Hummer H1 (2002+). Manual — part 135

________________________________________________________________________________

9-1

®

05745159

Section 9 Axles, Suspension, and Frame

TABLE OF CONTENTS

Airlift Brackets . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-48, 9-49

Axle

Output Shaft Seal Replacement . . . . . . . . . . . . . . . . . . . .9-25

Pinion Seal Replacement . . . . . . . . . . . . . . . . . . . . . . . . . .9-26

Support and Side Mounting Brackets . . . . . . . . . . . . . . . .9-59

Vent Line Replacement . . . . . . . . . . . . . . . . . . . . . . . . . . . .9-23

Cover Service . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .9-25

Repair . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .9-28

Replacement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .9-26

Front Bumper and Towing Brackets . . . . . . . . . . . . . . . . .9-45

Rear Bumper Outer Mounting and Tiedown Brackets . . .9-53

Rear Bumper Replacement . . . . . . . . . . . . . . . . . . . . . . . .9-52

Front Suspension Brace Replacement . . . . . . . . . . . . . . .9-50

Front Suspension Front Crossmember . . . . . . . . . . . . . . .9-60

Front Suspension Rear Crossmember . . . . . . . . . . . . . . .9-61

Inspection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .9-64

Left Engine Mount Bracket . . . . . . . . . . . . . . . . . . . . . . . .9-54

Left Intermediate Body Mount Bracket . . . . . . . . . . . . . . .9-57

Lifting Shackle Replacement . . . . . . . . . . . . . . . . . . . . . . .9-47

Radiator Front Mount Bracket . . . . . . . . . . . . . . . . . . . . . .9-46

Rear Suspension Front Crossmember . . . . . . . . . . . . . . .9-62

Rear Suspension Rear Crossmember . . . . . . . . . . . . . . . .9-63

Rear-Front Tiedown Bracket. . . . . . . . . . . . . . . . . . . . . . . .9-59

Rear-Rear Tiedown Bracket . . . . . . . . . . . . . . . . . . . . . . . .9-58

Repairs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .9-67

Right Engine Mount Bracket . . . . . . . . . . . . . . . . . . . . . . .9-55

Right Front Body Mount Bracket . . . . . . . . . . . . . . . . . . . .9-55

Right Intermediate Body Mount Bracket . . . . . . . . . . . . .9-57

Transmission Crossmember Support . . . . . . . . . . . . . . . .9-56

Input Seal Replacement . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-11

Repair . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-12

Replacement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-8

Side Cover Replacement . . . . . . . . . . . . . . . . . . . . . . . . . . 9-11

Spindle Bearing Adjustment . . . . . . . . . . . . . . . . . . . . . . . 9-19

Spindle Seal Replacement . . . . . . . . . . . . . . . . . . . . . . . . . 9-17

Vent Line Replacement. . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-24

Halfshaft Boot Replacement . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-21

Splash Shield Support Bracket Replacement . . . . . . . . . . . . . 9-51

Spring Seat Replacement. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-53

Suspension System

Control Arm Bushing Replacement . . . . . . . . . . . . . . . . . . 9-7

Frame Extension Replacement . . . . . . . . . . . . . . . . . . . . . 9-47

Front Bumper and Towing Brackets . . . . . . . . . . . . . . . . . 9-45

Front Bumper Mounting Bracket . . . . . . . . . . . . . . . . . . . . 9-46

Lower Ball Joint Replacement . . . . . . . . . . . . . . . . . . . . . . . 9-5

Lower Control Arm Replacement . . . . . . . . . . . . . . . . . . . . 9-7

Radius Rod Replacement . . . . . . . . . . . . . . . . . . . . . . . . . . 9-3

Rear Upper Control Arm Bracket. . . . . . . . . . . . . . . . . . . . 9-58

Stabilizer Bar Link Replacement . . . . . . . . . . . . . . . . . . . . . 9-2

Stabilizer Bar Replacement . . . . . . . . . . . . . . . . . . . . . . . . . 9-2

Upper Ball Joint Replacement . . . . . . . . . . . . . . . . . . . . . . 9- 4

Upper Control Arm Replacement . . . . . . . . . . . . . . . . . . . . 9-5

Assembly Repair . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-72, 9-81

Cable Replacement . . . . . . . . . . . . . . . . . . . . . . . . . 9-71, 9-80

Electric Thermal Switch/Brush Assembly . . . . . . . 9-76, 9-85

Replacement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-70, 9-79

Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-70

9-2

Axles, Suspension, and Frame

___________________________________________

®

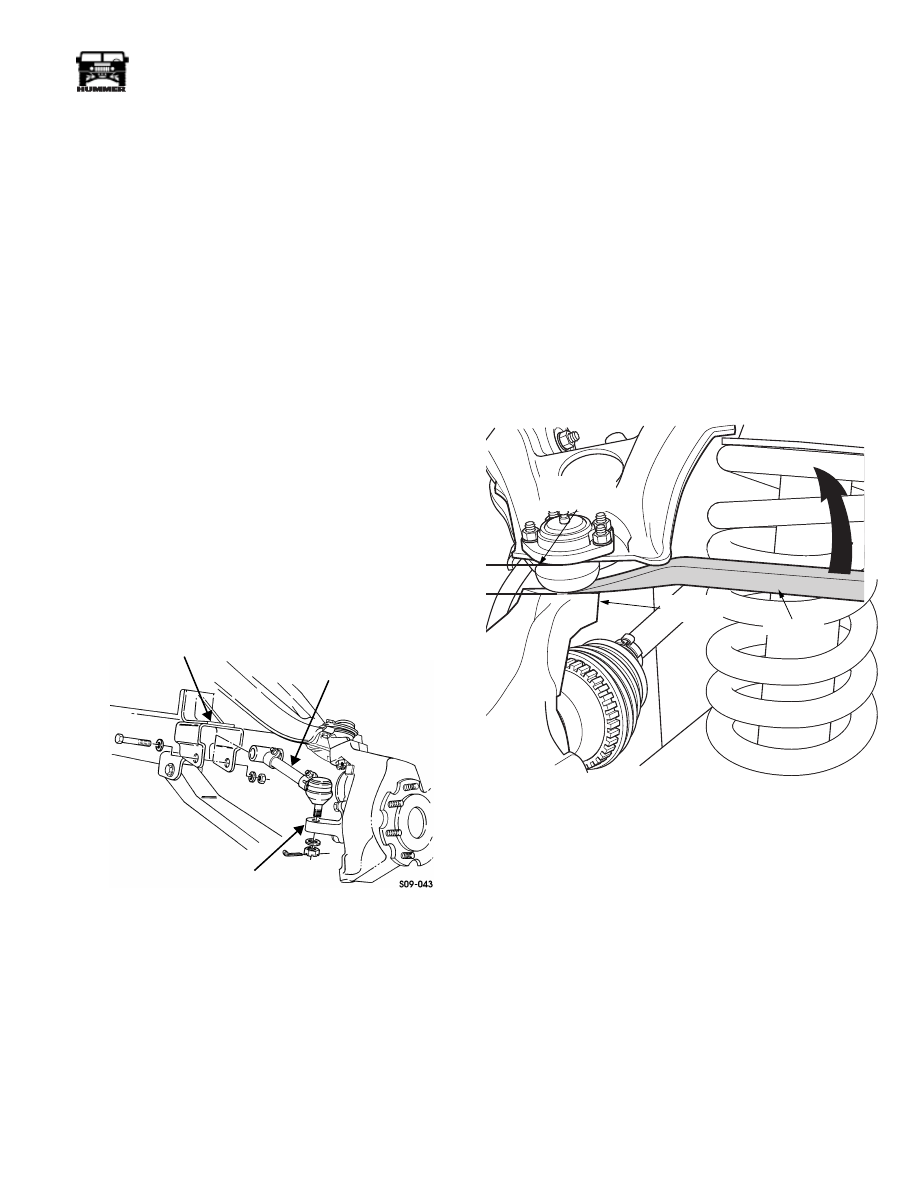

SUSPENSION SYSTEM DESCRIPTION

The HUMMER suspension system consists of a heavy-duty

coil spring, a heavy-duty hydraulic shock absorber, and an up-

per and lower control arm at each wheel. This suspension sys-

tem provides for a smoother ride and allows for more positive

control of the vehicle.

Ball joints allow the control arms and geared hubs to change

angles for smooth steering during turns. A stabilizer bar is lo-

cated on the front suspension to aid in stabilizing the vehicle

when it is turning. Each end of the stabilizer bar is attached to

the lower control arms (Figure 9-1).

Figure 9-1: Suspension System

STABILIZER BAR REPLACEMENT

Removal

NOTE:

Stabilizer bar must be removed from bar links at each

end of lower control arms.

1.

Remove two locknuts, three washers, and pin securing bar

link to stabilizer bar (Figure 9-2).

2.

Remove two locknuts, washers, clamp, and stabilizer bar

from frame bracket.

3.

Remove bushing from stabilizer bar.

Installation

1.

Install bushing on stabilizer bar (Figure 9-2).

2.

Install stabilizer bar on frame bracket with clamp, two

washers, and locknuts. Tighten locknuts to 60 lb-ft

(81 N•m).

3.

Install stabilizer bar on bar link with pin, three washers,

and two locknuts. Tighten locknuts to 75 lb-ft (102 N•m).

Figure 9-2: Stabilizer Bar Replacement

STABILIZER BAR LINK REPLACEMENT

Removal

1.

Remove locknut and two washers securing bar link to sta-

bilizer bar (Figure 9-3).

2.

Remove bolt, two washers, and bar link from lower

control arm.

Installation

1.

Apply thread-locking compound to threads of bolt. Install

bar link to lower control arm with two washers and bolt.

Tighten bolt to 70 lb-ft (95 N•m) (Figure 9-3).

2.

Install bar link on stabilizer bar with two washers and

locknut. Tighten locknut to 75 lb-ft (102 N•m).

Figure 9-3: Stabilizer Bar Link Replacement

UPPER

BALL

GEARED HUB

LOWER

SHOCK

COIL

CONTROL

JOINT

SPRING

ABSORBER

CONTROL

ARM

ARM

BUSHING

FRAME

BAR LINK

PIN

STABILIZER

BRACKET

BAR

BAR LINK

LOWER

STABILIZER

BAR

CONTROL ARM

__________________________________________

Axles, Suspension, and Frame 9-3

®

05745159

RADIUS ROD REPLACEMENT

Removal

1.

Remove wheel.

2.

Remove cotter pin, slotted nut, and washer securing radius

rod to geared hub (Figure 9-4).

3.

Using puller J–24319-B or equivalent, separate radius rod

from geared hub.

4.

Remove locknut, washers, bolt, and radius rod from

bracket.

Installation

1.

Install radius rod on bracket with washer, bolt, washer, and

locknut. Tighten locknut to 260 lb-ft (353 N•m)

(Figure 9-4).

CAUTION:

Do not loosen slotted nut to install cotter pin. Do-

ing this may result in damage to equipment.

NOTE:

When slotted nuts are tightened to prescribed torque

values, cotter pins must have a minimum of 50% engagement

with the nut slots.

2.

Install radius rod on geared hub with washer and slotted

nut. Tighten slotted nut to 70 lb-ft (95 N•m). Install cotter

pin in slotted nut.

3.

Install wheel.

Figure 9-4: Radius Rod Replacement

UPPER BALL JOINT WEAR CHECK PROCEDURE

NOTE:

If the vehicle was previously lifted off the ground for

other service, center the steering wheel, roll the vehicle for-

ward and back to settle the suspension and relieve the tension

on the ball joints before beginning checking procedure.

1.

With the vehicle on the ground (being careful not to dam-

age the boot), place the tip of a prybar between the steer-

ing knuckle and the ball joint boot (Figure 9-5).

2.

With the shank of the prybar contacting the upper control

arm as shown, pry upward and note the movement of the

ball joint against a ruler. Be careful to measure only the

ball joint movement and not the flex of the control arm

resulting from prying against it.

3.

Any upper ball joint with more than 1/16” (1.6 mm)

movement should be replaced.

Figure 9-5: Upper Ball Joint Wear Check

BRACKET

GEARED HUB

RADIUS ROD

7-S09-026.1

PRYBAR

MEASURE

MOVEMENT

HERE

STEERING

KNUCKLE

9-4

Axles, Suspension, and Frame

___________________________________________

®

UPPER BALL JOINT REPLACEMENT

Removal

1.

Remove wheel.

2.

Raise and support lower control arm.

3.

Disconnect the p-clamp securing the vent line and speed

sensor lead to the upper control arm.

4.

Remove cotter pin and slotted nut from upper ball joint

(Figure 9-6).

5.

Remove four locknuts, bolts, eight washers and upper ball

joint from upper control arm.

6.

Separate upper ball joint from geared hub using ball joint

remover J–24319-B or equivalent. Remove ball joint.

Installation

1.

Position upper ball joint on upper control arm, ensuring

upper ball joint is placed above upper control arm

(Figure 9-6).

NOTE:

Check upper ball joint torque 15 minutes after initial

installation. Adjust if necessary.

2.

Install upper ball joint on upper control arm with four

bolts, locknuts and eight washers. Tighten 3/8 fine thread

locknuts to 30 lb-ft (41 N•m).

NOTE:

Do not loosen slotted nut to install cotter pin.

3.

Install upper ball joint on geared hub with slotted nut.

Using crowfoot and adapter, tighten slotted nut to 65 lb-ft

(88 N•m). Install cotter pin in slotted nut.

4.

Install the p-clamp securing the vent line and speed sensor

lead to the upper control arm.

5.

Lubricate upper ball joint.

6.

Install wheel.

Figure 9-6: Upper Ball Joint Replacement

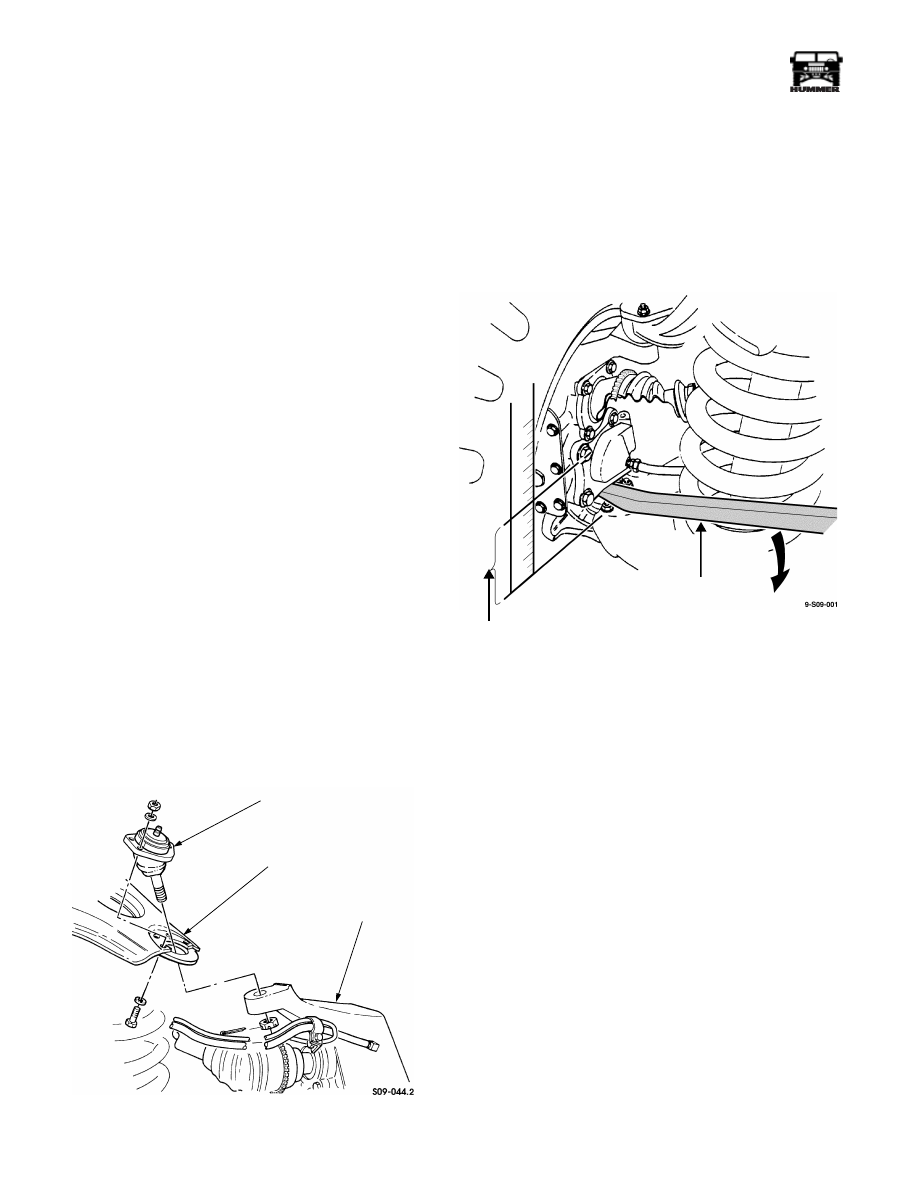

LOWER BALL JOINT WEAR CHECK

1.

Support lower control arm with a jack or stand to unload

lower ball joint.

2.

Place prybar between lower arm at ball joint and geared

hub and measure vertical play obtained by moving pry bar

down (Figure 9-7). Maximum play should not

exceed 1/8"

(3.5 mm).

3.

Replace ball joint if end play exceeds the limit.

Figure 9-7: Lower Ball Joint Wear Check

UPPER CONTROL ARM

UPPER BALL JOINT

GEARED HUB

MEASURE

MOVEMENT

HERE

PRYBAR

Нет комментариевНе стесняйтесь поделиться с нами вашим ценным мнением.

Текст