Loader Bobcat 773. Manual — part 102

A

P–04705

2

1

N–00960

SEAT SENSOR (Cont’d)

BICS

™

Controller Seat Sensor Circuit Test

Use Sensor Tester (MEL1428) for the following

procedure:

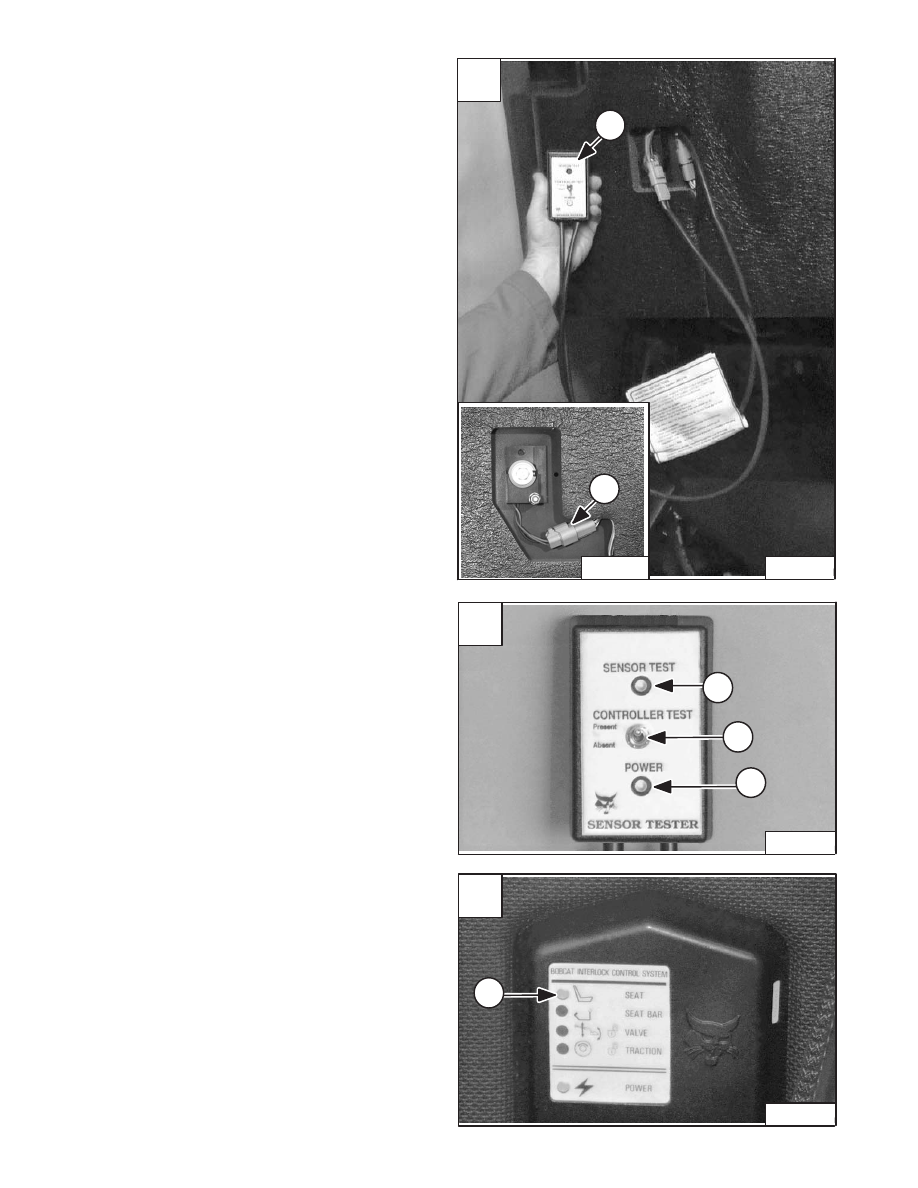

Disconnect the short adatper test leads if connected.

Revised Jan. 99

Turn the key to the ON position. DO NOT START THE

ENGINE.

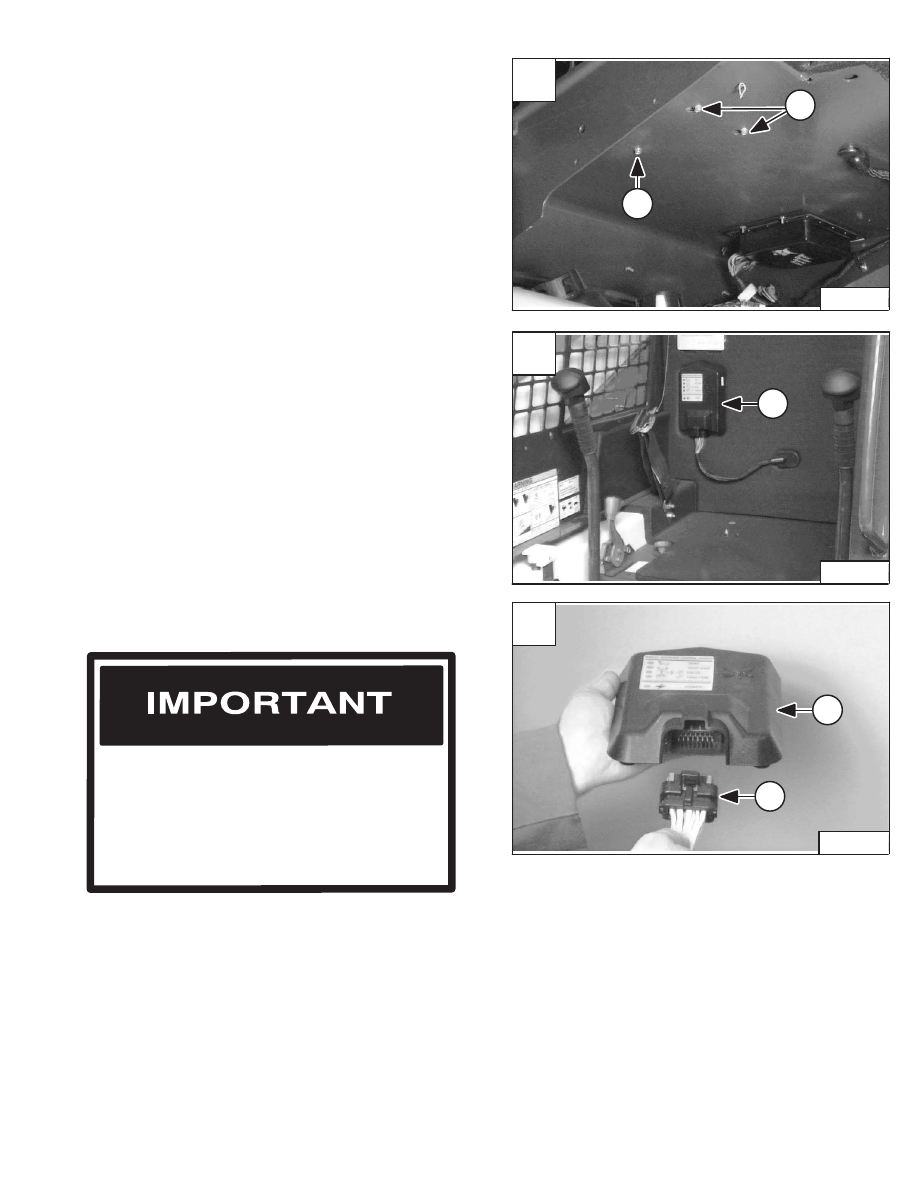

The power light (Item 1) [B] will illuminate, if the light is not

on, check the tester or wiring harenss.

Move the toggle switch (Item 2) [B] on the sensor tester

to the Present position.

Raise the operator cab. (See Page 1–1.)

Disconnect the seat sensor connector (Item 1 – Inset)

[A].

Connect MEL1428 Sensor Tester (Item 2) [A] inline as

shown to the seat sensor.

Lower the operator cab. (See Page 1–1.)

NOTE: Clean any debris, dirt or objects from under

or behind the operator seat before starting

the test. The rear of the seat must move up

and down.

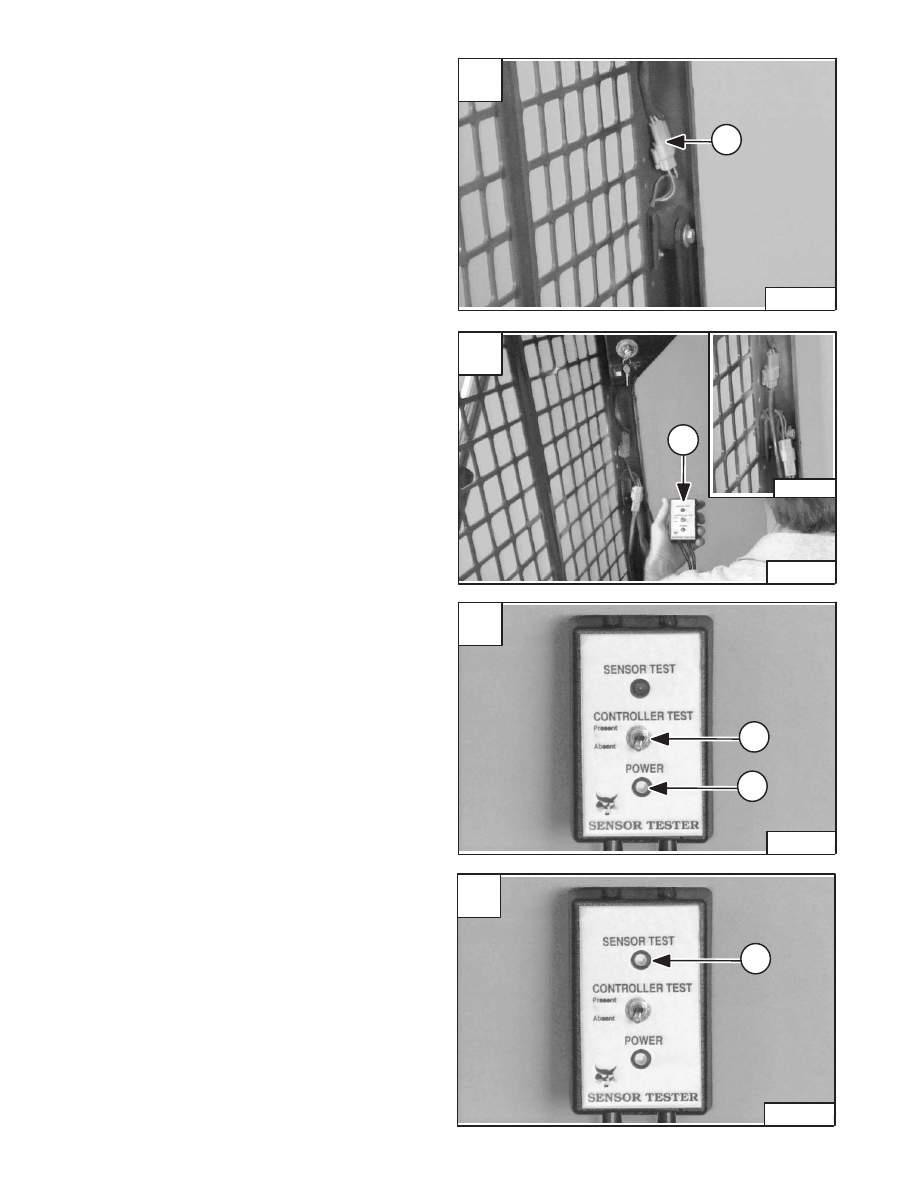

The Seat light (Item 1) [C] on the controller will illuminate.

Move the toggle switch to Absent position, the seat light

on the controller will go off.

If the tests above fail, there is a problem with the BICS

system controller or the wiring harness.

NOTE: The sensor test light (Item 3) [B] is activated

by the seat sensor switch.

B

P–04703

2

1

3

–8–14–

773 BICS Loader

Service Manual

C

P–04706

1

BICS

™

SYSTEM CONTROLLER

Removal And Installation

NOTE: The operator seat is removed in photo [B] for

clarity purpose only. The seat does not need

to be removed to remove the controller.

Slide the controller (Item 1) [B] up and remove it from the

back of the operator cab.

Disconnect the electrical harness from the controller and

remove the controller from the loader.

Installation: Tighten the controller mounting bolts to

80–90 in.–lbs. (9–10 Nm) torque.

Reverse the removal procedure to install the controller.

NOTE: Install the harness connector (Item 1) [C] into

the controller (Item 2) [C] before installing the

controller.

Raise the operator cab. (See Page 1–1.)

The controller mounting bolts are located on the back of

the operator cab [A].

Remove the top mounting bolt (Item 1) [A] from the

controller.

Loosen the two lower mounting bolts (Item 2) [A].

Lower the operator cab.

NOTE: Photo’s may be different but the procedure is

the same for all models.

Be sure the connector to the BICS system

controller are correctly engaged in the

controller when installing the controller. An

audible snap can be heard when the

connector is correctly installed. Try to pull the

connector out of the controller, if it cannot be

removed it has been correctly installed [C].

I–2087–1095

Revised Jan. 99

A

P–03997

2

1

C

P–04707

2

1

773 BICS Loader

–8–15–

Service Manual

B

P–03994

1

SEAT BAR SENSOR

Seat Bar Sensor Test

Use Sensor Tester (MEL1428) for the following

procedure:

Disconnect the short adatper test leads if connected.

Disconnect the seat bar sensor connector (Item 1) [A].

Connect Sensor Tester (Item 1) [B] inline as shown to the

seat bar sensor connectors. See inset [B].

Turn the key to the ON position. DO NOT START THE

ENGINE.

The toggle switch (Item 2) [C] can be in either the Absent

or Present position.

The power light (Item 1) [C] will illuminate, if the light is not

on, check the tester or wiring harness.

Lower the seat bar. The Sensor Test light (Item 1) [D]

should illuminate.

Raise the seat bar. The Sensor Test light (Item 1) [D]

should go off.

If the above tests fail, there is a problem with the seat bar

sensor.

Disconnect the Sensor Tester.

Replace the Seat Bar Sensor. (See Page 8–17.)

If the above tests pass, run BICS controller seat bar

circuit test. (See Page 8–18.)

Revised Jan. 99

A

P–04702

1

C

P–04698

1

2

D

P–04699

1

–8–16–

773 BICS Loader

Service Manual

B

P–04700

P–04701

1

SEAT BAR SENSOR (Cont’d)

Removal And Installation

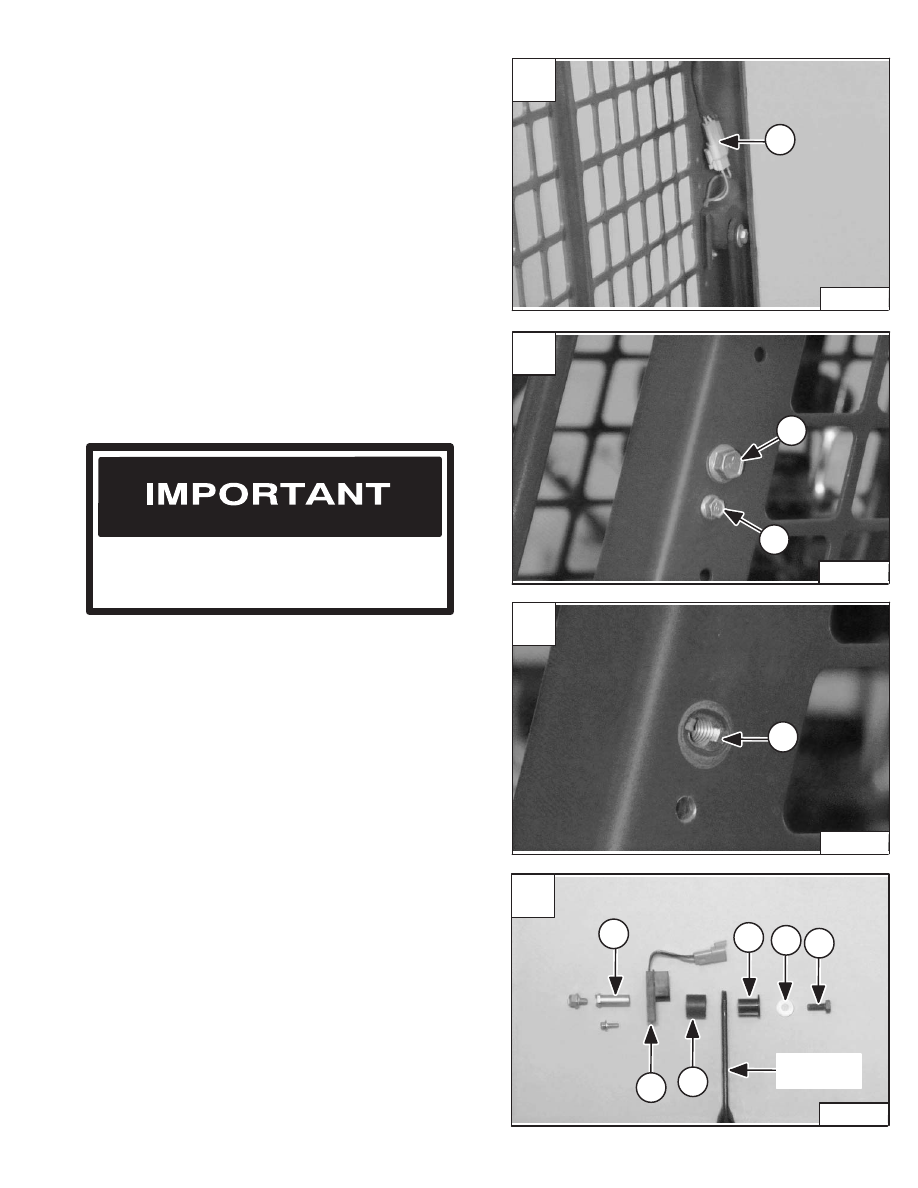

Disconnect the seat bar sensor connector (Item 1) [A].

Remove the mounting bolt (Item 1) [B] from the pivot

bushing.

Installation: Tighten the mounting bolt to 25–28 ft.–lbs.

(34–38 Nm) torque.

Remove the sensor mounting bolt (Item 2) [B] and nut.

NOTE: The sensor assembly [D] is shown removed

from the operator cab for clarity purpose

only. The sensor assembly can be removed

without removing the seat bar from the

operator cab.

Remove the pivot bushing mounting bolt (Item 1) [D] and

washer (Item 2) [D] from the pivot bushing (Item 3) [D].

Installation: Tighten the pivot bushing mounting bolt to

180–200 in.–lbs. (21–23 Nm) torque.

Remove the pivot bushing (Item 3) [D], sensor (Item 4)

[D], magnet (Item 5) [D] and plastic bushing (Item 6) [D]

from the seat bar.

Inspect all parts for damage and wear and replace if

necessary.

Reverse the removal procedure to install the seat bar

sensor.

Installation: Be sure the tabs on the pivot bushing are

positioned in the slotted hole (Item 1) [C] of the operator

cab as shown.

Pull the seat bar back and remove the assembly as

follows:

Be careful to not overtighten the sensor

mounting bolt and nut to prevent breakage of

the sensor.

I–2088–1095

Revised Jan. 99

A

P–04702

1

C

P–03247

1

D

P–03284

3

6

2

1

4

5

Left Side

of Seat Bar

773 BICS Loader

–8–17–

Service Manual

B

P–03246

1

2

Нет комментариевНе стесняйтесь поделиться с нами вашим ценным мнением.

Текст