Hummer H1 (2002+). Manual — part 130

_________________________________________________________

Steering System 8-27

®

05745159

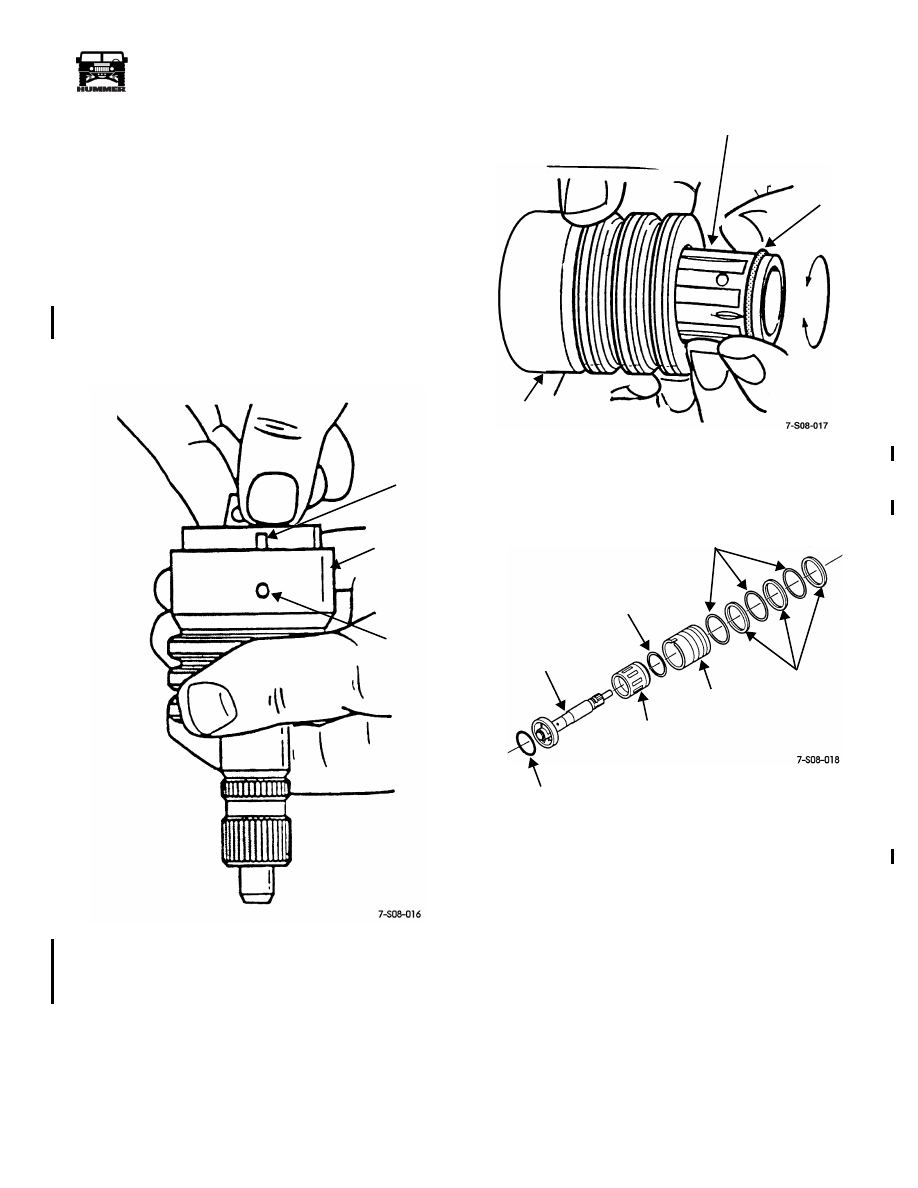

Valve Body-Stub Shaft-Wormshaft Removal

and Disassembly

1.

Grasp splined end of stub shaft and carefully rotate valve

body/stub shaft assembly out of gear housing.

2.

If wormshaft remained engaged in stub shaft cap,

disengage and remove wormshaft at this time.

3.

Remove O-ring from cap end of stub shaft.

4.

Lightly tap splined end of stub shaft on wood block to

disengage cap from valve body.

5.

Grasp stub shaft cap and pull it upward to expose shaft pin

(Figure 8-43). Then disengage shaft pin from valve body

and separate two components.

Figure 8-43: Stub Shaft Remova

l

6.

Remove spool from valve body with a rotating motion

(Figure 8-44).

Figure 8-44: Valve Spool Removal

7.

Remove O-ring from valve spool.

8.

Remove seals and O-rings from valve body (Figure 8-45).

Figure 8-45: Stub Shaft/Valve Body Components

NOTCH IN

VALVE

SHAFT

STUB SHAFT

CAP

BODY

PIN

VALVE SPOOL

O-RING

ROTATE

VALVE

SPOOL

TO REMOVE

BODY

STUB

STUB

VALVE

SPOOL

VALVE

SEAL RINGS

O-RINGS

O-RING

SHAFT

SPOOL

BODY

SHAFT

O-RING

4-1-00

8-28

Steering System

__________________________________________________________

®

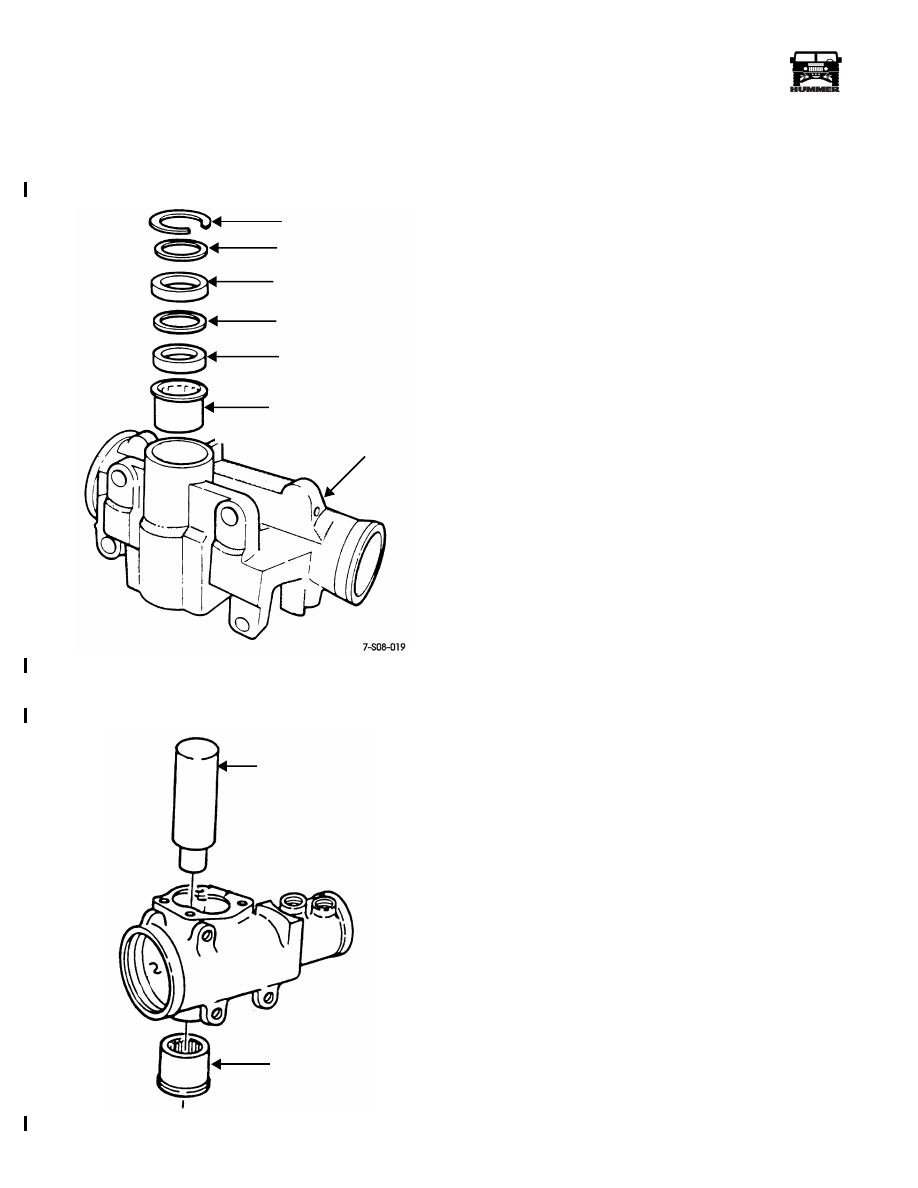

Pitman Shaft Bearing and Seal Removal

1.

Remove seal retaining ring with internal-type snap ring

pliers.

2.

Remove first backup washer (Figure 8-46).

Figure 8-46: Pitman Shaft Bearing and Seal Position

3.

Remove seals, second backup washer, and bearing with

tool J–6278 (Figure 8-47).

Figure 8-47: Pitman Shaft Bearing Removal

POWER STEERING GEAR CLEANING AND

INSPECTION

Discard all the old O-rings, seals, and seal rings. Do not reuse

these parts.

Clean the gear housing and components in a standard parts

cleaning solution and either wipe them dry with lint-free shop

towels or use low pressure compressed air.

Examine the wormshaft, pitman shaft, and stub shaft bearings

for wear, galling, flat spots, or loss of bearing material (flak-

ing). Also examine the wormshaft and stub shaft thrust bear-

ing races for wear, grooving, discoloration, scoring, or

spalling. Replace bearings and races as necessary. Do not re-

use parts in marginal condition.

Check the gear housing for cracks, damaged threads, scored-

worn valve bores, and damaged pressure hose seats. Replace

the housing if necessary. The hose seats can be replaced if

scored, distorted, or loose. Refer to the procedure in the assem-

bly and adjustment section.

Inspect condition of the rack piston, wormshaft, and recirculat-

ing bearing balls (Figure 8-48). Replace the bearing balls as a

set if any are scored, worn, distorted, have flat spots, or the

coating is flaking off. The rack piston should be free from

wear and scoring. Also be sure the seal ring groove is in good

condition and the edges are not chipped cracked, or peened

over. The wormshaft must be smooth and free of scoring or

wear to operate properly. Check the ball guide clamp threads in

the rack piston. Rough threads can be cleaned up with a tap but

damaged threads mean the rack piston will have to be replaced.

Check fit of the spool in the valve body. The spool should

move freely with a light coating of power steering fluid on it.

Replace the valve body and spool as an assembly if either part

is worn, scored, or damaged in any fashion.

Inspect the stub shaft for wear and damage. Minor nicks and

scratches on the shaft surface can be dressed off with crocus

cloth or 600 grit emery cloth wetted with oil. However, replace

the shaft if scored, or distorted.

The adjuster plug threads and bearing bore should be in good

condition especially the threads. Replace the plug if the threads

are rough, deformed, or chipped. Rough threads will prevent

proper preload on the wormshaft thrust bearing.

Examine the pitman shaft, side cover, and gasket. Replace the

shaft if the sector teeth are damaged, or the bearing and seal

contact surfaces are worn, scored, or damaged in any way.

Check condition of the side cover bushing. Replace the cover if

the bushing is worn as the bushing is not serviceable. Inspect

condition of the lash adjuster screw in the pitman shaft. Re-

place the shaft if the screw is damaged as the screw is not ser-

viced separately.

RETAINING RING

BACKUP WASHER

DOUBLE-LIP SEAL

BACKUP WASHER

SINGLE-LIP SEAL

PITMAN SHAFT BEARING

GEAR HOUSING

TOOL J–6278 OR J–21551

PITMAN SHAFT

BEARING

7-S08-020

4-1-00

_________________________________________________________

Steering System 8-29

®

05745159

Figure 8-48: Power Steering Gear Components

END PLUG

END PLUG

RACK PISTON

RACK PISTON

ADJUSTER

SIDE COVER

GASKET

ADJUSTER SCREW

PITMAN

HOSE

WORMSHAFT

WORMSHAFT

RACES

PITMAN SHAFT

SINGLE-LIP

DOUBLE-LIP

SNAP

SEAL RINGS

O-RINGS

VALVE

SPOOL

VALVE

STUB

STUB SHAFT

LOCKNUT

SNAP RING

DUST

OIL SEAL

STUB SHAFT

ADJUSTER

O-RING

INNER

THRUST

OUTER

SPACER

RETAINER

NUT AND

BACKUP

RACK PISTON

PISTON PLUG

BEARING

BALL

GUIDE

END PLUG

RACE

PLUG

BEARING

BEARING

SEAL

RACE

O-RING

BODY

SPOOL

SHAFT

O-RING

LOCKWASHER

WASHERS

SEAL

SEAL

BEARING

RING

CLAMP

GUIDES

BALLS (24)

RETAINING

RING

THRUST

BEARING

SEATS

SHAFT

BACKUP O-RING

NUT

O-RING

SEAL RING

4-1-00

8-30

Steering System

__________________________________________________________

®

POWER STEERING GEAR ASSEMBLY AND

ADJUSTMENT

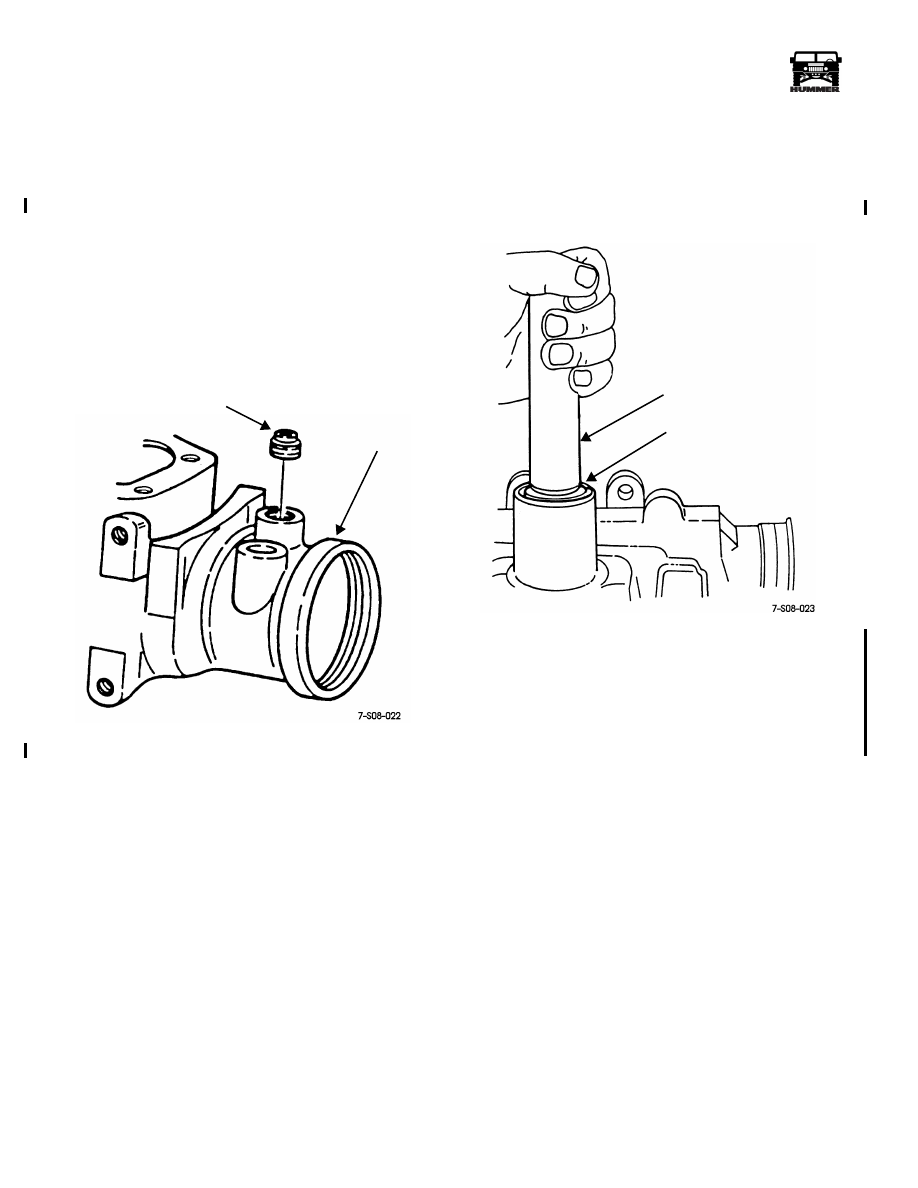

Gear Housing Hose Seat Replacement

The hose seats in the gear housing (Figure 8-49), can be re-

placed when necessary. Procedure is as follows:

1.

Thread appropriate size pan head, hardened sheet metal

screw into seat.

2.

Pry old seat out of housing using pry tools positioned

under screw head.

3.

Clean gear housing afterward to remove any chips.

4.

Install new seat using spare hose fitting and brass punch.

Figure 8-49: Pressure Hose Seat

Pitman Shaft Bearing and Seal Installation

1.

Lubricate bearing and seals with power steering fluid, or

petroleum jelly.

2.

Install bearing in gear housing with handle J–8092 and

installer J–6278 or J–21551 (Figure 8-50).

Figure 8-50: Pitman Shaft Bearing Installation

3.

Install single lip seal in housing with tool J–6219

(Figure 8-51). Be sure seal lip is toward gear housing.

4.

Install backup washer on single lip seal (Figure 8-51).

5.

Install double lip seal in housing with tool J–6219

(Figure 8-51). Be sure seal lip is toward gear housing.

6.

Install backup washer on double lip seal.

7.

Install seal retaining snap ring.

PRESSURE

HOUSING

HOSE

SEAT

TOOL HANDLE J–8092

INSTALLER TOOL

J–6278 OR J–21551

4-1-00

Нет комментариевНе стесняйтесь поделиться с нами вашим ценным мнением.

Текст