Suzuki Grand Vitara JB416 / JB420. Manual — part 38

1A-101 Engine General Information and Diagnosis:

4

ECM voltage check

1) Turn OFF ignition switch.

2) Remove ECM from its bracket with ECM connectors

connected.

3) Check for proper connection of ECM connector at “C37-

53” terminal.

4) If OK, measure voltage between “C37-53” terminal of

ECM connector and engine ground with ignition switch

turned ON.

Is voltage 4 – 6 V?

“WHT” wire is open or

high resistance circuit.

Go to Step 5.

5

Wire harness check

1) Disconnect connectors from ECM with ignition switch

turned OFF.

2) Measure resistance between “C37-53” terminal of ECM

connector and engine ground.

Is resistance infinity?

Substitute a known-

good ECM and recheck.

“WHT” wire is shorted to

ground circuit.

6

Wire harness check

1) Measure voltage between “BLK” wire terminal of electric

throttle body assembly connector and engine ground

with ignition switch turned ON.

Is voltage 4 – 6 V?

Go to Step 9.

Go to Step 7.

7

Wire harness check

1) Disconnect connectors from ECM with ignition switch

turned OFF.

2) Check for proper connection of ECM connector at “C37-

54” and “C37-41” terminals.

3) If OK, measure resistance between “GRN” and “BLK”

wire terminals of electric throttle body assembly

connector.

Is resistance infinity?

Go to Step 8.

“BLK” wire is shorted to

“GRN” wire.

8

Wire harness check

1) Measure resistance between “BLK” wire terminal of

electric throttle body assembly connector and engine

ground with ignition switch turned OFF.

Is resistance infinity?

Substitute a known-

good ECM and recheck.

“BLK” wire is shorted to

ground circuit.

9

Electric throttle body assembly check

1) Check throttle pedal position sensor referring to “Throttle

Position Sensor Performance Check” under “Electric

Throttle Body Assembly On-Vehicle Inspection in

Section 1C”.

Is output voltage within specified value?

Substitute a known-

good ECM and recheck.

Replace electric throttle

body assembly.

Step

Action

Yes

No

Engine General Information and Diagnosis: 1A-102

DTC P0123: Throttle Position Sensor (Main) Circuit High

S5JB0A1104074

Wiring Diagram

Refer to “DTC P0122: Throttle Position Sensor (Main) Circuit Low”.

DTC Detecting Condition and Trouble Area

NOTE

When DTC P0123 and P0223 are indicated together, it is possible that “WHT” wire shorted to power

circuit and/or “GRN” wire open.

DTC Confirmation Procedure

1) With ignition switch turned OFF, connect scan tool.

2) Turn ON ignition switch and clear DTC using scan tool.

3) Keep the accelerator pedal at idle position for 2 seconds.

4) Keep the accelerator pedal at fully depressed position for 2 seconds.

5) Repeat Step 3) and 4) for 3 times.

6) Check DTC.

DTC Troubleshooting

NOTE

Before this trouble shooting is performed, read the precautions for DTC troubleshooting referring to

“Precautions For DTC Troubleshooting”.

DTC detecting condition

Trouble area

Output voltage of throttle position sensor (main) is more than

specified value for specified time continuously.

(1 driving detection logic)

• Throttle position sensor (main) circuit

• Electric throttle body assembly

• ECM

Step

Action

Yes

No

1

Was “Engine and Emission Control System Check”

performed?

Go to Step 2.

Go to “Engine and

Emission Control

System Check”.

2

Throttle position sensor and its circuit check

1) Connect scan tool to DLC with ignition switch turned

OFF.

2) Turn ON ignition switch, check “TP Sensor 1 Volt”

displayed on scan tool when accelerator pedal is idle

position and fully depressed.

Is displayed TP sensor value as described voltage in “Scan

Tool Data”?

Intermittent trouble.

Check for intermittent

referring to “Intermittent

and Poor Connection

Inspection in Section

00”.

Go to Step 3.

1A-103 Engine General Information and Diagnosis:

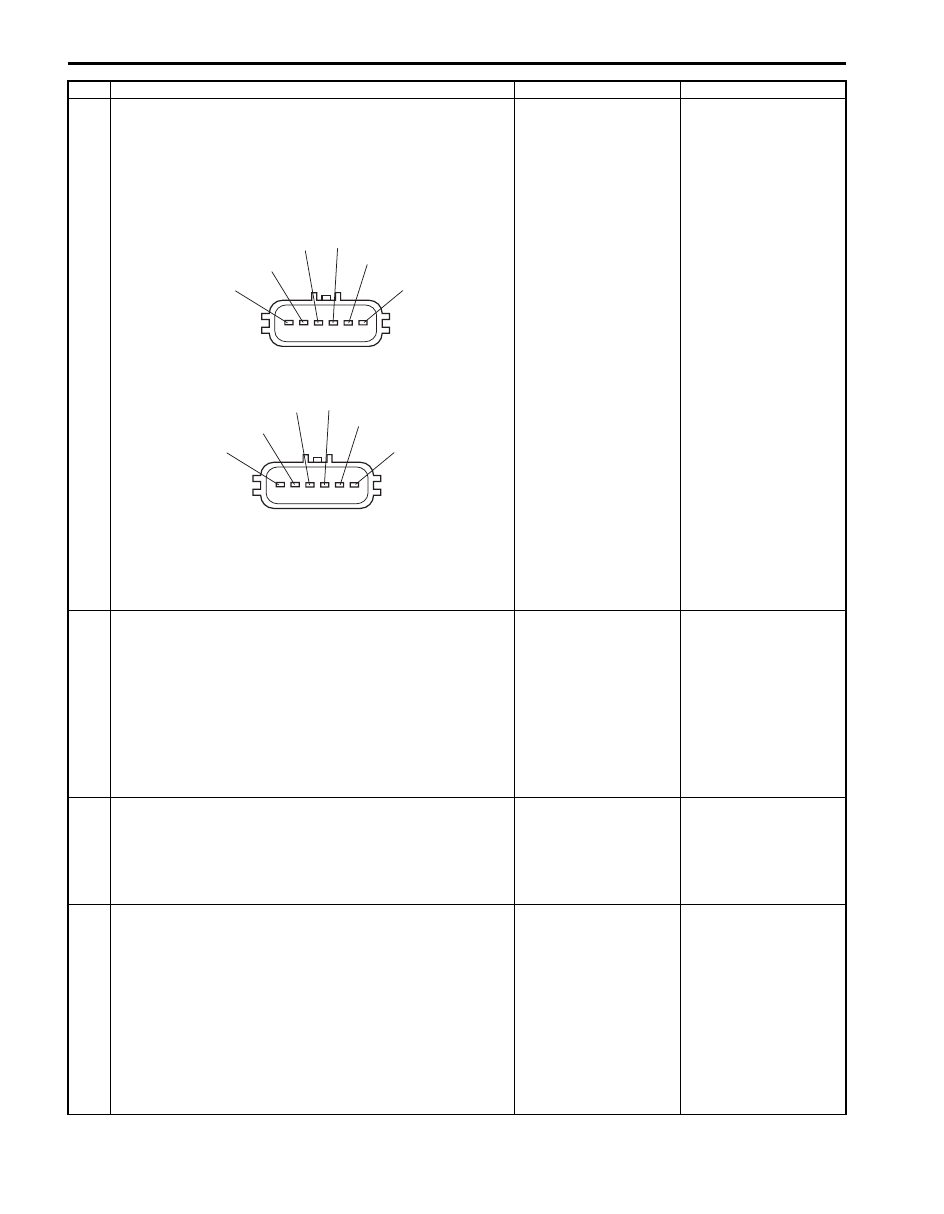

3

ECM voltage check

1) Disconnect connector from electric throttle body

assembly with ignition switch turned OFF.

2) Check for proper connection to electric throttle body

assembly at “WHT”, “GRN” and “BLK” wire terminals.

For J20 engine

For M16 engine

3) If OK, measure voltage between “WHT” wire terminal of

electric throttle body assembly connector and engine

ground with ignition switch turned ON.

Is voltage 4 – 6 V?

Go to Step 5.

Go to Step 4.

4

Wire harness check

1) Disconnect connectors from ECM with ignition switch

turned OFF.

2) Check for proper connection of ECM connector at “C37-

53” terminal.

3) Measure voltage between “C37-53” terminal of ECM

connector and engine ground with ignition switch turned

ON.

Is voltage 0 V?

Substitute a known-

good ECM and recheck.

“WHT” wire is shorted

to power circuit.

5

Wire harness check

1) Measure voltage between “BLK” wire terminal of electric

throttle body assembly connector and engine ground

with ignition switch turned ON.

Is voltage 4 – 6 V?

Go to Step 9.

Go to Step 6.

6

Wire harness check

1) Turn OFF ignition switch.

2) Remove ECM from its bracket with ECM connectors

connected.

3) Check for proper connection of ECM connector at “C37-

53” and “C37-54” terminals.

4) If OK, measure voltage between “C37-54” terminal of

ECM connector and engine ground with ignition switch

turned ON.

Is voltage 4 – 6 V?

“BLK” wire is open or

high resistance circuit.

Go to Step 7.

Step

Action

Yes

No

"BLK"

"WHT"

"RED"

"GRN"

"BLU/YEL"

"BLU/RED"

I5JB0A110042-01

"BLU/RED"

"BLU/YEL"

"GRN"

"RED"

"WHT"

"BLK"

I5JB0A110043-01

Engine General Information and Diagnosis: 1A-104

7

Wire harness check

1) Disconnect connectors from ECM with ignition switch

turned OFF.

2) Measure resistance between “BLK” and “WHT” wire

terminals of electric throttle body assembly connector.

Is resistance infinity?

Go to Step 8.

“BLK” wire is shorted to

“WHT” wire.

8

Wire harness check

1) Turn ON ignition switch.

2) Measure voltage between “C37-54” terminal of ECM

connector and engine ground.

Is voltage 0 V?

Substitute a known-

good ECM and recheck.

“BLK” wire is shorted to

power circuit.

9

Ground circuit check

1) Turn OFF ignition switch.

2) Measure resistance between “GRN” wire terminal of

electric throttle body assembly connector and engine

ground.

Is resistance below 5

Ω

?

Go to Step 11.

Go to Step 10.

10 Ground circuit check

1) Remove ECM from its bracket with ECM connectors

connected.

2) Check for proper connection of ECM connector at “C37-

41” terminal.

3) Measure resistance between “C37-41” terminal of ECM

connector and engine ground with ignition switch turned

OFF.

Is resistance below 5

Ω

?

“GRN” wire is open or

high resistance circuit.

Faulty ECM ground

circuit. If circuit is OK,

substitute a known-

good ECM and recheck.

11 Electric throttle body assembly check

1) Check throttle pedal position sensor referring to “Throttle

Position Sensor Performance Check” under “Electric

Throttle Body Assembly On-Vehicle Inspection in

Section 1C”.

Is output voltage within specified value?

Substitute a known-

good ECM and recheck.

Replace electric throttle

body assembly.

Step

Action

Yes

No

Нет комментариевНе стесняйтесь поделиться с нами вашим ценным мнением.

Текст