DAF LF45, LF55 Series. Manual — part 259

©

200508

4-7

Removal and installation

ALLISON 1000 & 2000 AUTOMATIC GEARBOXES

ΛΦ45/55 series

3

7

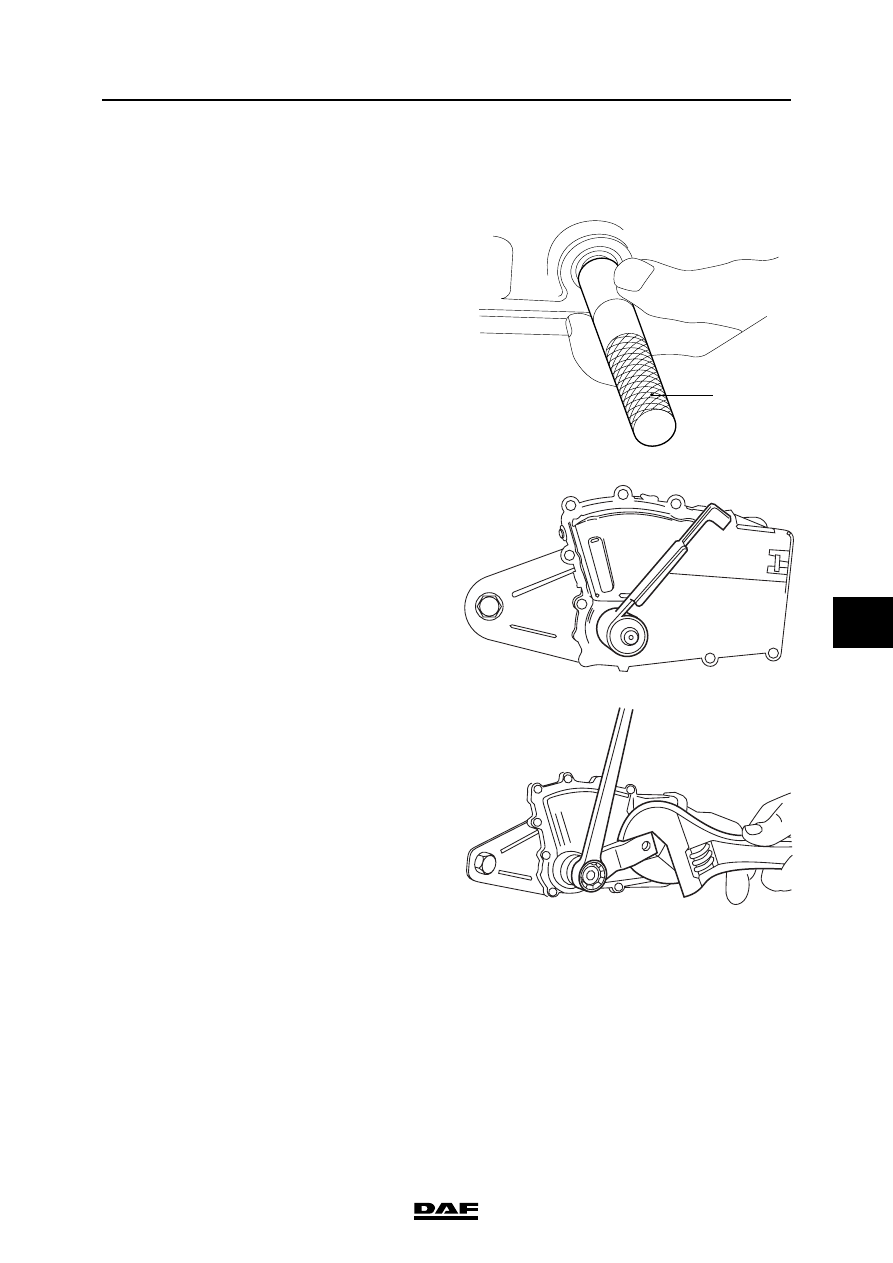

Fitting the selector shaft oil seal

1.

Lightly lubricate lip of the oil seal with clean

gearbox oil.

2.

Fit the oil seal on the special tool

(DAF no. 1453125).

3.

Fit the oil seal as far as possible into the

gearbox housing and remove the special

tool (1).

4.

Fit the selector switch using special tool

(DAF no. 1451992).

5.

Fit the selector arm onto the selector shaft

and tighten the attachment nut to the

specified torque. See "Technical data".

The selector shaft must not be

turned while the attachment nut is

being loosened or tightened. While

loosening or tightening the

attachment nut, lock the selector

shaft using the selector arm and an

appropriate tool.

6.

Fit the selector cable into the selector arm.

Note:

The attachment of the selector cable must be

fitted so that the connecting pin can move

freely in every gear.

1

V3 00 561

V3 00 481

V3 00 482

}

ALLISON 1000 & 2000 AUTOMATIC GEARBOXES

4-8

©

200508

Removal and installation

7

ΛΦ45/55 series

3

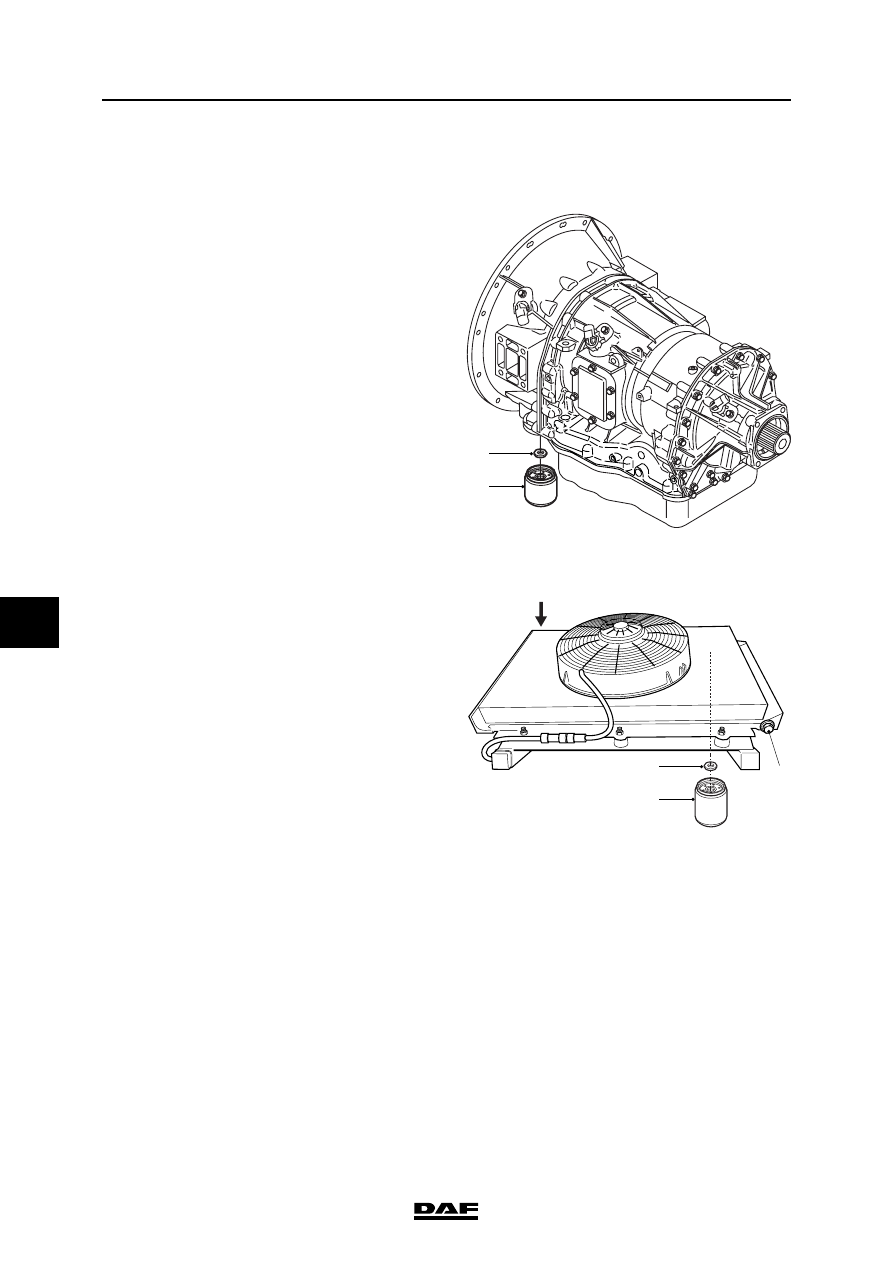

4.5 REMOVING AND INSTALLING OIL FILTERS

Removing oil filters

1.

Clean the oil filters (1) and (5) and the

surrounding area.

2.

Loosen the oil filters on the gearbox and the

heat exchanger.

3.

Remove the magnetic rings (2) and (4) and

check them for wear particles.

Note:

If there are large wear particles in the wear

swarf, this indicates excessive wear in the

gearbox and the cause must be ascertained.

4.

Clean the magnetic rings and the contact

surfaces on the gearbox housing and the

heat exchanger.

Installing oil filters

1.

Fit the magnetic rings (2) and (4) on the

gearbox housing and the heat exchanger.

2.

Lightly lubricate the new oil filters (1) and (5)

with clean gearbox oil and place the oil filters

on the gearbox and heat exchanger.

3.

Tighten the oil filters until they touch the

contact surface. Manually tighten the oil

filters another 360

″.

4.

Check the oil level. See "Inspection and

adjustment".

1

2

V3 00 480

5

4

6

3

V3 00 556

©

200508

5-1

Draining and filling

ALLISON 1000 & 2000 AUTOMATIC GEARBOXES

ΛΦ45/55 series

3

7

5. DRAINING AND FILLING

5.1 DRAINING AND FILLING GEARBOX

Draining gearbox

1.

Bring the gearbox to operating temperature

(approx. 71

″C - 93″C) so that the oil can be

drained more quickly and more completely.

2.

Place the vehicle on a level and horizontal

surface.

3.

Remove the drain plug from the gearbox oil

sump.

4.

Remove the drain plug (6) from the heat

exchanger and loosen the bleed screw (3).

5.

Remove the oil filters. See "Removal and

installation".

5

4

6

3

V3 00 556

ALLISON 1000 & 2000 AUTOMATIC GEARBOXES

5-2

©

200508

Draining and filling

7

ΛΦ45/55 series

3

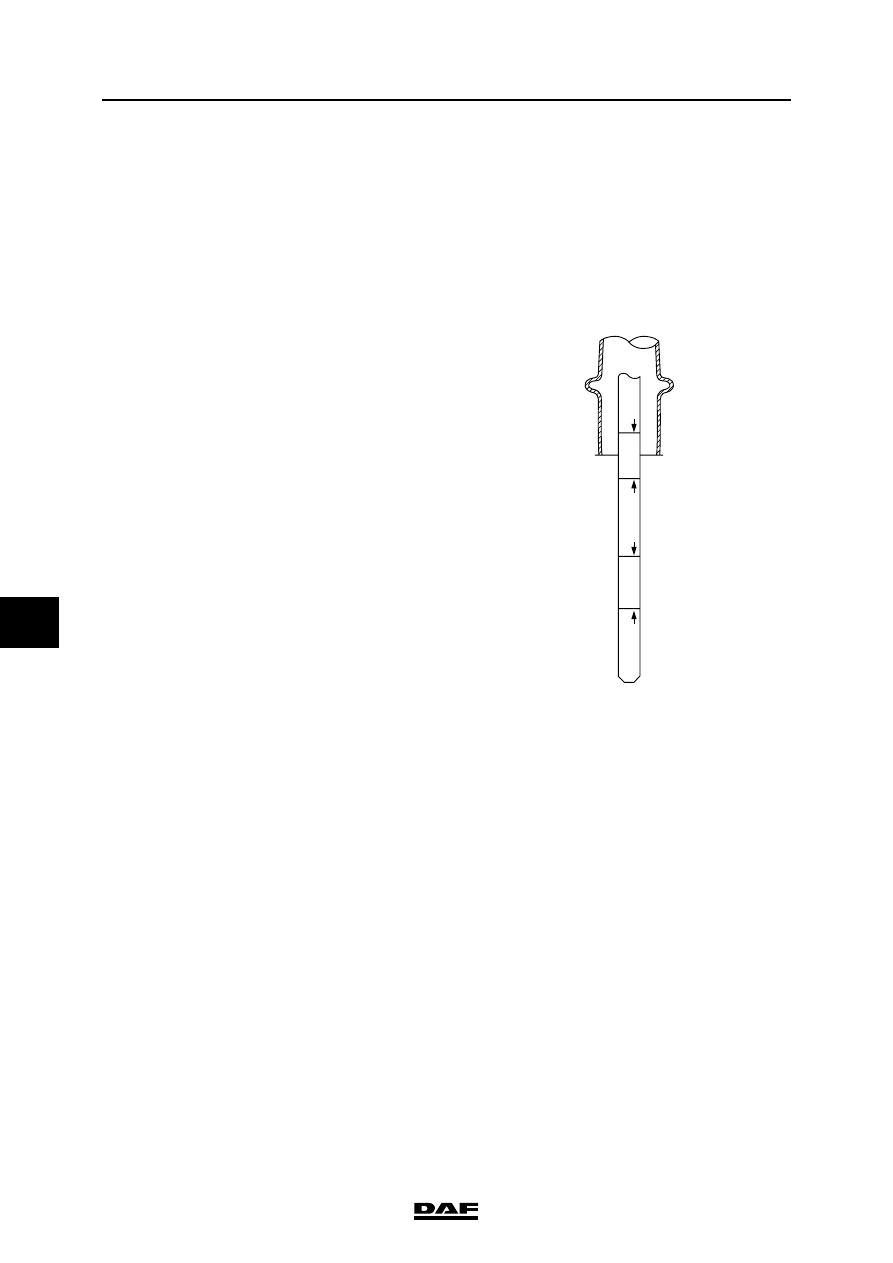

Filling gearbox

1.

Clean the drain plugs, provide them with new

sealing rings and fit them, tightening to the

specified torque. See "Technical data".

2.

Fill the gearbox through the dipstick holder

with the specified quantity of oil; see

"Technical data".

3.

Start the engine and run it at idling speed.

4.

If only gearbox oil escapes, tighten the bleed

screw (3) to the specified torque. See

"Technical data".

5.

While the engine is idling, add gearbox oil

until the oil level is between the "Cold add"

mark and the "Cold full" mark.

6.

Check the oil level. See "Inspection and

adjustment".

HOT FULL

COLD FULL

HOT ADD

COLD ADD

W 3 03 099

Нет комментариевНе стесняйтесь поделиться с нами вашим ценным мнением.

Текст