DAF LF45, LF55 Series. Manual — part 648

©

200515

3-21

Inspection and adjustment

EXPLANATORY NOTES ON THE MAINTENANCE ACTIVITIES

ΛΦ45/55 series

5

3.26 INSPECTION AND ADJUSTMENT, LOAD SENSING VALVE, LEAF

SUSPENSION

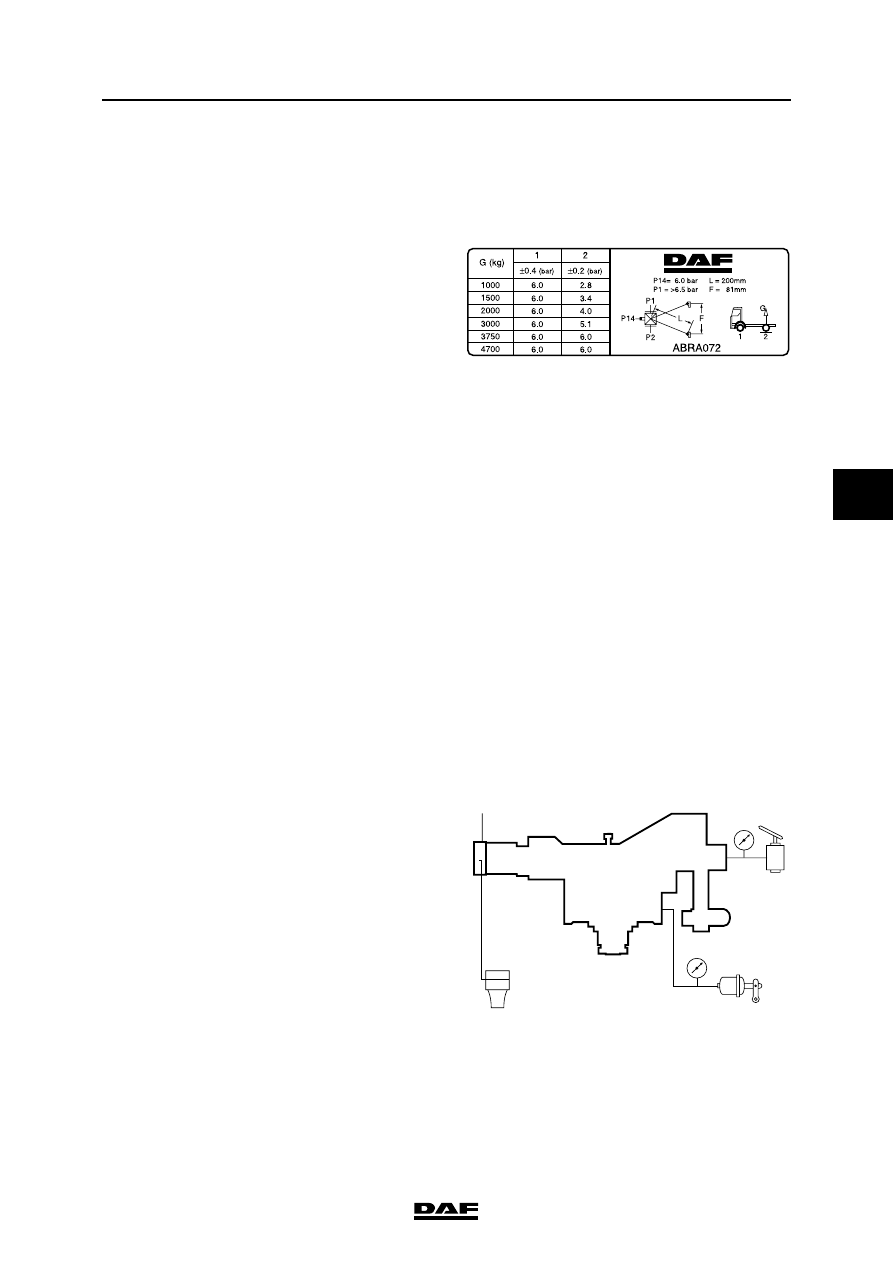

Explanatory notes on instruction plate

The data relating to axle loads and output

pressures are listed on the instruction plate

following the sequence of the axles beneath the

vehicle.

"1" refers to the (first) front axle, "2" to the

following axle, etc.

In the entire column, a reading of 6 bar has been

filled in under "1". If the vehicle is equipped with

an empty/load valve, a pressure ratio is entered

in the box under the valve illustration, e.g. "i = 1 :

1,5". The "output pressure P2" of axle 1 will give

variable readings.

These values can be used to check the brake

pressure values of the front axle and to carry out

the inspection/adjustment below at the same

time. To do this, connect a pressure gauge to the

test connection of one of the front axle brake

cylinders.

Inspection/adjustment

1.

Measure the weight plus load of the rear

axle.

2.

Check the attachment of the control lever

and its ease of operation.

3.

Check that the right type of valve has been

fitted.

4.

Check the length of the control lever

(see "L" on the instruction plate).

5.

Connect a pressure gauge (4) to the test

connection near connection 1/4 on the load

sensing valve (input pressure).

6.

Connect pressure gauge (2) to the test

connection on one of the brake cylinders

(service brake connection) of the rear axle.

7.

Make sure that the reservoir pressure is

higher than 6.5 bar throughout the testing

process.

8.

Depress the brake pedal until pressure

gauge (4) indicates a value of 6 bar.

9.

Read the brake pressure of the rear axle

from pressure gauge 2 and check that this

value matches the one listed on the

instruction plate in the table under "output

pressure p2" to the rear axle.

R6 00 549

1/4

4

2

2

R600562

1

EXPLANATORY NOTES ON THE MAINTENANCE ACTIVITIES

3-22

©

200515

Inspection and adjustment

5

ΛΦ45/55 series

10. If necessary, correct the brake pressure by

adjusting the length of the vertical

connecting rod (2). Never attempt to alter the

length L of the (horizontal) control lever.

11. Remove the ball coupling (1) and raise the

control lever. Check that the output pressure

is now allowed through (almost) without

reduction.

Note:

The small socket head screw in the centre of

the valve must not be adjusted.

Drive and chassis

1

2

R6 00 568

L

©

200515

3-23

Inspection and adjustment

EXPLANATORY NOTES ON THE MAINTENANCE ACTIVITIES

ΛΦ45/55 series

5

3.27 CHECKING THE DIFFERENTIAL FOR LEAKS

1.

Visually inspect the differential for leaks.

3.28 CHECKING THE OPERATION OF THE DIFFERENTIAL LOCK

1.

Jack up the rear axle and support the axle on

stands.

2.

Bring the air system to operating pressure.

3.

Engage the differential lock. The warning

indicator should now be active.

4.

Check that there is a "rigid" connection

between the driven wheels.

5.

Disengage the differential lock. The warning

light should now go out and the "rigid"

connection between the driven wheels

should be broken.

EXPLANATORY NOTES ON THE MAINTENANCE ACTIVITIES

3-24

©

200515

Inspection and adjustment

5

ΛΦ45/55 series

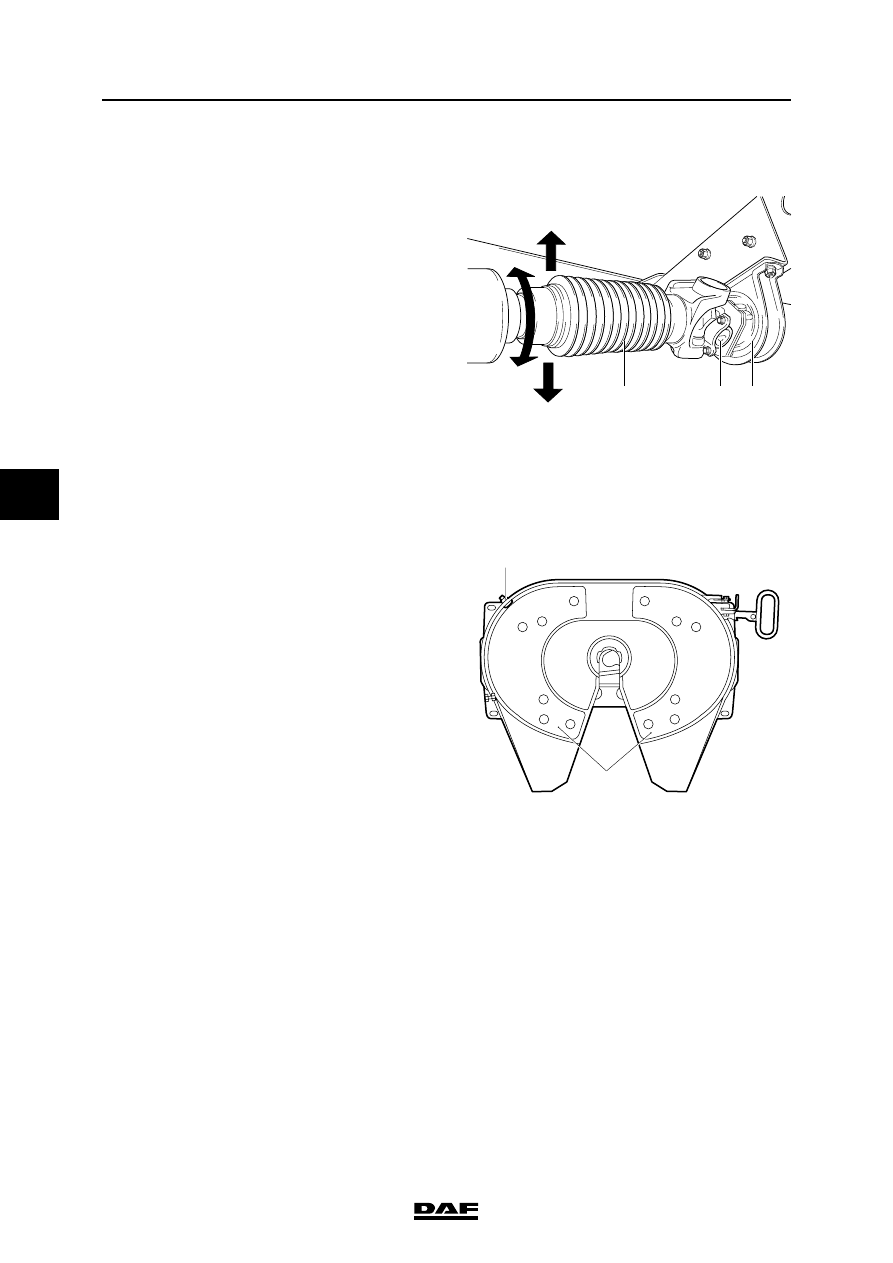

3.29 CHECK THE DRIVE SHAFT PLAY

1.

Check the universal joints (2) and

suspension bearing (3) for play and damage.

2.

Check the sliding joint for axial and radial

play. The rubber dust cover (1) over the

sliding joint should be undamaged.

3.

There must be no clearly perceptible play on

the universal joints, suspension bearing and

the sliding joint.

3.30 INSPECTING THE FIFTH WHEEL

1.

Check the attachment of the fifth wheel.

2.

Check the play of the closing gear of the fifth

wheel.

Note:

For maximum play values, consult the

manufacturer's instructions or the legal

requirements.

3.

In the case of fifth wheels with a plastic

sliding plate (1), check for wear. The plastic

sliding plate (1) must not lie flush with the top

of the attachment bolts.

1

2

3

V3 00 379

V300372

1

2

Нет комментариевНе стесняйтесь поделиться с нами вашим ценным мнением.

Текст