DAF LF45, LF55 Series. Manual — part 476

©

200436

1-1

General

BRAKING PERFORMANCE AND BRAKE EQUALISATION

ΛΦ45/55 series

6

5

1. GENERAL

1.1 INTRODUCTION

How is a good braking performance of a vehicle

combination (truck and trailer vehicle) achieved

while still guaranteeing interchangeability both for

new vehicle combinations and for combinations

following brake reconditioning?

The vehicles should meet the legal requirements

and all settings should be in accordance with the

directives. However, adhering to the directives

does not necessarily mean that there will be no

brake problems.

BRAKING PERFORMANCE AND BRAKE EQUALISATION

1-2

©

200436

General

5

ΛΦ45/55 series

6

1.2 WHAT IS A VEHICLE COMBINATION WITH A GOOD BRAKING

PERFORMANCE?

A vehicle combination of which, in laden condition

and with a 1 to 3 bar pressure at the service

coupling head, the braking deceleration of the

tractive unit is the same or virtually the same as

that of the drawn vehicle.

When problems occur which are related to the

brake system, such as excessive brake-lining

wear, brake vibrations or the vehicle pulling to

one side during braking, the cause should

primarily be sought in an unbalanced distribution

of braking forces.

-

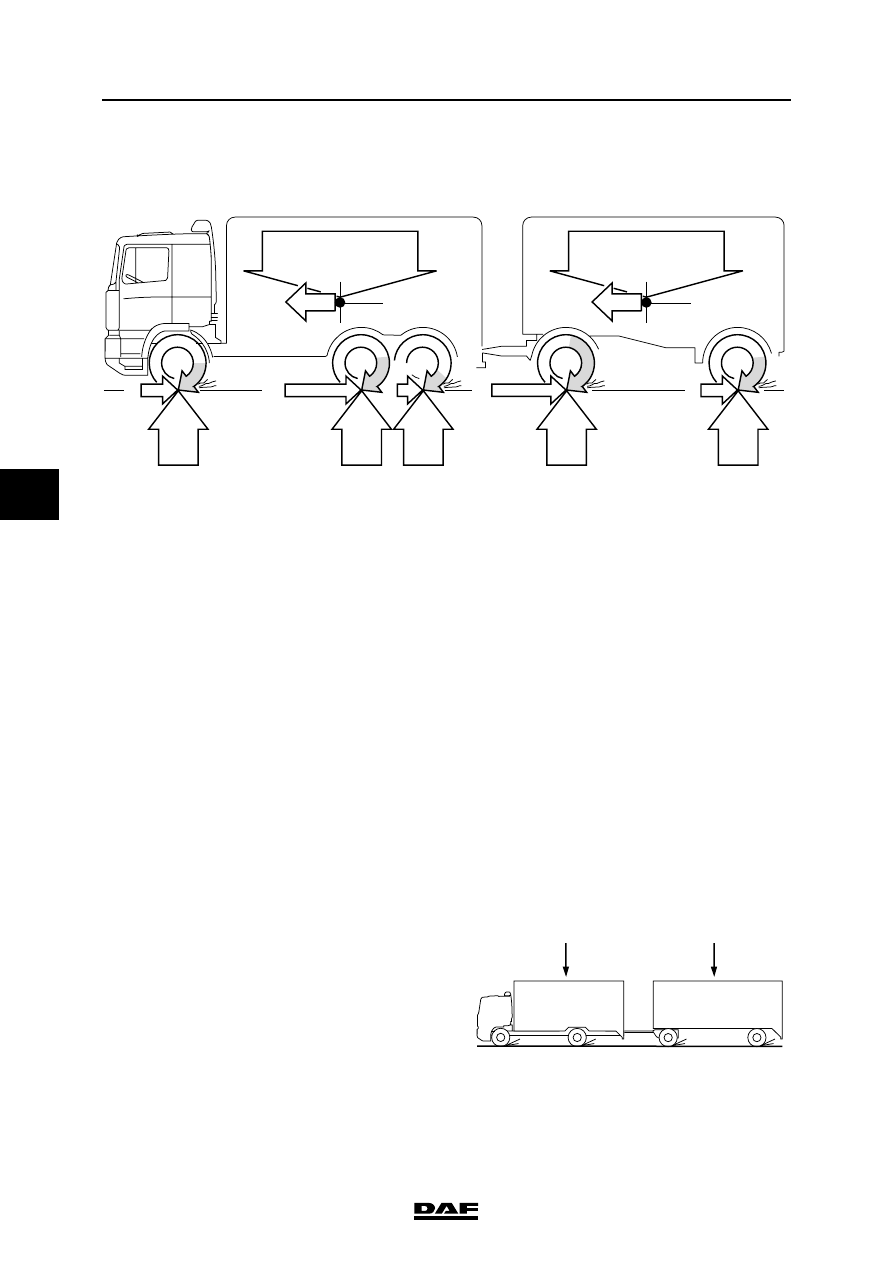

for vehicle combinations:

-

between prime mover and trailer

vehicle.

Fn

Gd

F

Fn

Gd

F

Z

m.a

Fn

Gd

F

Fn

Gd

F

Fn

Gd

F

Z

G

G

m.a

R600023

G =

weight

m =

mass

a =

deceleration (m x a is the force

changing the axle load)

Dynamic axle load: during braking, changes the

load on each axle.

F =

braking force (Fmax = Gd x m)

Gd =

dynamic axle load

m =

the friction coefficient between tyre and

road

Fn =

braking force of the wheel brake

a

R600024

a

©

200436

1-3

General

BRAKING PERFORMANCE AND BRAKE EQUALISATION

ΛΦ45/55 series

6

5

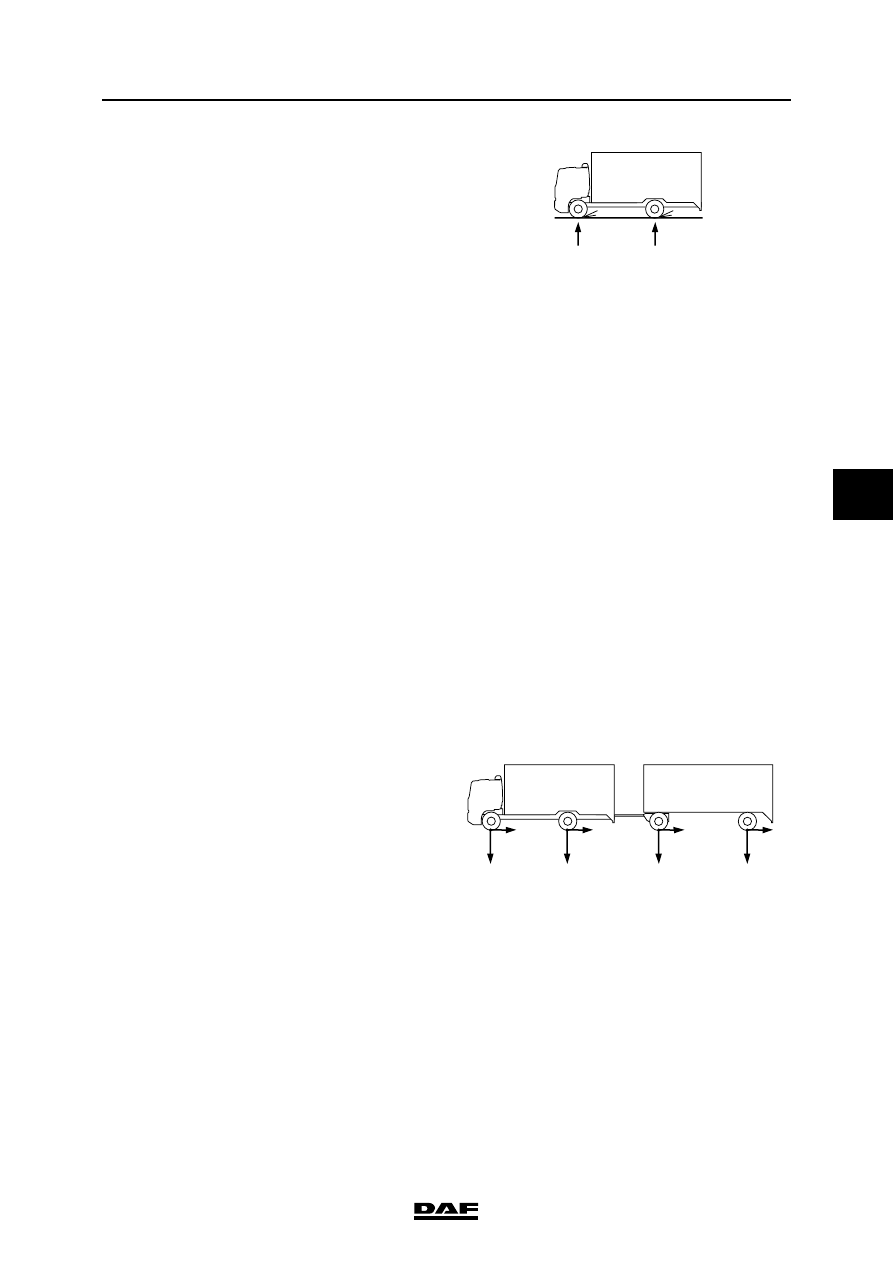

-

for rigid vehicles:

-

between the different axles.

Conditions for a practical distribution of

braking forces

-

Both the prime mover and the trailer vehicle

should have a sufficiently effective brake

system without mechanical defects or

failures in the air system.

With vehicle combinations the braking

performance level of the trailer vehicle may be

noticeably lower than that of the truck. This

means that the prime mover has to provide a

disproportionately large part of the deceleration

required for the total vehicle combination. As the

brakes of the trailer vehicle will consequently be

subjected to low loads only, their condition will

deteriorate (risk of glazing), which will lead to

even higher overloading of the prime mover

brakes. It is therefore important that the

adjustment is correct, as dangerous situations

can arise where the trailer is jostling the prime

mover.

Possible causes of poor braking performance

of a trailer vehicle

-

unduly large brake-chamber stroke.

-

damaged diaphragms in the brake

chambers.

-

greasy, glazed or fully worn linings.

-

the mechanical part of the wheel brake does

not operate smoothly.

-

a leak in the brake system.

-

a blockage in the brake pipe system.

-

not all the valves are in good working order.

-

incorrect setting of the load-sensing valve.

The starting point is that the braking forces

between the axles of the vehicle combination

should be distributed in proportion to the axle

loads. This will also distribute the temperature

correctly over the axles.

Whether this will give the correct distribution

between prime mover and trailer vehicle depends

not only on the quality of the two brake systems,

but also on a correct balancing of the brake

pressures. The latter can be achieved by

adjusting the advance between tractor and drawn

vehicle in such a way that at the most frequently

used brake pressures, i.e. 2-3 bar on the service

line, the braking performance of the prime mover

is the same as that of the trailer vehicle.

This can entail a change in the brake pressure

advance set by the factory.

a

a

R600025

R600026

m1

m3

m4

F1

F :

1

F2

F3

F4

F2 F3

4

m 2

m1

m3 m4

m 2

:

F

:

=

:

:

:

BRAKING PERFORMANCE AND BRAKE EQUALISATION

1-4

©

200436

General

5

ΛΦ45/55 series

6

1.3 BRAKE EQUALISATION MEASUREMENT BY MEANS OF BRAKE

DYNAMOMETER

1.

Make sure the vehicle combination is in

laden condition. A laden combination

makes for a more reliable and accurate

measurement. Furthermore, the maximum

braking performance will be achieved when

the vehicle combination is in laden condition.

2.

The braking forces must be measured on a

system with warm brakes. (Normal operating

temperature.)

3.

The brake linings must have been bedded in.

Only then can a reliable verdict on the

braking forces be obtained.

4.

Write down the braking forces of the various

axles on the "brake equalisation form for

brake dynamometer" at the following brake

pressures, measured at the service coupling

head:

p = 0.5 - 1.0 - 1.5 - 2.0 - 3.0 - 4.0 - 5.0 bar.

5.

Using the data on the "brake equalisation

form for brake dynamometer", calculate the

braking deceleration percentages.

6.

Plot the calculated values in the "brake

equalisation form for brake dynamometer" in

the appropriate EC band graph and evaluate

the measured brake equalisation.

p

R600028

Нет комментариевНе стесняйтесь поделиться с нами вашим ценным мнением.

Текст