Suzuki Grand Vitara JB416 / JB420. Manual — part 227

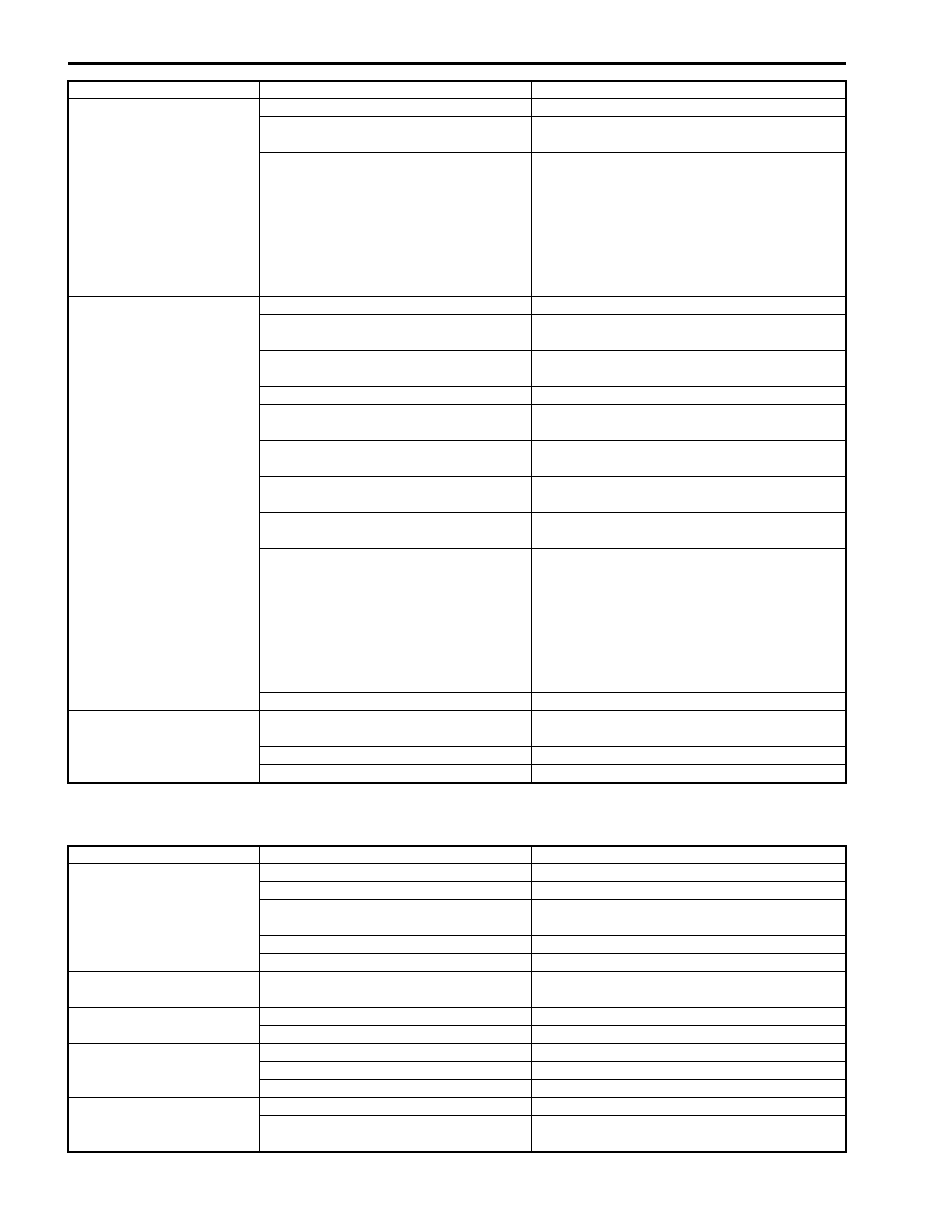

5A-42 Automatic Transmission/Transaxle:

Trouble Diagnosis 3

Off-vehicle repair

Incorrect shift point

Engine abnormal condition

Inspect and repair engine

Malfunction of output shaft speed

sensor

Inspect. If NG, replace.

Malfunction of accelerator pedal position

sensor

Inspect referring to “DTC P0122: Throttle

Position Sensor (Main) Circuit Low in Section

1A”, “DTC P0123: Throttle Position Sensor

(Main) Circuit High in Section 1A”, “DTC

P0222: Throttle Position Sensor (Sub) Circuit

Low in Section 1A” and “DTC P0223: Throttle

Position Sensor (Sub) Circuit High in Section

1A”.

Non operate TCC / lock-up

system

Malfunction of lock-up solenoid valve

Inspect. If NG, replace.

Malfunction of shaft solenoid valve No.1

and/or No.2

Inspect. If NG, replace.

Malfunction of output shaft speed

sensor

Inspect. If NG, replace.

Malfunction of input shaft speed sensor Inspect. If NG, replace.

Malfunction of transmission range

sensor

Inspect. If NG, replace.

Malfunction of transmission fluid

temperature sensor

Inspect. If NG, replace.

Malfunction of pressure control solenoid

valve

Inspect. If NG, replace valve body assembly.

Malfunction of brake light switch

Inspect referring to “Stop (Brake) Lamp Switch

Inspection in Section 9B”. If NG, replace.

Malfunction of accelerator pedal position

sensor

Inspect referring to “DTC P0122: Throttle

Position Sensor (Main) Circuit Low in Section

1A”, “DTC P0123: Throttle Position Sensor

(Main) Circuit High in Section 1A”, “DTC

P0222: Throttle Position Sensor (Sub) Circuit

Low in Section 1A” and “DTC P0223: Throttle

Position Sensor (Sub) Circuit High in Section

1A”.

Faulty valve body component

Replace valve body assembly.

Excessive “N”

→

“D” or

“N”

→

“R” time lag

Pressure control solenoid valve circuit

faulty

Inspect. If NG, replace valve body assembly.

Clogged oil strainer

Replace.

Faulty valve body component

Replace valve body assembly.

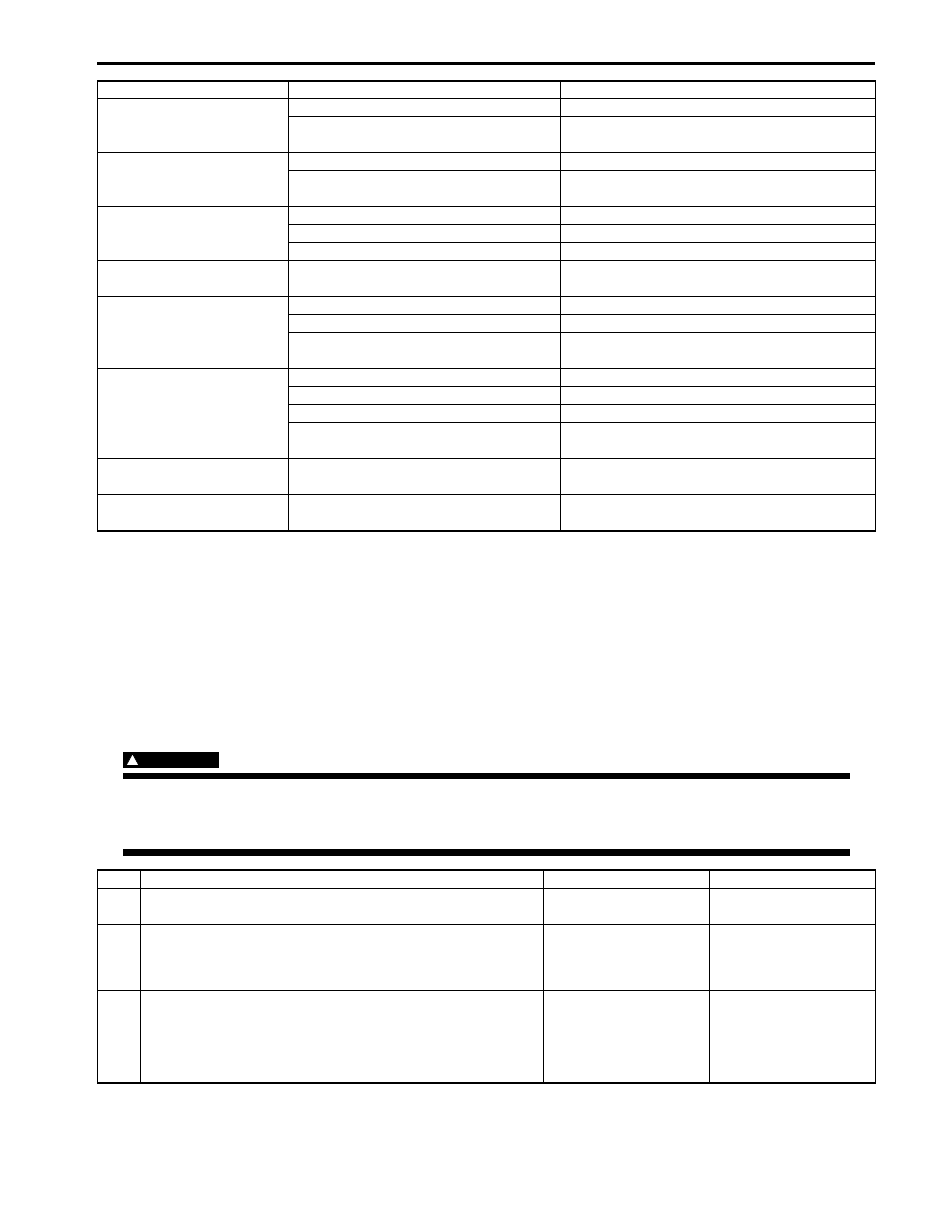

Condition

Possible cause

Correction / Reference Item

Condition

Possible cause

Correction / Reference Item

Unable to run in all range Faulty oil pump

Inspect. If NG, replace.

Seized or broken planetary gear

Inspect. If NG, replace.

Fluid pressure leakage to overdrive

clutch due to wear of oil pump bushing

Inspect. If NG, replace.

Damaged drive plate

Inspect. If NG, replace.

Faulty torque converter

Replace.

Excessive “N”

→

“D” shift

shock

Faulty forward clutch

Inspect. If NG, replace.

Excessive “N”

→

“R” shift

shock

Faulty reverse brake

Inspect. If NG, replace.

Faulty direct clutch

Inspect. If NG, replace.

Poor 1

→

2 shift,

excessive shock or

slippage

Faulty second brake

Inspect. If NG, replace.

Faulty one-way clutch No.1

Inspect. If NG, replace.

Faulty one-way clutch No.2

Inspect. If NG, replace.

Poor 2

→

3 shift,

excessive shock or

slippage

Faulty direct clutch

Inspect. If NG, replace.

Faulty one-way clutch No.1

Inspect. If NG, replace.

Automatic Transmission/Transaxle: 5A-43

No Gear Shift to 4th Gear

S5JB0A5104020

System Description

TCM does not shift to 5th gear under any of the following condition.

• “3” position switch signal is inputted.

• 4L/N switch is turned ON. (4L mode)

• TCM detects the following DTCs.

DTC, P0722, P0752, P0962, P0963, P0973, P0974, P0976, P0977, P1702

Troubleshooting

WARNING

!

• When performing a road test, select a place where there is no traffic or possibility of a traffic

accident and be very careful during testing to avoid occurrence of an accident.

• Road test should be carried out with 2 persons, a driver and tester, on a level road.

Poor 3

↔

O/D shift,

excessive shock or

slippage

Faulty O/D clutch

Inspect. If NG, replace.

Faulty O/D brake

Inspect. If NG, replace.

Poor 3

→

2 shift,

excessive shock or

slippage

Faulty direct clutch

Inspect. If NG, replace.

Faulty one-way clutch No.1

Inspect. If NG, replace.

Poor 2

→

1 shift,

excessive shock or

slippage

Faulty second brake

Inspect. If NG, replace.

Faulty one-way clutch No.1

Inspect. If NG, replace.

Faulty one-way clutch No.2

Inspect. If NG, replace.

Non operate TCC / lock-up

system

Faulty torque converter

Replace.

Excessive “N”

→

“D” time

lag

Faulty oil pump

Inspect. If NG, replace.

Faulty forward clutch

Inspect. If NG, replace.

Leakage from “D” range fluid pressure

circuit

Overhaul or replace valve body assembly.

Excessive “N”

→

“R” time

lag

Faulty oil pump

Inspect. If NG, replace.

Faulty direct clutch

Inspect. If NG, replace.

Faulty reverse brake

Inspect. If NG, replace.

Leakage from “R” range fluid pressure

circuit

Overhaul or replace valve body assembly.

Poor engine brake in

downshift to “2” range

Faulty 2nd coast brake

Inspect. If NG, replace.

Poor engine brake in

downshift to “L” range

Faulty reverse brake

Inspect. If NG, replace.

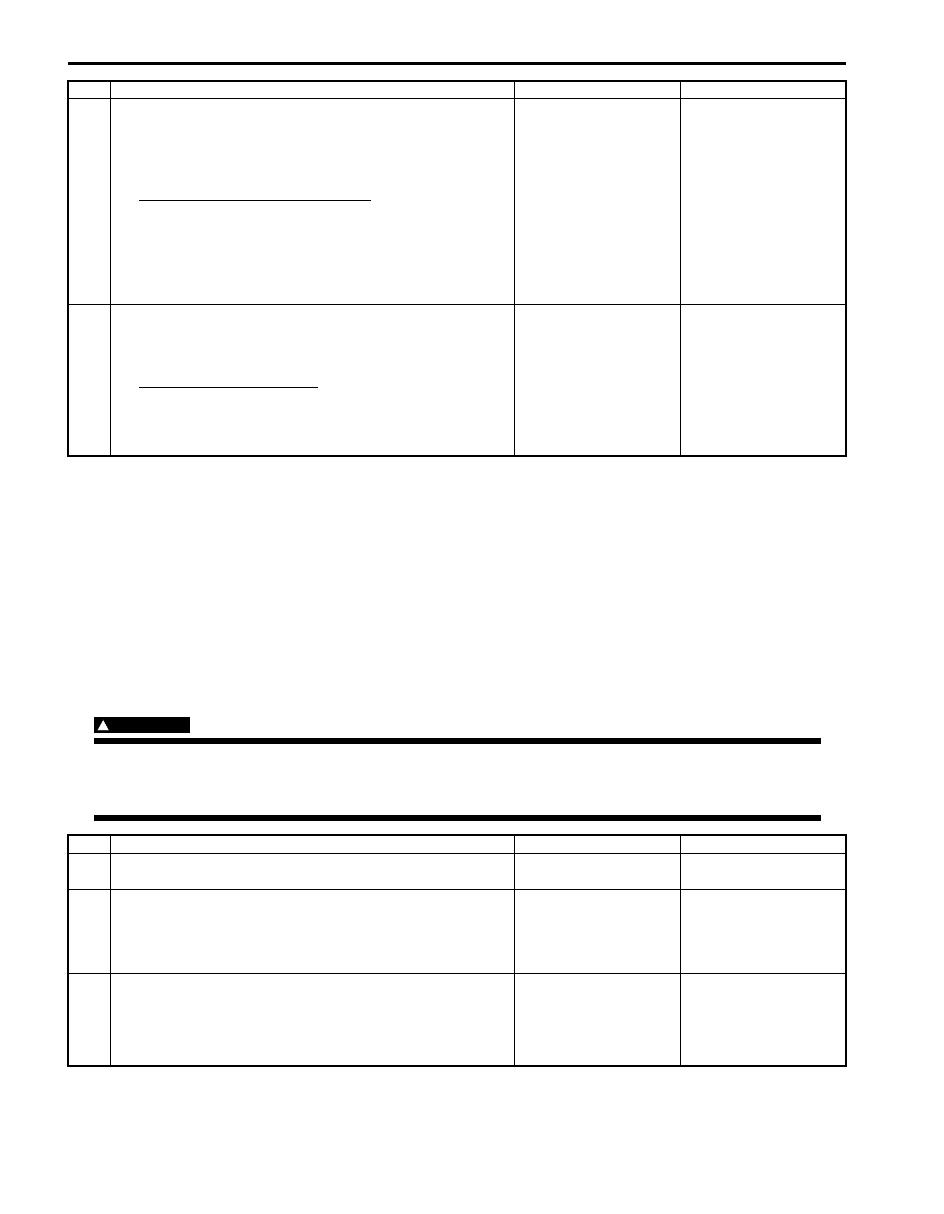

Condition

Possible cause

Correction / Reference Item

Step

Action

Yes

No

1

Was “A/T System Check” performed?

Go to Step 2.

Go to “A/T System

Check”.

2

Check DTC

Is DTC, P0722, P0752, P0962, P0963, P0973, P0974,

P0976, P0977 or P1702 detected?

Perform DTC Flow to

repair and retry.

Go to Step 3.

3

ECT check

1) Warm up engine to normal operating temperature.

2) Check ECT monitored by TCM using scan tool.

Is ECT indicated –40

°

C (–40

°

F)?

Go to Step 4.

Faulty ECT sensor, its

circuit or engine cooling

system. If OK, substitute

a known-good TCM and

recheck.

5A-44 Automatic Transmission/Transaxle:

No Lock-Up Occurs

S5JB0A5104021

System Description

TCM turns TCC pressure control solenoid OFF under any of the following conditions.

• Engine coolant temperature is lower than 60

°C (140 °F).

• 4L/N switch is turned ON. (4L mode)

• Brake light switch is turned ON. (Brake pedal is depressed)

• TCM detects the following DTCs.

P0712, P0713, P0717, P0722, P0962, P0963, P0973, P0974, P0976, P0977, P1702, P1703, P1774, P1777, P2763

and P2764

Troubleshooting

WARNING

!

• When performing a road test, select a place where there is no traffic or possibility of a traffic

accident and be very careful during testing to avoid occurrence of an accident.

• Road test should be carried out with 2 persons, a driver and tester, on a level road.

4

“3” position switch signal inspection

1) With ignition switch ON, check voltage between terminal

“E92-20” of TCM connector and ground under the

following conditions.

“3” position switch specification

Shift selector lever to “P”, “R”, “N” or “D” range: 2.9

– 3.8 V

Shift selector lever to “3”, “2” or “L” range: 1.4 – 2.0

V

Is result as specified?

Go to Step 5.

Faulty “3” position

switch or its circuit. If

OK, substitute a known-

good TCM and recheck.

5

4L/N switch signal inspection

1) With ignition switch ON, check voltage between terminal

“E93-4” of TCM connector and ground.

4L/N switch specification

Transfer gear position “4H”: Battery voltage

Transfer gear position “4L” or “N”: 0 – 2 V

Is result as specified?

Substitute a known-

good TCM and recheck.

Faulty 4L/N switch or its

circuit. If OK, substitute

a known-good TCM and

recheck.

Step

Action

Yes

No

Step

Action

Yes

No

1

Was “A/T System Check” performed?

Go to Step 2.

Go to “A/T System

Check”.

2

Check DTC

Is DTC P0712, P0713, P0717, P0722, P0962, P0963,

P0973, P0974, P0976, P0977, P1702, P1703, P1774,

P1777, P2763 or P2764 detected?

Perform DTC Flow to

repair and retry.

Go to Step 3.

3

ECT check

1) Warm up engine to normal operating temperature.

2) Check ECT using scan tool.

Is ECT more than 60

°

C (140

°

F)?

Go to Step 4.

Faulty ECT sensor, its

circuit or engine cooling

system. If OK, substitute

a known-good TCM and

recheck.

Automatic Transmission/Transaxle: 5A-45

Transmission Warning Light Circuit Check – Light Does Not Come “ON” at Ignition Switch ON

(Vehicle is equipped with engine diagnosis connector)

S5JB0A5104063

Troubleshooting

Transmission Warning Light Circuit Check – Light Remains “ON” at Ignition Switch ON (Vehicle is

equipped with engine diagnosis connector)

S5JB0A5104064

Troubleshooting

4

4L/N switch signal inspection

1) With ignition switch ON, check voltage between terminal

“E92-4” of TCM connector and ground.

4L/N switch specification

Transfer gear position or “4H”: Battery voltage

Transfer gear position “4L” or “N”: 0 – 2 V

Is result as specified?

Go to Step 5.

Faulty “4L” switch or its

circuit. If OK, substitute

a known-good TCM and

recheck.

5

Brake light switch signal inspection

1) With ignition switch ON, check voltage between terminal

“E61-34” of ECM connector and ground.

Brake light switch specification

Brake pedal is released: 0 – 1 V

Brake pedal is depressed: Battery voltage

Is result as specified?

Substitute a known-

good TCM and recheck.

Mis-adjusted brake light

switch, faulty brake light

switch or its circuit. If

OK, substitute a known-

good TCM and recheck.

Step

Action

Yes

No

Step

Action

Yes

No

1

Combination Meter Power Supply Check

1) Turn ignition switch ON.

Does other indicator / warning lights in combination meter

comes ON?

Go to Step 2.

Repair combination

meter power supply

circuit referring to

“Combination Meter

Circuit Diagram in

Section 9C”.

2

1) TCM power and ground circuit check referring to “TCM

Power and Ground Circuit Check”.

Is it in good condition?

Go to Step 3.

Repair or replace.

3

DTC check

1) Check DTC referring to “DTC Check”.

Is there DTC P1774 or P1775?

Go to applicable DTC

diag. flow.

Go to Step 4.

4

Combination Meter Function Check

1) Turn ignition switch ON.

Does A/T selector position indicator show correct select

lever position?

Replace combination

meter.

Substitute a known-

good TCM and recheck.

Step

Action

Yes

No

1

Diagnostic Trouble Code (DTC) Check

1) Check DTC referring to “DTC Check”.

Is there any DTC(s)?

Perform DTC Flow to

repair and retry.

Substitute a known-

good TCM and recheck.

If OK, substitute a

known-good

combination meter and

recheck.

Нет комментариевНе стесняйтесь поделиться с нами вашим ценным мнением.

Текст