Hummer H1 (2002+). Manual — part 131

_________________________________________________________

Steering System 8-31

®

05745159

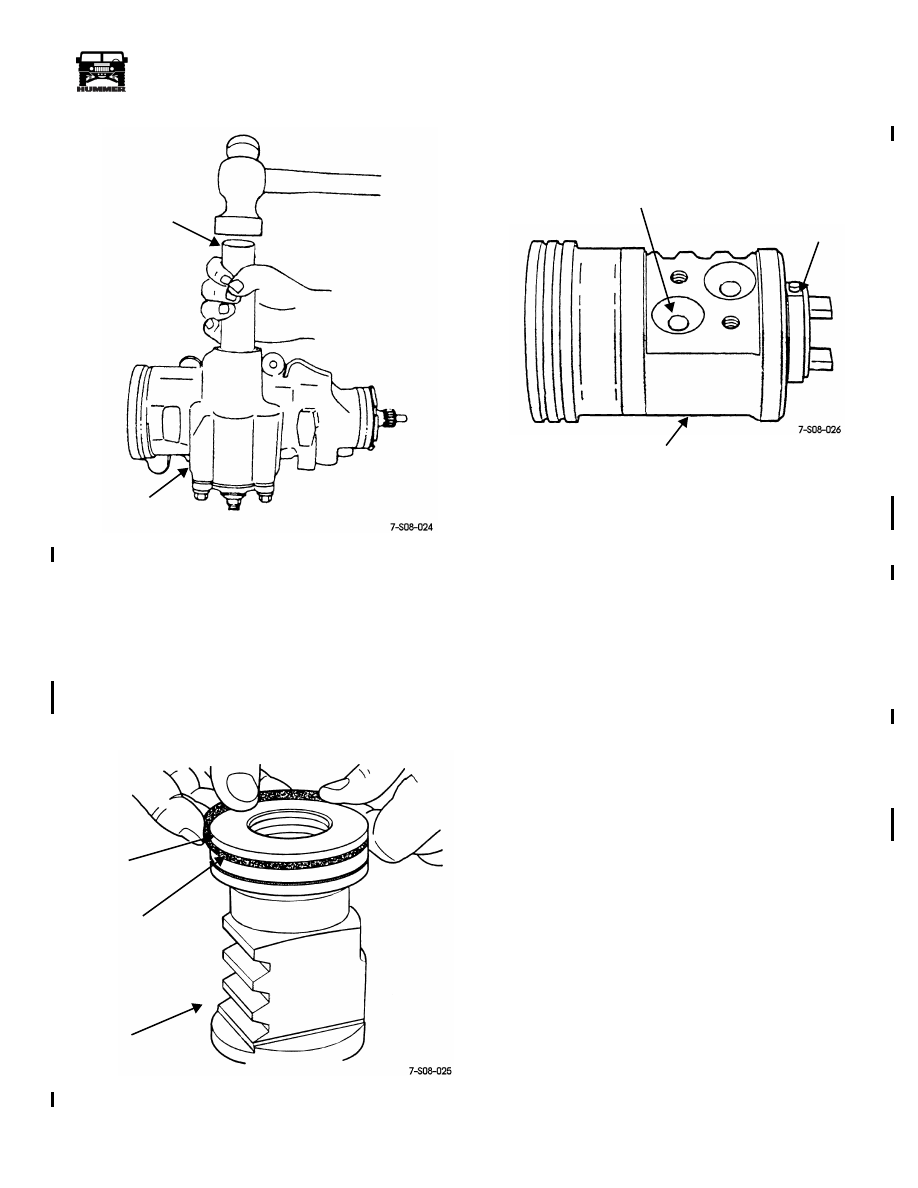

Figure 8-51: Pitman Shaft Seal Installation

Rack Piston Assembly

1.

Lubricate rack piston bore in gear housing and new O-ring

and seal ring with power steering fluid.

2.

Install new backup O-ring in rack piston seal groove.

3.

Install new teflon seal ring in groove

over

backup O-ring

(Figure 8-52).

Figure 8-52: Rack Piston Seal Ring Installation

4.

Install wormshaft in rack piston. Wormshaft flange should

be seated against piston as shown (Figure 8-53).

Figure 8-53: Rack Piston Loading Port

For Bearing Balls

5.

Align worm shaft spiral groove with indicated ball guide

circuit port in rack piston (Figure 8-53).

6.

Load recirculating bearing balls in rack piston and in ball

guides as follows:

a.

Lubricate bearing balls with power steering fluid.

b.

Turn wormshaft

counterclockwise

to load bearing

balls in rack piston.

c.

Load balls in rack piston through indicated ball guide

port (Figure 8-53).

d.

Load balls alternately. Start with chrome ball

followed by black ball until rack piston is full (piston

will only accommodate around 18 balls).

e.

Load remaining balls in ball guides. Use petroleum

jelly to hold balls and guide halves in place

(Figure 8-54).

f.

Verify that 12 black and 12 chrome balls were

installed in correct sequence.

g.

Assemble and install ball guides (with enclosed balls)

on rack piston and secure guides with clamp. Tighten

clamp bolts to 43 lb-ft (58 N•m) torque.

WARNING: The chrome recirculating balls are

slightly larger in diameter than the black coated balls.

This is required in order to generate and maintain

proper wormshaft preload. It is also why the balls must

be installed alternately. Incorrect installation, or failure

to load all 24 balls will result in loss of preload, bind,

and partial loss of steering control. Verify that the balls

are correctly loaded before proceeding.

INSTALLER

GEAR

TOOL

J–6219

HOUSING

TEFLON RING

NOTE: BACK-UP

UNDER SEAL RING

RACK PISTON

O-RING IS INSTALLED

LOAD BEARING BALLS

WORMSHAFT

RACK

PISTON

FLANGE

INTO THIS BALL GUIDE PORT

4-1-00

8-32

Steering System

__________________________________________________________

®

Figure 8-54: Assembling Remaining Bearing Balls

and Ball Guides

7.

Remove wormshaft and temporarily install arbor tool

J–21552 as follows:

a.

Insert arbor tool J–21552 into rack piston end plug

hole.

b.

Hold arbor tool firmly against wormshaft and turn

wormshaft

counterclockwise

. This allows wormshaft

to back out of piston as arbor tool enters and holds

recirculating balls in place.

8.

Set rack piston aside temporarily for later installation. Do

not allow the arbor tool to slip out of the piston. If this

occurs, it will be necessary to disassemble and reload the

bearing balls.

Valve Body-Stub Shaft-Wormshaft Assembly

1.

Lubricate valve body spool, O-rings, and seal rings with

power steering fluid.

2.

Install new backup O-rings in valve body grooves.

3.

Install new teflon coated seal rings in valve body grooves.

Note that the seal rings are installed on top of (over) the

backup O-rings (Figure 8-55).

Figure 8-55: Valve Body Seal Ring Installation

4.

Install new O-ring on valve spool.

5.

Install spool in valve body with a turning motion

(Figure 8-59). Note that O-ring end of spool faces out.

CAUTION:

Do not force the spool into the valve. This could

score the spool and valve body resulting in steering problems

after installation. Install the spool with a push and turn motion

only.

Figure 8-56: Valve Body Seal Ring Installation

BEARING

BALL

PETROLEUM

JELLY

BALLS

GUIDE

HALVES

TEFLON COATED

SEAL RING

(OVER O-RING)

VALVE BODY

SPOOL

4-1-00

_________________________________________________________

Steering System 8-33

®

05745159

6.

Install stub shaft in valve body as follows:

a. Insert stub shaft into valve body.

b. Leave approximately 1/4 inch (6 mm) space between

stub shaft cap and valve body for access to pin

(Figure 8-57).

c. Align and engage stub shaft pin in valve spool pin bore

(Figure 8-57).

d. Align notch in stub shaft cap with pin in valve body

(Figure 8-58). Then fully seat stub shaft in valve body.

Verify that valve body pin is seated in cap notch before

proceeding.

Figure 8-57: Aligning Stub Shaft Pin and Valve Spool

Pin Bore

Figure 8-58: Aligning and Seating Stub Shaft

In Valve Body

7.

Lubricate wormshaft thrust bearings and races with

petroleum jelly to hold them in place. Then install first

race followed by the bearing and remaining race

(Figure 8-59).

CAUTION:

The thrust bearing races both have a concave

shape. Be sure the concave side is toward the wormshaft flange

as shown. The races will not maintain proper preload on the

bearing otherwise.

STUB

6mm

PIN BORE

IN SPOOL

SHAFT

PIN

(1/4 ")

NOTCH IN

VALVE

STUB SHAFT CUP

BODY

PIN

(SEAT IN

CAP

NOTCH)

4-1-00

8-34

Steering System

__________________________________________________________

®

Figure 8-59: Aligning and Seating Stub Shaft In

Valve Body

8.

Install O-ring on stub shaft cap (Figure 8-63).

9.

Align slot in valve body with pin in wormshaft flange and

insert wormshaft into valve body (Figure 8-63). Be sure

wormshaft flange is fully seated in stub shaft.

10. Set assembly aside for later installation.

Figure 8-60: Wormshaft and Valve Body/Stub Shaft

Assembly

Adjuster Plug Assembly

1.

Position new stub shaft bearing on installer tool J–6221.

Position bearing so ID number is toward installer tool.

This will minimize any chance of damaging the bearing

during installation.

2.

Install stub shaft bearing in adjuster plug with tool J–6221

(Figure 8-61). Place adjuster plug on wood block as

shown.

Figure 8-61: Installing Stub Shaft Bearing and Seals

In Adjuster Plug

3.

Install stub shaft oil seal and dust seal in adjuster plug with

tool J–6221. Then install snap ring to secure seals and

bearing (Figure 8-62).

4.

Assemble and install thrust bearing and races in adjuster

plug (Figure 8-62). Be sure races are installed as shown

(Figure 8-62).

5.

Install spacer and retainer in adjuster plug (Figure 8-62).

6.

Seat retainer in adjuster plug with pin punch (Figure 8-63).

7.

Install O-ring on adjuster plug (Figure 8-63).

THRUST

CONCAVE (ANGLED) SIDE OF RACES

MUST BE TOWARD WORMSHAFT FLANGE

BEARING

THRUST BEARING

ALIGN PIN

VALVE BODY/

O-RING

WORMSHAFT

MAKE SURE ANGLE OF

THRUST RACES ARE AS SHOWN

AND RACES

STUB SHAFT

ASSEMBLY

AND SLOT

TOOL J–6221

ADJUSTER

WOOD

STUB SHAFT

BLOCK

PLUG

BEARING

4-1-00

Нет комментариевНе стесняйтесь поделиться с нами вашим ценным мнением.

Текст