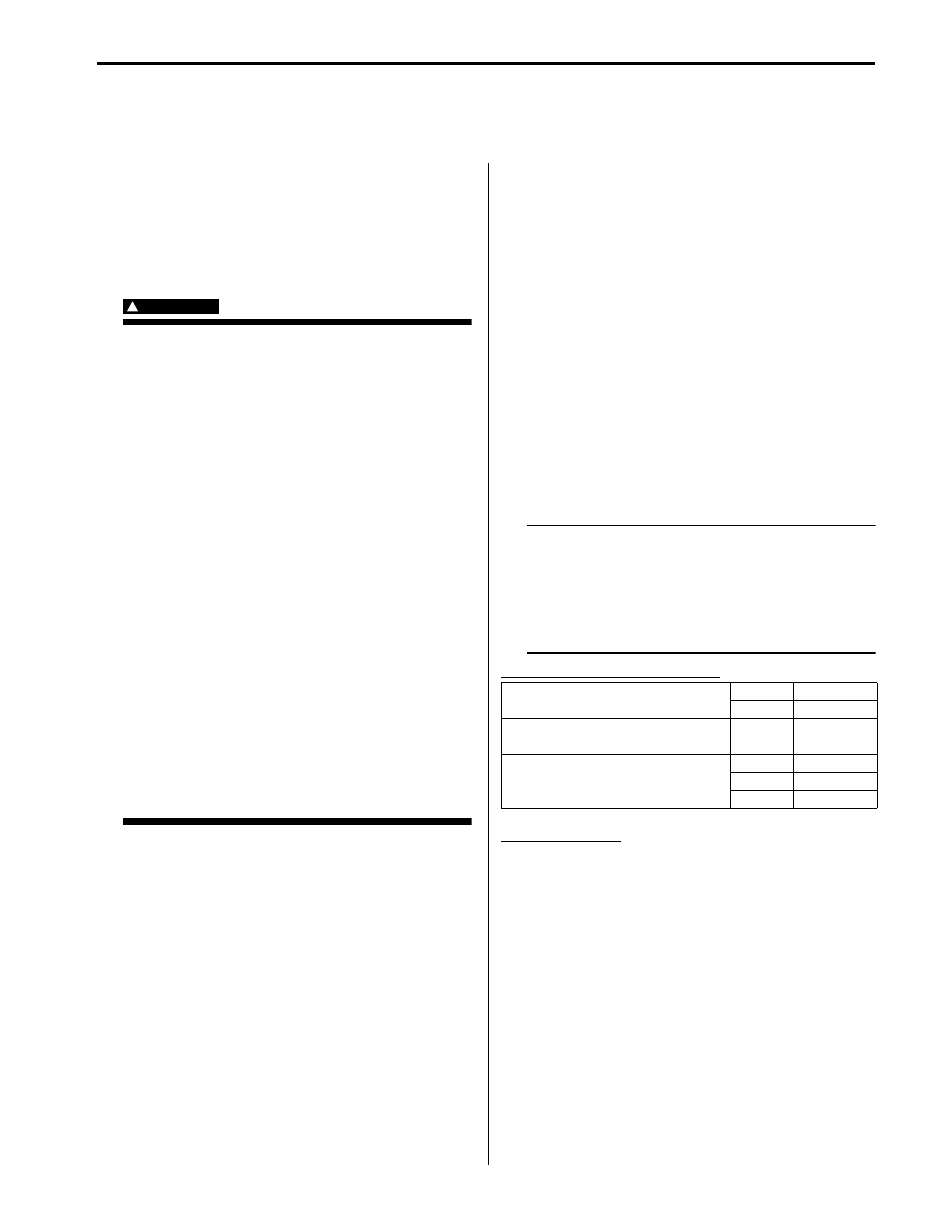

• Radial clearance

Measure clearance of oil pump rotor and oil pump

case using thickness gauge.

Check radial clearance between outer rotor (2) and

case (1), using thickness gauge (3).

If clearance exceeds its limit, replace oil pump

assembly.

Radial clearance between oil pump outer rotor

and oil pump case

Limit: 0.19 mm (0.0075 in.)

• Side clearance

Using straightedge (5) and thickness gauge (4),

measure side clearance. If clearance exceeds its limit,

replace oil pump assembly.

Oil pump side clearance

Limit: 0.11 mm (0.0043 in.)

IYSQ01141105-01

IYSQ01153020-01

1. Oil pump case No.1

2. Outer rotor

3. Inner rotor

IYSQ01153021-01

1E-10 Engine Lubrication System:

Specifications

Tightening Torque Specifications

S6JB0B1507001

NOTE

The specified tightening torque is also described in the following.

“Oil Pan and Oil Pump Strainer Components”

“Oil Pump and Oil Pump Chain Components”

Reference:

For the tightening torque of fastener not specified in this section, refer to “Fastener Information in Section 0A”.

Special Tools and Equipment

Recommended Service Material

S6JB0B1508001

NOTE

Required service material is also described in the following.

“Oil Pan and Oil Pump Strainer Components”

Special Tool

S6JB0B1508002

Fastening part

Tightening torque

Note

N

⋅m

kgf-m

lb-ft

Oil pressure switch

13

1.3

9.5

Oil pump strainer bolt

11

1.1

8.0

Upper oil pan bolt (M6)

11

1.1

8.0

Upper oil pan bolt (M8)

25

2.5

19.5

Upper oil pan nut

11

1.1

8.0

Oil pump strainer bracket bolt

11

1.1

8.0

Lower oil pan bolt

11

1.1

8.0

Lower oil pan nut

11

1.1

8.0

Engine oil drain plug

35

3.5

25.5

Drive plate cover (A/T) bolt or clutch housing

lower plate (M/T) bolt

11

1.1 8.0

Oil level gauge guide bolt

11

1.1

8.0

Oil pump mounting bolt

25

2.5

18.0

Oil pump chain guide bolt

11

1.1

8.0

Oil pump bolt

12

1.2

9.0

Material

SUZUKI recommended product or Specification

Note

Sealant

SUZUKI Bond No.1217G

P/No.: 99000–31260

09915–76510

09915–77311

Oil pressure gauge

attachment

Oil pressure gauge

Engine Cooling System: 1F-1

Engine

Engine Cooling System

General Description

Cooling System Description

S6JB0B1601001

The cooling system consists of the radiator cap, radiator,

coolant reservoir, hoses, water pump, cooling fan and

thermostat. The radiator is of tube-and-fin type.

Coolant Description

S6JB0B1601002

WARNING

!

• Do not remove radiator cap to check

engine coolant level; check coolant

visually at the see-through coolant

reservoir. Coolant should be added only to

reservoir as necessary.

• As long as there is pressure in the cooling

system, the temperature can be

considerably higher than the boiling

temperature of the solution in the radiator

without causing the solution to boil.

Removal of the radiator cap while engine is

hot and pressure is high will cause the

solution to boil instantaneously and

possibly with explosive force, spewing the

solution over engine, fenders and person

removing cap. If the solution contains

flammable anti-freeze such as alcohol (not

recommended for use at any time), there is

also the possibility of causing a serious

fire.

• Check to make sure that engine coolant

temperature is cold before removing any

part of cooling system.

• Also be sure to disconnect negative (–)

cable from battery terminal before

removing any part.

The coolant recovery system is standard. The coolant in

the radiator expands with heat, and the coolant is

overflowed to the reservoir.

When the system cools down, the coolant is drawn back

into the radiator.

The cooling system has been filled with a quality coolant

that is a 50/50 mixture of water and ethylene glycol

antifreeze.

This 50/50 mixture coolant solution provides freezing

protection to –36

°C (–33 °F).

• Maintain cooling system freeze protection at –36

°C (–

33

°F) to ensure protection against corrosion and loss

of coolant from boiling. This should be done even if

freezing temperatures are not expected.

• Add ethylene glycol base coolant when coolant has to

be added because of coolant loss or to provide added

protection against freezing at temperature lower than

–36

°C (–33 °F).

NOTE

• Alcohol or methanol base coolant or plain

water alone should not be used in cooling

system at any time as damage to cooling

system could occur.

• Coolant must be mixed with deminerated

water or distilled water.

Anti-freeze proportioning table

Coolant capacity

Engine, radiator and heater: 7.4 liters (15.64/13.03

US/lmp pt.)

Reservoir: 0.8 liters (1.69/1.41 US/lmp pt.)

Total: 8.2 liters (17.49/14.43 US/lmp pt.)

Freezing temperature

°C

–36

°F

–33

Anti-freeze / Anti-corrosion

coolant concentration

%

50

Ratio of compound to cooling

water

ltr.

4.1/4.1

US pt.

8.75/8.75

Imp pt.

7.22/7.22

Нет комментариевНе стесняйтесь поделиться с нами вашим ценным мнением.

Текст