Suzuki Grand Vitara JB416 / JB420. Manual — part 129

1G-18 Fuel System:

3) Install fuel tank to vehicle.

Tightening torque

Fuel tank bolt (a): 50 N·m (5.0 kgf-m, 36.5 lb-ft)

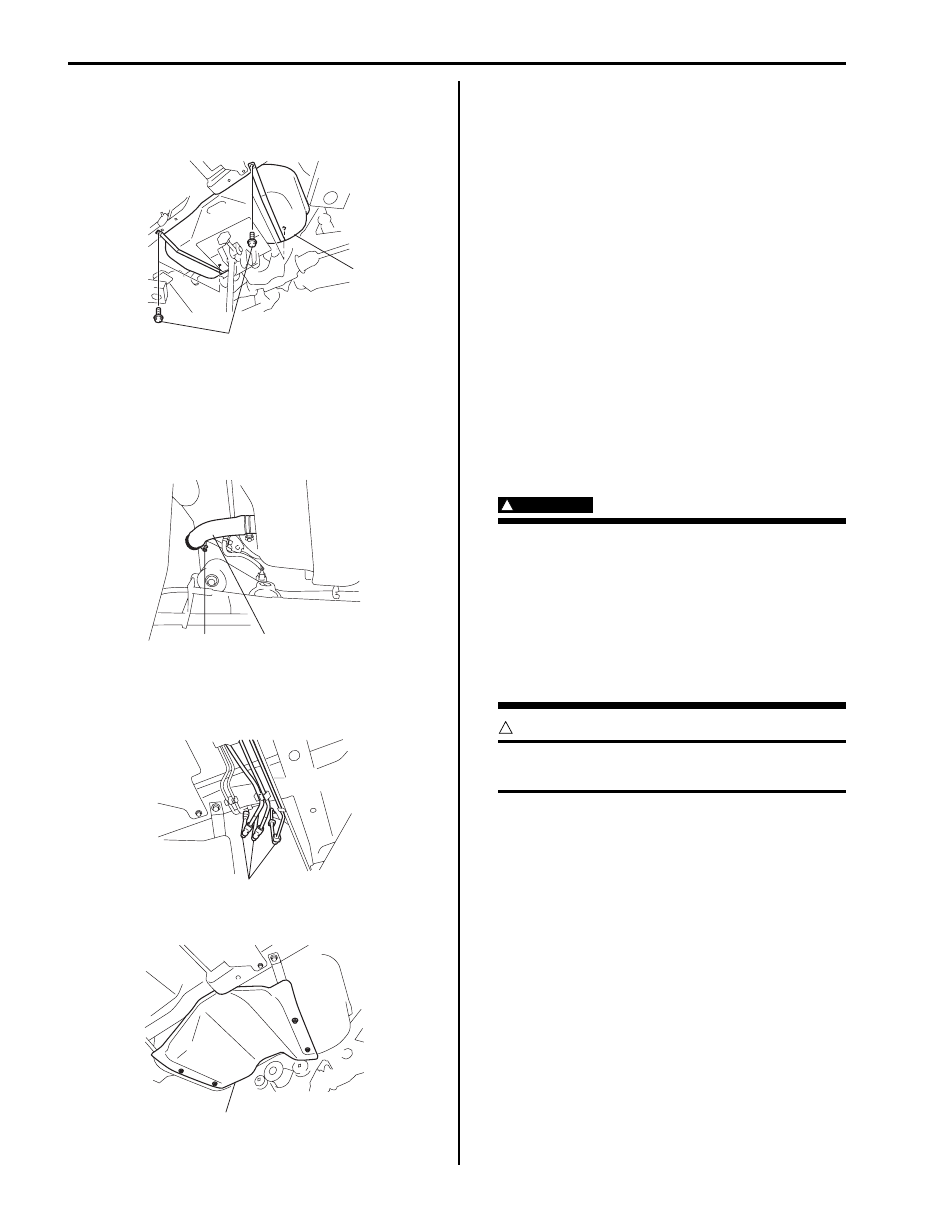

4) Connect fuel filler hose (1) and breather hose to filler

neck as shown in figure, and clamp them securely.

Tightening torque

Fuel filler hose clamp (a): 2 N·m (0.2 kgf-m, 1.5

lb-ft)

5) Connect fuel feed hoses (1) to each pipe as shown

in figure, and clamp them securely referring to “Fuel

Hose Disconnecting and Reconnecting”.

6) Install fuel tank cover (1).

7) Install parking brake cable clamp to fuel tank cover

referring to “Parking Brake Cable Location in Section

4D”

8) Install rear propeller shaft referring to “Propeller

Shaft Removal and Installation in Section 3D”

9) Install exhaust center pipe referring to “Exhaust

System Components in Section 1K”.

10) Connect negative cable at battery.

11) With engine OFF, turn ignition switch to ON position

and check for fuel leaks.

Fuel Tank Inspection

S5JB0A1706013

After removing fuel tank, check hoses and pipes

connected to fuel tank for leaks, loose connections,

deterioration or damage. Also check fuel pump

assembly gaskets for leaks, visually inspect fuel tank for

leaks and damage.

Replace any damaged or malconditioned parts.

Fuel Tank Purging Procedure

S5JB0A1706014

WARNING

!

• Before starting the following procedure, be

sure to observe “Precautions on Fuel

System Service” in order to reduce the risk

or fire and personal injury.

• This purging procedure will not remove all

fuel vapor.

Do not attempt any repair on tank using

heat of flame as an explosion resulting in

personal injury could occur.

CAUTION

!

Never remain water in fuel tank after washing,

or fuel tank inside will get corrosion.

The following procedure are used for purging fuel tank.

1) After removing fuel tank, remove all hoses, pipes,

sub fuel level gauge and fuel pump assembly from

fuel tank.

2) Drain all remaining fuel from tank.

3) Place fuel tank to flushing area.

4) Fill tank with warm water or tap water, and agitate

vigorously and drain. Repeat this washing until

inside of tank is clean. Replace tank if its inside is

rusty.

5) Completely flush out remaining water after washing.

1

(a)

I5JB0A171020-01

1

(a)

I5JB0A171021-01

1

I5JB0A171022-01

1

I5JB0A171017-01

Fuel System: 1G-19

Fuel Pump On-Vehicle Inspection

S5JB0A1706017

WARNING

!

Before starting the following procedure, be

sure to observe “Precautions on Fuel System

Service” in order to reduce the risk or fire

and personal injury.

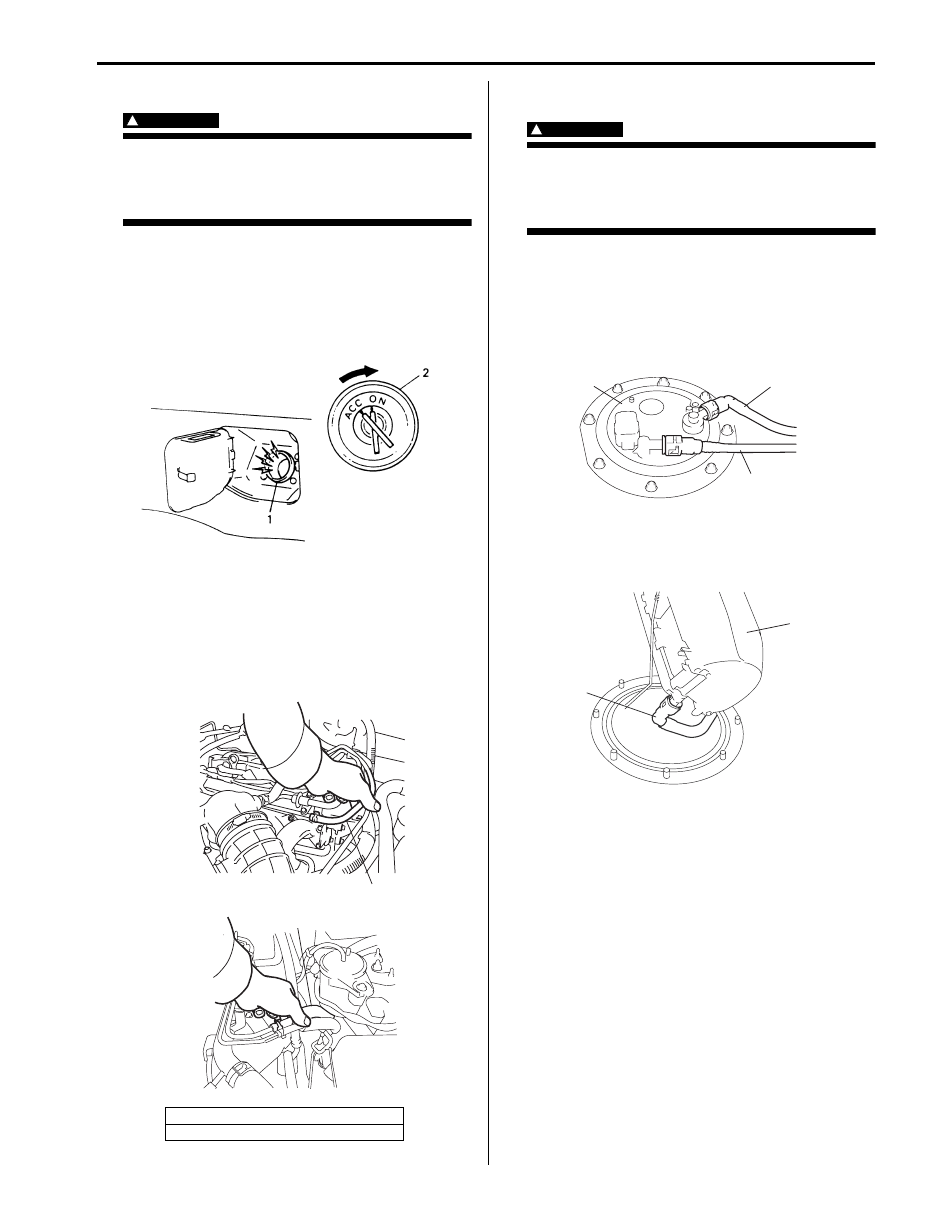

1) Remove filler cap and turn ON ignition switch (2).

Then fuel pump operating sound should be heard

from fuel filler (1) for about 2 seconds and stop. Be

sure to reinstall fuel filler cap after checking.

If the check result is not satisfactory, go to “Fuel

Pump and Its Circuit Check in Section 1A”.

2) Turn OFF ignition switch and leave over 10 minutes

as it is.

3) Fuel pressure should be felt at fuel feed hose (1) for

about 2 seconds after ignition switch ON.

If fuel pressure is not felt, go to “Fuel Pressure

Check in Section 1A”.

Fuel Pump Assembly Removal and Installation

S5JB0A1706019

WARNING

!

Before starting the following procedure, be

sure to observe “Precautions on Fuel System

Service” in order to reduce the risk or fire

and personal injury.

Removal

1) Remove fuel tank from vehicle Refer to “Fuel Tank

2) Disconnect fuel feed pipe (1) and fuel return pipe (3)

from fuel pump assembly (2) referring to “Fuel Hose

Disconnecting and Reconnecting”.

3) Disconnect fuel suction hose (2) referring to “Fuel

Hose Disconnecting and Reconnecting”.

4) Remove fuel pump assembly (1) from fuel tank.

[A]. For M16 engine model

[B]. For J20 engine model

IVSY01170013-01

[A]

[B]

1

1

I5JB0A171023-01

3

1

2

I5JB0A171024-01

2

1

I5JB0A170005-01

1G-20 Fuel System:

Installation

CAUTION

!

When connecting joint, clean outside surface

of pipe where joint is to be inserted, push

joint into pipe till joint lock clicks and check

to ensure that pipes are connected securely,

or fuel leak may occur.

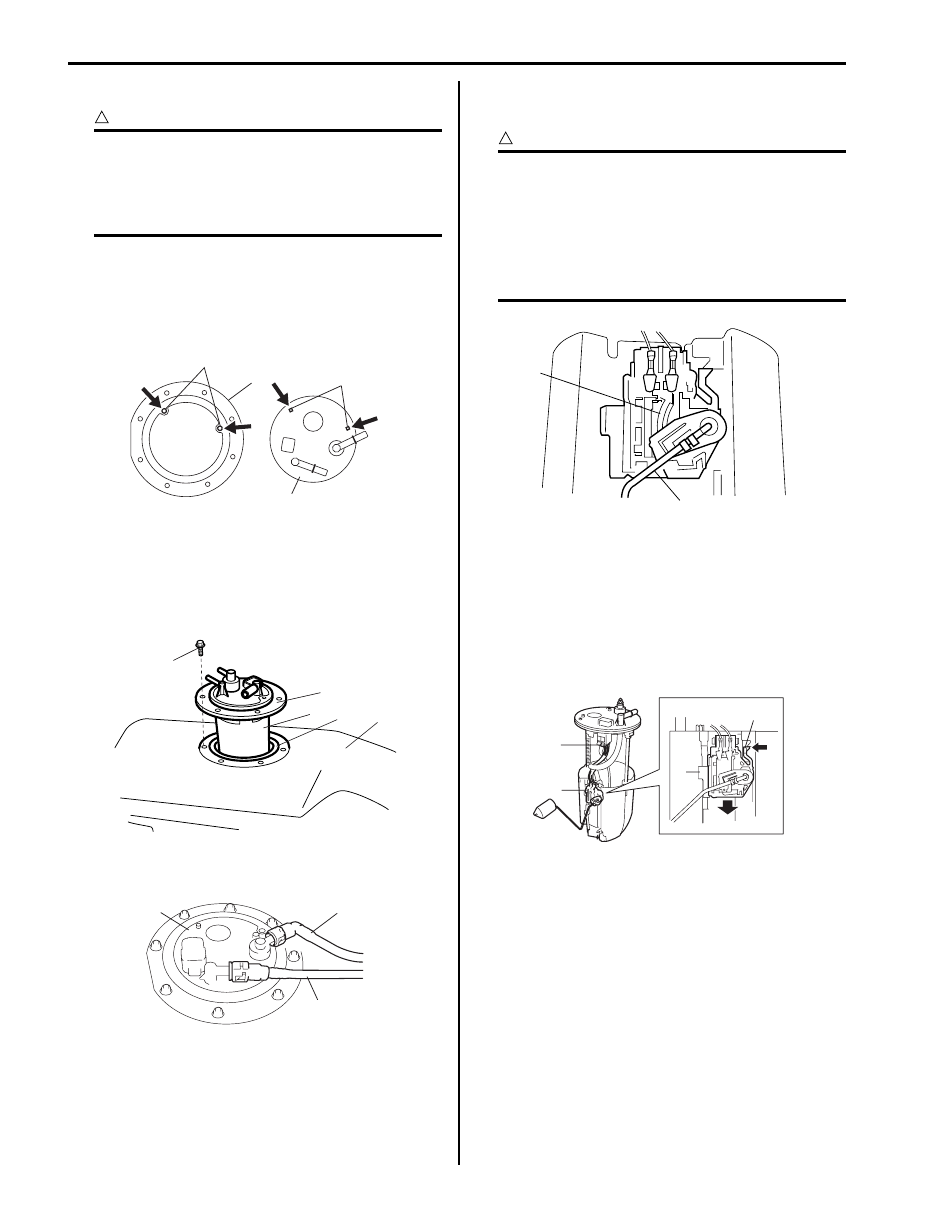

1) Clean mating surfaces of fuel pump assembly (1)

and fuel tank.

2) Put plate (2) on fuel pump assembly (1) by matching

the protrusion of fuel pump assembly (3) to plate

hole (4) as shown.

3) Install new gasket (2) and fuel pump assembly (1)

with plate (3) to fuel tank (4).

Tightening torque

Fuel pump assembly bolt (a): 11 N·m (1.1 kgf-m,

8.0 lb-ft)

4) Connect fuel feed pipe (1) (pipe joint) and fuel return

pipe (3) (pipe joint) to fuel pump assembly (2).

5) Install fuel tank to vehicle. Refer to “Fuel Tank

Main Fuel Level Sensor Removal and

Installation

S5JB0A1706022

CAUTION

!

• Do not touch resister plate (1) and deform

arm (2). It may cause main fuel level sensor

to fail.

• Be very careful not to cause damage to

fuel tube installed section (sealed section

in bore). If it be damaged, replace it with

new one, or fuel will leak from the part.

Removal

1) Remove fuel pump assembly from fuel tank referring

to “Fuel Pump Assembly Removal and Installation”.

2) Disconnect main fuel level sensor connector (3).

3) With pressing snap-fit part (2), remove main fuel

level sensor (1) by sliding it in the arrow direction as

shown in figure.

Installation

Reverse removal procedure for installation.

3

1

2

4

I5JB0A171025-01

3

1

2

(a)

4

I3RM0A170023-01

3

1

2

I5JB0A171024-01

1

2

I4RS0A170016-01

1

3

1

2

I5JB0A171026-01

Fuel System: 1G-21

Fuel Pump Inspection

S5JB0A1706021

• Check fuel pump assembly for damage.

• Check fuel suction filter for evidence of dirt and

contamination.

If present, replace or clean and check for presence of

dirt in fuel tank.

• For electrical circuit, refer to “Fuel Pressure Check in

• For inspection of main fuel level sensor (1), refer to

“Fuel Level Sensor Inspection in Section 9C”.

Sub Fuel Level Sensor Removal and Installation

S5JB0A1706026

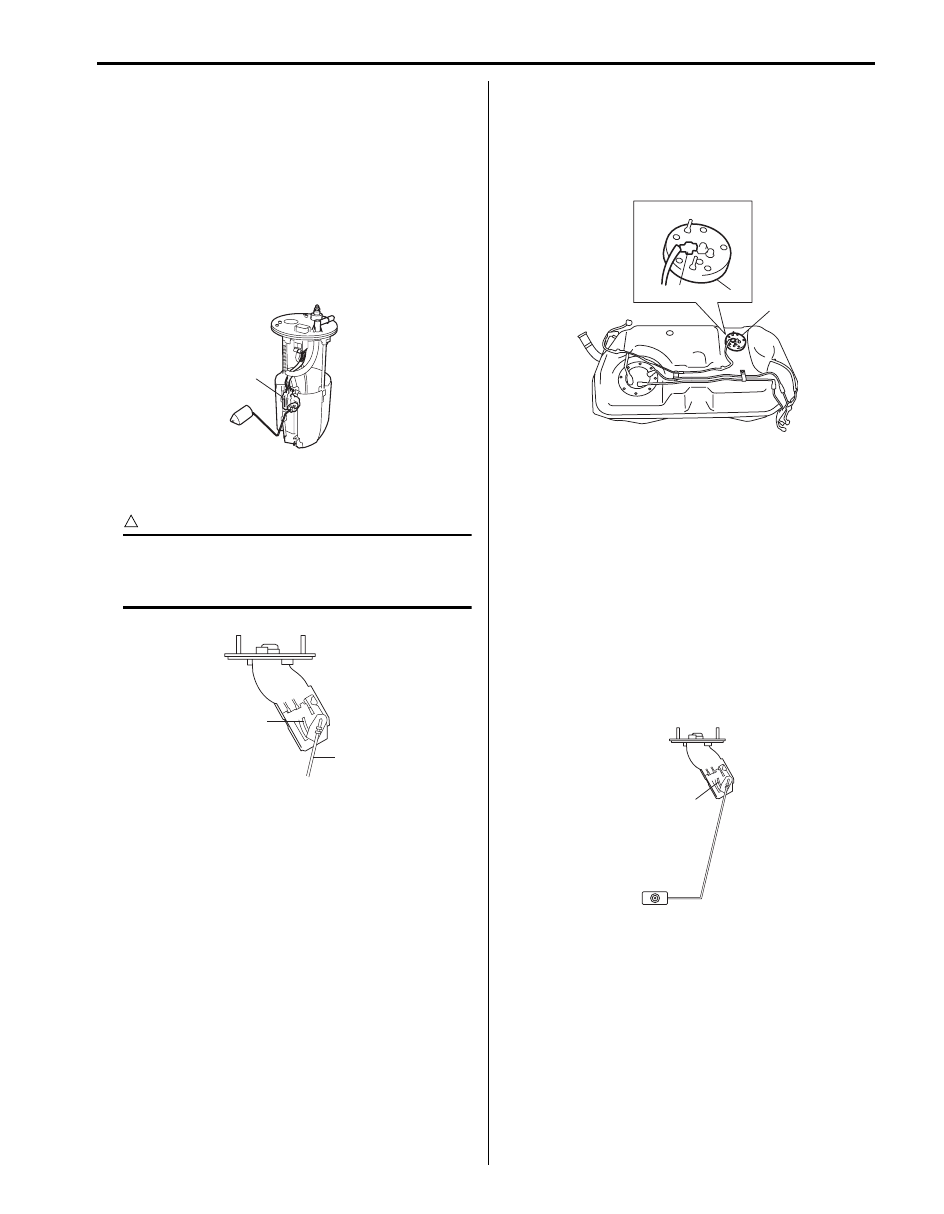

CAUTION

!

• Do not touch resister plate (1) and deform

arm (2). It may cause sub fuel level sensor

to fail.

Removal

1) Remove fuel tank from vehicle Referring to “Fuel

Tank Removal and Installation”

2) Disconnect sub fuel level sensor connector (1).

3) Remove sub fuel level sensor (2).

Installation

Reverse removal procedure for installation noting the

following.

• Replace O-ring with new one using care not to

damage it.

• Apply thin coat of fuel to O-ring, and then install sub

fuel level sensor.

Sub Fuel Level Sensor Inspection

S5JB0A1706027

• Check sub fuel level sensor for damage.

• For inspection of sub fuel sensor (1), refer to “Fuel

Level Sensor Inspection in Section 9C”

1

I5JB0A171027-01

2

1

I5JB0A171028-01

2

2

1

I5JB0A171029-01

1

I5JB0A171030-01

Нет комментариевНе стесняйтесь поделиться с нами вашим ценным мнением.

Текст