DAF LF45, LF55 Series. Manual — part 448

©

200436

2-13

Description of components

OPERATION OF BRAKE COMPONENTS

ΛΦ45/55 series

6

3

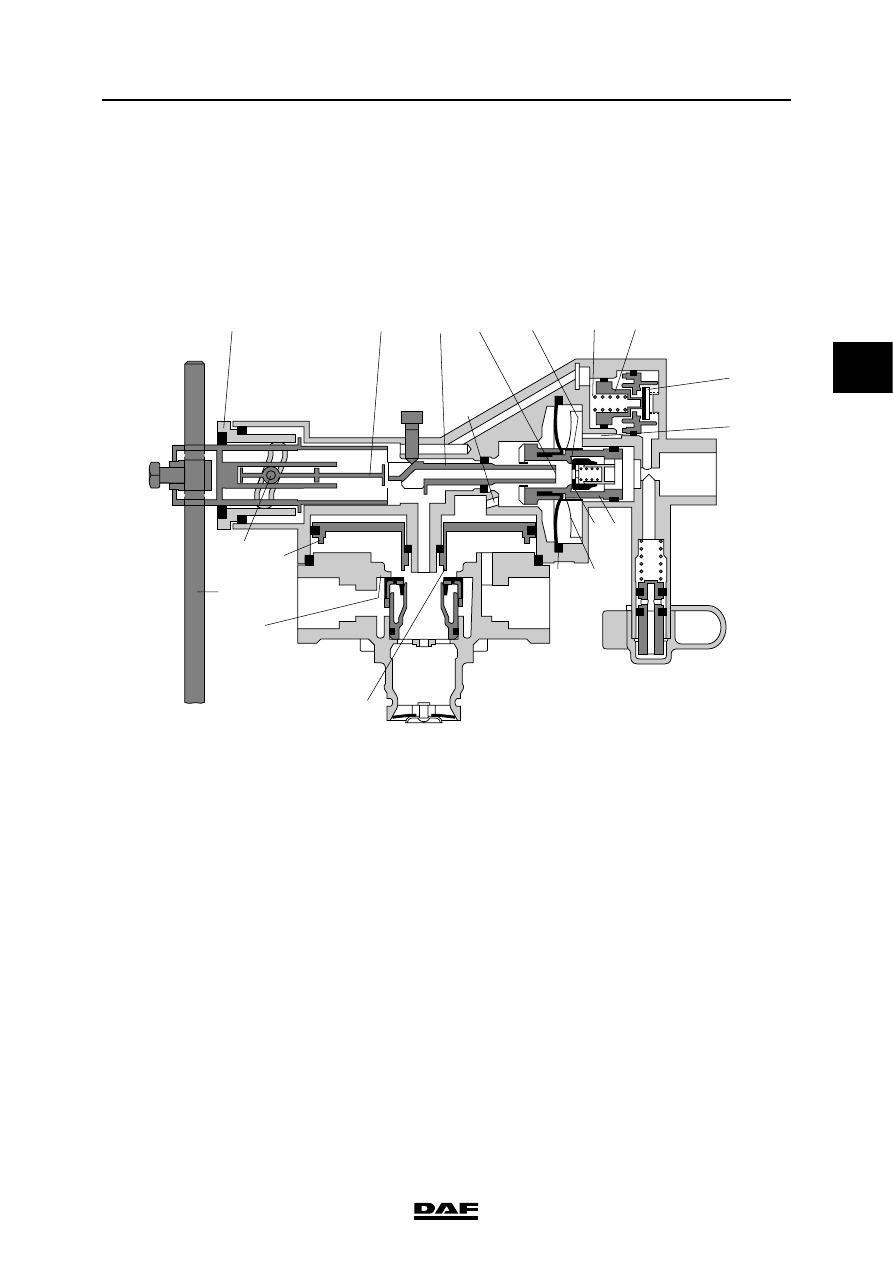

2.8 LOAD SENSING VALVE, LEAF SUSPENSION

Purpose

Automatic control of the brake force depends on

the deflection of the springs and therefore on the

loading condition of the vehicle. Thanks to the

integrated relay valve, the brake cylinders are

aerated and bled quickly.

Operation

The control valve is attached to the chassis and

connected to the rear axle by means of a rod.

With unladen vehicles, the distance between the

regulator and the axle is largest and the lever (j)

points fully downwards. When the vehicle is

loaded, this distance decreases and the lever

moves upwards, towards full load position.

Pin i rotates at the same time as the lever and as

a result thereof moves to the right via the control

groove in bearing cover p. Rod "q" brings the

tappet (g) in a position that corresponds with the

loading condition.

The compressed air provided by the foot brake

valve flows via connecting point 4 into space A,

pushing piston b to the left. Outlet "d" is closed

and inlet "m" is opened, causing compressed air

to enter space C to the left of diaphragm "e".

Relay piston "f" is operated via duct F and

chamber G.

3

2

1

4

E

C

C

F

D

A

G

B

a

n

o

m

d

g

q

j

i

f

e

l

k

p

h

c b

R600456

OPERATION OF BRAKE COMPONENTS

2-14

©

200436

Description of components

3

ΛΦ45/55 series

6

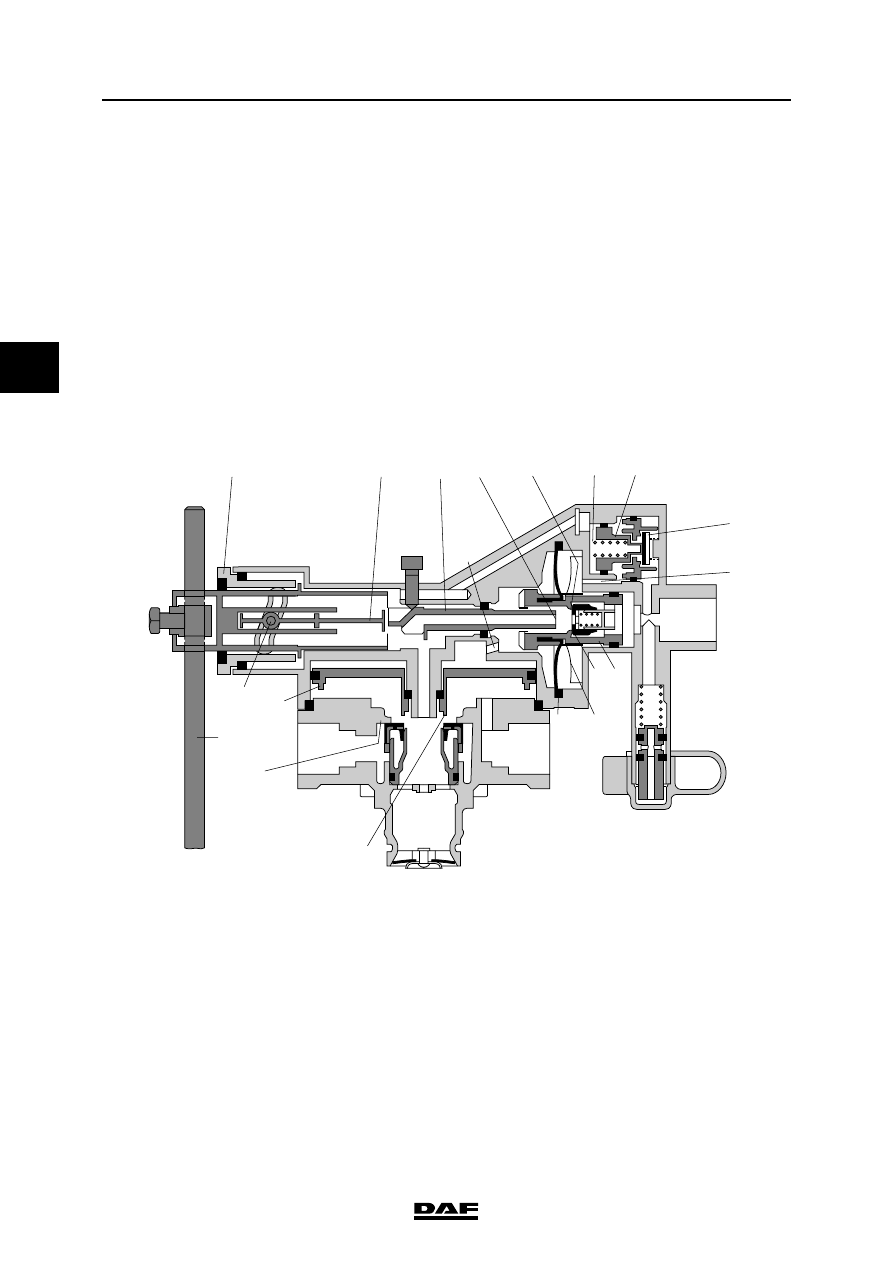

At the same time, compressed air flows through

the open valve (a) and duct E into space D to the

right of diaphragm "e". Due to this control, the

output pressure at partial load and low control

pressures is increased (to max. 1.4 bar). If the

control pressure increases further, piston "n" is

moved to the left against the pressure of spring

"o" and valve "a" closes.

As pressure builds up in space G, relay piston "f"

is pressed downwards. Outlet "h" closes and inlet

"k" opens. The air at connecting point 1 now flows

to the brake cylinders via connecting point 2.

Now pressure will start to build up in space B

under relay piston "f". As soon as this pressure is

somewhat higher than that in space G, the piston

is pushed upwards and closes inlet "k".

When piston "b" is moved to the left, the vanes (l)

attached to it will gradually loosen the diaphragm

(e) from the fixed vanes in the fan housing. As a

result, the effective diaphragm surface will

gradually increase. As soon as the force of the air

to the left of the diaphragm exceeds that to the

right, piston "b" will move to the right. The inlet

(m) will be closed and a set position is reached.

The position of the tappet (g), which is dependent

on the position of lever "j", is indicative of the

effective diaphragm surface and therefore of the

output brake pressure.

3

2

1

4

E

C

C

F

D

A

G

B

a

n

o

m

d

g

q

j

i

f

e

l

k

p

h

c b

R600456

©

200436

2-15

Description of components

OPERATION OF BRAKE COMPONENTS

ΛΦ45/55 series

6

3

The position of the tappet (g) determines to what

extent piston "b" must be moved with the vane

disc (l) to allow the valve to build up pressure.

Due to this movement, the effective surface of the

diaphragm will alter.

In full-load position, this surface and that of piston

"b" are equally large. The control pressure at

connecting point 4 is therefore let through

(ratio 1:1) to spaces C and G. The output

pressure at 2 will now be equal to the control

pressure at connecting point 4.

If the pressure decreases at connecting point 4,

piston "b" will be pushed to the right by the

pressure in space C. Bleed vent d will open and

the pressure in spaces C and G will fall. The relay

piston will be pushed up due to the pressure still

present in space B, causing bleed vent "h" to

open. The pressure at connecting point 2 will now

fall via bleed vent 3.

A stop bolt in front of the tappet (g) ensures that

this valve can always provide the minimum brake

pressure if lever "j" is in too low a position due to

a fault. The factory setting of this bolt must not be

changed.

OPERATION OF BRAKE COMPONENTS

2-16

©

200436

Description of components

3

ΛΦ45/55 series

6

2.9 ABS VALVE

The ABS valve must keep the pressure constant

in the brake chamber during an ABS control, or

decrease the pressure in the brake chamber

regardless of the pressure leaving the foot brake

valve.

If the ABS valve is not operative, it has no

function and the input pressure at connecting

point 1 is the same as the output pressure at

connecting point 2 to the brake chamber.

Increasing pressure at connecting point 2

Input pressure at connecting point 1 coming from

the foot brake valve will lift diaphragm 5 from

seat 7, causing the brake pressure to be guided

to the brake chamber via connecting point 2.

The input pressure will also be guided through a

bore past the magnet coil (10) in space 19 under

diaphragm 6, causing diaphragm 6 to form a seal

on seat 8. Connecting point 2 is thus sealed off

from the bleed vent.

1

2

R600264

6

8

19

10

7

5

2

1

R600629

P (bar)

t (sec)

2

Нет комментариевНе стесняйтесь поделиться с нами вашим ценным мнением.

Текст