Hummer H1 (2002+). Manual — part 284

_____________________________________________________

PCM/Tech 1 Scan Tool 69

®

05745159

55555555555

DTC P0236 - Turbocharger (TC) Boost System

Step

Action

Value(s)

Yes

No

1

Important:

Before clearing DTC(s) use the scan tool “Capture Info”.

Was the

“On-Board Diagnostic (OBD) System Check”

performed?

—

Go to Step 2.

Go to

OBD

System Check.

2

Is DTC P1656 set?

—

Go to

DTC table.

Go to Step 3

3

1. Disconnect the vacuum line at the turbocharger wastegate actuator.

2. Install a vacuum gauge in place of the turbocharger wastegate actuator.

3. Start the engine.

4. Observe the vacuum at idle.

Is the vacuum greater than or equal to the specified value?

15 in. Hg Go to Step 4. Go to Step 6

4

1. Disconnect wastegate solenoid electrical connector with engine running.

2. With the vacuum gauge still in place, observe the vacuum at idle.

Is the vacuum greater than the specified value?

1 in. Hg

Go to Step

12

Go to Step 5

5

1. Turn the engine OFF.

2. Connect a hand held vacuum pump to the turbocharger wastegate actuator.

3. Apply 5 in. Hg of vacuum.

Does the turbocharger wastegate actuator hold vacuum?

—

Go to Step 7 Go to Step 14

6

1. Check all vacuum lines from vacuum pump to turbocharger wastegate actuator:

• leaks

• deformities

• pinches

2. If a problem is found, repair as necessary.

Was a problem found?

—

Go to Step

15

Go to Step 8

7

1. Verify the engine if OFF.

2. Disconnect all vacuum lines to the wastegate actuator.

3. Grip the wastegate actuator rod with a pair of pliers.

4. Attempt to move the wastegate actuator rod back and forth.

Does the turbocharger wastegate actuator rod move freely?

—

Go to Step 8 Go to Step 14

8

Check the vacuum pump for proper output (refer to Engine Mechanical).

Is the action complete?

—

Go to Step

15.

Go to Step 9

9

1. Access engine data with a scan tool

2. Start the engine and bring to a steady idle.

3. Observe the Boost Pressured display on the scan tool.

4. Increase the engine RPM to 1,500 then back to idle.

Does the scan tool display a change in the boost pressure?

—

Go to Step

10

Go to Step 11

10

DTC is intermittent. If no additional DTCs are stored, refer to diagnostic Aids.

Are any additional DTCs stored?

—

Go to the

DTC table.

Go to Diag-

nostic Aids

11

Replace the boost sensor. Refer to the Boost Sensor Replacement.

Is the sensor installed?

—

Go to Step

16

—

12

Check for a plugged wastegate solenoid filter.

Is the wastegate solenoid filter plugged?

—

Go to Step

13

Go to Step 16

13

Replace the wastegate solenoid.

Is the action complete?

—

Go to Step

16

—

14

Replace the turbocharger wastegate actuator.

Is the action complete?

—

Go to Step

16

—

15

Replace the vacuum pump. Refer to Engine Mechanical.

Is the pump installed?

—

Go to Step

16

—

16

1. Using the Scan Tool, select DTC, clear info.

2. Start engine and idle at normal operating temperature.

3. Select DTC, Specific, then enter the DTC number which was set.

4. Operate the vehicle until the Scan Tool indicates that the diagnostic ran.

Does the Scan Tool indicate that this diagnostic Passed?

—

Go to Step

17

Go to Step 2

17

Using the Scan Tool, select Capture Info, Review Info.

Are any DTCs displayed that have not been diagnosed?

—

Go to the

DTC Table

System OK

4-1-00

70

PCM/Tech 1 Scan Tool

_____________________________________________________

®

DTC P0237 Turbocharger (TC) Boost Sensor

Circuit Low Voltage

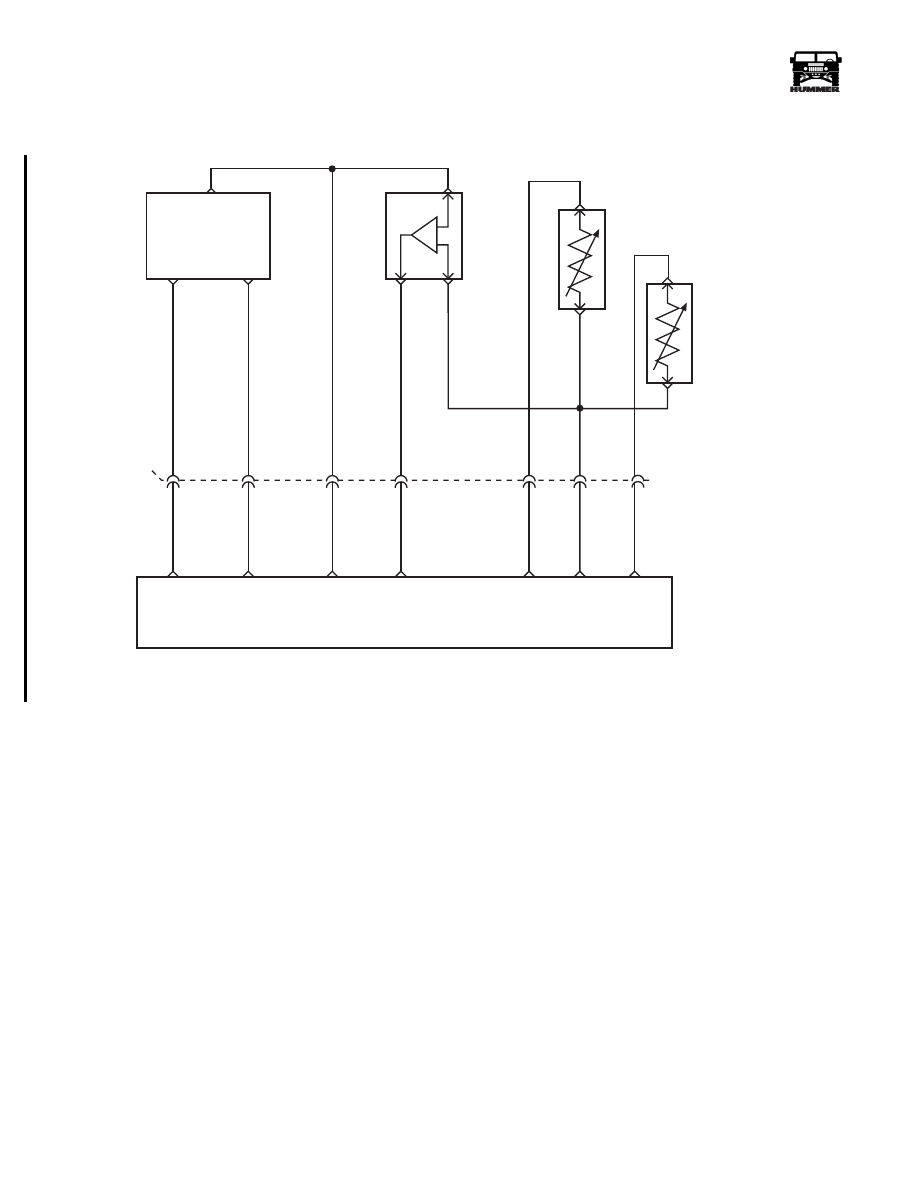

Circuit Description

The PCM sends a 5 volt reference signal to the boost sensor.

As manifold pressure changes, the electrical resistance of the

boost sensor also changes. By monitoring the sensor output

voltage, the PCM detects how much pressure is being pro-

duced by the turbocharger in the intake manifold. The PCM

uses the boost sensor to control turbo boost and fuel at different

loads. This is a type B DTC.

Conditions for Setting the DTC

• Boost pressure less than 40 kPa.

• Conditions met for 2 seconds.

Action Taken When the DTC Sets

No turbo boost.

Conditions for Clearing the MIL/DTC

• The PCM will turn the MIL off after three consecutive

trips without a fault condition.

• A History DTC will clear when forty consecutive

warm-up cycles that the diagnostic does not fail (coolant

temperature has risen 5°C (40°F) from start up coolant

temperature and engine coolant temperature exceeds

71°C (160°F) that same ignition cycle).

• Use of a Scan Tool.

Diagnostic Aids

With the ignition “ON” and the engine stopped, boost pressure

is equal to atmospheric pressure. Comparison of this reading

with known good vehicle using the same sensor is a good way

to check accuracy of a “suspect” sensor. Readings should be

the same +.4 volt. Very little boost can be attained by revving

the engine in neutral. If the Boost sensor signal circuit is open

or shorted to ground, Boost solenoid will show a zero duty cy-

cle. A J–39200 can be used to measure (actual) signal voltage

at the PCM harness connector.

Test Description

Number(s) below refer to the number(s) on the diagnostic table.

2. This step will determine if DTC P0237 is the result of a hard

failure or an intermittent condition.

3. This step simulates conditions for a DTC P0237. If the PCM

recognizes the change, the PCM and signal circuit are OK.

5 VOLT

REFERNCE

CKP

SENSOR

SIGNAL

SENSOR

GROUND

CRANK

SHAFT

POSITION

SENSOR

(CKP)

A

B

B

A

B

B

A

A

C

C

C5

BOOST/

BARO

PRESSURE

SENSOR

INTAKE AIR

TEMPERATURE

SENSOR (IAT)

ENGINE

COOLANT

TEMP

SENSOR

(ECT)

POWERTRAIN

CONTROL

MODULE

CKP

SENSOR

SIGNAL

SENSOR

GROUND

5 VOLT

REFERENCE

BOOST

SENSOR

SIGNAL

SENSOR

GROUND

IAT

SENSOR

SIGNAL

ECT

SENSOR

SIGNAL

C29-A5

651 BK

C29-B12

C27-D13

C27-C14

C27-C1

349 YL

359 BK

350 GY

394 LG

651 PP

354 YL

357 TN

9-S12-066

B9

B11

B12

B10

B5

C4

C5

C27-C11

C27-C4

359 PP

651 BK

4-1-00

_____________________________________________________

PCM/Tech 1 Scan Tool 71

®

05745159

DTC P0237 - Turbocharger (TC) Boost Sensor Circuit Low Voltage

Step

Action

Value(s)

Yes

No

1

Important:

Before clearing DTC(s) use the scan tool “Capture Info” to

record freeze frame and failure records for reference, as data will be lost

when “Clear Info” function is used.

Was the

“On-Board Diagnostic (OBD) System Check”

performed?

—

Go to Step 2.

Go to

OBD

System Check.

2

1. Scan tool connected.

2. Engine idling.

3. With J–39200 connected to ground, probe PCM harness connector Boost

signal circuit.

Does the J–39200 display a voltage less than the specified value?

1.0v

(40 kPa)

Go to Step 3. Go to Step 5.

3

1. Turn the ignition “OFF”.

2. Disconnect the Boost sensor electrical connector.

3. Jumper the Boost sensor 5 volt reference to the Boost sensor signal cir-

cuit at the harness.

4. Turn the ignition “ON”.

Does the scan tool display a Pressure greater than specified value?

202 kPa

Go to Step 6.

Go to Step 4.

4

1. Turn the ignition “OFF”.

2. Boost sensor still disconnected.

3. Remove the jumper wire.

4. Jumper the Boost sensor signal circuit at the harness with a test light con-

nected to B+.

5. Turn the ignition “ON”.

Does the scan tool display a Pressure greater than specified value?

202 kPa

(4.0v)

Go to Step 8.

Go to Step 7.

5

DTC is intermittent.

Are additional DTCs stored?

—

Go to DTC

table.

See Diagnostic

Aids

6

Check for a faulty connection at the Boost sensor.

Was a problem found?

—

Go to Step 13. Go to Step 10.

7

Check for an open or short to ground in Boost sensor signal circuit.

Was a problem found?

—

Go to Step 13. Go to Step 11.

8

Check for an open in the Boost sensor 5 volt reference circuit.

Was a problem found?

—

Go to Step 13.

Go to Step 9.

9

Check for a short to ground in Boost sensor 5 volt reference circuit.

Was a problem found?

—

Go to Step 13. Go to Step 12.

10

Replace the faulty Boost sensor.

Is the action complete?

—

Go to Step 13.

—

11

Check the terminal connectors at the PCM for a poor connections and repair

if necessary. Was a problem found?

—

Go to Step 13. Go to Step 12.

12

Replace the faulty PCM.

Notice:

If the PCM is faulty, the new PCM must

be programmed. Go to

PCM replacement and programming procedures.

Is the action complete?

—

Go to Step 13.

—

13

1. Using the Scan Tool, select “DTC”, “Clear Info”.

2. Start engine and idle at normal operating temperature.

3. Select “DTC”, “Specific”, then enter the DTC number which was set.

4. Operate vehicle within the conditions for setting this DTC as specified in

the supporting text.

Does the Scan Tool indicate that this diagnostic Ran and Passed?

—

Go to Step 14.

Go to Step 2.

14

Using the Scan Tool, select “Capture Info”, “Review Info”.

Are any DTCs displayed that have not been diagnosed?

—

Go to the

DTC table

System OK.

72

PCM/Tech 1 Scan Tool

_____________________________________________________

®

DTC P0238 Turbocharger (TC) Boost Sensor

Circuit High Voltage

Circuit Description

The PCM sends a 5 volt reference signal to the boost sensor.

As manifold pressure changes, the electrical resistance of the

boost sensor also changes. By monitoring the sensor output

voltage, the PCM detects how much pressure is being pro-

duced by the turbocharger in the intake manifold. The PCM

uses the boost sensor to control turbo boost and fuel at different

loads. This is a type B DTC.

Conditions for Setting the DTC

• Boost Pressure greater than or equal to 4.8 volts

(202 kPa).

• Engine Speed less than 3506 RPM.

Action Taken When the DTC Sets

No turbo boost.

Conditions for Clearing the MIL/DTC

• The PCM will turn the MIL off after three consecutive

trips without a fault condition.

• A History DTC will clear when forty consecutive

warm-up cycles that the diagnostic does not fail (coolant

temperature has risen 5°C (40°F) from start up coolant

temperature and engine coolant temperature exceeds

71°C (160°F) that same ignition cycle).

• Use of a Scan Tool.

Diagnostic Aids

With the ignition “ON” and the engine stopped, boost pressure

is approximately equal to Baro. Comparison of this reading

with known good vehicle using the same sensor is a good way

to check accuracy of a “suspect” sensor. Readings should be

the same +.4 volt. Very little boost can be attained by revving

the engine in neutral. A J–39200 can be used to measure (ac-

tual) signal voltage at the PCM harness connector.

Test Description

Number(s) below refer to the number(s) on the diagnostic table.

2. This step simulates conditions for a DTC P0237. If the PCM

recognizes the change, the PCM and the signal circuit are

OK.

3. This step will make sure the PCM is responding to a low

signal voltage. This will indicate that the PCM is OK.

5 VOLT

REFERNCE

CKP

SENSOR

SIGNAL

SENSOR

GROUND

CRANK

SHAFT

POSITION

SENSOR

(CKP)

A

B

B

A

B

B

A

A

C

C

C5

BOOST/

BARO

PRESSURE

SENSOR

INTAKE AIR

TEMPERATURE

SENSOR (IAT)

ENGINE

COOLANT

TEMP

SENSOR

(ECT)

POWERTRAIN

CONTROL

MODULE

CKP

SENSOR

SIGNAL

SENSOR

GROUND

5 VOLT

REFERENCE

BOOST

SENSOR

SIGNAL

SENSOR

GROUND

IAT

SENSOR

SIGNAL

ECT

SENSOR

SIGNAL

C29-A5

651 BK

C29-B12

C27-D13

C27-C14

C27-C1

349 YL

359 BK

350 GY

394 LG

651 PP

354 YL

357 TN

9-S12-066

B9

B11

B12

B10

B5

C4

C5

C27-C11

C27-C4

359 PP

651 BK

4-01-00

Нет комментариевНе стесняйтесь поделиться с нами вашим ценным мнением.

Текст