Suzuki Grand Vitara JB416 / JB420. Manual — part 132

1H-7 Ignition System:

Repair Instructions

High-Tension Cord Removal and Installation

(For M16 Engine)

S5JB0A1806001

Removal

1) Remove engine cover.

2) Disconnect No.1 cylinder (2) and No.3 cylinder (3)

high-tension cords from ignition coil assemblies (1)

while gripping each cap.

3) Pull out high-tension cords from spark plugs while

gripping each cap.

CAUTION

!

• Removal of high-tension cords together

with clamps will be recommended so as

not to damage their inside wire (resistive

conductor).

• For the same reason, pull out each

connection by gripping cap portion.

Installation

1) Install No.1 cylinder (2) and No.3 cylinder (3) high-

tension cords to spark plugs and ignition coil

assemblies (1) while gripping each cap.

CAUTION

!

• Never attempt to use metal conductor

high-tension cords as replacing parts.

• Insert each cap portion fully when

installing high-tension cords.

High-Tension Cord Inspection (For M16 Engine)

S5JB0A1806002

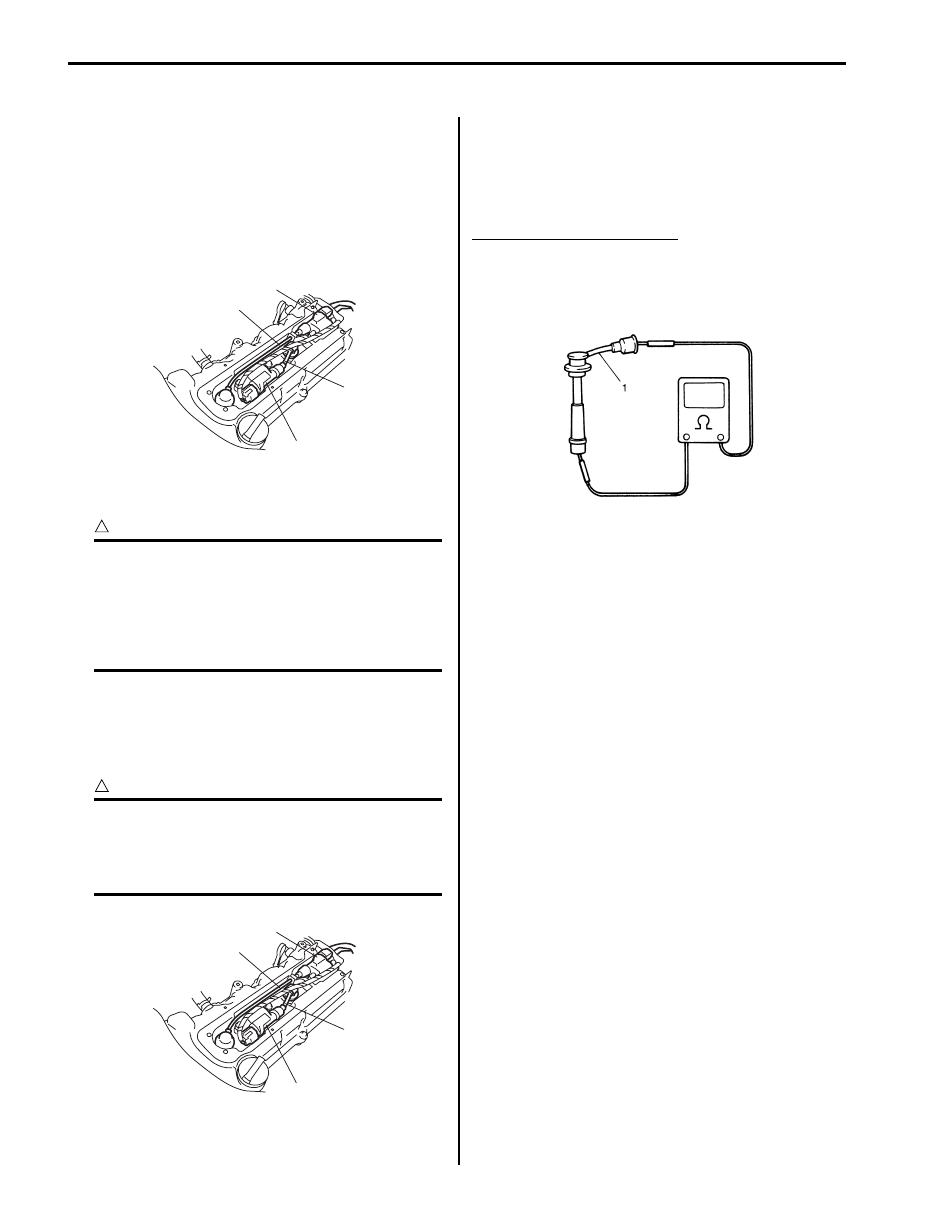

Measure resistance of high-tension cord (1) by using

ohmmeter.

If resistance exceeds specification, replace high-tension

cord(s).

High-tension cord resistance

No.1 cylinder high-tension cord resistance: 1.4 – 4.0

k

Ω

No.3 cylinder high-tension cord resistance: 0.6 – 2.0

k

Ω

Spark Plug Removal and Installation

S5JB0A1806003

Removal

1) Remove engine cover.

2) Pull out high-tension cords by gripping their caps (for

M16 engine) and then remove ignition coil

assemblies referring to “Ignition Coil Assembly

(Including ignitor) Removal and Installation”.

3) Remove spark plugs.

Installation

1) Install spark plugs and tighten them to specified

torque.

Tightening torque

Spark plug: 25 N·m (2.5 kgf-m, 18.0 lb-ft)

2) Install ignition coil assemblies referring to “Ignition

Coil Assembly (Including ignitor) Removal and

Installation”.

3) Install high-tension cords securely by gripping their

caps. (for M16 engine)

4) Install engine cover.

1

1

2

3

I5JB0A180004-01

1

1

2

3

I5JB0A180004-01

I2RH0B180005-01

Ignition System: 1H-8

Spark Plug Inspection

S5JB0A1806004

CAUTION

!

• When servicing the iridium / platinum

spark plugs (slender center electrode type

plugs), do not touch the center electrode

to avoid damage to it. The electrode is not

strong enough against mechanical force

as it is slender and its material is not

mechanically tough.

• Do not clean or adjust gap for the iridium /

platinum spark plugs.

Inspect spark plug for:

• Electrode wear

• Carbon deposits

• Insulator damage

If any abnormality is found for nickel spark plugs, adjust

air gap, clean with spark plug cleaner or replace them

with specified new plugs.

For iridium / platinum spark plugs, replace them with

new plugs.

Spark plug air gap “a”

: 1.0 – 1.1 mm (0.040 – 0.043 in.)

Spark plug type (M16 Engine)

NGK: BKR6E-11 (Nickel) / IFR6J11 (Iridium)

DENSO: K20PR-U11 (Nickel)

Spark plug type (J20 Engine)

NGK: BKR6E-11 (Nickel) / IFR5J11 (Iridium)

DENSO: K20PR-U11 (Nickel)

NOTE

NGK IFR6J11 and IFR5J11 is highly

recommended for better engine starting

performance under –25

°C (–13 °F).

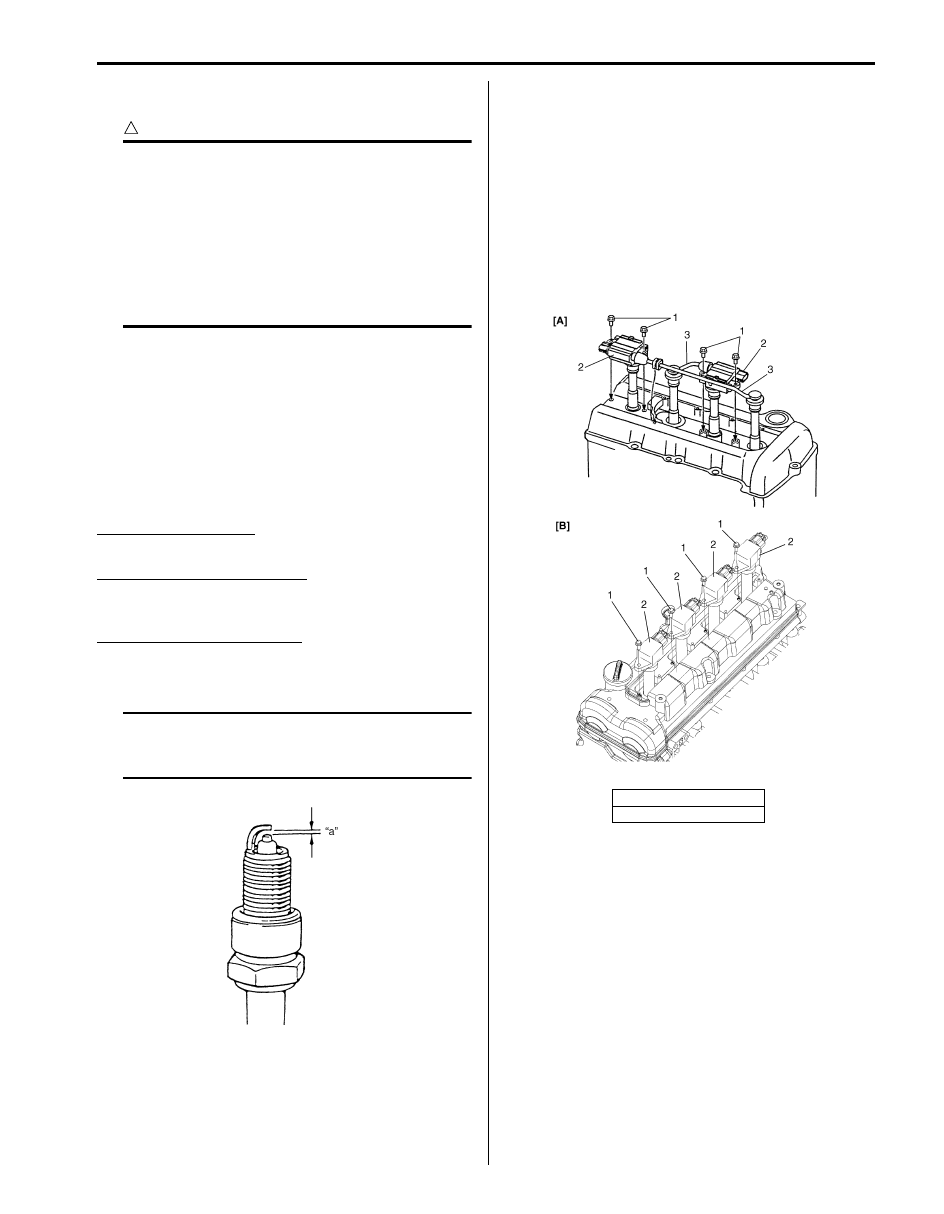

Ignition Coil Assembly (Including ignitor)

Removal and Installation

S5JB0A1806005

Removal

1) Disconnect negative cable at battery.

2) Remove engine cover.

3) Disconnect ignition coil coupler.

4) Disconnect high-tension cord (3) from ignition coil

assembly (2). (for M16 engine)

5) Remove ignition coil bolts (1) and then pull out

ignition coil assembly.

IYSQ01181012-01

[A]: For M16 engine

[B]: For J20 engine

I5JB0A180005-01

1H-9 Ignition System:

Installation

1) Install ignition coil assembly (2).

2) Tighten ignition coil bolts (1) to specified torque, and

then connect ignition coil coupler.

Tightening torque

Ignition coil bolt for M16 engine (a): 10 N·m (1.0

kgf-m, 7.5 lb-ft)

Ignition coil bolt for J20 engine (b): 6.5 N·m (

0.65 kgf-m, 5.0 lb-ft)

3) Install high-tension cord (3) to ignition coil assembly

while gripping its cap. (for M16 engine)

4) Install engine cover.

5) Connect negative cable to battery.

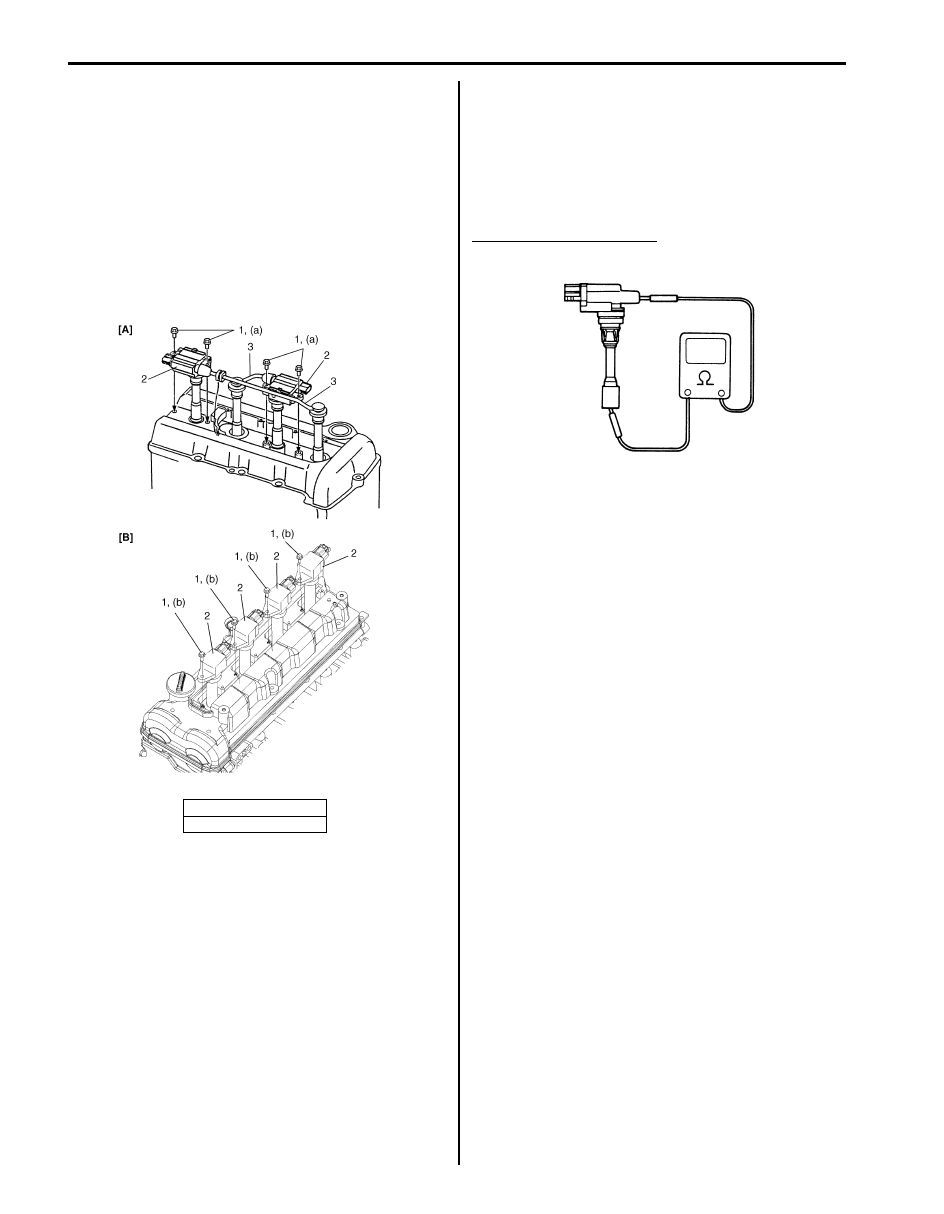

Ignition Coil Assembly (Including ignitor)

Inspection

S5JB0A1806006

For M16 Engine

Measure secondary coil for resistance.

If resistance is out of specification, replace ignition coil

assembly.

Secondary coil resistance

7.6 – 10.2 k

Ω at 20 °C, 68 °F

For J20 Engine

Check ignition coil assembly for the following:

• Damage

• Deterioration

• Terminal for corrosion

If any abnormality is found, replace ignition coil

assembly.

[A]: For M16 engine

[B]: For J20 engine

I5JB0A180006-01

I2RH0B180007-01

Ignition System: 1H-10

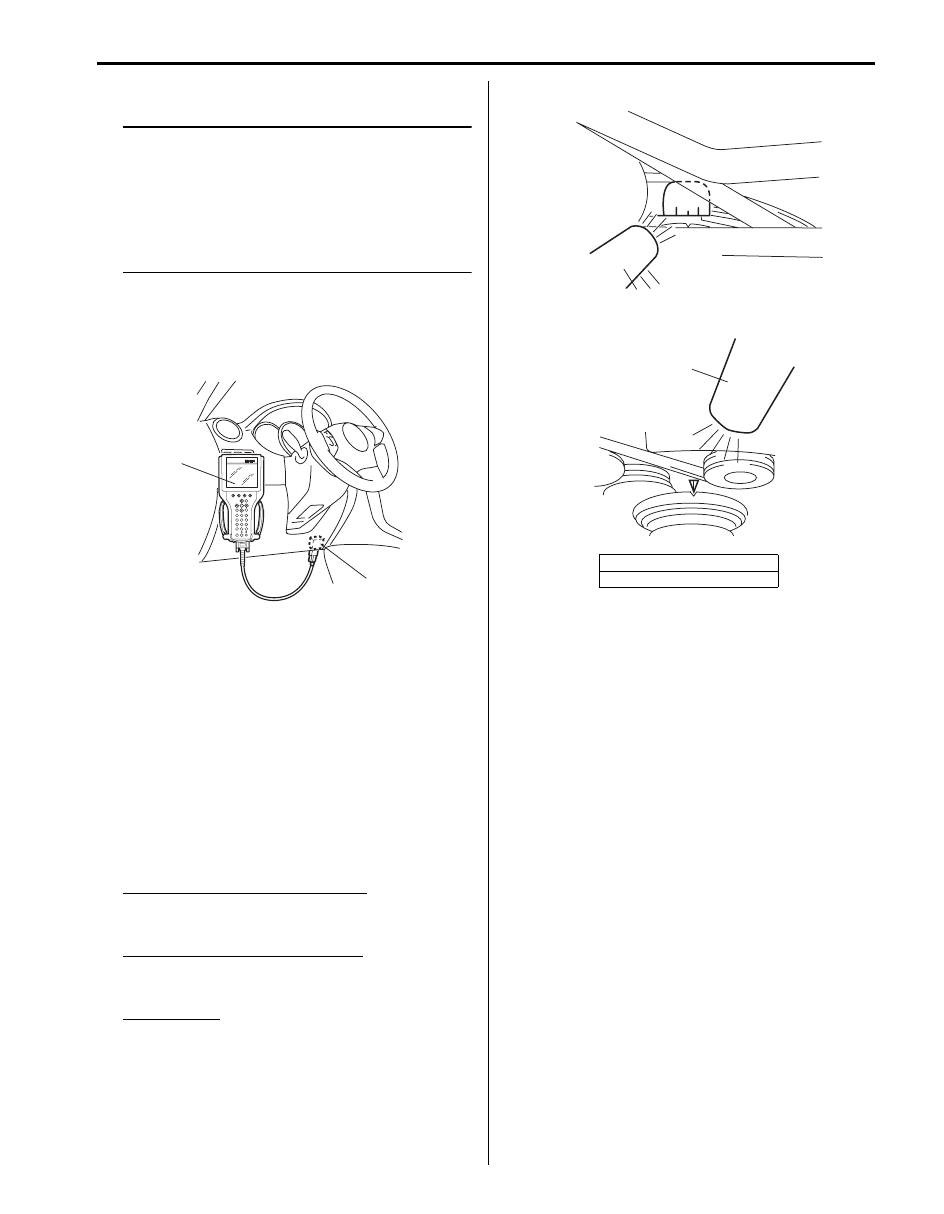

Ignition Timing Inspection

S5JB0A1806007

NOTE

• Ignition timing is not adjustable. If ignition

timing is out of specification, check

system related parts.

• Before starting engine, place transmission

gear shift lever in “Neutral” (shift selector

lever to “P” range for A/T model), and set

parking brake.

1) Connect scan tool to DLC (1) with ignition switch

OFF.

Special tool

(A): SUZUKI scan tool

2) Start engine and warm it up to normal operating

temperature.

3) Make sure that all of electrical loads except ignition

are switched off.

4) Check to be sure that idle speed is within

specification referring to “Idle Speed and IAC

Throttle Valve Opening Inspection in Section 1A”.

5) Fix ignition timing by using “Fixed Spark” of “Misc

Test” mode on scan tool.

6) Set timing light (1) to high-tension cord (for M16

engine) or ignition coil harness (for J20 engine) for

No.1 cylinder and check that ignition timing is within

specification.

Initial ignition timing (M16 Engine)

Fixed with SUZUKI scan tool: 7

° – 17° BTDC (at

specified idle speed)

Initial ignition timing (J20 Engine)

Fixed with SUZUKI scan tool: 5

° – 15° BTDC (at

specified idle speed)

Ignition order

1 – 3 – 4 – 2

Special tool

(A): 09930–76420

7) If ignition timing is out of specification, check the

followings.

• CKP sensor

• CKP sensor plate

• TP sensor

• CMP sensor

• CMP sensor rotor tooth of camshaft

• Wheel speed sensor (VSS)

• Knock sensor

• Timing chain cover installation

8) After checking initial ignition timing, release ignition

timing fixation by using scan tool.

9) With engine idling (throttle opening at closed position

and vehicle stopped), check that ignition timing is

about 7

° – 17° BTDC for M16 engine or 5° – 15°

BTDC for J20 engine. (Constant variation within a

few degrees from 7

° – 17° BTDC for M16 engine or

5

° – 15° BTDC for J20 engine indicates no

abnormality but proves operation of electronic timing

control system.) Also, check that increasing engine

speed advances ignition timing.

If the check results are not satisfactory, check CKP

sensor and ECM.

(A)

1

I5JB0A180007-01

[A]: For M16 engine

[B]: For J20 engine

1, (A)

1, (A)

10

0

[A]

[B]

I5JB0A180008-01

Нет комментариевНе стесняйтесь поделиться с нами вашим ценным мнением.

Текст