Suzuki Grand Vitara JB416 / JB420. Manual — part 223

5A-26 Automatic Transmission/Transaxle:

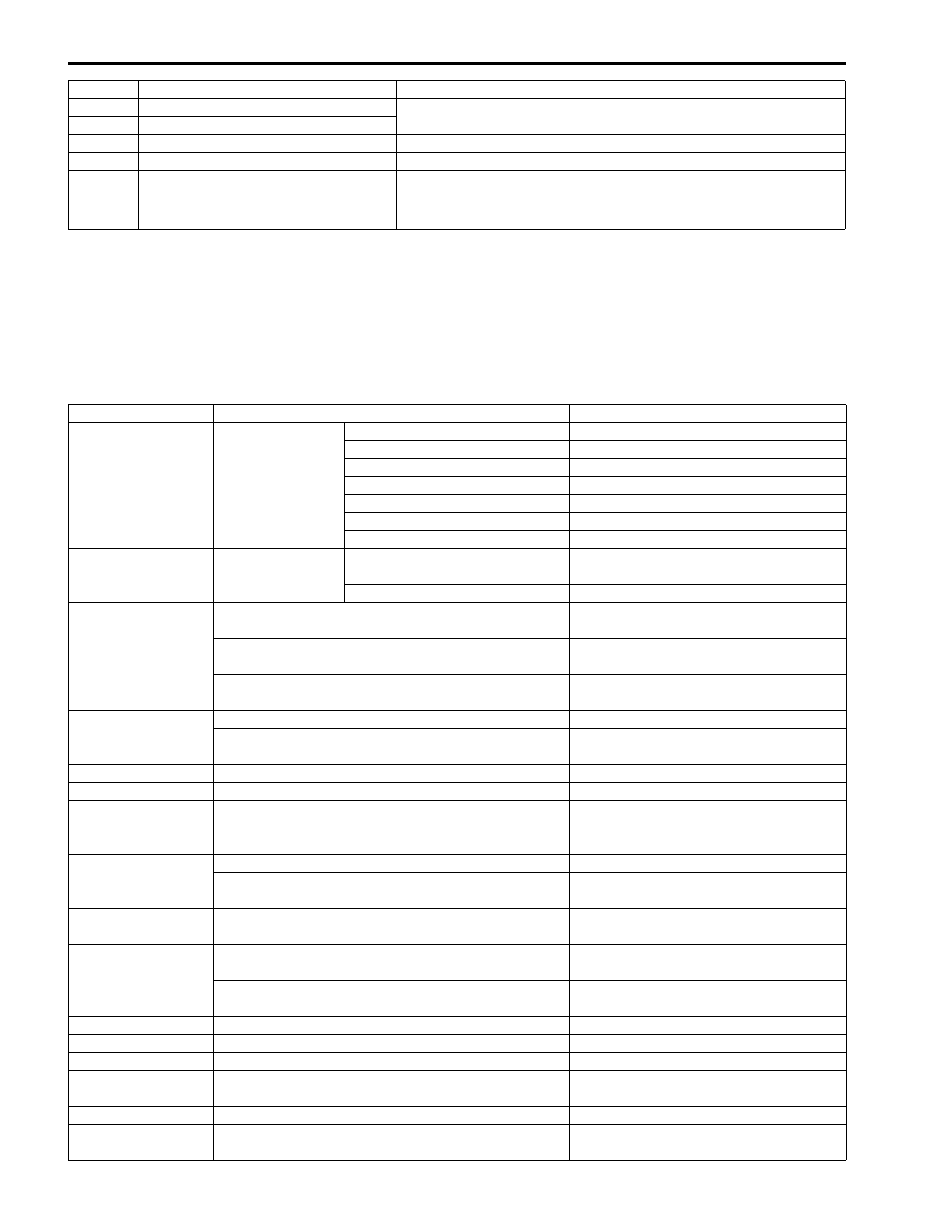

Scan Tool Data

S5JB0A5104009

As the data values given in the following table are standard values estimated on the basis of values obtained from the

normally operating vehicles by using a scan tool, use them as reference value. Even when the vehicle is in good

condition, there may be cases where the checked value does not fall within each specified data range. Therefore,

judgment as abnormal should not be made by checking with these data alone.

Also, condition in the following table that can be checked by the scan tool are those detected by TCM and output from

TCM as commands and there may be cases where the automatic transmission or actuator is not operating (in the

condition) as indicated by the scan tool.

P1874 4L switch circuit malfunction (Short)

Slip controlled lock-up function is inhibited to operate.

P1875 4L switch circuit malfunction (Open)

P1878 Torque Converter Clutch Shudder

Slip controlled lock-up function is inhibited to operate.

P2763 Torque Converter Clutch Circuit High Power supply for TCC pressure control solenoid is cut.

P2764

Torque Converter Clutch Circuit Low

• Lock-up function is inhibited to operate.

• When vehicle speed is less than 10 km/h (6 mile/h), gear

position is fixed in 1st gear for prevention of engine stall.

Scan Tool Data

Vehicle Condition

Normal Condition / Reference Values

Gear Position

Ignition switch ON

POWER mode

OFF

Select lever is in “P” position

P/N

Select lever is in “R” position

R

Select lever is in “N” position

P/N

Select lever is in “D” position

1st

Select lever is in “3” position

1st

Select lever is in “2” position

1st

Select lever is in “L” position

1st

Throttle Position

Ignition switch ON Accelerator pedal is depressed

0 – 100% (varies depending on

depressed value)

Accelerator pedal is released

0 – 5%

Input Shaft Rev

At engine idle speed and selector lever is in “P”

position

(Engine idle speed is displayed in

increments of 50 rpm)

At 40 km/h (25 mile/h) constant speed, 20% or less

throttle opening and 3rd gear (“3” range)

2300 RPM

(displayed in increments of 50 rpm)

At 60 km/h (37.5 mile/h) constant speed, 20% or less

throttle opening and 4th gear (“D” range)

0 RPM

Output Shaft Rev

At vehicle stop

0 RPM

At 40 km/h (25 mile/h) constant speed, 20% or less

throttle opening and 3rd gear (“3” range)

2300 RPM

(displayed in increments of 50 rpm)

Vehicle Speed 1

At vehicle stop

0 km/h, 0 MPH

Battery Voltage

Ignition switch ON and engine stop

Battery voltage is displayed (8 – 16 V)

ATF Temp

After driving at 60 km/h (37.5 mile/h) for 15 minutes

or more, and A/T fluid temperature around sensor

reaches 70 – 80

°C (158 – 176 °F)

70 – 80 °C (158 – 176 °F)

TCC Sol Duty

At vehicle stop, closed throttle and 1st gear

0%

At 80 km/h (50 mile/h) constant speed, 30% or less

throttle opening and 3th gear. (“3” range)

100%

Press Cont Sol

At vehicle stop, closed throttle, engine idle speed and

1st gear

9.5%

Slip RPM

Engine running at idle speed and selector lever is in

“P” range

0

±25 RPM

Engine running, vehicle stop and selector lever is in

“D” range

Engine speed is displayed

Vehicle Speed 2

At vehicle stop

0 km/h, 0 MPH

Engine Speed

At engine idle speed

Engine idle speed is displayed

Coolant Temp

Ignition switch ON

Engine coolant temperature is displayed

Target Engine

Torque

Ignition switch ON

0 N

⋅m

Engine Torque

Ignition switch ON

0 N

⋅m

MIL request (for E-

OBD)

Ignition switch ON

OFF

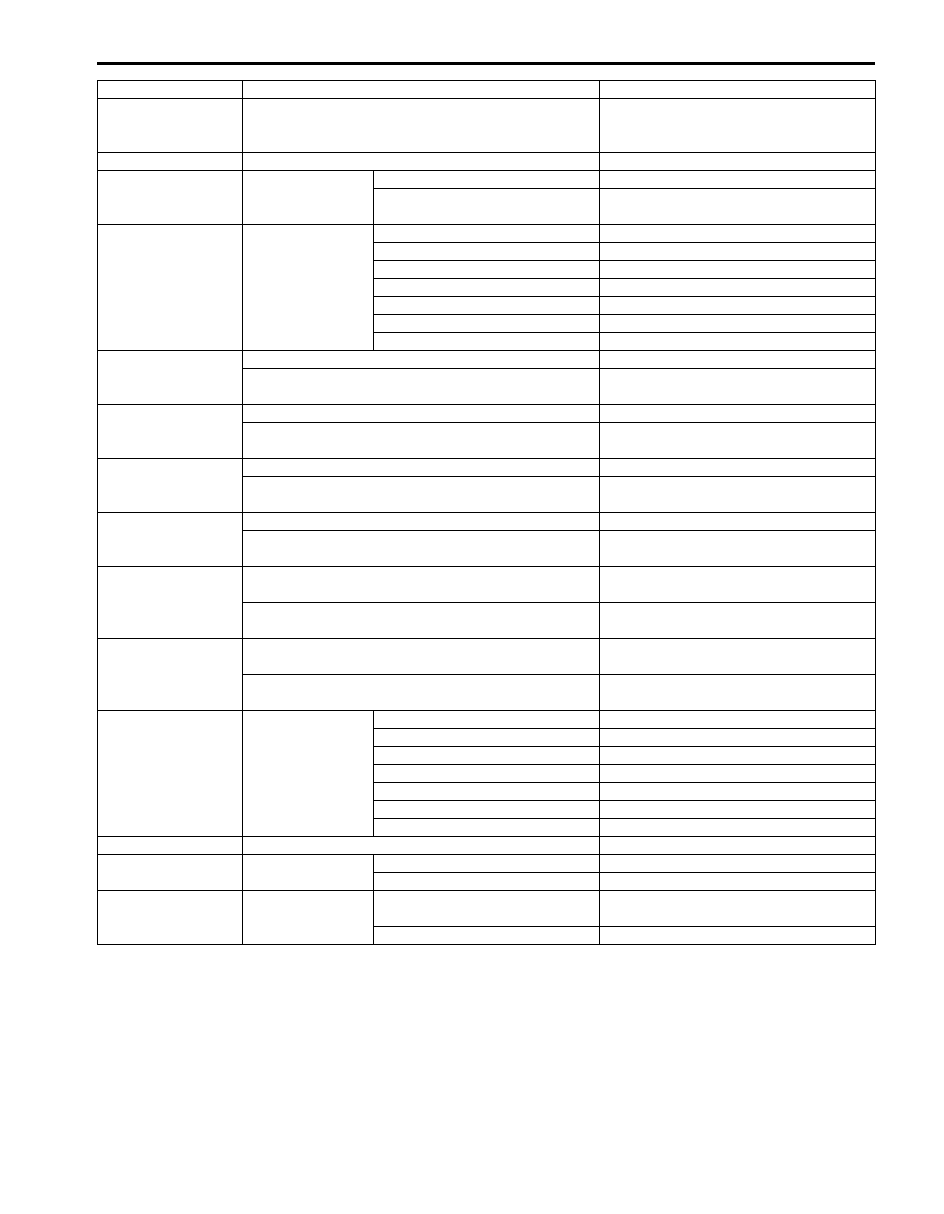

DTC No.

Trouble Area

Fail Safe Operation

Automatic Transmission/Transaxle: 5A-27

Malfunction

Indication On (for

Non E-OBD)

Ignition switch ON

OFF

Fuel Cut Flag

Ignition switch ON

OFF

O/D Off Switch

Ignition switch ON Shift selector lever to “3” range

ON

Shift selector lever to other

above range

OFF

Trans Range

Ignition switch ON Select lever is in “P” position

P

Select lever is in “R” position

R

Select lever is in “N” position

N

Select lever is in “D” position

D

Select lever is in “3” position

D

Select lever is in “2” position

2

Select lever is in “L” position

L

Shift Sol A Con

At vehicle stop, closed throttle and 1st gear

ON

At 60 km/h (37.5 mile/h) constant speed, 20% or less

throttle opening and 3rd gear

OFF

Shift Sol A Mon

At vehicle stop, closed throttle and 1st gear

ON

At 60 km/h (37.5 mile/h) constant speed, 20% or less

throttle opening and 3rd gear

OFF

Shift Sol B Con

At vehicle stop, closed throttle and 1st gear

OFF

At 20 km/h (12.5 mile/h) constant speed, 20% or less

throttle opening and 2nd gear

ON

Shift Sol B Mon

At vehicle stop, closed throttle and 1st gear

OFF

At 20 km/h (12.5 mile/h) constant speed, 20% or less

throttle opening and 2nd gear

ON

Mode Select Switch Ignition switch ON, P/N mode switch is at Normal

position

NORMAL

Ignition switch ON, P/N mode switch is at Power

position

POWER

4WD Low Switch

Ignition switch ON, transfer position switch is “4H”

position

OFF

Ignition switch ON, transfer position switch is “4L”

position

ON

D Range Signal

Ignition switch ON Select lever is in “P” position

P/N range

Select lever is in “R” position

D range

Select lever is in “N” position

P/N range

Select lever is in “D” position

D range

Select lever is in “3” position

D range

Select lever is in “2” position

D range

Select lever is in “L” position

D range

A/C Switch

Ignition switch ON and air conditioner switch OFF

Cancel

Brake Switch

Ignition switch ON Brake pedal is depressed

ON

Brake pedal is released

OFF

Accel Actual Pos

Ignition switch ON Accelerator pedal is depressed

0 – 100% (varies depending on

depressed value)

Accelerator pedal is released

0%

Scan Tool Data

Vehicle Condition

Normal Condition / Reference Values

5A-28 Automatic Transmission/Transaxle:

Scan Tool Data Definitions

Gear Position (1

ST

, 2

ND

, 3

RD

, 4

TH

, N, R): This

parameter is indicated actual gear position.

Throttle Position (%): Throttle valve opening ratio sent

from ECM on CAN communication line.

Input Shaft Rev (RMP): Input shaft revolution

computed by reference pulses coming from input

shaft speed sensor on transmission case.

Output Shaft Rev (RMP): Output shaft revolution

computed by reference pulses coming from output

shaft speed sensor on transmission case.

Vehicle Speed 1 (Km/h): This parameter is competed

by output shaft speed sensor and 4WD low switch on

TCM. Gear shift schedule relate this parameter.

Battery Voltage (V): Battery voltage read by TCM as

analog input signal by TCM.

ATF Temp (

°C): ATF temperature detected by signal

from transmission fluid temperature sensor installed

in valve body.

TCC Sol Duty (%): Electric current value ration

between electric current value being outputted from

TCM to TCC pressure control solenoid and

maximum value can be outputted by TCM.

Press Cont Sol (%): Electric current value ratio

between electric current value being outputted from

TCM to pressure control solenoid-A and maximum

value can be outputted by TCM.

Slip RPM (RMP): This parameter indicates slipping

rotation in the torque converter (difference between

input shaft rotation and engine rotation).

Vehicle Speed 2 (Km/h): Actual vehicle speed

detected by signal on CAN communication line fed

from ECM.

Engine Speed (RPM): Engine speed computed by

signal on CAN communication line fed from ECM.

Coolant Temp (

°C): Engine coolant temperature

detected by signal on CAN communication line fed

from ECM.

Target Engine Torque (N

⋅m): Target engine torque

detected by signal on CAN communication line fed

from ECM.

Engine Torque (N

⋅m): Actual engine torque detected

by signal on CAN communication line fed from ECM.

MIL Request (ON, OFF) (for E-OBD model): ON:

Signal which TCM requires combination meter to

turn ON malfunction indicator lamp.

OFF: Signal which TCM does not require

combination meter to turn ON malfunction indicator

lamp.

Malfunction Indication On (ON, OFF) (for non E-OBD

model): ON: Signal which TCM requires

combination meter to turn ON transmission warning

lamp.

OFF: Signal which TCM does not require

combination meter to turn ON transmission warning

lamp.

Fuel Cut Flag: ON: Signal which inform that fuel cut is

operating.

OFF: Signal which inform that fuel cut is not

operating.

O/D Off Switch (ON, OFF): Inputted signal from “3”

position switch in selector lever assembly.

ON: Shift selector lever to “3” range

OFF: Shift selector lever to other above range

Trans Range (P, R, N, D, 2, L): It indicates

transmission range according to transmission range

switch signal.

Shift Sol A Con/ MON (ON, OFF): COM-ON: ON

command being outputted to shift solenoid-A.

COM-OFF: OFF command not being outputted to

shift solenoid-A.

MON-ON: Electricity being passed to shift solenoid-

A.

MON-OFF: Electricity not being passed to shift

solenoid-A.

Shift Sol B Con / MON (ON, OFF): COM-ON: ON

command being outputted to shift solenoid-B.

COM-OFF: OFF command not being outputted to

shift solenoid-B.

MON-ON: Electricity being passed to shift solenoid-

B.

MON-OFF: Electricity not being passed to shift

solenoid-B.

Mode Select Switch (NORMAL, POWER): Inputted

signal from P/N mode switch on center console.

NORMAL: P/N mode switch is at OFF position.

POWER: P/N mode switch is at ON position.

4WD Low Switch (ON, OFF): Inputted signal from 4L/

N switch on transfer case.

ON: Transfer gear position is 4L

OFF: Transfer gear position is 4H

D RANGE SIGNAL (P/N range, D range): ON: Signal

which TCM require ECM to increase idle speed

OFF: Signal which TCM does not require ECM to

increase idle speed

A/C Switch (ON, OFF): ON: Signal which inform that

air conditioner compressor is turned ON.

OFF: Signal which inform that air conditioner

compressor is turned OFF.

Brake Switch (ON, OFF): Brake light switch position

detected by signal on CAN communication line fed

from ECM.

ON: Brake pedal depressed

OFF: Brake pedal released

Accel Actual Pos (%): Accelerator pedal opening ratio

detected by signal on CAN communication line fed

from ECM.

Automatic Transmission/Transaxle: 5A-29

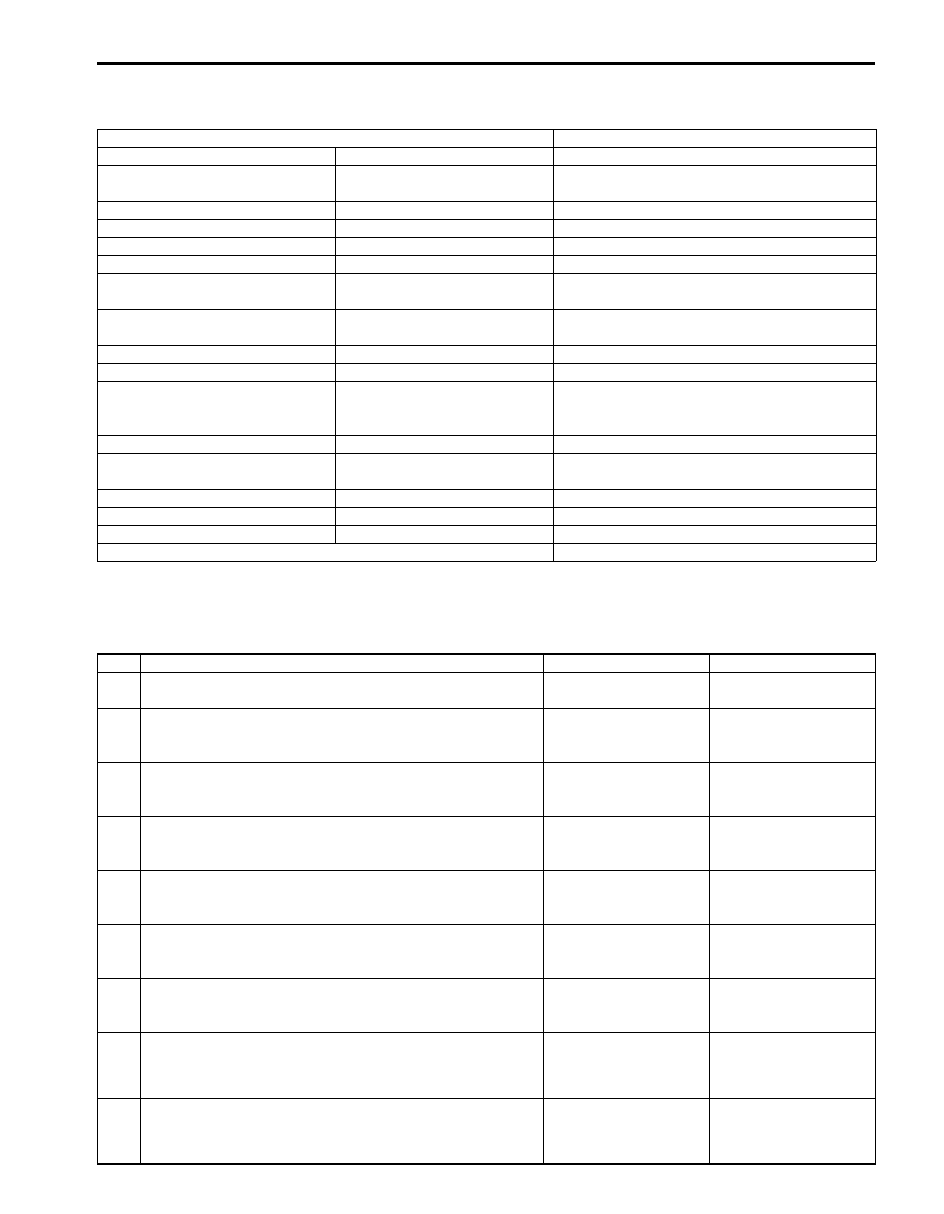

Visual Inspection

S5JB0A5104010

Visually check the following parts and systems.

A/T Basic Check

S5JB0A5104011

This check is important for troubleshooting when TCM has detected no DTC and no abnormality has been noted in

visual inspection. Follow the flow table carefully.

Inspection Item

Referring

A/T fluid

Level, leakage, color

A/T fluid hoses

Disconnection, looseness,

deterioration

“Oil Cooler Hose and Pipe Components”

A/T select cable

Installation, operation

Engine oil

Level, leakage

“Engine Oil and Filter Change in Section 0B”

Engine coolant

Level, leakage

“Engine Coolant Change in Section 0B”

Battery

Fluid level, corrosion of terminal

Connectors of electric wire harness Disconnection friction

“Intermittent and Poor Connection Inspection in

Section 00”

Fuses

Burning

“Cautions in Body Electrical System Servicing in

Section 9A”

Parts

Installation, damage

Bolt

Looseness

Transmission warning light

Operation at engine start

“Transmission Warning Light Operation Check

(Vehicle is Equipped with Engine Diagnosis

Connector)”

“POWER” lamp

Operation at engine start

““POWER” Lamp Operation Check”

Malfunction indicator lamp

Operation at engine start

“Malfunction Indicator Lamp (MIL) Check in

Section 1A”

Charge warning lamp

Operation at engine start

“Generator Symptom Diagnosis in Section 1J”

Engine oil pressure warning lamp

Operation at engine start

“Oil Pressure Switch Inspection in Section 9C”

Engine coolant temp. meter

Operation at engine start

Other parts that can be checked visually

Step

Action

Yes

No

1

Was “A/T System Check” performed?

Go to Step 2.

Go to “A/T System

Check”.

2

Perform “Road Test”

Is it OK?

Go to Step 3.

Proceed to

“Troubleshooting” in

“Road Test”.

3

Perform “Manual Road Test”

Is it OK?

Go to Step 4.

Proceed to

“Troubleshooting” in

“Manual Road Test”.

4

Perform “Engine Brake Test”

Is it OK?

Go to Step 5.

Proceed to

“Troubleshooting” in

“Engine Brake Test”.

5

Perform “Stall Test”

Is it OK?

Go to Step 6.

Proceed to

“Troubleshooting” in

“Stall Test”.

6

Perform “Time Lag Test”

Is it OK?

Go to Step 7.

Proceed to

“Troubleshooting” in

“Time Lag Test”.

7

Perform “Line Pressure Test”

Is it OK?

Go to Step 8.

Proceed to

“Troubleshooting” in

“Line Pressure Test”.

8

1) Proceed to “Trouble Diagnosis 1” in “A/T Symptom

Is trouble identified?

Repair or replace faulty

parts.

Go to Step 9.

9

1) Proceed to “Trouble Diagnosis 2” in “A/T Symptom

Is trouble identified?

Repair or replace faulty

parts.

Proceed to “Trouble

Diagnosis 3” in “A/T

Symptom Diagnosis”.

Нет комментариевНе стесняйтесь поделиться с нами вашим ценным мнением.

Текст