DAF LF45, LF55 Series. Manual — part 469

©

200436

3-27

Removal and installation

BRAKE SYSTEM AND COMPONENTS

ΛΦ45/55 series

6

4

3.16 REMOVING AND INSTALLING BELLOWS WITH BRAKE CALLIPER THRUST

PIECE, KNORR SB7000 VERSION

Removing bellows with SB7000 brake calliper

thrust piece

1.

Using the hexagonal adjusting bolt, unscrew

the thrust pieces as far as is necessary to

gain access to the bellows.

Note:

Unscrew the thrust pieces a maximum of

30 mm. Do not screw them completely out of

the brake calliper, as the brake calliper

assembly would then have to be replaced.

Note:

Never turn the hexagonal adjusting bolt

without using an adapter. The adapter is a

torque safety and will break off when the

torque is too high. Without the use of an

adapter the mechanics in the brake calliper

may become damaged when the torque is

too high, so that replacement of the brake

calliper may be necessary.

2.

Using a screwdriver, ease the bellows

behind the thrust piece out of the brake

calliper.

Note:

Do not insert the screwdriver too deeply into

the brake calliper. This could damage the

seat of the inner seal of the thrust pieces.

These cannot be replaced and the brake

calliper would then have to be replaced.

3.

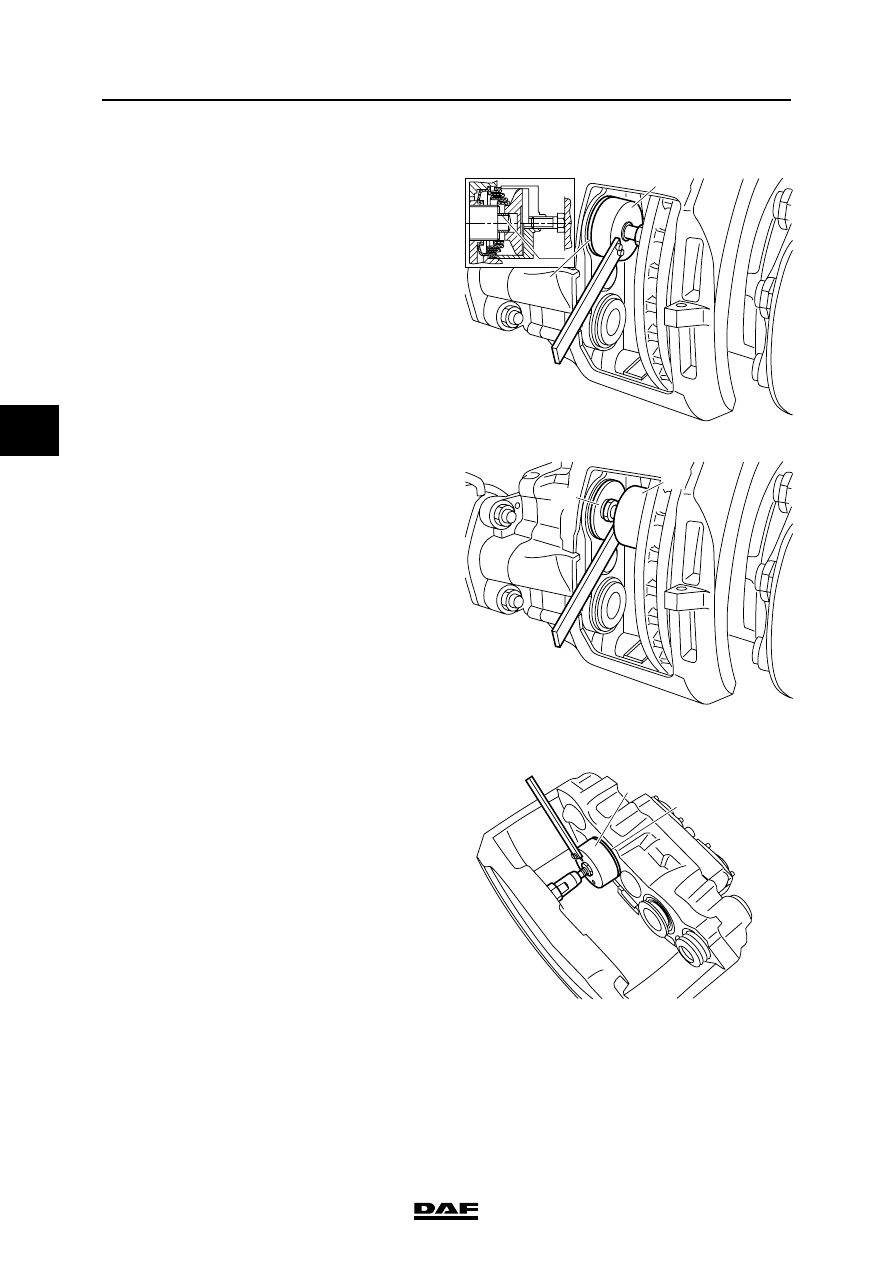

Press the thrust pieces (13) off the adjusters

with the disassembly fork (A), special tool set

(DAF no. 1329494).

4.

Remove the bearing bushes (161) from the

thrust pieces.

R600468

A 13

13

R600469

161

A

BRAKE SYSTEM AND COMPONENTS

3-28

©

200436

Removal and installation

4

ΛΦ45/55 series

6

Fitting bellows

Note:

Do not screw the adjusters entirely out of the

brake calliper, as the entire brake calliper

would then have to be replaced.

1.

Check the screw thread in the adjusters.

2.

Grease the screw thread of the adjusters.

See "Technical data".

3.

Screw the adjusters back into the brake

calliper.

4.

Fit new bearing bushes (161) on the

adjusters.

5.

Fit the thrust pieces and bellows (13) on the

adjusters.

6.

Using the pressure tool and a pin from the

special tool set (DAF no. 1329494) (B),

press the bellows into its seat.

7.

Turn the pressure tool (B) round and press

the thrust pieces (13) onto the adjusters.

Note:

The operations described above can also be

performed if the brake calliper has been

removed. In that case an additional pin (8) from

the special tool set (DAF no. 1329494) must be

used, since the brake disc cannot be used for

support.

B

13

161

R600470

B

13

R600465

B

13

R600464

©

200436

3-29

Removal and installation

BRAKE SYSTEM AND COMPONENTS

ΛΦ45/55 series

6

4

3.17 REMOVING AND INSTALLING BELLOWS WITH BRAKE CALLIPER THRUST

PIECE, KNORR SN7000 VERSION

Removing bellows with SN7000 brake calliper

thrust piece

1.

Using the hexagonal adjusting bolt, unscrew

the thrust pieces as far as is necessary to

gain access to the bellows.

Note:

Unscrew the thrust pieces a maximum of

30 mm. Do not screw them completely out of

the brake calliper, as the brake calliper

assembly would then have to be replaced.

Note:

Never turn the hexagonal adjusting bolt

without using an adapter. The adapter is a

torque safety and will break off when the

torque is too high. Without the use of an

adapter the mechanics in the brake calliper

may become damaged when the torque is

too high, so that replacement of the brake

calliper may be necessary.

2.

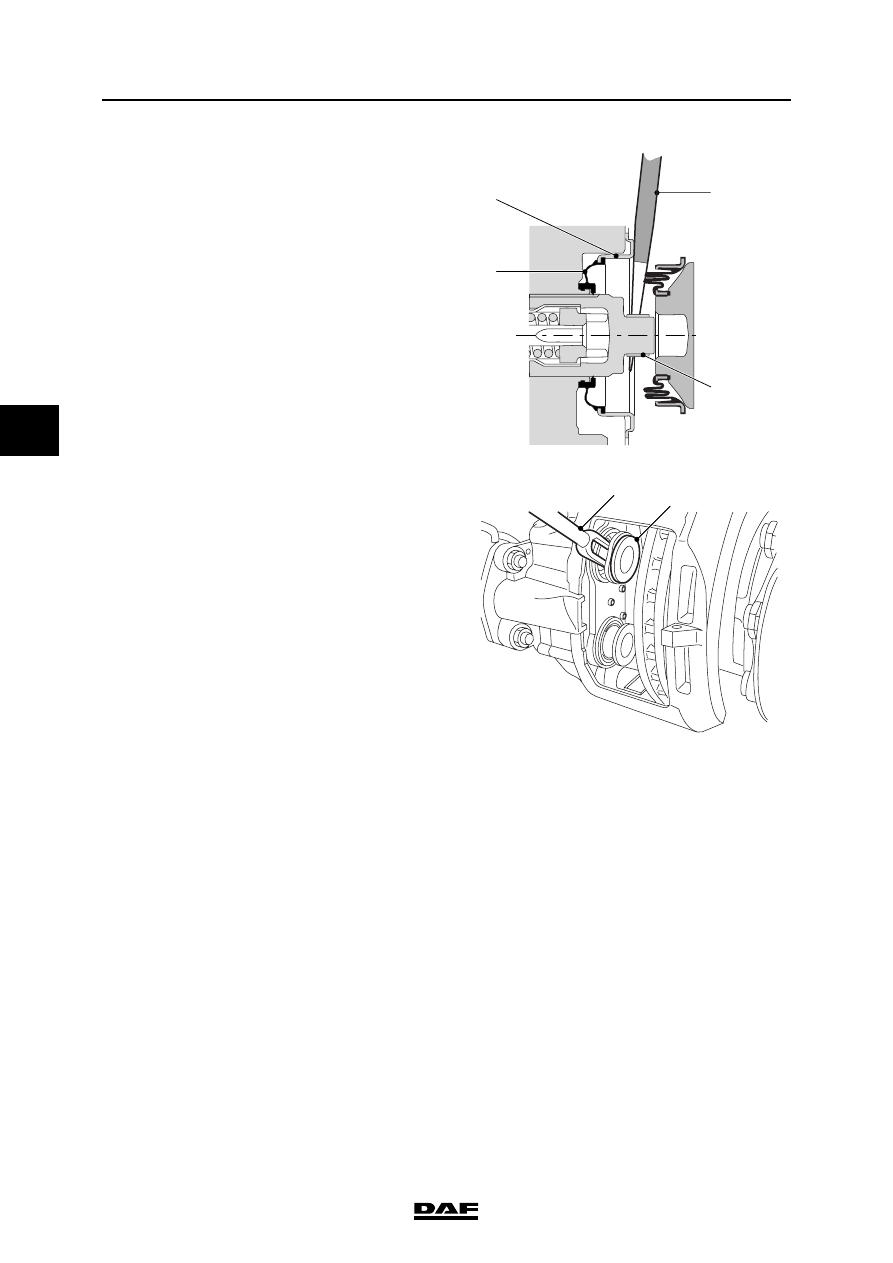

Using a screwdriver (1), ease the bellows

behind the thrust piece (2) out of the brake

calliper.

30 mm

2

2

1

2

R600713

BRAKE SYSTEM AND COMPONENTS

3-30

©

200436

Removal and installation

4

ΛΦ45/55 series

6

Note:

Do not insert the screwdriver (3) too deeply

into the brake calliper. This could damage

the seat (6) of the inner seal (5) of the thrust

pieces. These cannot be replaced and the

brake calliper would then have to be

replaced.

3.

Press the thrust pieces (2) off the adjusters

with the disassembly fork (3), special tool set

(DAF no. 1329495).

4.

Remove the bearing bushes (4) from the

thrust pieces.

Note:

If the bellows of the thrust piece is replaced,

the inner seal must also always be replaced.

5.

Place a brake pad in the brake calliper on the

outside so that the adjusters cannot be

screwed out of the brake calliper at the next

check. Place a 70-mm-thick spacer (self-

made) if the brake calliper has been

removed from the axle.

6.

Screw the adjuster about 30 mm out of the

brake calliper and check the thread of the

adjuster for dirt, corrosion and damage.

7.

Screw the adjuster all the way back into the

brake calliper.

8.

Using a screwdriver, ease the inner seal out

of the brake calliper.

R600714

2

3

3

5

6

4

Нет комментариевНе стесняйтесь поделиться с нами вашим ценным мнением.

Текст