Jaguar XJ (X350). Manual — part 516

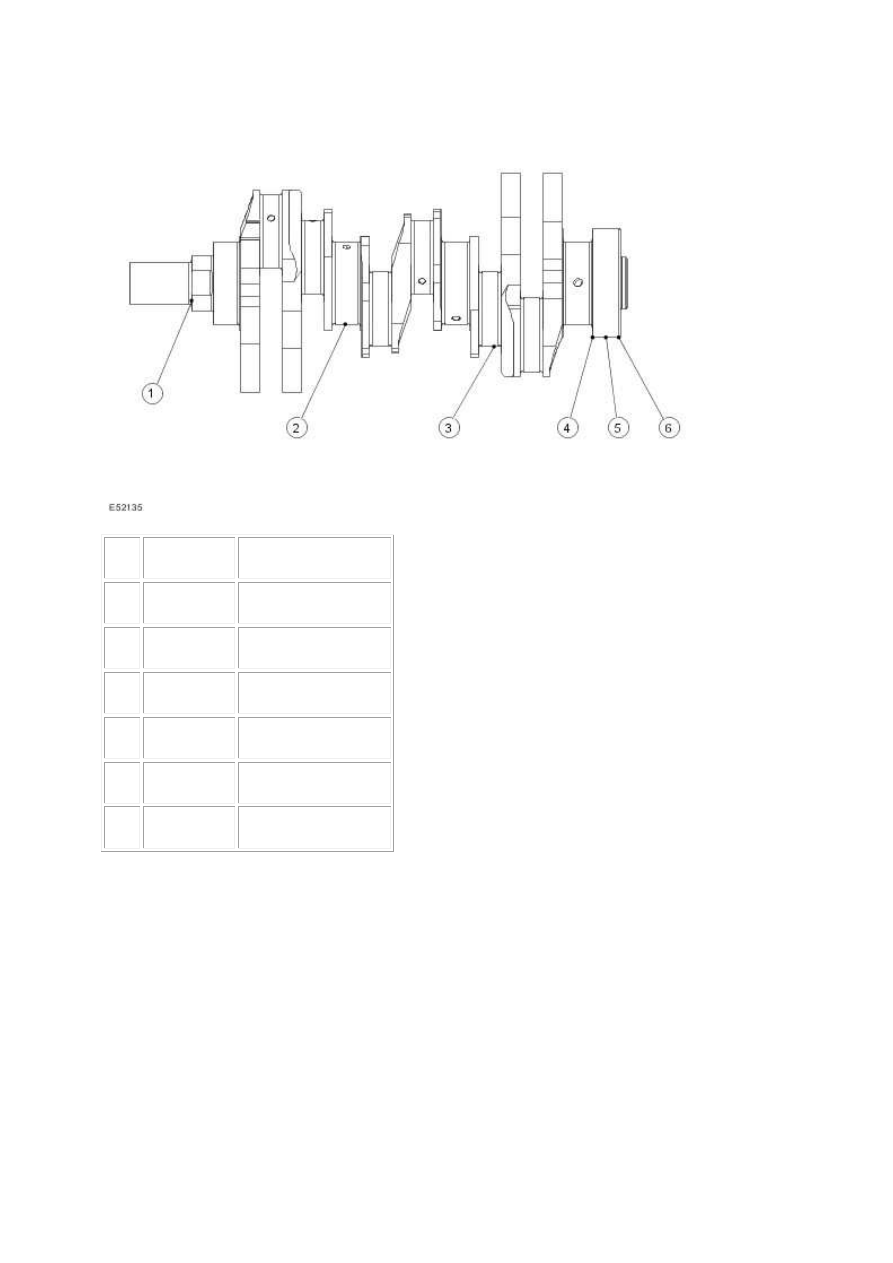

Crankshaft

Item

Part Number

Description

1

—

Oil pump drive

2

—

Main bearing journal

3

—

Big end journal

4

—

Rear drive flange

5

Rear oil seal location

6

Trigger wheel location

The crankshaft is forged steel and fillet rolled with induction hardened journals, which run in four

bearings with clamped two layer bearing shells. The upper and lower shells of bearing number four

are flanged, which limits the end float of the crankshaft. The main bearing caps are double bolted

and cross bolted to increase the strength and rigidity of the engine block.

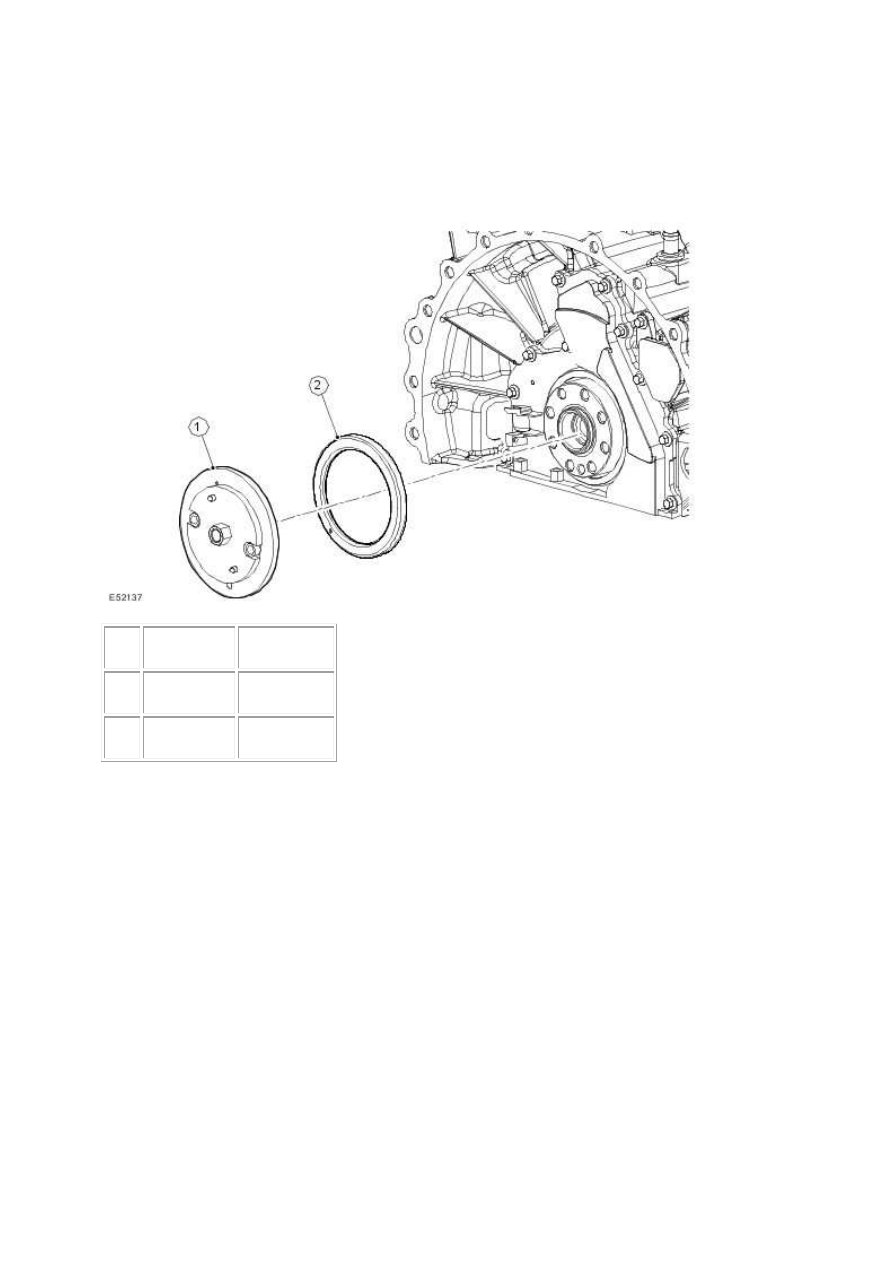

The rear main oil seal and retainer assembly is a one piece unit and is supplied with its own plastic

fitting sleeve. The seal and retainer have two locating dowels and ten fixing bolts. In addition the

retainer has a location for the crankshaft position sensor.

A torsional vibration crankshaft damper pulley is bolted to the front of the crankshaft.

The crankshaft trigger wheel is located on the rear of the crankshaft. It is pressed onto the crank

using a special tool which also precisely aligns the trigger wheel for crankshaft position and timing.

The trigger wheel consists of 60 magnets minus two for ECM crankshaft position reference and

synchronisation. The magnets cannot be seen on the trigger wheel, which therefore can only be

positioned using a special tool.

Item

Part Number

Description

1

—

Special tool

2

—

Trigger wheel

If the trigger is removed for any reason, then a new trigger wheel MUST be fitted.

www.

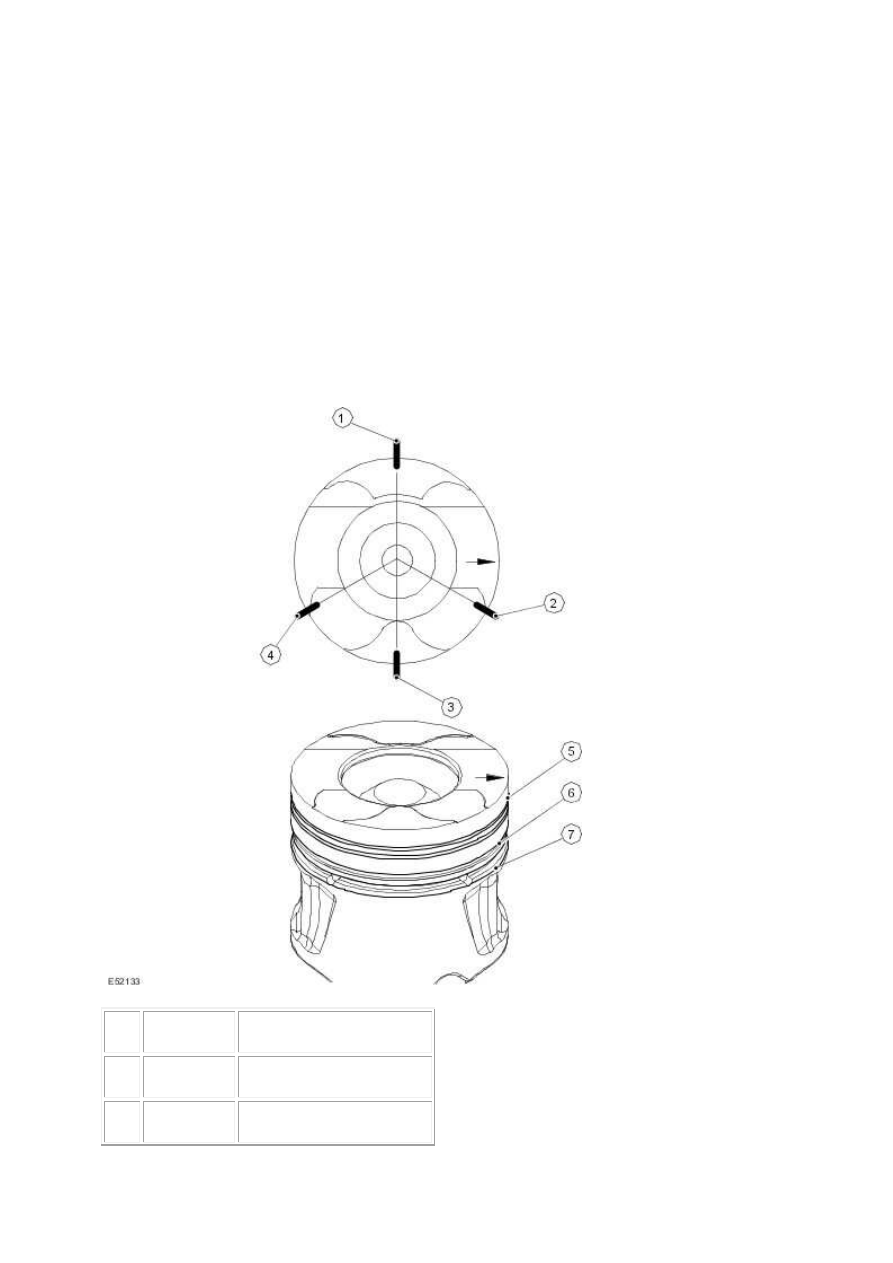

Connecting Rods and Pistons

Item

Part Number

Description

1

—

Connecting rod bolts

2

—

Connecting rod

3

—

Piston

4

—

Gudgeon pin

5

Circlips

6

Connecting rod identification

In production the connecting rods are fitted in sets of six. The connecting rods are offset fracture

split. Each connecting rod is marked (etched) with the cylinder number on either side of the fracture

split line.

The pistons are made from aluminium alloy and fitted with three rings. The piston crown

incorporates a pronounced bowl. This forms the combustion chamber which promotes swirl and

turbulence, necessary for good combustion and improved emission. In addition, the piston skirt,

which comes into contact with the cylinder bore, has molybdenum-coated surfaces. These

counteract scoring of the cylinder and piston, therefore helping to increase engine life.

The piston also incorporates a double wave gallery within the piston crown to enhance piston

cooling. The piston is supplied with oil by spray jets which are located in the engine block oil gallery.

This ensures optimum piston cooling due to the high temperatures that are generated by the

combustion process.

The arrows on the piston crown point to the front of the engine.

Item

Part Number

Description

1

—

Ring gap oil control

2

—

Ring gap upper compression

www.

Нет комментариевНе стесняйтесь поделиться с нами вашим ценным мнением.

Текст