Suzuki: Engine K6A-YH6. Manual — part 20

7-34

REPAIR

7

Outer Rotor Side Clearance

Figure 7-81

1.

Place a straightedge (1) across the oil pump rotor

bore. Use a feeler gauge (2) to measure the

clearance between the straightedge and the outer

rotor side surface. If measurement is beyond service

limit, replace the oil pump assembly.

Oil Pump Outer Rotor Side Clearance Limit:

0.003—0.005 in. (0.076—0.127 mm)

Inner Rotor and Pump Case Clearance

Figure 7-82

1.

Using a micrometer, measure the outside diameter of

the inner rotor shoulder (1).

2.

Measure the inside diameter of the oil pump bore

hole (2). If measurements are not within service limit,

replace oil pump assembly.

Inner Rotor and Pump Case Clearance:

0.001—0.003 in. (0.025—0.076 mm)

TN0392

1

2

TN0394

1

2

REPAIR

7-35

7

Relief Valve Spring

Figure 7-83

1.

Use a veneer caliper to measure the free length of

relief valve spring (1). If relief valve spring measures

less than specification, replace the spring.

Oil Pump Relief Valve Spring Free Length: 2.063 in.

(52.40 mm)

2.

Using a spring compression gauge (2), compress

relief valve spring to specification and record the

force reading. If force reading is less than

specification, replace the spring.

Oil Pump Relief Valve Spring Tension at 1.516 in.

(38.5 mm) of Length: 17.3 lb-ft (23.45 N•m)

Required Tools

Veneer Caliper

Spring Compression Gauge

TN0558, 0559

1

2

7-36

REPAIR

7

Installation

Figure 7-84

1.

Using bushing, bearing, and seal driver (1), install

new oil seal (2) into front cover (3).

Figure 7-85

NOTE

Install inner and outer rotor as previously marked.

2.

Install relief valve (11), spring (10), retainer (9), and

circlip (8).

3.

Install inner rotor (4) and outer rotor (5).

4.

Install oil pump housing (6) using screws (7). Tighten

to specification.

Oil Pump Housing Torque: 60 lb-in. (6.78 N•m)

Required Tools

Bushing, Bearing and Seal Driver (Suzuki PN

09913-75520) or equivalent

TN0561

1

2

3

TN0557

4

5

6

7

8

11

10

9

REPAIR

7-37

7

7.8 Cylinder Block and Lower

Crankcase

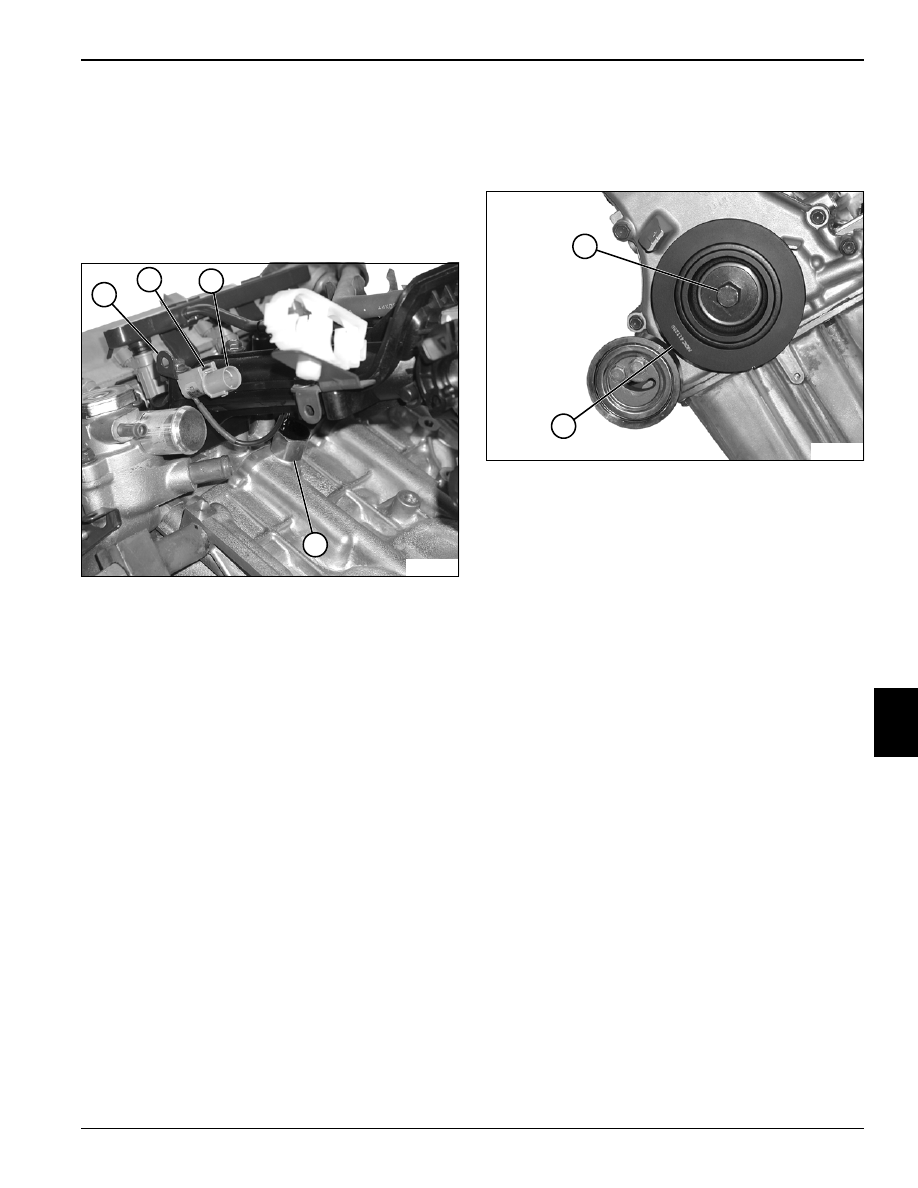

Knock Sensor

Removal and Installation

Figure 7-86

1.

Use a small screwdriver to depress internal tab (2)

and release electrical connector (3) from bracket (1).

2.

Remove knock sensor (4) from cylinder block.

3.

Inspect and replace as needed.

Installation Notes

Install knock sensor by reversing the order of removal.

Tighten knock sensor to specification.

Knock Sensor Torque: 203 lb-in. (23 N•m)

Crankshaft Pulley

Removal and Installation

Figure 7-87

1.

Remove cap screw (1) and crankshaft pulley (2).

2.

Inspect and replace as needed.

Installation Notes

Install crankshaft pulley by reversing the order of

removal.

Tighten crankshaft pulley cap screw to specification.

Crankshaft Pulley Cap Screw: 72 lb-ft (98 N•m)

TN0718

1

2

3

4

TN0721

2

1

Нет комментариевНе стесняйтесь поделиться с нами вашим ценным мнением.

Текст