Suzuki Grand Vitara JB416 / JB420. Manual — part 278

7B-3 Air Conditioning System:

• Never use heat for bending pipes. When bending a pipe, try to make its bending radius as slight as possible.

• Keep internal parts of air conditioning free from moisture and dirt. When disconnecting any line from system, install

a blind plug or cap to the fitting immediately.

• When tightening or loosening a fitting, use two wrenches, one for turning and the other for support.

• Tighten bolts to specified torque.

Tightening torque

Refrigerant line bolt: 12 N·m (1.2 kgf-m, 9.0 lb-ft)

• Route drain hose so that drained water does not make any contact to vehicle components.

Precautions on Refrigerant Recovery

S5JB0A7200009

When discharging refrigerant out of A/C system, always

recover it by using refrigerant recovery and recycling

equipment. Discharging refrigerant HFC-134a (R-134a)

into atmosphere would cause adverse effect to

environments.

NOTE

When handling recovery and recycling

equipment, be sure to follow the instruction

manual for the equipment.

Precautions on Refrigerant Charge

S5JB0A7200010

Charge a proper amount of refrigerant to A/C system

according to charging procedure described in recovery,

evacuation and charging. Refer to “Charge” in

“Operation Procedure for Charging A/C with

Refrigerant”.

Precautions on Replenishing Compressor Oil

S5JB0A7200011

When replacing air conditioning parts with new ones, it is

necessary to replenish oil by the amount supposedly

remaining in each part.

When Charging Refrigerant Only

When charging refrigerant without replacing any

component, replenish the same amount of measured oil

when recovering refrigerant (if not measure, replenish 20

cm

3

(20 cc) oil).

When Replacing Compressor

CAUTION

!

Be sure to use specified compressor oil or an

equivalent compressor oil.

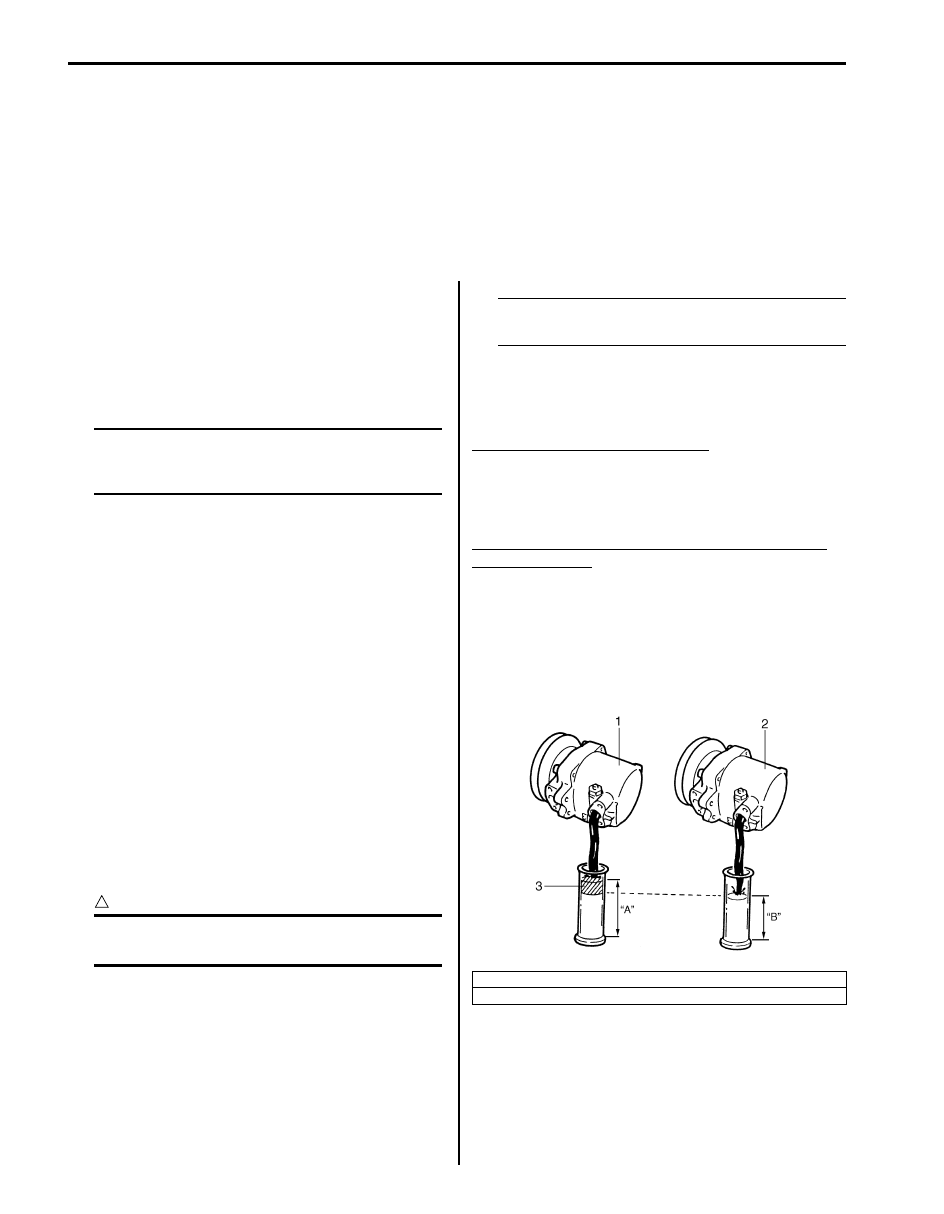

Compressor oil is sealed in each new compressor (1) by

the amount required for air conditioner cycle. Therefore,

when using a new compressor for replacement, drain oil

from it by the amount calculated as follows.

“C” = “A” – “B”

“C”: Amount of oil to be drained

“A”: Amount of oil sealed in a new compressor

“B”: Amount of oil remaining in removed

compressor

NOTE

Compressor assembly supplied from factory

is filled up with the following amount of oil.

: Compressor oil 99000–99015–00A

(MATSUSHITADENKI GU10) (M16 engine model)

: Compressor oil 99000–99022–00E (Compressor oil

(DH-PS, 250cc)) (J20 engine model)

Amount of oil in new compressor

M16 engine model: 120 (+10, –0) cm

3

(120 (+10, –0)

cc)

J20 engine model: 150 (+20, –0) cm

3

(150 (+20, –0)

cc)

Amount of compressor oil to be replenished after

part replacement

Evaporator: 50 cm

3

(50 cc)

Condenser for M16 engine model: 30 cm

3

(30 cc)

Condenser for J20 engine model: 30 cm

3

(30 cc)

Receiver/dryer for M16 engine model: 10 cm

3

(10 cc)

Receiver/dryer for J20 engine model: 10 cm

3

(10 cc)

Hoses: 10 cm

3

(10 cc)

Pipes: 10 cm

3

(10 cc)

2. Removed compressor

3. Excess oil (A – B)

I5JB0A720003-01

Air Conditioning System: 7B-4

Precautions on Servicing Compressor Assembly

S5JB0A7200002

CAUTION

!

• None of refrigerant, compressor oil and component parts is interchangeable between two types of

A/C: one using CFC-12 (R-12) and the other using HFC-134a (R-134a).

For identification between these two types, refer to “A/C Refrigerant Type Description”.

When replenishing or changing refrigerant and compressor oil and when replacing parts, make sure

that the material or the part to be used is appropriate to the A/C installed in the vehicle being

serviced. Use of incorrect refrigerant or compressor oil will result in leakage of refrigerant, damage

in parts or other faulty condition.

• When servicing the compressor, keep dirt or foreign material away from getting on or into the

compressor parts and system. Clean tools and a clean work area are important for proper service.

The compressor connection and the outside of the compressor should be cleaned before any “On-

vehicle” repair or before removal of the compressor. The parts must be kept clean at all times and

any parts to be reassembled should be cleaned with trichloromethane, naphtha, kerosene or

equivalent solvent and dried with dry air. Use only lint free cloths to wipe parts.

• When compressor is removed from the vehicle for servicing, the oil remaining in the compressor

should be discarded and new refrigerant oil added to the compressor.

Minor repair procedures may be done on the vehicle without discharging the system. Major repair

procedures require that the system be discharged of refrigerant.

General Description

AUTO A/C System Description

S5JB0A7201004

The automatic air conditioning system (auto A/C), HVAC

control module automatically controls inside air

temperature, blower speed, airflow outlet and so forth.

Once users set up desired inside air temperature with

the temperature control selector, select “AUTO” position

of blower speed selector and push auto A/C switch,

HVAC control module detects inside air temperature,

outside air temperature, amount of sunlight, and engine

coolant temperature by means of inside air temperature

sensor, outside air temperature sensor, sunload sensor,

and engine coolant temperature (ECT) sensor

respectively.

Then, HVAC control module keeps desired in-car

temperature at any time.

Then, HVAC control module keeps in-car temperature at

desired level and auto A/C indicator lamp of HVAC

control module turns on.

HVAC Control System Description

S5JB0A7201005

For CAN communication system, refer to description on

“CAN Communication System Description in Section

1A”.

When following data are sent from control modules to

BCM through CAN communication, they are sent from

BCM to HVAC control module through serial

communication line.

• Engine coolant temperature

• Engine speed

• A/C refrigerant pressure

• Vehicle Speed (wheel speed)

• Outside air temperature

Based on above data, HVAC control module sends A/C

compressor ON / OFF request signal to BCM through

serial communication line.

BCM sends this signal through CAN communication to

ECM which then causes compressor relay to turn ON /

OFF.

For more information on signal transmission and

reception of Auto A/C system, refer to “Auto A/C

Electronic Control Input / Output Diagram”.

HVAC control module has a function to make initial

settings of temperature control actuator, air intake

actuator and air flow actuator.

Initial settings of actuators are automatically made when

engine is started for the first time after battery is

connected.

When initial settings are made, each actuator is forced to

operate for about 15 seconds continuously.

7B-5 Air Conditioning System:

HVAC Control Module Operation Description

S5JB0A7201007

Temperature Control

HVAC control module calculates the target temperature

control door position based on signals from the

temperature selector, inside air temperature sensor,

outside air temperature sensor and sunload sensor and

controls the temperature control actuator so that the

current position of the temperature control door matches

its target position.

Fan Speed Control

HVAC control module calculates the target blower fan

speed based on signals from the temperature selector,

inside air temperature sensor, outside air temperature

sensor and sunload sensor, compares it with the current

blower fan speed inputted from the blower motor

controller to control the current blower fan speed to the

target level.

Air Flow Outlet Control

HVAC control module calculates the target temperature

control door position based on signals from the

temperature selector, inside air temperature sensor,

outside air temperature sensor and sunload sensor.

Using thus obtained target temperature control door

position, it further calculates the target air flow control

door position and controls the air flow control actuator so

that the current air flow control door position becomes

the target position.

Air Intake Position Control

HVAC control module determines the air intake position

based on signals from the temperature selector, inside

air temperature sensor, outside air temperature sensor

and sunload sensor and controls the air intake actuator.

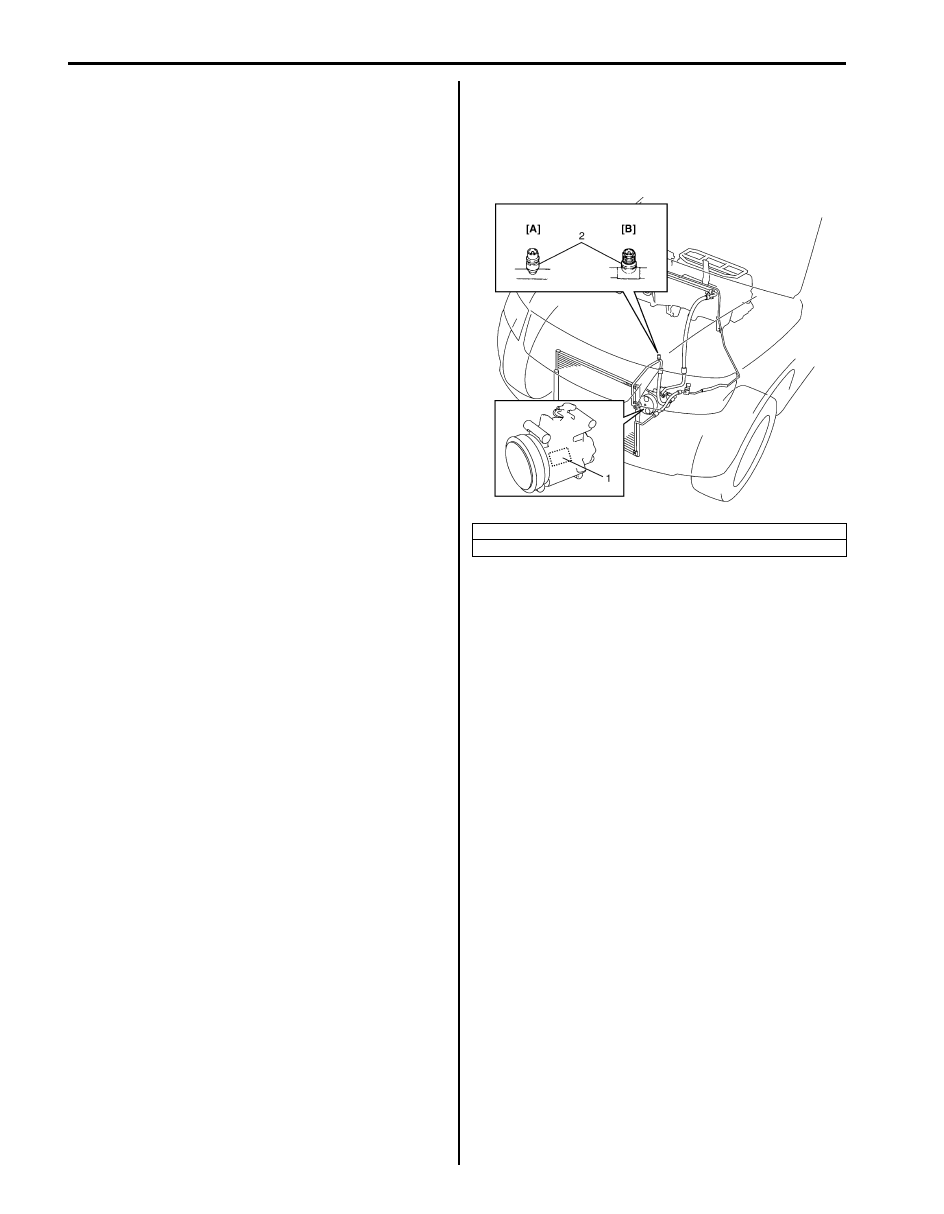

A/C Refrigerant Type Description

S5JB0A7201001

Whether the A/C in the vehicle being serviced uses

HFC-134a (R-134a) or CFC-12 (R-12) is indicated on

LABEL (1) on the compressor. Also, it can be checked

by the shape of the service (charge) valve (2).

[A]: HFC-134a (R-134a)

[B]: CFC-12 (R-12)

I5JB0A720005-01

Air Conditioning System: 7B-6

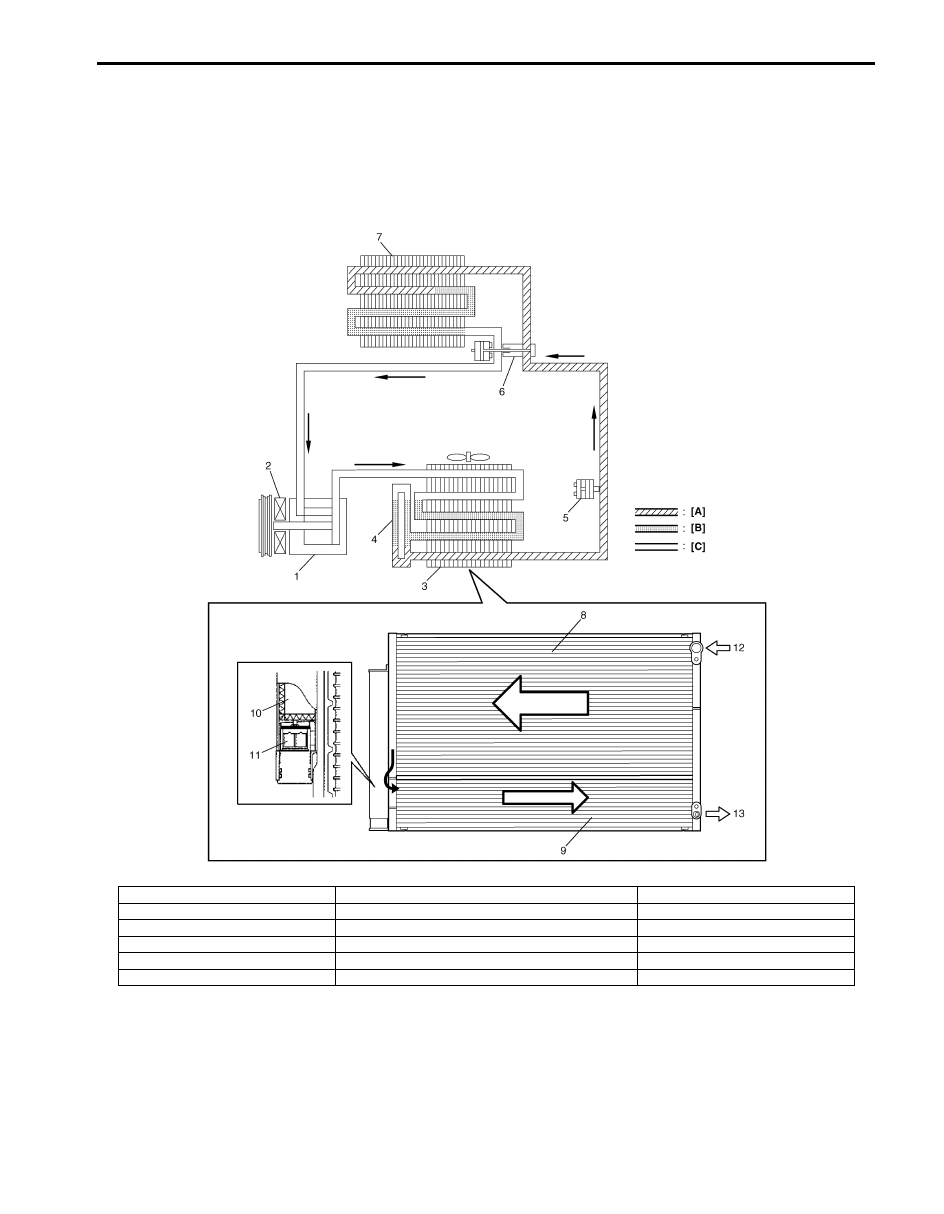

Sub-Cool A/C System Description

S5JB0A7201008

In the sub-cool A/C system (condenser (3) integrated with receiver / dryer (4)), the inside of the condenser is divided

into the condensation part and the sub-cooler part, and the receiver / dryer is located between those. In the receiver /

dryer (4), the refrigerant is separated into the vapor refrigerant and the liquid refrigerant. Only the liquid refrigerant is

delivered to the sub-cooler part of the condenser. The refrigerant is supercooled by the sub-cooler part of the

condenser.

I5JB0A720006-02

[A]: Liquid

4. Receiver / dryer

10. Desiccant

[B]: Vapor

5. Refrigerant pressure sensor

11. Filter

[C]: Superheated vapor

6. Expansion valve

12. Vapor refrigerant

1. Compressor

7. Evaporator

13. Liquid refrigerant

2. Magnet clutch

8. Condensation part

3. Condenser

9. Sub-cooler part

Нет комментариевНе стесняйтесь поделиться с нами вашим ценным мнением.

Текст