DAF LF45, LF55 Series. Manual — part 467

©

200436

3-19

Removal and installation

BRAKE SYSTEM AND COMPONENTS

ΛΦ45/55 series

6

4

3.

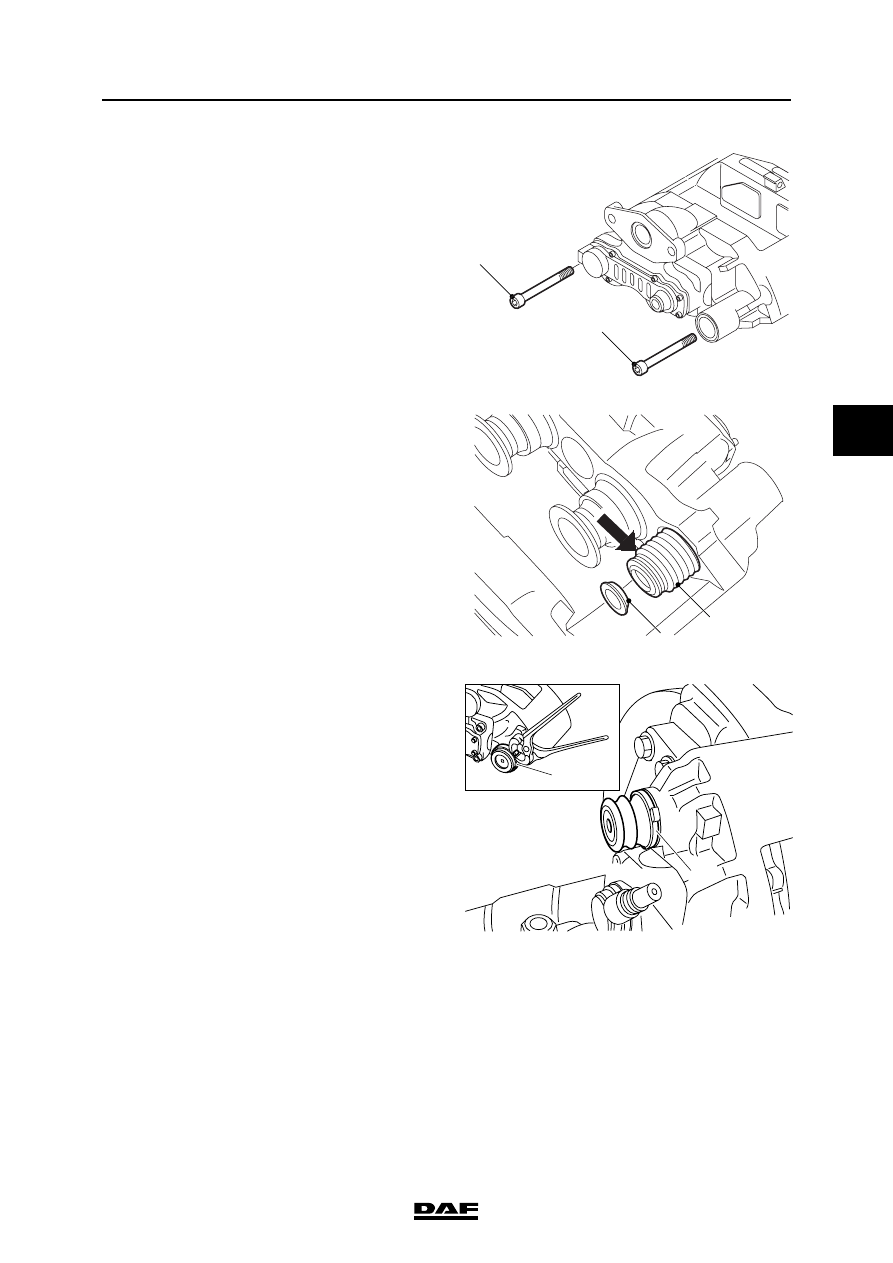

Fit the two Allen screws (2 and 3) and tighten

them to the specified torque. See "Technical

data". Do not re-use these screws. Always

use new screws which have locking

compound applied.

4.

Check that the brake calliper can move

freely.

5.

Check that the bellows (5) and the ring (4) of

the guide bush are properly in place on the

inside of the brake calliper.

6.

Check that the automatic adjustment is

working properly.

7.

Fit the bellows (10) and clamping strap (31).

Check the bellows for proper sealing.

8.

Fit the brake pads.

9.

Fit the plug for the brake pad wear indicator.

10. Fit the brake cylinder.

2

3

R600720

R600721

5

4

39

31

R600467

31

BRAKE SYSTEM AND COMPONENTS

3-20

©

200436

Removal and installation

4

ΛΦ45/55 series

6

3.13 REMOVAL AND INSTALLATION, BRAKE CALLIPER, KNORR SN7000

VERSION

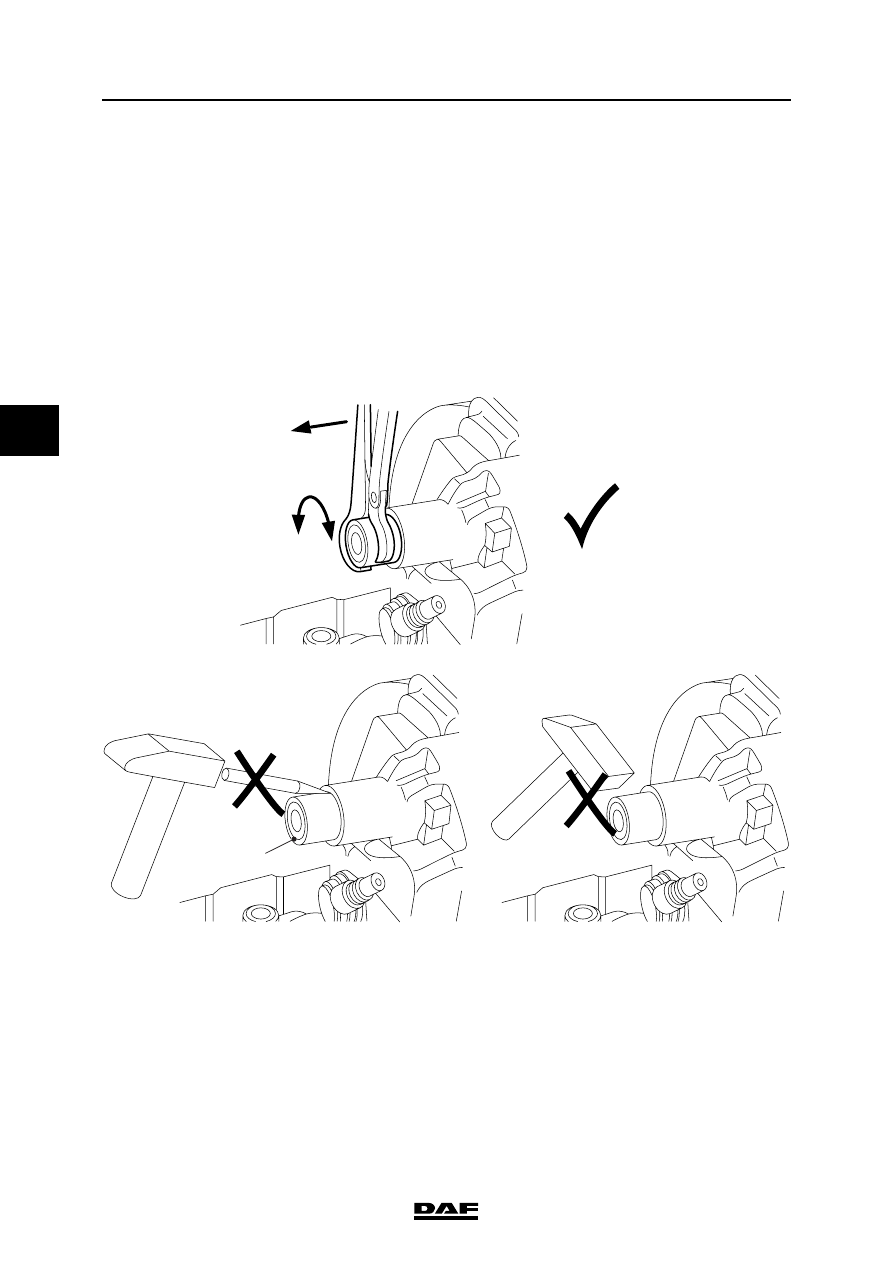

Never insert fingers between the

brake calliper and the brake calliper

carrier during and following removal

of the brake pads and when a new

brake calliper is installed (danger of

getting them trapped). Always take

hold of the brake calliper on the

outside.

Removing the brake calliper

1.

Remove the brake pads.

2.

Remove the brake cylinder.

3.

Remove the plug for the brake pad wear

indicator.

}

R600765

1

©

200436

3-21

Removal and installation

BRAKE SYSTEM AND COMPONENTS

ΛΦ45/55 series

6

4

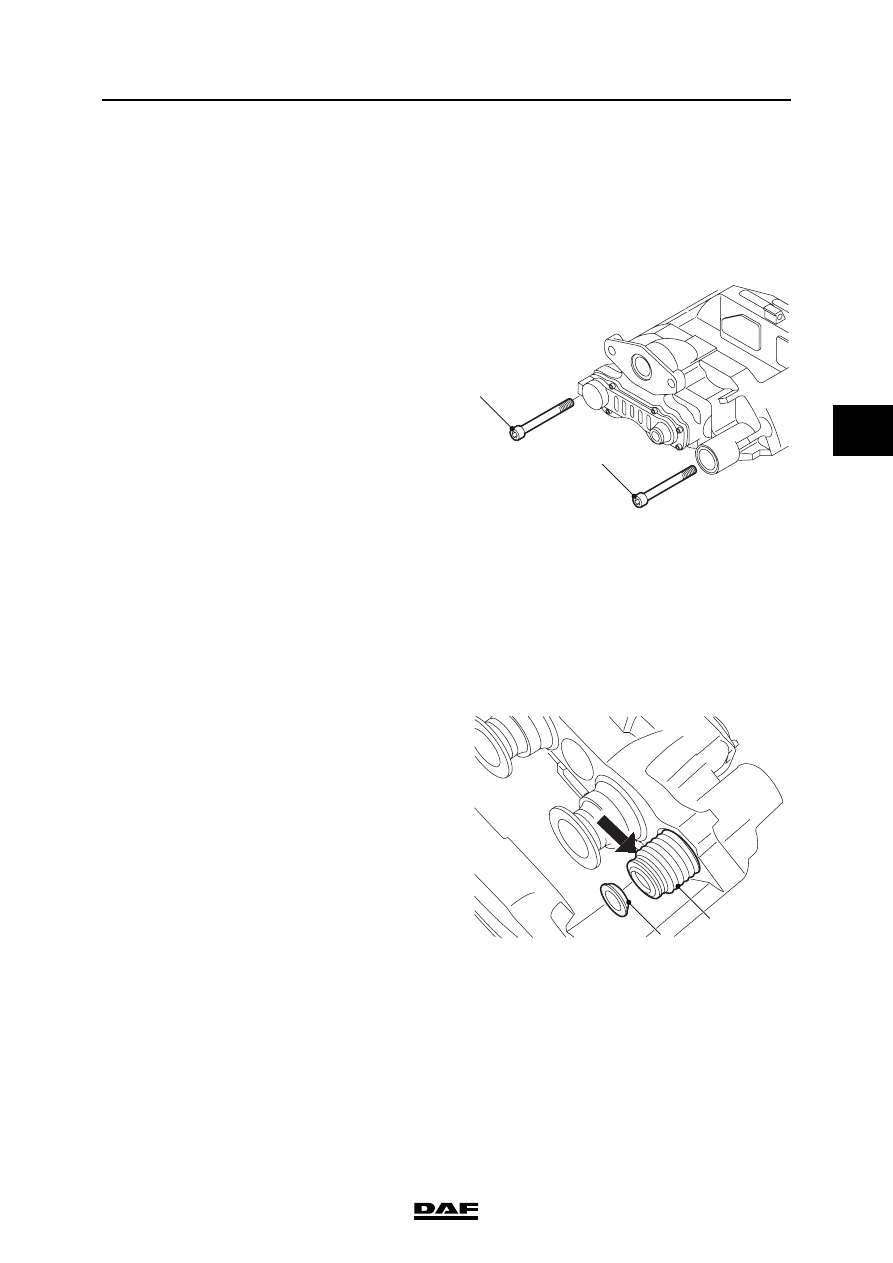

4.

Remove the steel cap (1) from the brake

calliper. When doing this, do not use force

and avoid damage to the brake calliper. If in

particular the internal part of the brake

calliper is damaged this may result in the

movable guide of the brake calliper no longer

working. The steel cap must not be re-used.

5.

Remove the Allen screws (2 and 3).

6.

Remove the brake calliper.

Fitting the brake calliper

1.

Clean all parts and check for damage. The

sliding surfaces of moving parts must be

clean and undamaged.

2.

Make sure that the guide pin in the brass

bearing bush is positioned in such a way that

the rubber bellows is compressed on the

inside.

3.

Position the brake calliper on the brake

calliper carrier.

4.

Fit the two Allen screws (2 and 3) and tighten

them to the specified torque. See "Technical

data". Never re-use these screws. Always

use new screws which have locking

compound applied.

5.

Check that the brake calliper can move

freely.

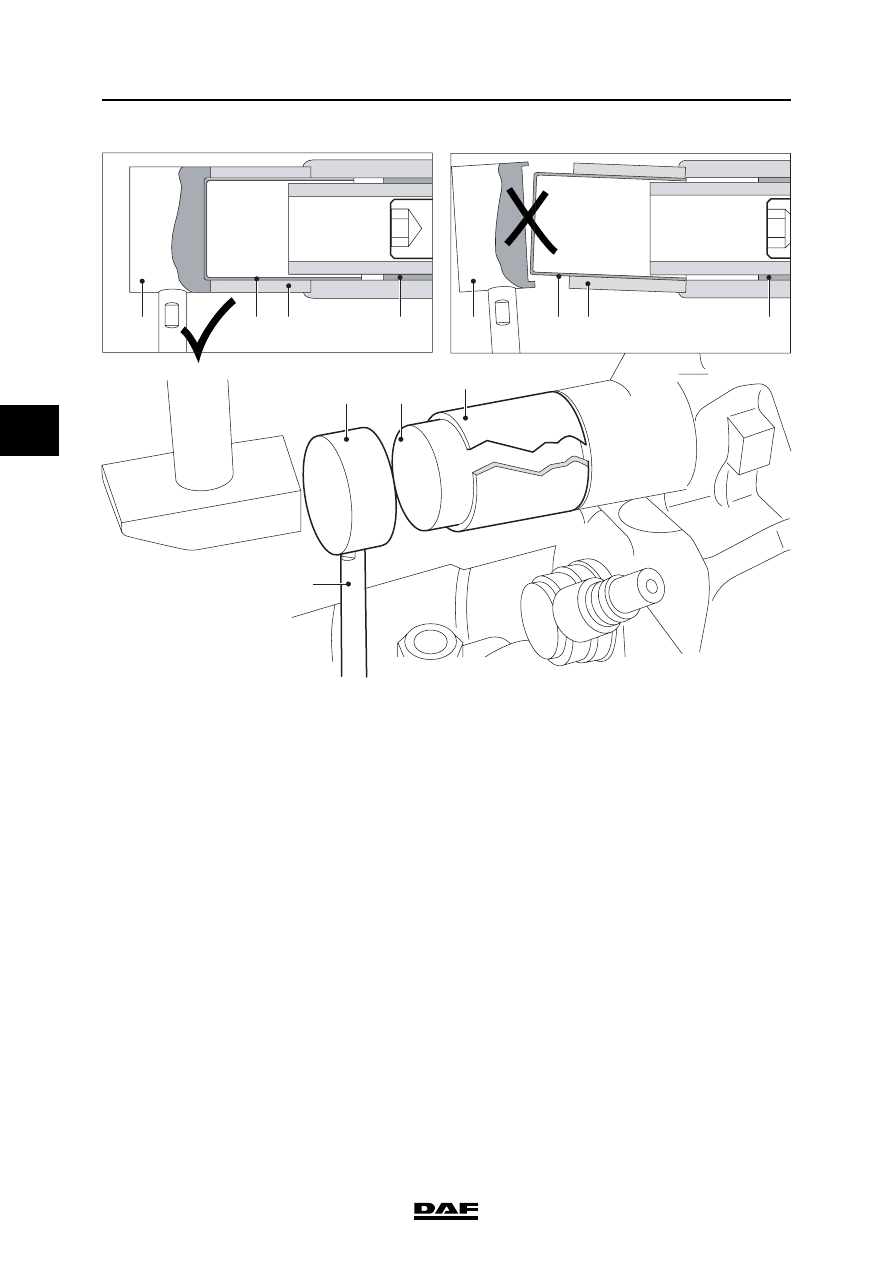

6.

Check that the bellows (5) and the ring (4) of

the guide bush are properly in place on the

inside of the brake calliper.

7.

Check that the automatic adjustment is

working properly.

2

3

R600720

R600721

5

4

BRAKE SYSTEM AND COMPONENTS

3-22

©

200436

Removal and installation

4

ΛΦ45/55 series

6

8.

Assemble a punch from the special tool set

(DAF no. 1329495) by means of T2 (only the

handle) and T17.

9.

Clean the bore in the brake calliper and

manually fit a new, clean steel cap (1).

10. Slide the press-in tool (2), special tool

(DAF no. 1453140), over the steel cap.

11. Using a hammer and the assembled punch,

knock the steel cap as far as the stop in the

brake calliper.

12. Fit the brake pads.

13. Fit the plug for the brake pad wear indicator.

14. Fit the brake cylinder.

R600766

3

1

T17

T17

T2

T17

1

2

3

1

2

2

Нет комментариевНе стесняйтесь поделиться с нами вашим ценным мнением.

Текст