DAF LF45, LF55 Series. Manual — part 465

©

200436

3-11

Removal and installation

BRAKE SYSTEM AND COMPONENTS

ΛΦ45/55 series

6

4

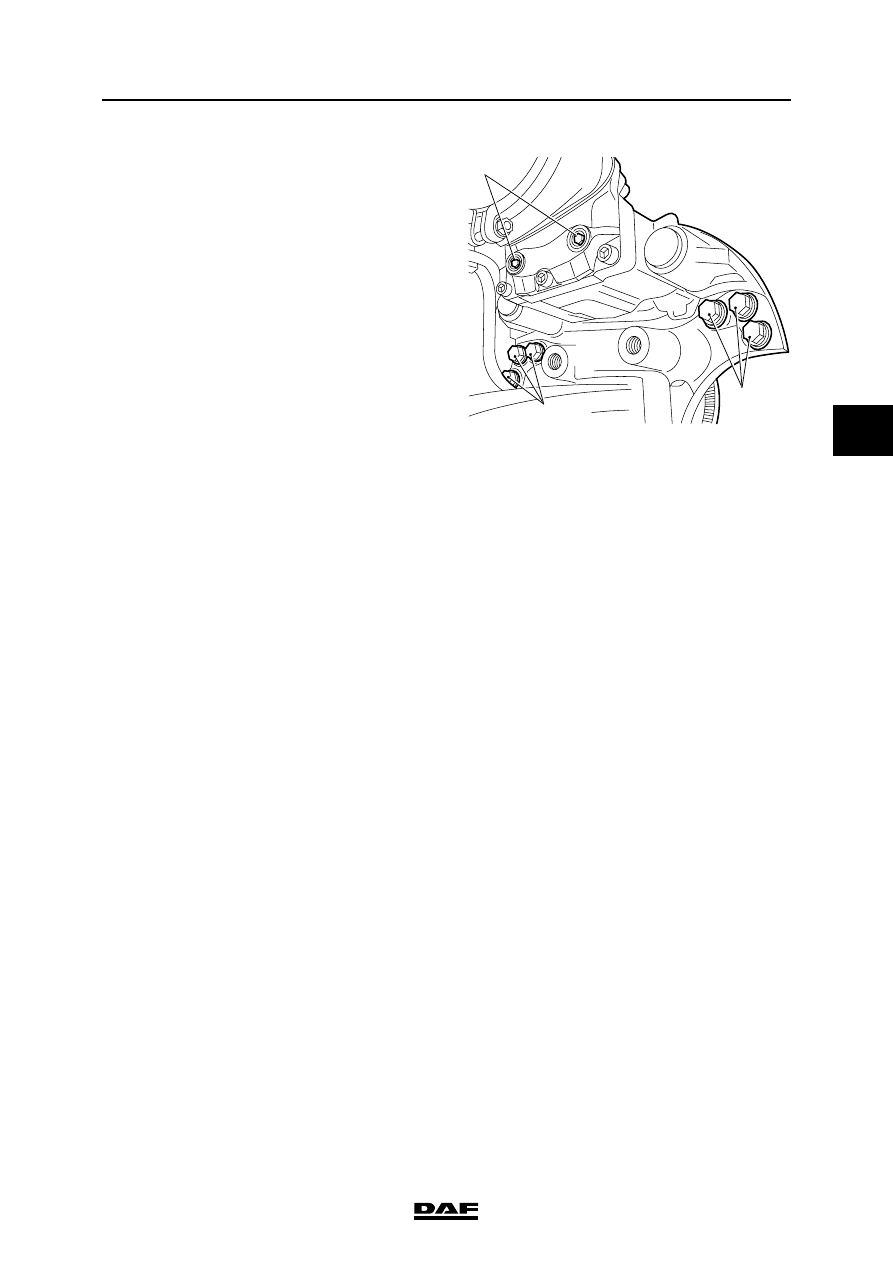

12. Shift the brake calliper towards the cylinders.

13. Check the dust covers, guide pins and

adjusting screws for wear and damage.

Replace in the event of damage and/or wear.

14. Shift the brake calliper manually over the

guide pins and check the freedom of

movement in this way.

15. Check the brake adjuster.

16. Turn the hexagon (9) completely back

(clockwise).

17. Depress the brake pedal lightly a few times

to check that the automatic brake adjuster

works. Turn the hexagon (9) back

(clockwise).

Installing the brake pads

If the brake pads have wear end indicators, they

must be replaced at the same time as the brake

pads, including accessories.

Note:

Brake pads must always be replaced on both

sides of the axle.

1.

If necessary, turn the hexagon (9) back

completely.

2.

Clean the brake pad seats.

3.

First, place a brake pad on the brake piston

side.

4.

Shift the brake calliper towards the wheel

until it touches the brake disc.

5.

Now position the other brake pad as well.

6.

Separate the inner brake pad from the thrust

pieces.

7.

Position a feeler gauge with the correct

thickness (see "Technical data") between

the brake pad and the thrust piece and adjust

the play using the adjuster with the

hexagonal adjusting bolt.

8.

Turn the hexagon clockwise until the feeler

gauge just fits.

R600572

9

8

8

BRAKE SYSTEM AND COMPONENTS

3-12

©

200436

Removal and installation

4

ΛΦ45/55 series

6

9.

Position the new wear sensor with the

strip (4).

10. Position the new spring clips.

11. Position the new locking bracket and tighten

it with the bolt (1). (See "Technical data").

12. Fit the wear sensor connector.

13. Fit the cap(s) to the brake adjuster.

©

200436

3-13

Removal and installation

BRAKE SYSTEM AND COMPONENTS

ΛΦ45/55 series

6

4

3.8 REMOVAL AND INSTALLATION, BRAKE PADS, KNORR MODEL

Never insert fingers between the

brake calliper and the brake calliper

carrier during and following removal

of the brake pads. Always take hold

of the brake calliper on the outside.

Removing the brake pads

1.

Apply the parking brake.

If the respective axle has spring brake

cylinders, place chocks in front of and behind

the wheels of another axle and release the

parking brake.

2.

Remove the wheels in question.

3.

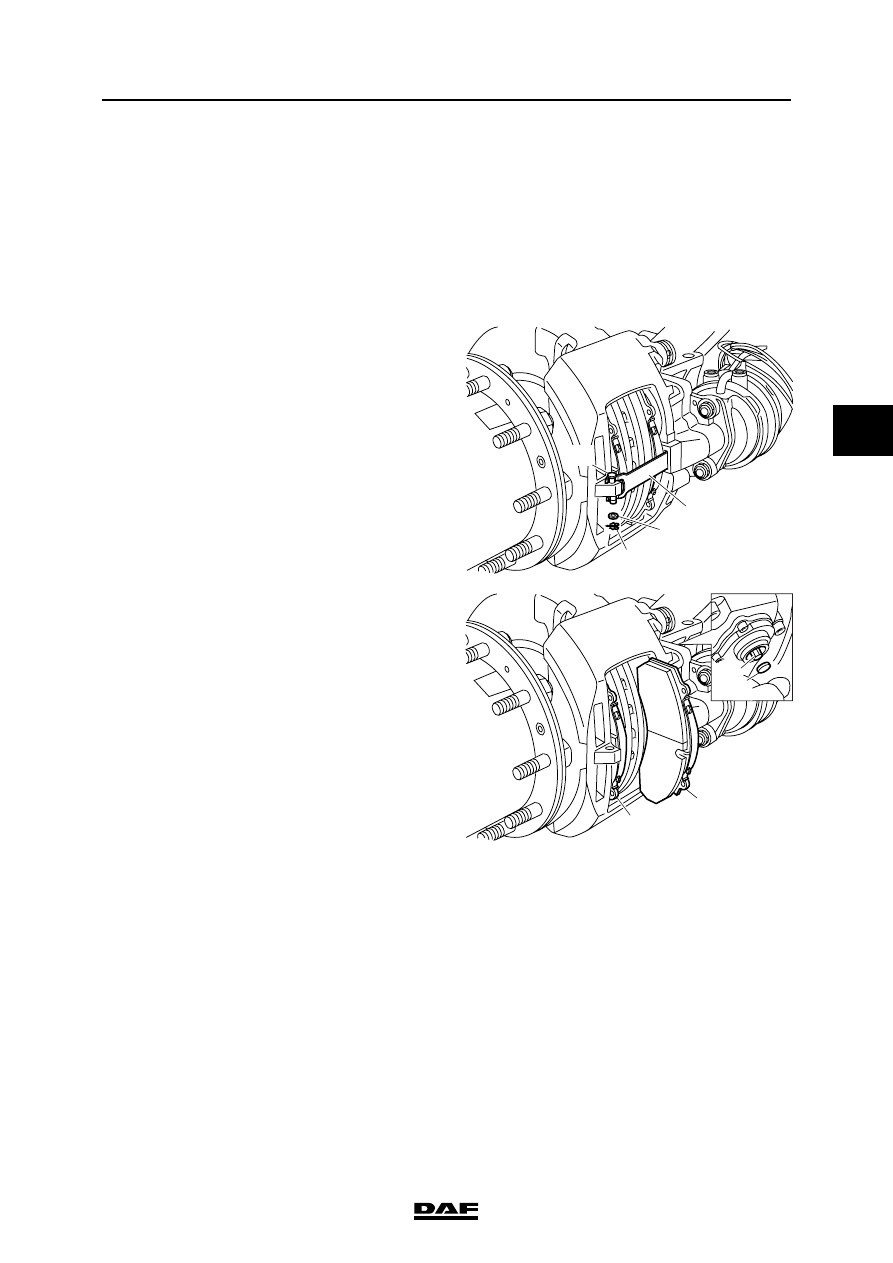

Remove the hairpin spring (26) and washer

(45) from the yoke pin (44) of the locking

strip (11).

4.

Press the strip on and remove the yoke

pin (44).

5.

Check the strip for corrosion; replace if

necessary.

6.

Remove the sealing cap (37).

7.

Using a ring spanner and the adapter, turn

the hexagonal bolt (23) anti-clockwise until

the brake pads (12) can be removed (a

clicking noise can be heard).

Note:

Never turn the hexagonal adjusting bolt

without using an adapter. The adapter is a

torque safety and will break off when the

torque is too high. Without the use of an

adapter the mechanics in the brake calliper

may become damaged when the torque is

too high, so that replacement of the brake

calliper may be necessary.

8.

Remove the brake pads.

}

26

45

11

44

R600461

12

12

R600462

37

23

BRAKE SYSTEM AND COMPONENTS

3-14

©

200436

Removal and installation

4

ΛΦ45/55 series

6

Installing the brake pads

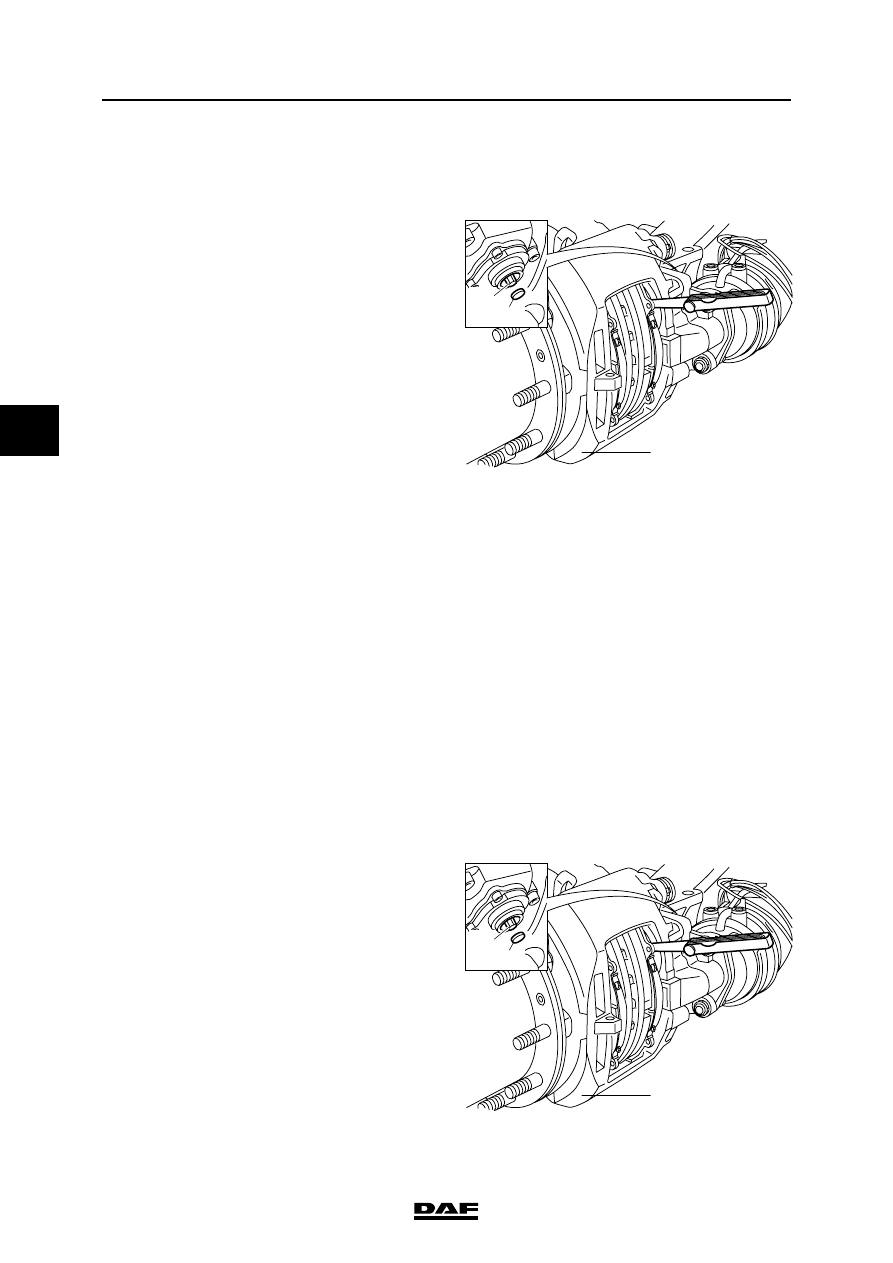

1.

Check the brake calliper play. See

"Inspection and adjustment".

2.

If necessary, turn the hexagonal adjusting

bolt (23) back completely, using the adapter.

3.

Clean the brake pad seats.

4.

Check all brake calliper seals (guide bushes,

thrust pieces).

5.

Shift the brake calliper (1) towards the wheel

side.

6.

Fit the outer brake pad.

7.

Shift the brake calliper towards the brake

cylinder side.

8.

Fit the inner brake pad.

9.

Separate the inner brake pad from the thrust

pieces.

10. Position a feeler gauge with the correct

thickness (see "Technical data") between

the brake pad and the thrust piece of the

adjuster with the hexagonal adjusting bolt.

11. Turn the hexagonal adjusting bolt clockwise

with the ring spanner and the adapter until

the feeler gauge just fits. Remove the feeler

gauge.

12. Check the play between the end of the brake

pads and the brake calliper carrier (see

"Technical data"). If the play is too small,

material must be ground off the steel plate of

the brake pad. If the play is too large, the

brake pads and/or brake carrier must be

replaced.

13. Lightly grease the sealing cap (see

"Technical data") and replace it on the slack

adjuster.

14. Fit the locking strip (11).

15. Press the strip and fit the yoke pin.

16. Fit the washer (45) and the hairpin spring

(26) on the yoke pin (44).

17. Apply the service brake once and check that

the hub can move freely. If necessary,

increase the play.

18. Put the wheels back on.

23

37

1

R600463

23

37

1

R600463

Нет комментариевНе стесняйтесь поделиться с нами вашим ценным мнением.

Текст