DAF LF45, LF55 Series. Manual — part 658

©

200515

5-5

Draining and filling

EXPLANATORY NOTES ON THE MAINTENANCE ACTIVITIES

ΛΦ45/55 series

5

5.4 DRAINING AND FILLING, RAS-EC STEERING CIRCUIT

Drained steering oil must not be re-

used. Store this hydraulic oil

separately from the other drained

oils and have the oil collected by a

waste-removal company authorised

to do so.

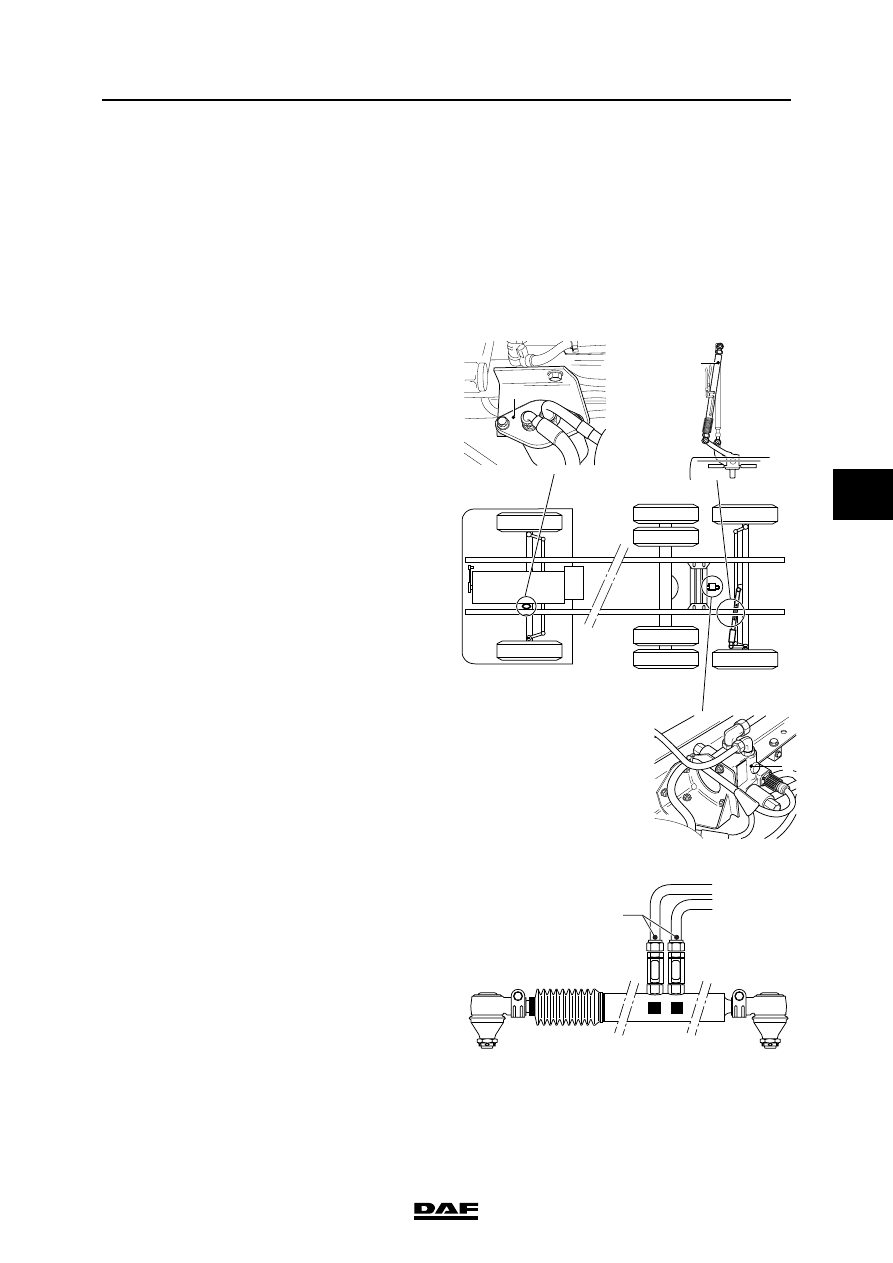

Draining the RAS-EC steering circuit

1.

Jack up the trailing axle and support the axle

on stands.

2.

Place suitable catch pans under the high-

pressure filter (1), the steering cylinder (2)

and the valve block (3).

3.

Clean the steering oil reservoir and the

surrounding area.

4.

Remove the filter element from the steering

oil reservoir.

5.

Clean the housing and the surrounding area

of the high-pressure filter. Remove the high-

pressure filter.

6.

Mark the position of the pipes on the

damping valves (1) and remove the pipes

from the damping valves.

7.

Mark the position of the damping valves, if

necessary, and remove the damping valves.

8.

Slowly turn the trailing axle manually several

times, until the steering oil gently comes out

of the steering cylinder.

9.

Check the sealing rings of the damping

valves for damage and wear. Replace them

if necessary.

}

S7 00 801

1

3

2

S7 00 800

B

25 bar

A

33 bar

A

B

1

EXPLANATORY NOTES ON THE MAINTENANCE ACTIVITIES

5-6

©

200515

Draining and filling

5

ΛΦ45/55 series

10. Correctly position the damping valves on the

steering cylinder.

Note:

The mixing up of damping valves must be

avoided under all circumstances. The mixing

up of damping valves has a negative impact

on vehicle handling.

11. Fit the pipes to the damping valves

according to the relevant marks.

12. Fit a new high-pressure filter, see chapter

"Removal and installation".

13. Insert a new filter element in the steering oil

reservoir, see chapter "Removal and

installation".

Filling the RAS-EC steering circuit

1.

Fill the steering oil reservoir with the

specified steering oil.

2.

Start the engine, run it at idling speed and

continuously top up the steering oil reservoir.

Note:

The steering oil level should not drop below

the minimum level. However, if the steering

oil level is below the minimum level, it may

well be that the steering pump draws in air

only. This may cause additional foaming.

3.

Bleed the RAS-EC steering circuit.

©

200515

5-7

Draining and filling

EXPLANATORY NOTES ON THE MAINTENANCE ACTIVITIES

ΛΦ45/55 series

5

5.5 BLEEDING THE RAS-EC STEERING CIRCUIT

Bleeding the RAS-EC steering circuit

1.

Gently turn the steering wheel in both

directions, if the level in the reservoir hardly

drops, if at all.

Note:

It is possible that the system fails at the

slightest steering movement. The yellow

warning will be displayed on the DIP and the

trailing axle will no longer steer. In the case

of a failure, switch the vehicle ignition off and

on again.

Note:

The foam that develops during bleeding will

have disappeared after the test drive.

2.

Check the steering oil level and run the

engine at idling speed for a couple of

minutes.

3.

Gently turn the steering wheel in both

directions and check the oil level. Top up, if

necessary.

4.

Make a test run and check the steering oil

level. Top up, if necessary.

Drive and chassis

EXPLANATORY NOTES ON THE MAINTENANCE ACTIVITIES

5-8

©

200515

Draining and filling

5

ΛΦ45/55 series

5.6 DRAINING AND FILLING, DIFFERENTIAL

To prevent skin injury, avoid

unnecessary contact with the

drained oil.

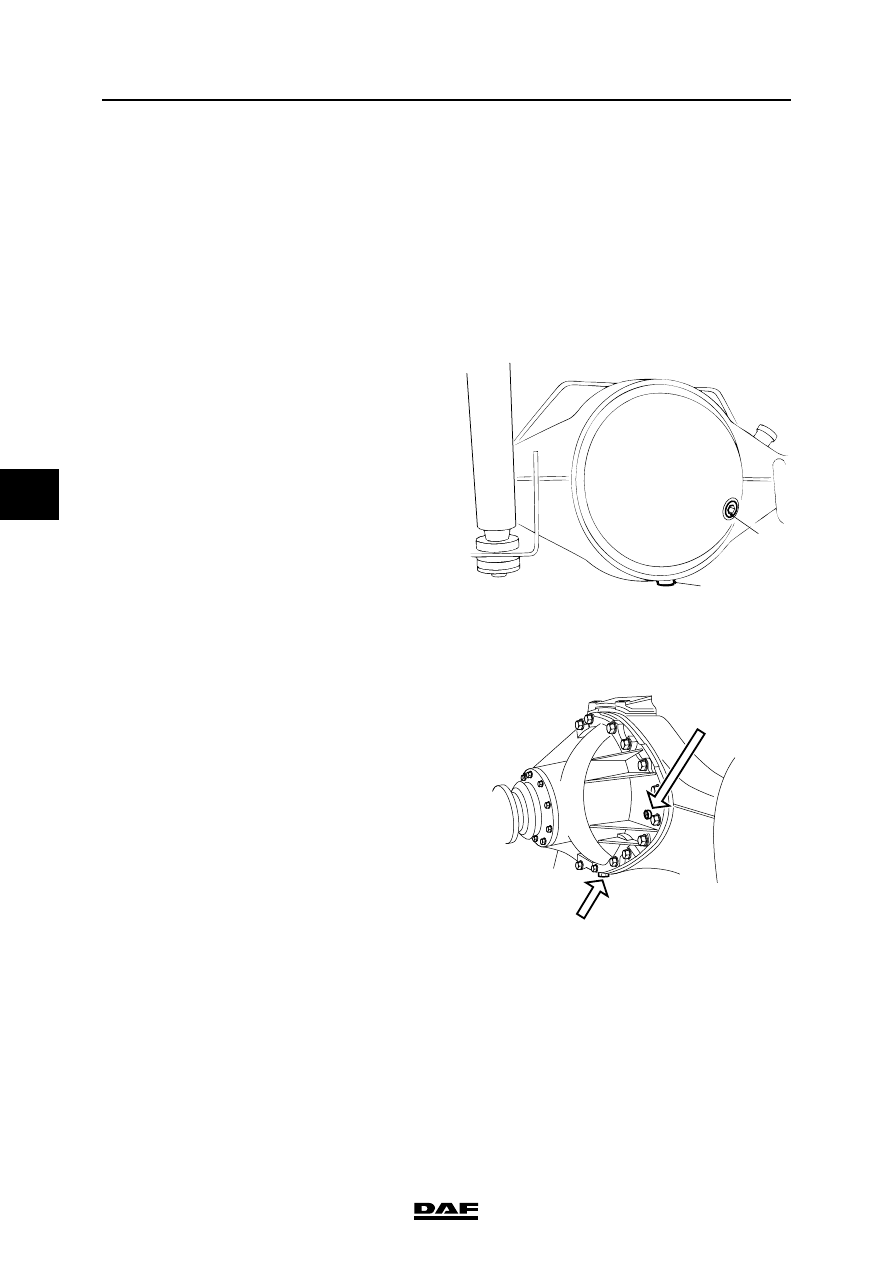

Draining the differential

1.

Position the vehicle on a level surface.

2.

Place a suitable tray beneath the differential

to collect the oil.

3.

Remove the drain plug (1) and the level

check/filler plug (2). Drain the oil.

4.

Apply sealant to the thread of the drain

plug (1). Fit the drain plug (1).

Filling the differential

1.

Fill the differential gear via the level check/

filler plug (2) with the specified, correct

quantity of oil. See "Technical data".

2.

Check the oil level after approx. 5 minutes;

it should reach up to the level check/filler

plug (2). If necessary, top up.

3.

Apply sealant to the thread of the level

check/filler plug (2). Fit the level check/filler

plug (2).

Draining the 1132 axle differential

1.

Position the vehicle on a level surface.

2.

Remove the level check/filler plug (A) and

drain plug (B). Drain the oil.

3.

Fit the plug using the special Torx wrench

(DAF no. 1329493) and tighten to the

specified torque; see "Technical data".

Filling the 1132 axle differential

1.

Fill the differential gear through the level

check/filler plug (A) with the specified

quantity of oil; see "Technical data".

2.

Check the oil level after 5 minutes, it must

reach the edge of the level check/filling

opening.

3.

Fit the level check/filler plug (A) using the

special Torx wrench (DAF no. 1329493) and

tighten to the specified torque; see

"Technical data".

}

1

2

A8 00 370

M8013

A

B

Нет комментариевНе стесняйтесь поделиться с нами вашим ценным мнением.

Текст