Suzuki Grand Vitara JB416 / JB420. Manual — part 128

1G-14 Fuel System:

iii) Turn ignition switch ON.

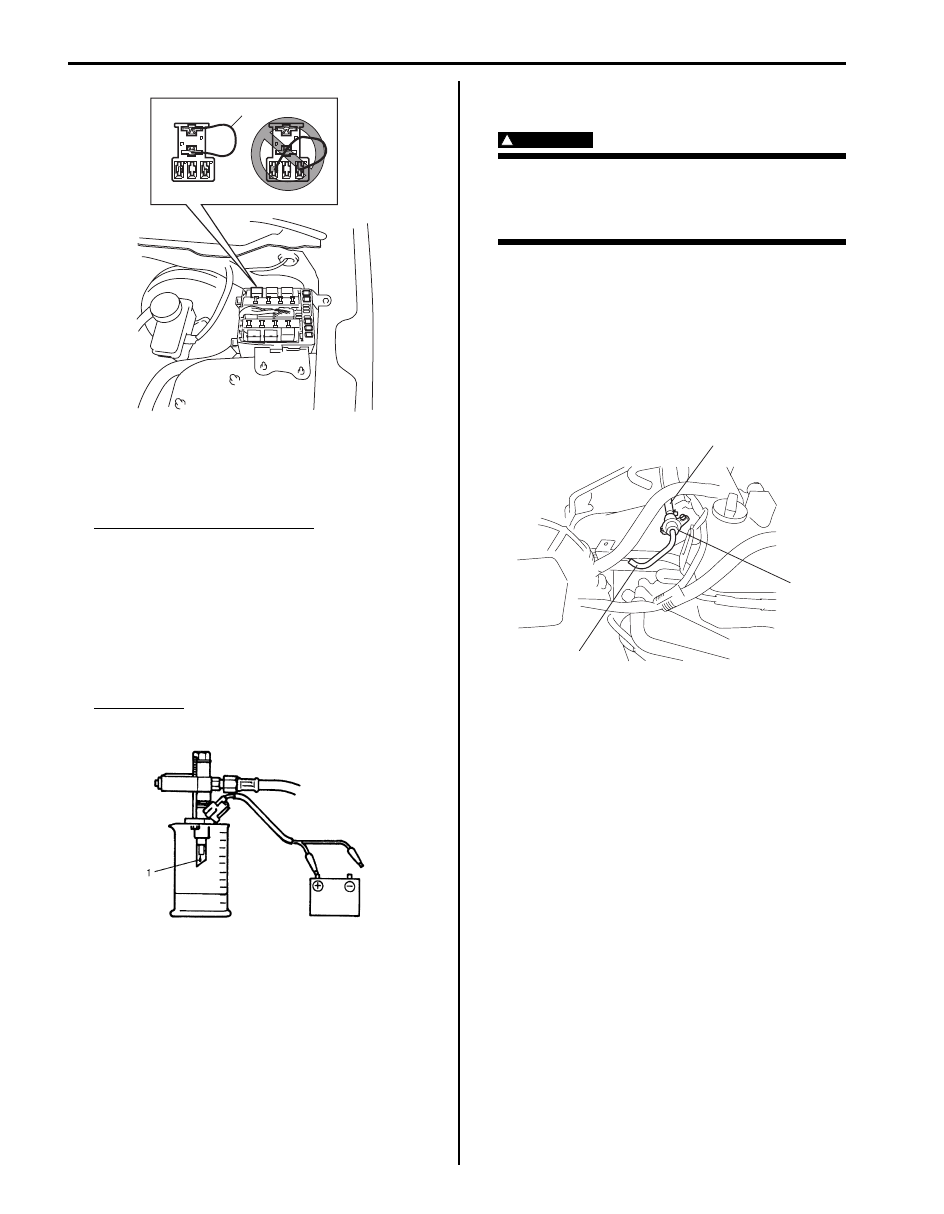

8) Apply battery voltage to injector (1) for 15 seconds

and measure injected fuel volume with graduated

cylinder. Test each injector two or three times.

Reference injected fuel volume

(For M16 engine model) Approx. 46 cc / 15 sec.

(1.62/1.55 US/Imp oz / 15 sec.)

(For J20 engine model) Approx. 65 cc / 15 sec.

(2.20/2.29 US/Imp oz / 15 sec.)

9) Check fuel leakage from injector nozzle. Do not

operate injector for this check (but fuel pump should

be at work). If fuel leaks (1) more than the following

specifications, replace.

Fuel leakage

Less than 1 drop/min.

Fuel Pressure Regulator Removal and

Installation

S5JB0A1706024

WARNING

!

Before starting the following procedure, be

sure to observe “Precautions on Fuel System

Service”in order to reduce the risk or fire and

personal injury.

Removal

1) Relieve fuel pressure according to “Fuel Pressure

2) Disconnect negative cable at battery.

3) Disconnect fuel return hose (1) and vacuum hose (2)

from fuel pressure regulator.

4) Remove fuel pressure regulator (3) from delivery

pipe.

1

I5JB0A171010-02

I2RH0B170013-01

1

2

3

I5JB0A171011-02

Fuel System: 1G-15

Installation

Reverse removal procedure for installation noting the

following.

• Replace O-ring with new one using care not to

damage it.

• Apply thin coat of fuel to O-ring and then install fuel

pressure regulator (1) to delivery pipe.

• Tighten fuel pressure regulator bolts to specified

torque.

Tightening torque

Fuel pressure regulator bolt (a): 11 N·m (1.1 kgf-

m, 8.0 lb-ft)

• After installation, with engine OFF and ignition switch

ON, check for fuel leaks around fuel line connection.

Fuel Pressure Regulator Inspection

S5JB0A1706025

Confirm fuel pressure of fuel line is decreased when fuel

pressure regulator is applied negative pressure by

special tool.

Special tool

(A): 09917–47011

Fuel Filler Cap Inspection

S5JB0A1706011

WARNING

!

Before starting the following procedure, be

sure to observe “Precautions on Fuel System

Service” in order to reduce the risk or fire

and personal injury.

Remove cap (1), and check gasket for even filler neck

imprint, and deterioration or any damage. If gasket (2) is

in malcondition, replace cap.

NOTE

If cap requires replacement, only a cap with

the same features should be used. Failure to

use correct cap can result in fire and

personal injury.

Fuel Tank Inlet Valve Removal and Installation

S5JB0A1706015

WARNING

!

Before starting the following procedure, be

sure to observe “Precautions on Fuel System

Service” in order to reduce the risk or fire

and personal injury.

Removal

1) Remove fuel filler cap.

2) Insert hose of a hand operated pump into fuel filler

hose (1) and drain fuel in space “A” as shown in

figure.

CAUTION

!

Do not force pump hose into fuel tank, or

pump hose may damage to fuel tank inlet

valve (2).

(a)

1

I5JB0A171012-01

I5JB0A171013-01

I2RH01170008-01

IYSQ01170010-01

1G-16 Fuel System:

3) Hoist vehicle, and remove clamp (2) and fuel filler

hose (1) from fuel filler neck.

4) Remove fuel tank inlet valve (1) using flat head rod

(2) or the like.

CAUTION

!

Be careful not to damage fuel tank inlet valve

(1) with flat head rod (2) or the like.

Installation

1) Install fuel tank inlet valve (1) to fuel tank.

2) Install fuel filler hose (1) to fuel tank and secure it

with clamp (2).

For proper installation, refer to “Fuel Hose

Disconnecting and Reconnecting”.

3) Lower vehicle and install fuel filler cap.

Fuel Tank Inlet Valve Inspection

S5JB0A1706016

WARNING

!

Before starting the following procedure, be

sure to observe “Precautions on Fuel System

Service” in order to reduce the risk or fire

and personal injury.

Check fuel tank inlet valve for the following.

If any damage or malfunction is found, replace.

• Damage

• Smooth opening and closing

Fuel Tank Removal and Installation

S5JB0A1706012

WARNING

!

Before starting the following procedure, be

sure to observe “Precautions on Fuel System

Service” in order to reduce the risk or fire

and personal injury.

Removal

1) Relieve fuel pressure in fuel feed line according to

“Fuel Pressure Relief Procedure”.

2) Disconnect negative cable at battery.

3) Hoist vehicle.

4) Remove exhaust center pipe.

5) Remove rear propeller shaft referring to “Propeller

Shaft Removal and Installation in Section 3D”

6) With cable connected, detach parking brake cable

clamp from fuel tank cover referring to “Parking

Brake Cable Location in Section 4D”

7) Disconnect fuel filler hose and breather hose from

filler neck referring to “Fuel Tank Inlet Valve Removal

and Installation”.

1

2

I5JB0A171014-01

I2RH0B170017-01

I2RH0B170018-01

1

2

I5JB0A171014-01

I5JB0A170009-01

Fuel System: 1G-17

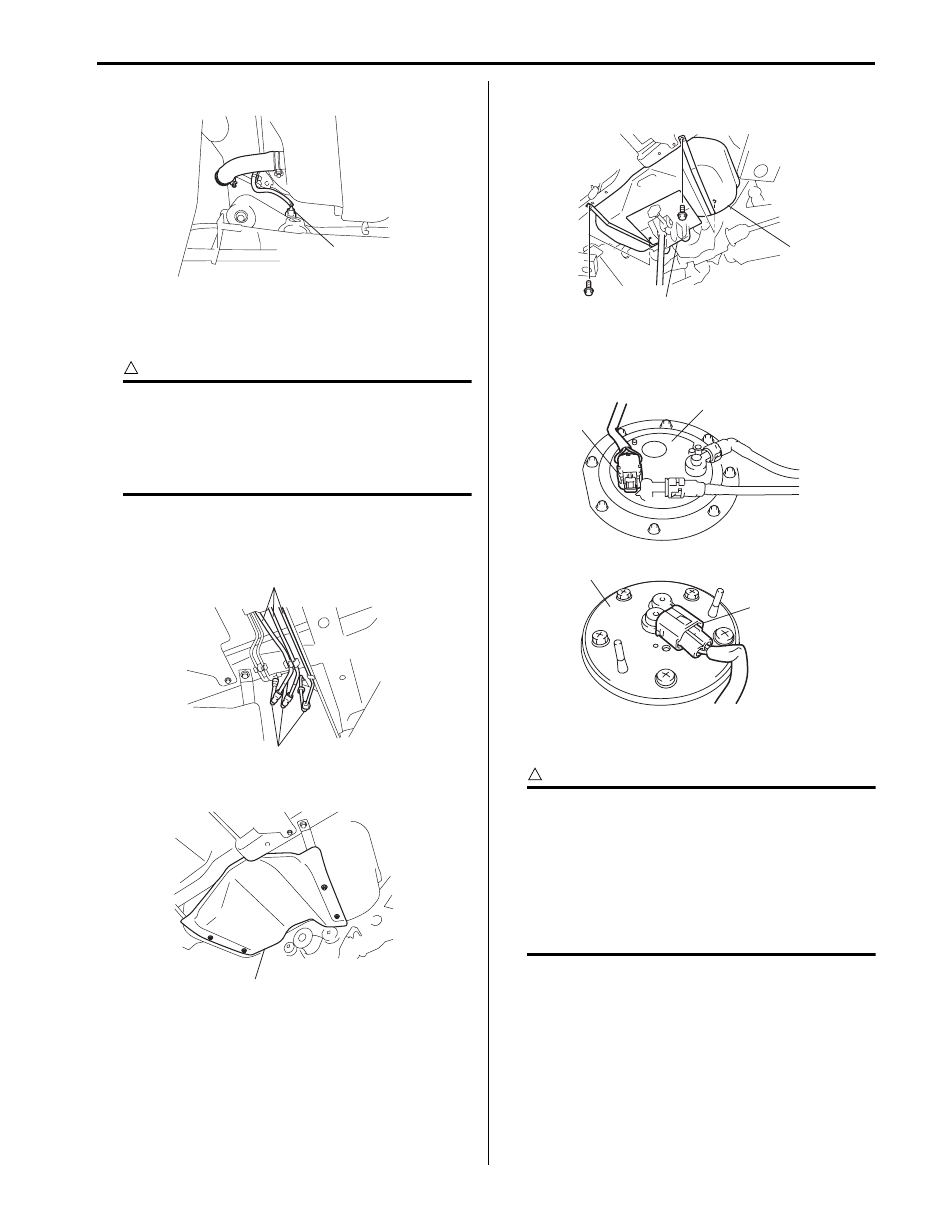

8) For J20 engine, disconnect fuel pump connector (1).

9) Due to absence of fuel tank drain plug, drain fuel

tank by pumping fuel out through fuel tank filler.

Use hand operated pump device to drain fuel tank.

CAUTION

!

• Do not force pump hose into fuel tank, or

pump hose may damage fuel tank inlet

valve.

• Never store fuel in an open container due

to possibility of fire or explosion.

10) Disconnect fuel pipe joint and fuel hoses (1) from

fuel pipes (2) referring to “Fuel Hose Disconnecting

and Reconnecting”.

11) Remove fuel tank cover (1).

12) Support fuel tank (1) with jack (2) and remove its

mounting bolts.

13) For M16 engine, lower fuel tank a little as to

disconnect connectors (1) of fuel pump (2) and sub

fuel level gauge (3), then remove fuel tank.

Installation

CAUTION

!

• When connecting joint, clean outside

surfaces of pipe where joint is to be

inserted, push joint into pipe till joint lock

clicks and check to ensure that pipes are

connected securely, or fuel leak may

occur.

• Never let the fuel hoses touch the ABS

sensor harness (if equipped).

1) If parts have been removed from fuel tank, install

them before installing fuel tank to vehicle.

2) Raise fuel tank (1) with jack, and connect connectors

of fuel pump and sub fuel level gauge and clamp

wire harness.

1

I5JB0A171015-01

2

1

I5JB0A171016-01

1

I5JB0A171017-01

1

2

I5JB0A171018-01

1

3

2

1

I5JB0A171019-01

Нет комментариевНе стесняйтесь поделиться с нами вашим ценным мнением.

Текст