Suzuki Grand Vitara JB416 / JB420. Manual — part 238

5A-86 Automatic Transmission/Transaxle:

4) Pass and connect interlock cable as shown in the figure.

5) Pull out lock button (1) of selector side cable end (2).

6) Shift selector lever to “N” position.

7) Install cable casing cap (3) to selector bracket (4).

8) Connect cable end (1) to interlock cam (2) with

ignition switch turned to “ACC” position.

9) Drive lock button (5) in cable end until it locks cable

expansion and contraction.

10) Install steering column cover.

11) If the vehicle is equipped with air bag system,

connect negative cable at battery and enable air bag

system, referring to “Enabling Air Bag System in

Section 8B”.

I5JB0A510065-02

1-1. Interlock cable for LH steering vehicle

2-1. Key cylinder for LH steering vehicle

1-2. Interlock cable for RH steering vehicle

2-2. Key cylinder for RH steering vehicle

1

2

I5JB0A510066-01

4

5

3

2

1

I5JB0A510067-01

Automatic Transmission/Transaxle: 5A-87

Brake and key Interlock System Inspection

S5JB0A5106052

1) Check that selector lever cannot be moved to any

other range from “P” range position when ignition

switch key is at ACC position, at LOCK position or it

is removed from keyhole of ignition switch, or brake

pedal is not depressed.

2) Shift select lever to “P” range position, release knob

button and check for the following.

• Ignition key can be turned between LOCK and

ACC positions back and forth and also it can be

removed from ignition switch.

• With shift lock solenoid release button (1) pushed

and ignition key turned to ACC position, selector

lever can be shifted from “P” range position to any

other range.

• For LH steering vehicle, remove manual release

button hole cover (1). With shift lock solenoid

release button pushed by key or flat end rod and

ignition key turned to LOCK position, selector

lever can not be shifted from “P” range position to

any other range.

• For RH steering vehicle, with shift lock solenoid

release button (1) pushed and ignition key turned

to LOCK position, selector lever can not be shifted

from “P” range position to any other range.

• When ignition switch is turned ON and brake

pedal is depressed, selector lever can be shifted

from “P” range position to any other range.

3) With ignition lever shifted to any position other than

“P” range, check that ignition key cannot be turned

LOCK position and it cannot be removed from

ignition switch unless it is at LOCK position.

I5JB0A510165-01

I5JB0A510166-01

1

I5JB0A510167-01

1

I5JB0A510168-01

I5JB0A510169-01

I5JB0A510170-01

5A-88 Automatic Transmission/Transaxle:

Mode Select Switch Inspection

S5JB0A5106053

1) Pull out mode select switch from front center console

box.

2) Disconnect mode select switch connector.

3) Check continuity between mode select switch

terminals.

Mode select switch specification

Input Shaft Speed Sensor Removal and

Installation

S5JB0A5106054

Removal

1) Disconnect negative cable at battery.

2) Hoist vehicle.

3) Disconnect input shaft speed sensor connector.

4) Remove input shaft speed sensor (1) from

transmission.

Installation

1) Check that sensor is free from any metal particles

and damage.

2) Apply A/T fluid to new O-ring and then install input

shaft speed sensor (1) to transmission.

Tighten sensor bolt to specified torque.

Tightening torque

Input shaft speed sensor bolt (a): 7 N·m (0.7 kgf-

m, 5.0 lb-ft)

3) Connect input shaft speed sensor connector.

4) Lower hoist.

5) Connect negative cable at battery.

Mode select

switch

Normal position Power position

Continuity

No continuity

Continuity

A: Push

B: Push again to release

B

A

I5JB0A510042-01

1

I5JB0A510043-01

1

(a)

I5JB0A510044-01

Automatic Transmission/Transaxle: 5A-89

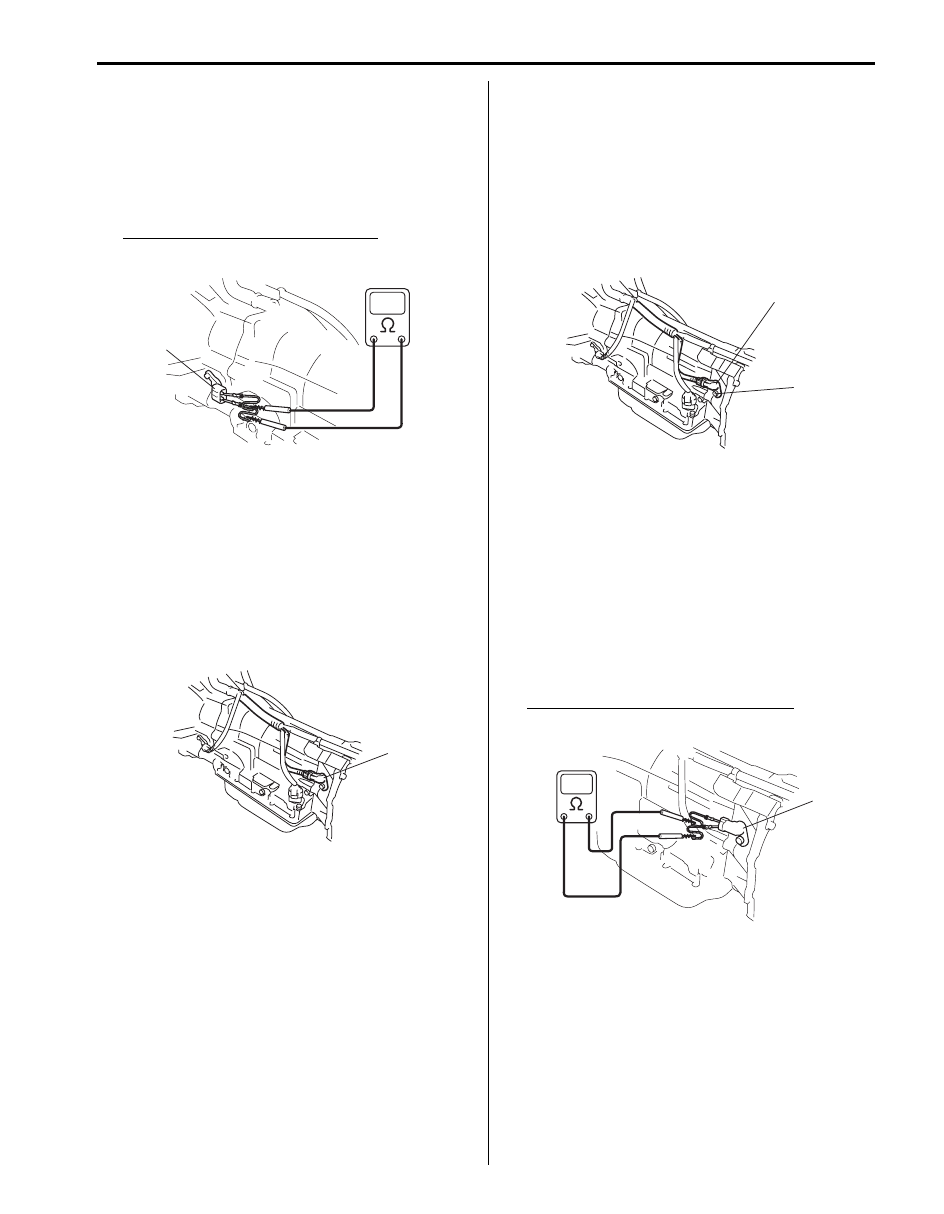

Input Shaft Speed Sensor Inspection

S5JB0A5106055

1) Disconnect negative cable at battery.

2) Hoist vehicle.

3) Disconnect input shaft speed sensor connector.

4) Check input shaft speed sensor (1) for resistance

between terminals of sensor.

Input shaft speed sensor resistance

Standard: 560 – 680

Ω (at 20 °C (68 °F))

Output Shaft Speed Sensor Removal and

Installation

S5JB0A5106056

Removal

1) Disconnect negative cable at battery.

2) Hoist vehicle.

3) Disconnect output shaft speed sensor connector.

4) Remove output shaft speed sensor (1) from

transmission.

Installation

1) Check that sensor is free from any metal particles

and damage.

2) Apply A/T fluid to new O-ring and then install output

shaft speed sensor (1) to transmission.

Tighten sensor bolt to specified torque.

Tightening torque

Output shaft speed sensor bolt (a): 7 N·m (0.7

kgf-m, 5.0 lb-ft)

3) Connect output shaft speed sensor connector.

4) Lower hoist.

5) Connect negative cable at battery.

Output Shaft Speed Sensor Inspection

S5JB0A5106057

1) Disconnect negative cable at battery.

2) Hoist vehicle.

3) Disconnect output shaft speed sensor connector.

4) Check output shaft speed sensor (1) for resistance

between terminals of sensor.

Output shaft speed sensor resistance

Standard: 560 – 680

Ω (at 20 °C (68 °F))

1

I5JB0A510045-01

1

I5JB0A510048-01

1

(a)

I5JB0A510049-01

1

I5JB0A510050-01

Нет комментариевНе стесняйтесь поделиться с нами вашим ценным мнением.

Текст