Hummer H1 (2002+). Manual — part 110

______________

Wheels and Tires/Central Tire Inflation System (CTIS) 6-55

®

05745159

Installation

NOTE: Ensure that any new fittings have pipe sealant pre-ap-

plied to threads. If none is present, apply a pipe sealant to fit-

ting threads.

1.

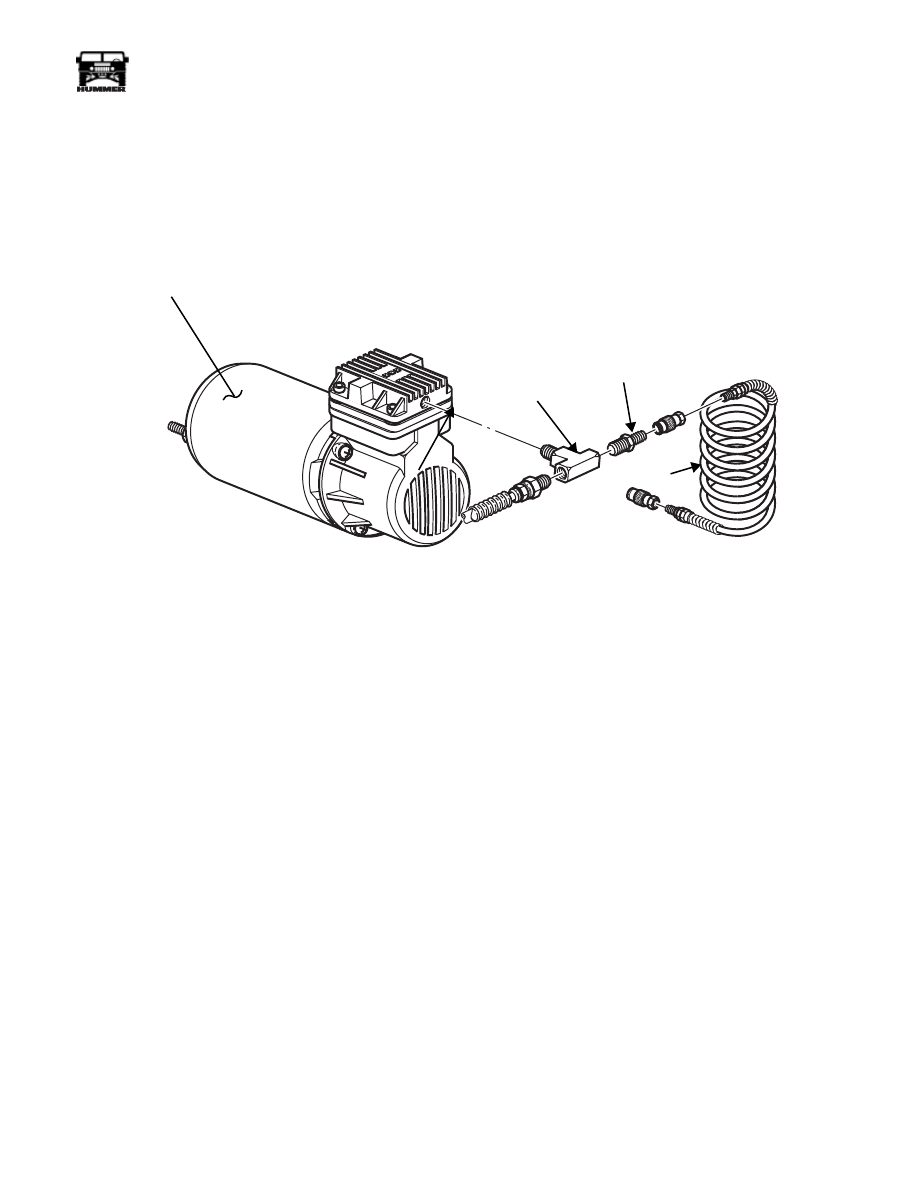

Secure auxiliary air valve to existing tee (Figure 6-81).

2.

Connect tires to CTIS by pushing in quick-disconnect

valve body until valve tee section locks (clicks) into place.

Perform this procedure on remaining three wheels

(Figure 6-80).

3.

Start engine and check CTIS for air leaks around installed

fittings.

4.

Lower and secure hood.

Figure 6-81: CTIS Auxiliary Air Hose

9-S06-017

COMPRESSOR

AIR HOSE

EXISTING TEE

AUXILIARY

AIR VALVE

6-56

Wheels and Tires/Central Tire Inflation System (CTIS)

_______________

®

SPECIAL TOOLS

Tool No.

Description

05710216

Internal tubeless tire repair kit

05710215

External tubeless tire repair kit

05710215

05710216

________________________________________________________________________________

7-1

®

05745159

Section 7 Brake System

TABLE OF CONTENTS

Anti-lock Brake System (ABS) and Automatic Traction Control,

TorqTrac 4™ (TT4™) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7-34

ABS ECU Replacement . . . . . . . . . . . . . . . . . . . . . . . . . . . .7-50

ABS Modulator Replacement . . . . . . . . . . . . . . . . . . . . . . .7-48

ABS/TT4 Diagnostics . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7-34

Fault Diagnostic Procedure . . . . . . . . . . . . . . . . . . . . . . . .7-34

Fuse and Relay Replacement . . . . . . . . . . . . . . . . . . . . . . .7-50

System Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7-34

System Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7-34

Bench Bleeding . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7-12

Bleeding . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7-12

Replacement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7-11

Bleeding Instructions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7-8

Brake Line Replacement . . . . . . . . . . . . . . . . . . . . . . . . . . .7-14

Brake Rotor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7-32

Burnishing Linings and Rotors . . . . . . . . . . . . . . . . . . . . .7-10

Caliper Overhaul, Rear . . . . . . . . . . . . . . . . . . . . . . . . . . . .7-29

Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7-1

Diagnosis . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7-2

Disc Brake Caliper Repair, Front . . . . . . . . . . . . . . . . . . . .7-27

Front Service Brake Caliper . . . . . . . . . . . . . . . . . . . . . . . .7-10

Hydro-Boost System Diagnosis. . . . . . . . . . . . . . . . . . . . . . 7-7

Left Parking Brake Cable Replacement . . . . . . . . . . . . . . 7-23

Pad Replacement, Service Brake. . . . . . . . . . . . . . . . . . . . . 7-9

Parking Brake Cable Replacement, L . . . . . . . . . . . . . . . . 7-24

Parking Brake Cable Replacement, R . . . . . . . . . . . . . . . . 7-23

Parking Brake Lever Adjustment. . . . . . . . . . . . . . . . . . . . 7-33

Parking Brake Lever Replacement . . . . . . . . . . . . . . . . . . 7-26

Parking Brake Switch Replacement . . . . . . . . . . . . . . . . . 7-33

Pedal Replacement, Service Brake . . . . . . . . . . . . . . . . . . 7-17

Proportioning Valve Replacement. . . . . . . . . . . . . . . . . . . 7-17

Rotor Replacement, Service Brake . . . . . . . . . . . . . . . . . . 7-17

Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-4

Rear Dual Service/Parking Brake

Adjustment. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-25

Caliper Replacement. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-20

Pad Replacement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-18

Rod Replacement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-25

Speed Sensor Replacement. . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-49

Tone Wheel Replacement. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-50

POWER BRAKE SYSTEM DESCRIPTION

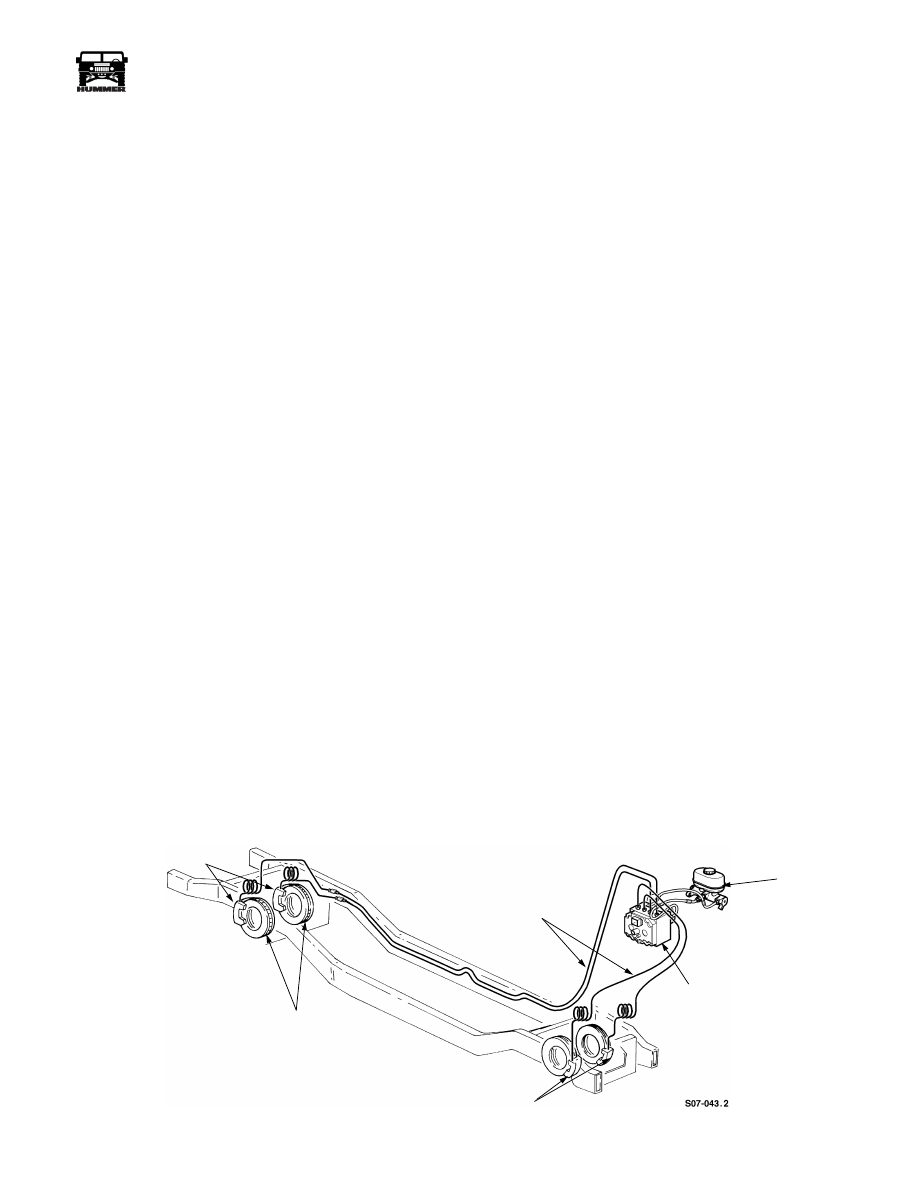

The hydraulic power disc brake system is a four-wheel, inboard-

mounted design. The dual reservoir master cylinder stores brake

fluid and converts mechanical brake pedal force to hydraulic

pressure. The proportioning valve provides balanced front-to-rear

braking and activates the brake warning lamp in case of a brake

hydraulic system malfunction. The dual reservoir master cylinder

provides fluid for separate front and rear brake systems

(Figure 7-1). The hydro-boost provides power brake assist and is

operated by fluid pressure from the power steering pump. The

hydro-boost is equipped with an accumulator. The accumulator

stores nitrogen gas under pressure in

the event that both the normal assist and accumulator assist are

not available. The power steering pump provides hydraulic oil

pressure to operate the brake system’s hydro-boost feature. If the

power steering pump fails to supply hydraulic pressure to the hy-

dro-boost, the pressure stored in the accumulator will provide

enough hydraulic pressure for approximately four power-assisted

stops. Applying the parking brake prevents the rear brake rotors

from rotating and can also be used to help stop the vehicle in low

speed emergency situations.

The disc brakes are mounted on the output flanges of the front

and rear axle assemblies.

Figure 7-1: Brake System

BRAKE

BRAKE ROTORS

BRAKE CALIPERS

HYDRAULIC BRAKE

LINES

CALIPERS

MASTER

CYLINDER

ABS

MODULATOR

7-2

Brake System

______________________________________________________________

®

BRAKE SYSTEM DIAGNOSIS

Road Testing

1.

If red warning light is illuminated, note pedal action and

brake response.

2.

Check brake pedal response with transmission in Neutral

and engine running. Pedal should remain firm under

steady foot pressure. If pedal falls away, problem is either

in hydro-boost, master cylinder, or brakeline.

3.

During road test, make normal and firm brake stops in 25-

40 mph range. Note faulty brake operation such as pull,

grab, drag, noise, fade, pedal pulsation, etc. (noise and

pedal pulsation during an ABS event is normal).

4.

Inspect suspect brake components and refer to problem

diagnosis information for causes of various brake

conditions.

Component Inspection

Fluid leak points and dragging brake units can usually be lo-

cated without removing any components. The area around a

leak point will be wet with fluid. The components at a dragging

brake unit will be quite warm or hot to the touch.

During component inspection, pay particular attention to

heavily rusted/corroded brake components (e.g. rotors, caliper

pistons, lines, etc.).

Heavy accumulations of rust may be an indicator of rust and

corrosion damage to a brake component. It is wise to remove

surface rust in order to accurately determine the depth of rust

penetration and damage. Light surface rust is fairly normal and

not a major concern (as long as it is removed). However, heavy

rust buildup, especially on high mileage vehicles, may actually

cover structural damage to such important components as

brakelines and rotors.

Diagnosing Service Brake Problems

Brake Warning Light Operation

The red brake warning light will illuminate when the parking

brakes are applied, and when there is a low fluid level in the

brake fluid reservoir. If the light comes on, first verify that the

parking brakes are fully released. Then check pedal action and

fluid level. If a problem is confirmed, inspect the wheel brake

hydraulic system.

Pedal Falls Away

A brake pedal that falls away under steady foot pressure is gen-

erally the result of a system leak. The leak point could be at a

brakeline, fitting, hose, or caliper. Internal leakage in the mas-

ter cylinder caused by worn or damaged piston cups, may also

be the problem cause.

If leakage is severe, fluid will be evident at or around the leak-

ing component. However internal leakage in the master cylin-

der will not be physically evident. Refer to the cylinder test

procedure in this section.

Low Pedal

If a low pedal is experienced and the warning light is

not

on,

worn lining and worn rotors are the most likely cause.

If the red warning light is on, low fluid in the master cylinder is

the most likely cause. A leak at a caliper, brakeline, or brake

hose will cause the fluid level in the master cylinder reservoir

to become low, triggering the low fluid switch and the red

brake warning light.

Spongy Pedal

A spongy pedal is most often caused by air in the system.

However, substandard brake lines and hoses will also cause a

condition similar to a spongy pedal. The proper course of ac-

tion is to bleed the system, or replace suspect quality brake

lines and hoses.

Hard Pedal or High Pedal Effort

A hard pedal or high pedal effort may be due to lining that is

water soaked, contaminated, glazed, or badly worn.

Brake Drag

Brake drag occurs when the lining is in constant contact with

the rotor. Drag can occur at one wheel, all wheels, fronts only,

or rears only. It is a product of incomplete brakeshoe release.

Drag can be minor or severe enough to overheat the linings,

and rotors.

Brake drag also has a direct effect on fuel economy. If undetec-

ted, minor brake drag can be misdiagnosed as an engine or

transmission/torque converter problem.

Minor drag will usually cause slight surface glazing of the lin-

ing. It can also generate hard spots in rotors from the overheat-

cool down process. In most cases, the rotors, wheels and tires

are quite warm to the touch after the vehicle is stopped.

Severe drag can char the brake lining all the way through. It

can also distort and score rotors to the point of needing replace-

ment. The wheels, tires and brake components will be ex-

tremely hot. In severe cases, the lining may generate smoke as

it chars from overheating.

Нет комментариевНе стесняйтесь поделиться с нами вашим ценным мнением.

Текст