Hummer H1 (2002+). Manual — part 114

____________________________________________________________

Brake System 7-15

®

05745159

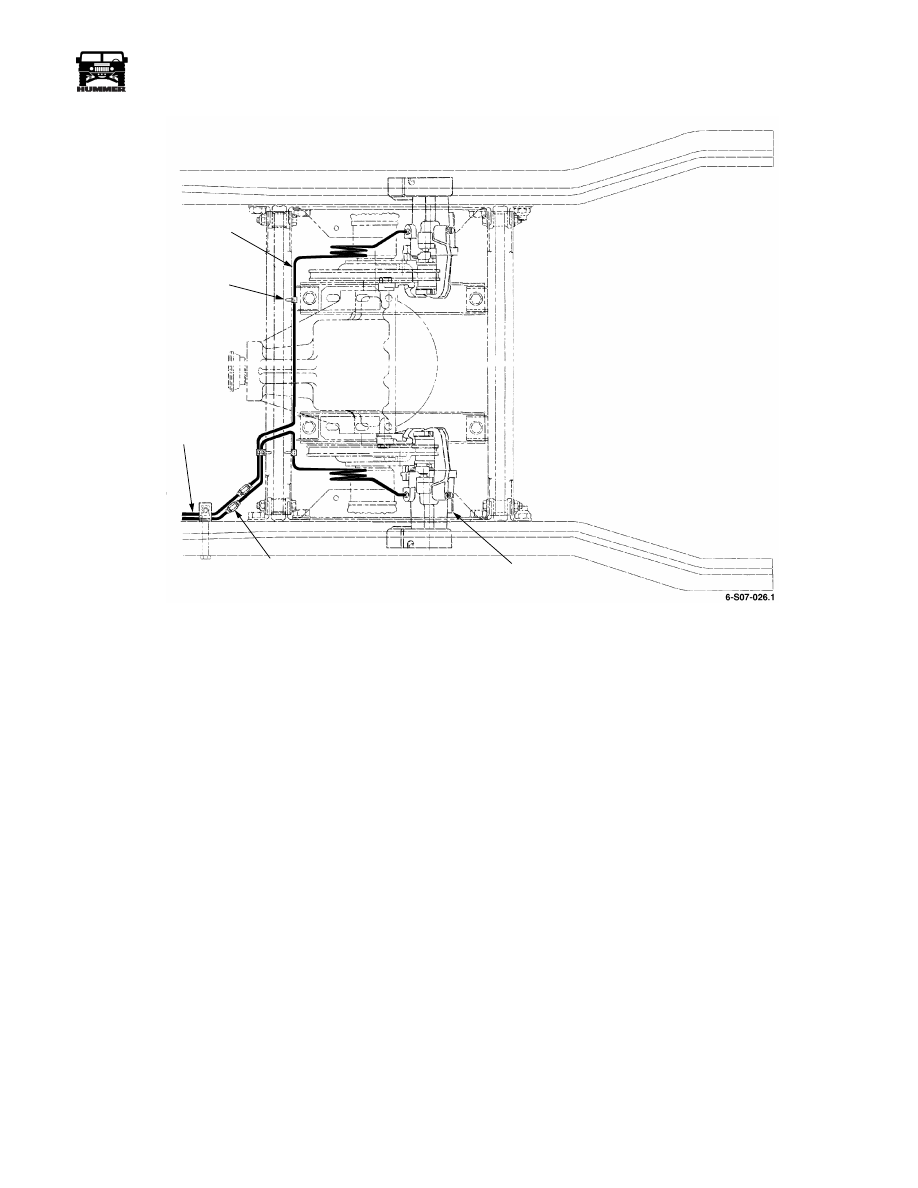

Figure 7-13: Rear Brake Component Location

METAL

BRAKE

LINES

CALIPER

FROM

ABS/TT4

MODULATOR

LINE

MOUNTIG

CLIP

UNION

7-16

Brake System

_____________________________________________________________

®

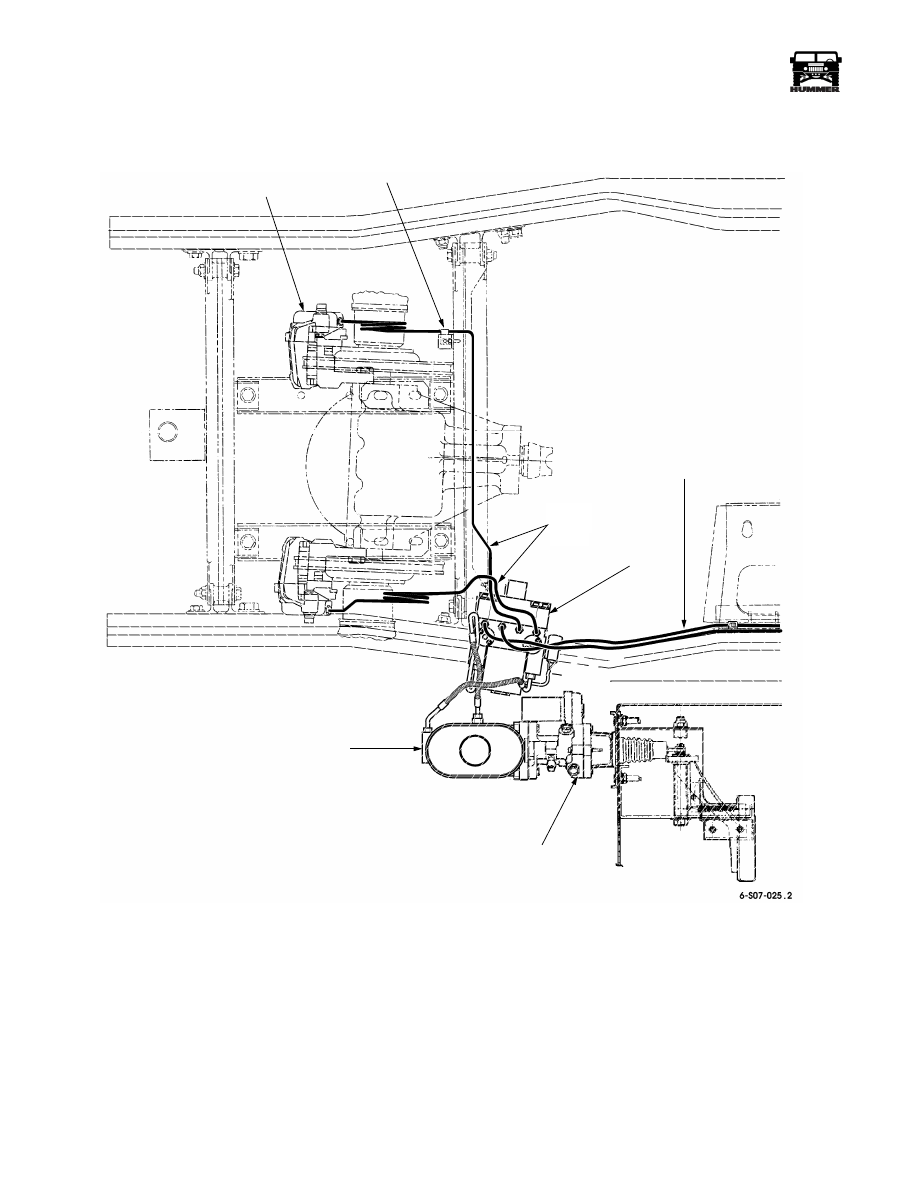

Figure 7-14: Front Brake Component Location

CALIPER

MASTER CYLINDER

HYDROBOOST

METAL

BRAKE

LINES

LINE

MOUNTING

CLIP

METAL LINES

TO REAR CALIPERS

ABS

MODULATOR

____________________________________________________________

Brake System 7-17

®

05745159

SERVICE BRAKE PEDAL REPLACEMENT

Removal

1.

Disconnect the stoplight switch (Figure 7-15).

2.

Remove pushnut and disconnect stoplight switch rod (if so

equipped) from brake pedal assembly. Discard pushnut.

(Figure 7-15).

3.

Disconnect return spring from brake pedal assembly.

4.

Remove cotter pin and washer securing hydro-boost

pushrod to brake pedal bellcrank, and disconnect hydro-

boost pushrod from brake pedal bellcrank. Remove spring

washer. Discard cotter pin and spring washer.

5.

Remove nut, two washers, pivot pin, and brake pedal

assembly from bracket.

6.

Remove two bushings from brake pedal assembly. Discard

two bushings.

Installation

1.

Apply silicone grease to inside of two bushings. Install two

bushings in brake pedal assembly.

2.

Install brake pedal assembly on bracket with pivot pin, two

washers, and nut. Using adapter and crowfoot, tighten nut to

60 lb-ft (81 N•m).

3.

Install spring washer on brake pedal bellcrank. Connect

hydro-boost pushrod to brake pedal bellcrank with washer

and cotter pin.

4.

Connect return spring to brake pedal assembly.

5.

Use the pushnut to install the stoplight switch rod (if so

equipped) to brake pedal assembly.

6.

Connect the stoplight switch.

7.

Operate vehicle and check brakes for proper operation.

8.

Check brake lights for proper operation.

Figure 7-15: Service Brake Pedal Components

SERVICE BRAKE ROTOR REPLACEMENT

Removal

1.

Remove service brake caliper.

2.

Remove six capscrews, lockwashers, halfshaft, and rotor

from output flange. Discard lockwashers (Figure 7-17).

Installation

1.

Apply thread-locking compound to threads of capscrews.

2.

Install rotor on output flange.

3.

Secure halfshaft and rotor to output flange with twelve

inclined cam lockwashers and capscrews with preapplied

threadlocker. Tighten capscrews to 57 lb-ft (77 N•m).

4.

Install service brake caliper.

Figure 7-16: Hydro-Boost And Master Cylinder

Mounting

Figure 7-17: Service Brake Rotor

PIVOT PIN

STOPLIGHT

BRACKET

BUSHING

BRAKE PEDAL

BRAKE PEDAL

HYDRO-BOOST

RETURN SPRING

PUSHROD

BELLCRANK

ASSEMBLY

STRIKER

SPRING

SWITCH

WASHER

FRONT BRAKE LINE

HYDRO-

MASTER

REAR BRAKE LINE

BOOST

CYLINDER

HALFSHAFT

ROTOR

OUTPUT FLANGE

7-18

Brake System

_____________________________________________________________

®

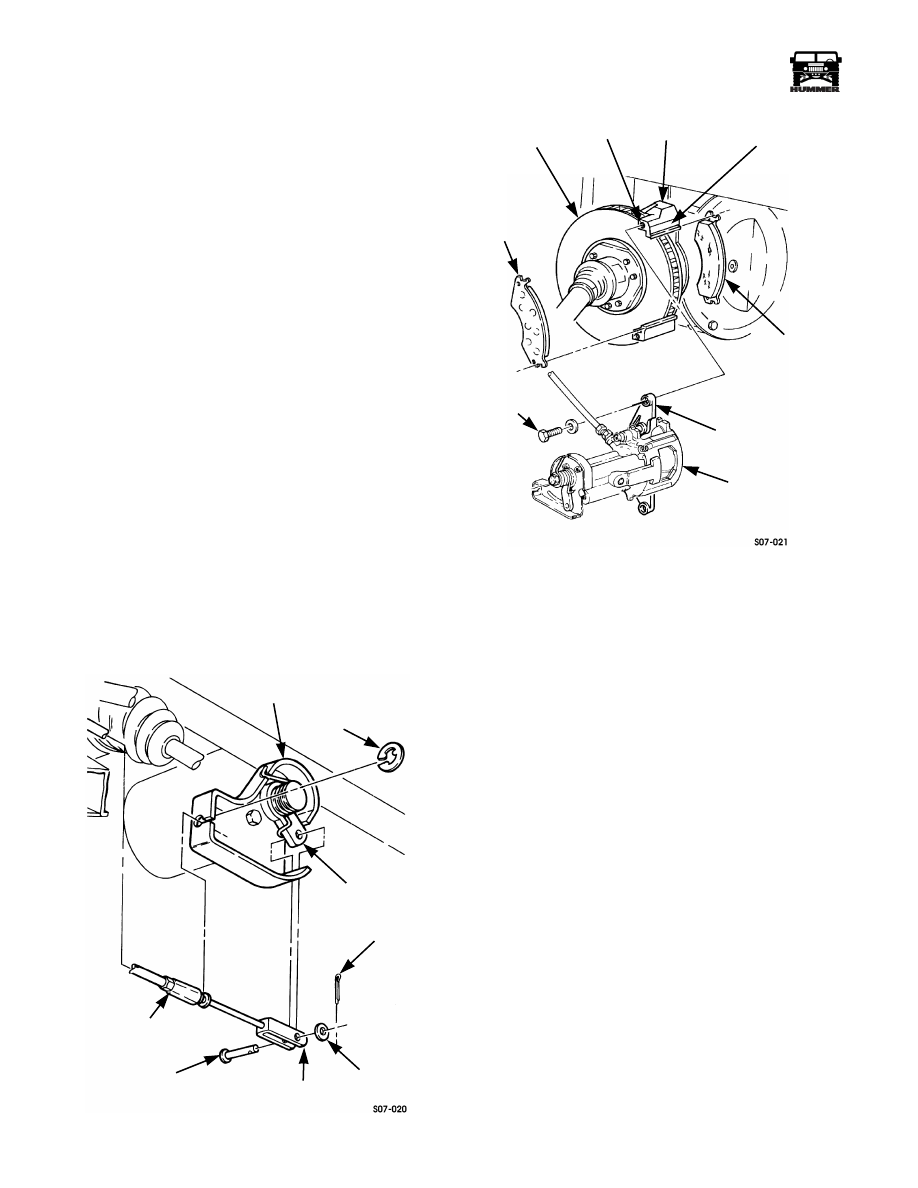

REAR DUAL SERVICE/PARKING BRAKE PAD

REPLACEMENT

Removal

1.

Put transmission in PARK, chock wheels, and release

parking brake.

2.

Remove cotter pin, washer, and clevis pin securing

parking brake cable to lever. Discard cotter pin

(Figure 7-18).

3.

Remove clip securing parking brake cable to caliper cable

bracket and disconnect cable from caliper cable bracket.

Discard clip.

CAUTION: Caliper must be supported during removal to pre-

vent damage to brake line.

4.

Remove two capscrews and washers securing yoke and

caliper to adapter, and pull yoke and caliper away from

rotor (Figure 7-19).

NOTE:

Note positioning of brake pad surfaces for installation.

5.

Remove two brake pads from adapter and rotor.

Cleaning and Inspection

NOTE:

Clean all components, examine for wear or damage,

and replace if necessary.

1.

Clean mating surfaces of caliper and adapter and lightly

lubricate adapter slides with brake component lubricant

(Figure 7-19).

Figure 7-18: Rear Dual Brake Components

Figure 7-19: Rear Dual Brake Pad and Rotor

2.

Inspect caliper and caliper piston face for pitting or

damage (Figure 7-20).

3.

Inspect piston dust boot and bushings for tears or

deterioration.

4.

Inspect caliper cable bracket for looseness, damage, and

rotation.

5.

Thoroughly clean and inspect rotor for heat checks,

discoloration, pitting, or scoring (Figure 7-19).

CAUTION: Ensure that grease and oil are not in contact with

rotor and/or brake pad friction surface. Failure to do so will

result in damage to equipment and poor performance.

NOTE:

Replace brake pads in sets only. If operation in wet

and muddy conditions is expected, replace brake pads if brake

lining thickness is less than 1/8 in. (3.2 mm).

6.

Inspect brake pads for glazing, oil saturation, or wear. If

glazed, oil saturated, or if brake lining thickness is less

than 1/8 in. (3.2 mm), replace both pads and pads on

opposite caliper.

CALIPER CABLE

CLIP

PARKING BRAKE

CABLE

CLEVIS PIN

PARKING BRAKE

LEVER

CLEVIS

BRACKET

COTTER

PIN

WASHER

ADAPTER

BRAKE PAD

ADAPTER SLIDE

YOKE

CALIPER

BRAKE PAD

ROTOR

TAPPED

HOLE

CAP

SCREW

Нет комментариевНе стесняйтесь поделиться с нами вашим ценным мнением.

Текст