Suzuki: Engine K6A-YH6. Manual — part 18

7-26

REPAIR

7

Installation

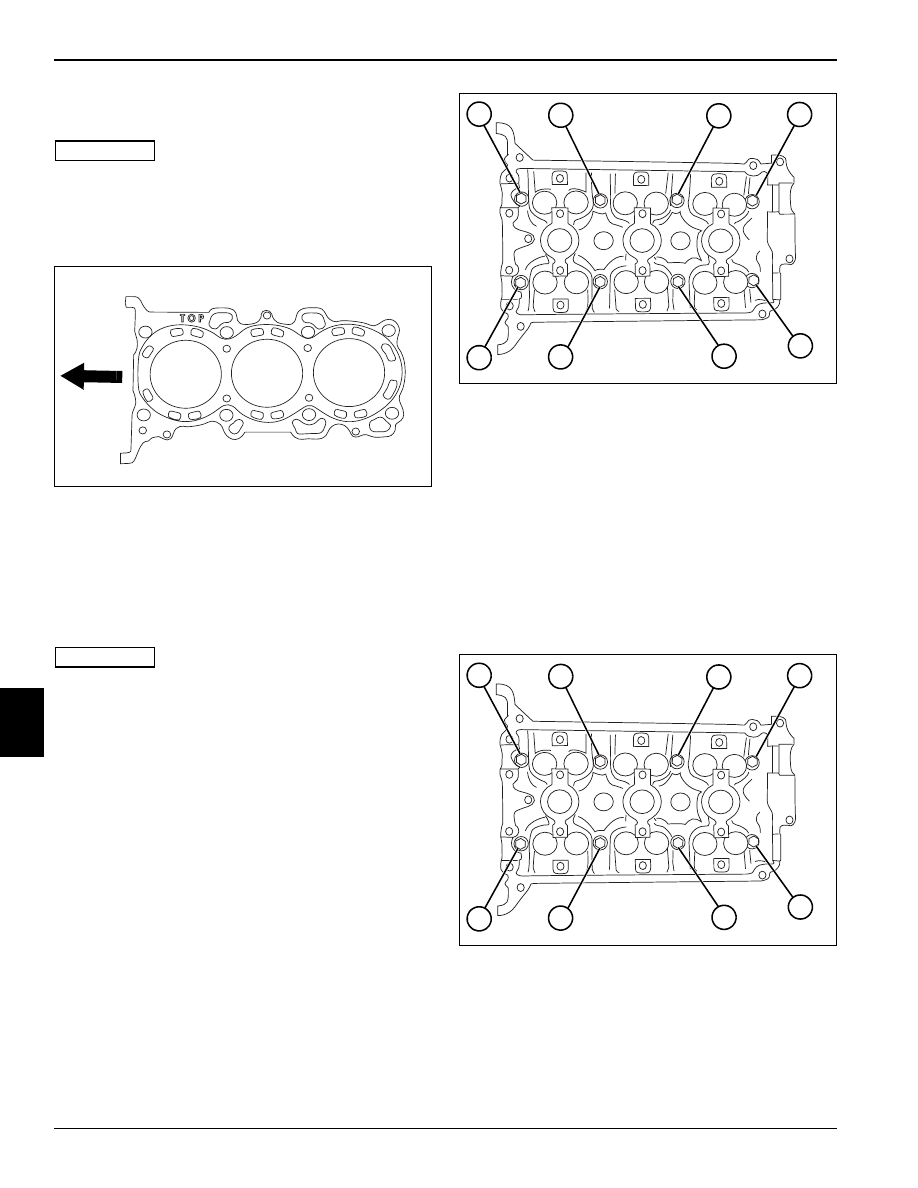

See Figures 7-65 through 7-67.

IMPORTANT

Make sure cylinder head and cylinder block are free

of oil and debris.

Make sure cylinder head bolt holes are free of oil,

water, or debris.

Figure 7-65

1.

Clean cylinder head and cylinder block mating

surfaces. Place head gasket on cylinder block with

forked end toward the front of the engine (arrow).

2.

Install cylinder head using care to align dowel pins.

3.

Apply oil to cylinder head cap screw threads and

seating faces and install. Do not tighten at this time.

IMPORTANT

If the cylinder head, cylinder block, or the cylinder

head cap screw have been replaced, go to step 4.

If installing previously removed parts, go to step 5.

Figure 7-66

4.

Torque the cap screws in sequence to 22 lb-ft (30

N•m).

• Set torque wrench to 35 lb-ft (47 N•m) and repeat

torque sequence.

• Reverse the torque sequence and loosen all cap

screws.

• Re-torque cap screws in sequence to 35 lb-ft

(47 N•m).

• Torque cap screws (1 through 8) in sequence to final

specification.

Cylinder Head Cap Screw Torque: 43.5 lb-ft (59 N•m)

Figure 7-67

5.

Tighten cap screws (1 through 8) in sequence, to

specification.

Cylinder Head Cap Screw Torque: 43.5 lb-ft (59 N•m)

TN0413

TN0403

1

2

3

4

5

6

7

8

TN0403

1

2

3

4

5

6

7

8

REPAIR

7-27

7

Valves

Disassembly

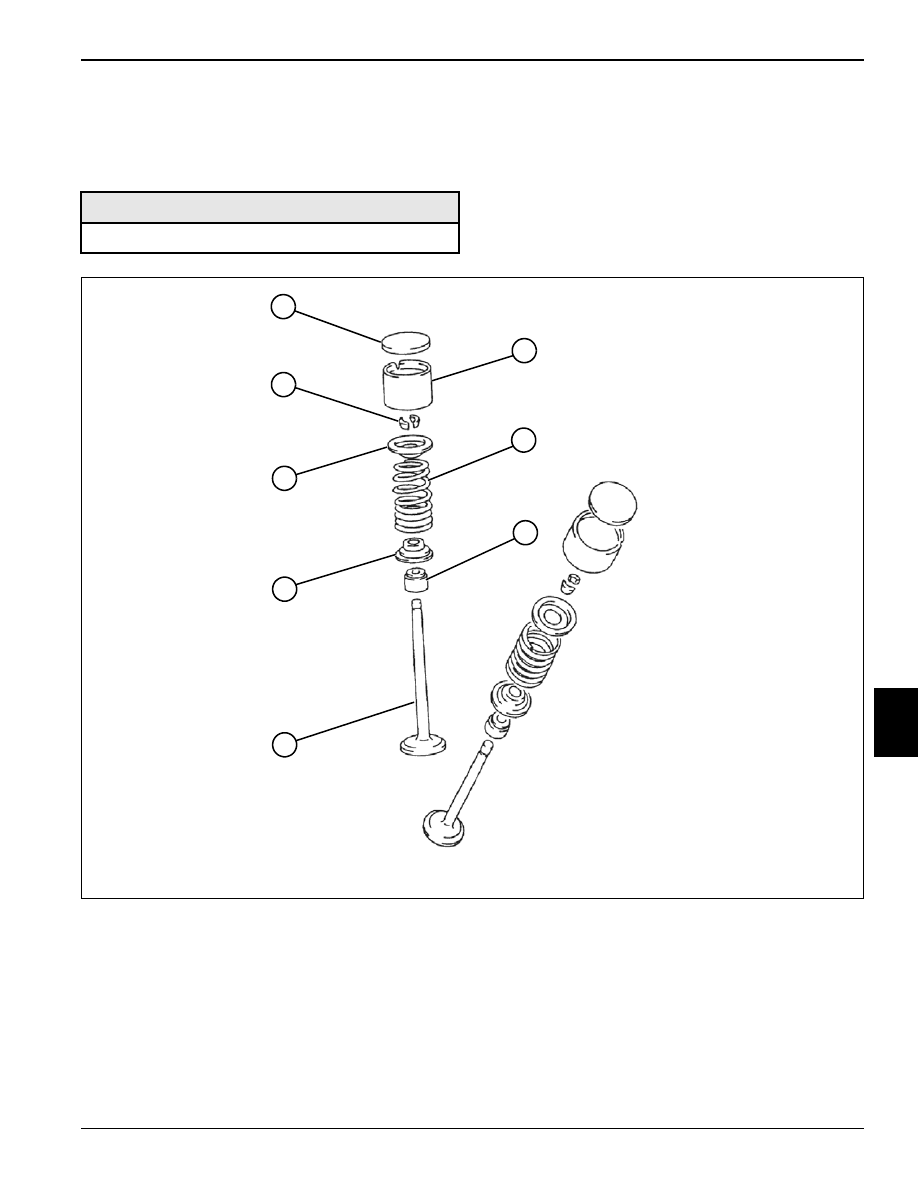

Figure 7-68

1.

Remove shims (1) and tappets (2).

2.

Using a valve spring compressor, remove retainer

locks (8).

3.

Release valve spring compressor and remove

valve (5).

4.

Remove valve spring retainer (7), valve spring (3),

valve seal (4), and valve spring seat (6).

5.

Inspect all parts for wear or damage. (See

“Inspection” on page 7-28.)

Required Tools

Valve Spring Compressor

TN0492

6

8

1

5

3

4

2

7

7-28

REPAIR

7

Inspection

Valves

Figure 7-69

1.

Clean and inspect intake (5) and exhaust (4) valves,

valve stems (3), valve stem tips (1), and retainer lock

grooves (2).

2.

Using a micrometer, measure the valve stem (3) OD.

3.

Using an inside micrometer, measure the ID of valve

guide.

Compare valve stem OD measurement to valve

guide ID measurement. Calculate clearance and

replace as needed.

Valve Guide to Valve Stem Clearance, Intake:

0.0007—0.0018 in. (0.020—0.047 mm)

Valve Guide to Valve Stem Clearance Limit, Intake:

0.002 in (0.07 mm)

Valve Guide to Valve Stem Clearance, Exhaust:

0.0017—0.0028 in. (0.045—0.072 mm)

Valve Guide to Valve Stem Clearance Limit, Exhaust:

0.003 in. (0.09 mm)

Valve Springs

Figure 7-70

Figure 7-71

1.

Measure the free length of valve springs using a

veneer caliper (1). Compare measurement to

specification. Replace as needed.

Valve Spring Free Length: 1.35 in. (34.3 mm)

TN0506

1

3

3

1

2

2

4

5

Required Tools

Veneer Caliper

Spring Compression Gauge

Square

TN0558, 0559

1

2

TN0760

3

4

REPAIR

7-29

7

2.

Using a spring compression gauge (2), compress the

valve spring to 1.17 in. (29.9 mm). Compare the

tension reading to specification and replace as

needed.

Pound Force at 1.17 in. (29.9 mm) Height:

Valve Spring Tension Standard: 22—26 lb-ft

(100—116 N•m)

Valve Spring Tension Limit: 20 lb-ft (88 N•m)

3.

Using a square (4), check valve spring right angle.

Use a feeler gauge to measure distance (3).

Compare measurement to specification. Replace as

needed.

Valve Spring Right Angle Range: 0.000—0.059 in.

(0.00—1.5 mm)

Installation Notes

Always use new O-rings, gaskets, and seals.

Apply clean engine oil to tappet and valve stem contact

surfaces.

Install valve assemblies with new valve seals by reversing

the order of removal.

Check valve clearance. (See “Valve Clearance Check

and Adjustment” on page 5-3.)

Нет комментариевНе стесняйтесь поделиться с нами вашим ценным мнением.

Текст