DAF 95XF. Manual — part 174

©

200438

1-21

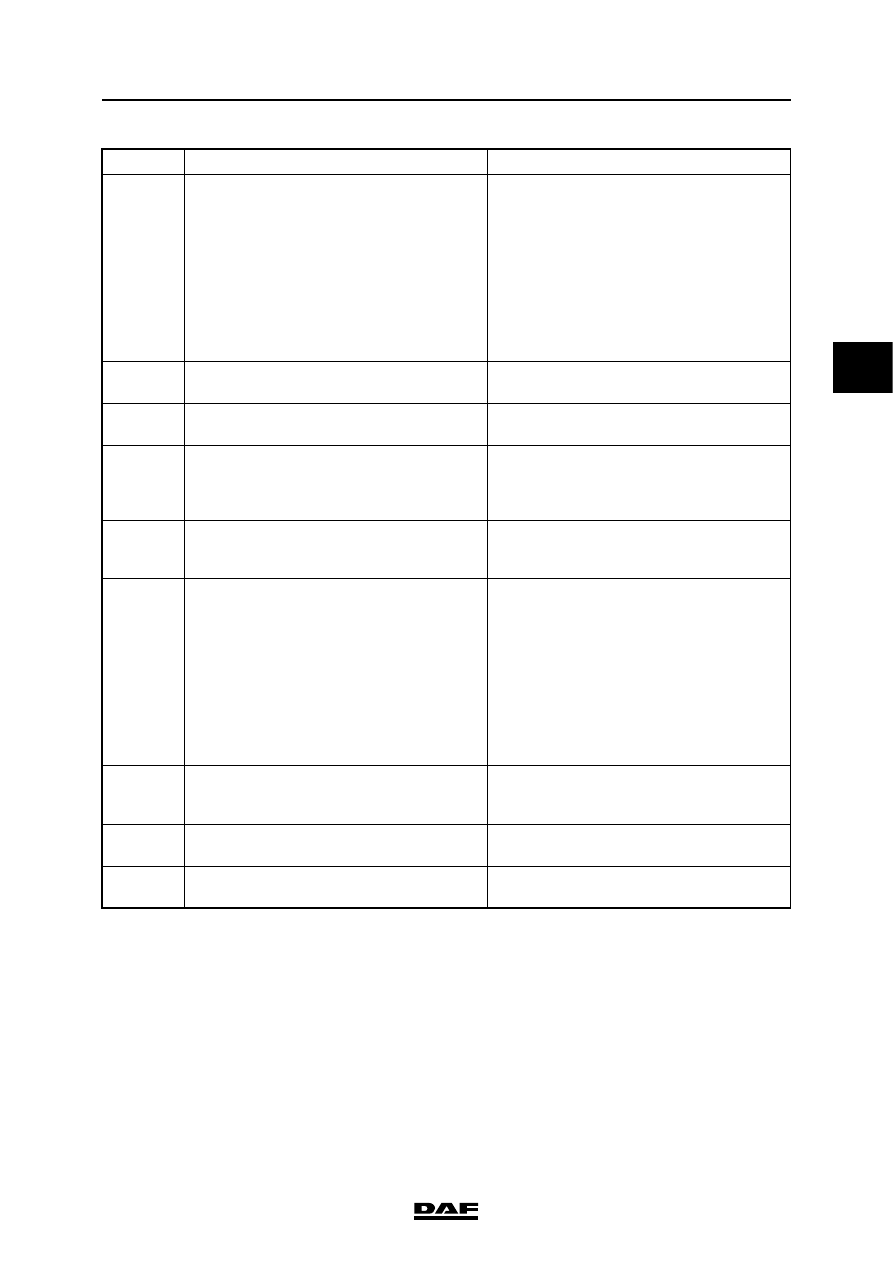

AS Tronic fault codes

AS TRONIC

DAVIE XD diagnostics manual

3

3193

The modulator temperature measured by the

integrated temperature sensor is too high:

-

temperature > 130 degrees Celsius

When driving:

-

no gear changes possible

-

automatic mode not available

At standstill:

-

if the vehicle comes to a halt, the clutch will

open and the gearbox is automatically

shifted to the neutral position

-

driving off from a stationary position is not

possible

-

system is not available

3194

Front axle speed signals not recognised via

message on CAN network

-

No noticeable system limitation

-

Automatic mode not available

3198

Relative wheel speed sensor signals not

recognised via message on CAN network

-

No noticeable system limitation

-

Automatic mode available

3199

No CAN message received from ABS/EBS unit

due to:

-

communication problem with ABS/EBS

-

An average drive-off gear is selected when

driving off from a stationary position

-

No noticeable system limitation

-

Automatic mode available

3210

No CAN message received from the MTCO due

to:

-

communication problem with the MTCO

-

No noticeable system limitation, if there is a

redundant internal speed signal

-

Automatic mode available

3227

Internal modulator fault (D954) due to:

-

missing or defective basic program(s)

-

fault recognised during self-test

When driving:

-

no gear changes possible

-

automatic mode not available

At standstill:

-

if the vehicle comes to a halt, the clutch will

open and the gearbox is automatically

shifted to the neutral position

-

driving off from a stationary position is not

possible

-

system is not available

3235

No PTO active signal received by AS Tronic ECU

from VIC via CAN message due to:

-

communication problem with the VIC

-

No PTO 1 and PTO 2 actuation possible

3236

No CAN message received from the VIC due to:

-

communication problem with the VIC

-

No PTO 1 actuation possible

3237

No CAN message received from the VIC due to:

-

communication problem with the VIC

-

No PTO 2 actuation possible

Fault code

Fault code description with possible cause

Symptom

AS TRONIC

1-22

©

200438

AS Tronic fault codes

3

DAVIE XD diagnostics manual

©

200438

2-1

System inspection with DAVIE XD

AS TRONIC

DAVIE XD diagnostics manual

3

2. SYSTEM INSPECTION WITH DAVIE XD

2.1 GENERAL

If the tyre size is changed or if the vehicle is

adjusted in such a way that the configuration is

changed, the electronic unit may have to be re-

programmed.

AS TRONIC

2-2

©

200438

System inspection with DAVIE XD

3

DAVIE XD diagnostics manual

2.2 'TRANSMISSION' MENU

The 'Transmission' menu is subdivided into two

tests:

-

static selector shaft position test

-

dynamic selector shaft position test

Both tests are used to check the mechanical

operation of the AS Tronic gearbox. This is done

by reading the position of all selector shafts in

gears that have been determined beforehand.

These positions are shown on the DAVIE display

by means of a position value, the so-called INC

(increment). Upon the start of both tests the

accessory test report needs to be printed. The

measured position values should be incorporated

in the test report, so that the mechanical

operation of the gearbox can be evaluated.

Static selector shaft position test

This test is carried out with a stationary vehicle

and running engine. Using the "+" and "-" buttons

on the DAVIE display the gearbox can be shifted

up and down respectively. Changing between RL

and RH is done by means of button "Reverse

gears". In this way the desired gears of the

relevant test report can be selected. Per selected

gear the measured position values can be

compared with the correct position values that

are stated between brackets in the test report.

Dynamic selector shaft position test

If no appreciable deviations are found in the static

selector shaft position test, the dynamic selector

shaft position test can be carried out

subsequently. This test is carried out while driving

with a loaded gearbox. Again, the accessory test

report should be printed (both test reports are

identical, however the test conditions differ).

While driving, the desired gears of the relevant

test report can be selected using the operating

unit. Per selected gear the measured position

values can be compared with the correct position

values that are stated between brackets in the

test report.

Нет комментариевНе стесняйтесь поделиться с нами вашим ценным мнением.

Текст