Jaguar XJ (X350). Manual — part 515

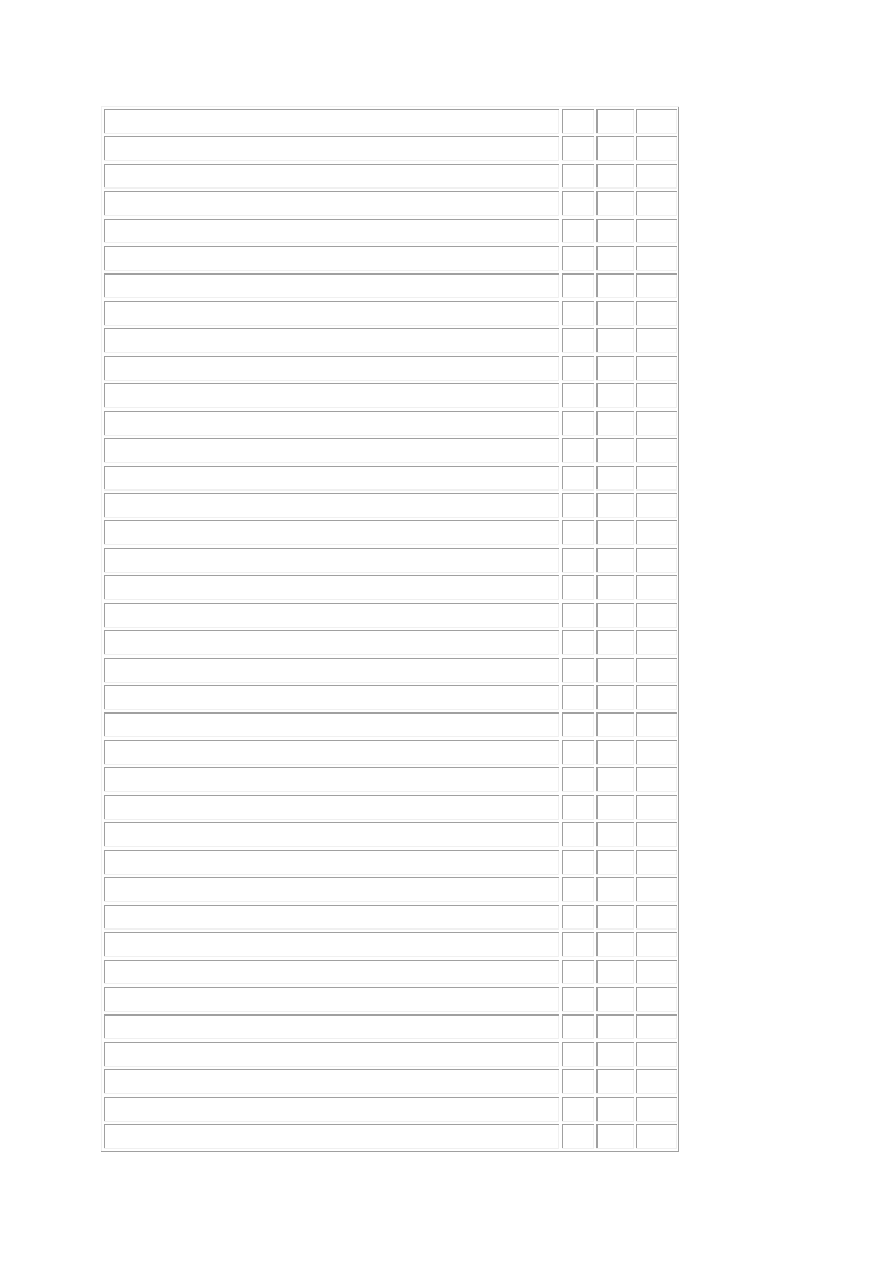

Camshaft bearing caps retaining bolts

A –

–

Camshaft position sensor retaining bolt

10 –

89

Camshaft hub retaining bolts

A –

–

Camshaft pulley retaining bolts

23 17 –

Crankshaft pulley retaining bolt

A –

–

Crankshaft position sensor retaining bolt

5

–

44

Coolant inlet housing

10 –

89

Cylinder head retaining bolts

A –

–

Engine mount retaining nuts to crossmember

63 46 –

Engine mount bracket to engine mount retaining nut

48 35 –

Engine mount bracket to engine block retaining bolts

90 66 –

Engine wiring harness retaining bracket

4

–

35

Exhaust manifold heat shield retaining bolts

10 –

89

Exhaust manifold retaining bolts

23 17 –

Flexplate retaining bolts

A –

–

Fuel injection pump

23 17 –

Fuel injection pump pulley retaining nut

50 37 –

Fuel injector retaining bolts

10 –

89

Generator retaining bolts

47 35 –

Generator mount bracket retaining bolts

23 17 –

Glow plugs

10 –

89

Knock sensor retaining nuts

20 15 –

Oil cooler to cylinder block retaining bolt

10 –

89

Oil level indicator tube retaining bolt

10 –

89

Oil pan retaining bolts

10 –

89

Oil pump to engine block retaining bolts

10 –

89

Oil pan drain plug

25 18 –

Oil separator pipe retaining bolts

10 –

89

Oil filter

25 18 –

Piston cooling jet retaining bolt

10 –

89

Power steering bracket retaining bolts

23 17 –

Power steering pump retaining bolts

22 16 –

Primary timing chain tensioner retaining bolts

12 9

–

Starter motor retaining bolts

48 35 –

Timing belt tensioner retaining bolt

24 18 –

Timing belt idler pulley retaining bolt

45 33 –

Water pump retaining bolts

10 –

89

Water pump pulley retaining bolts

24 18 –

Water pump outlet pipe retaining bolts

10 –

89

Valve cover retaining bolts

10 –

89

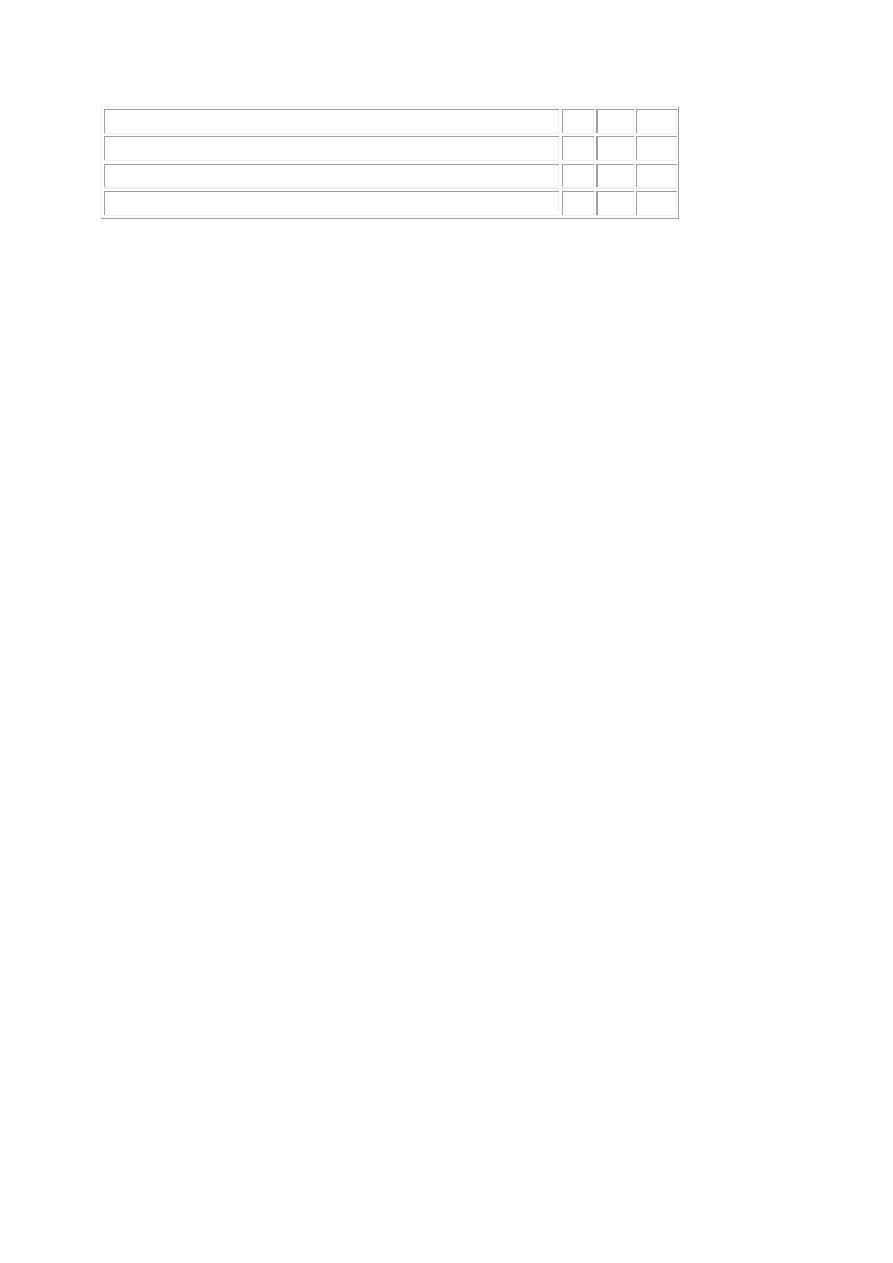

Vacuum pump retaining bolts

23 17 –

Vacuum pump retaining nuts

13 10 –

www.

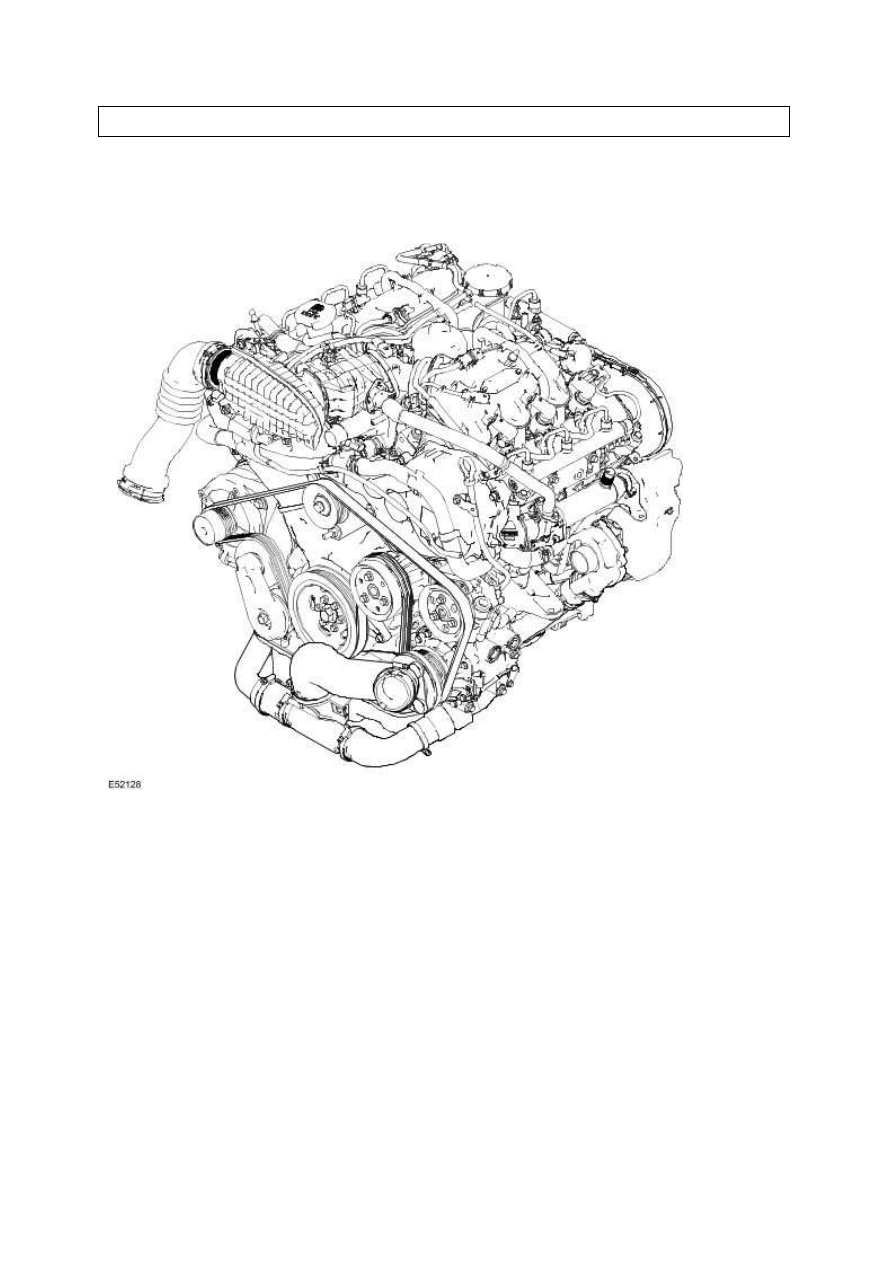

Description and operation

Engine

The 2.7 litre engine consists of a six cylinder 60-degree 'Enclosed Vee' configuration liquid cooled

Compacted Graphite Iron (CGI) with the cylinder bores machined directly into the block.

Viewed from the driving position, the right-hand cylinder bank is numbered 1 to 3, from the front of

the vehicle and the left-hand cylinder bank are numbered 4 to 6, from the front of the vehicle.

Knock Sensors

The knock sensor registers increased vibrations which occur due to increased combustion noise. The

ECM uses the signal as a correction factor for calculating the quantity of fuel to be injected during the

injection phase.

Active Engine Mounts

The function of the engine mounts is to support the engine, whilst also isolating vibrations

transmitted from the engine to the vehicle body.

The active engine mounts are functional only when the engine is at idle, as this is when the engine

high frequency vibrations are the dominant vibrations noticeable to the vehicle's occupants.

The mechanical construction of the active engine mounts is similar to the passive hydraulic engine

mounts, but with the added element of an internal shaker mechanism. The shaker mechanism of the

active engine mounts works on the same concept as a speaker diaphragm to move the top section of

the active engine mounts to oppose the vibrations generated by the engine. The active engine

mounts mechanism estimates the vibration caused by fluctuations in the engine crank rotation and

isolates these vibrations by generating additional vibrations through the internal shaker mechanism.

The result gives vibration isolation and reduction of chassis vibration.

To ensure accurate vibration suppression the active engine mounts have an electronic control

module attached to the body and an accelerometer attached to the base.

www.

Нет комментариевНе стесняйтесь поделиться с нами вашим ценным мнением.

Текст