DAF LF45, LF55 Series. Manual — part 303

©

200416

3-3

Inspection and adjustment

BE ENGINE INLET/EXHAUST SYSTEM

ΛΦ45/55 series

4

3

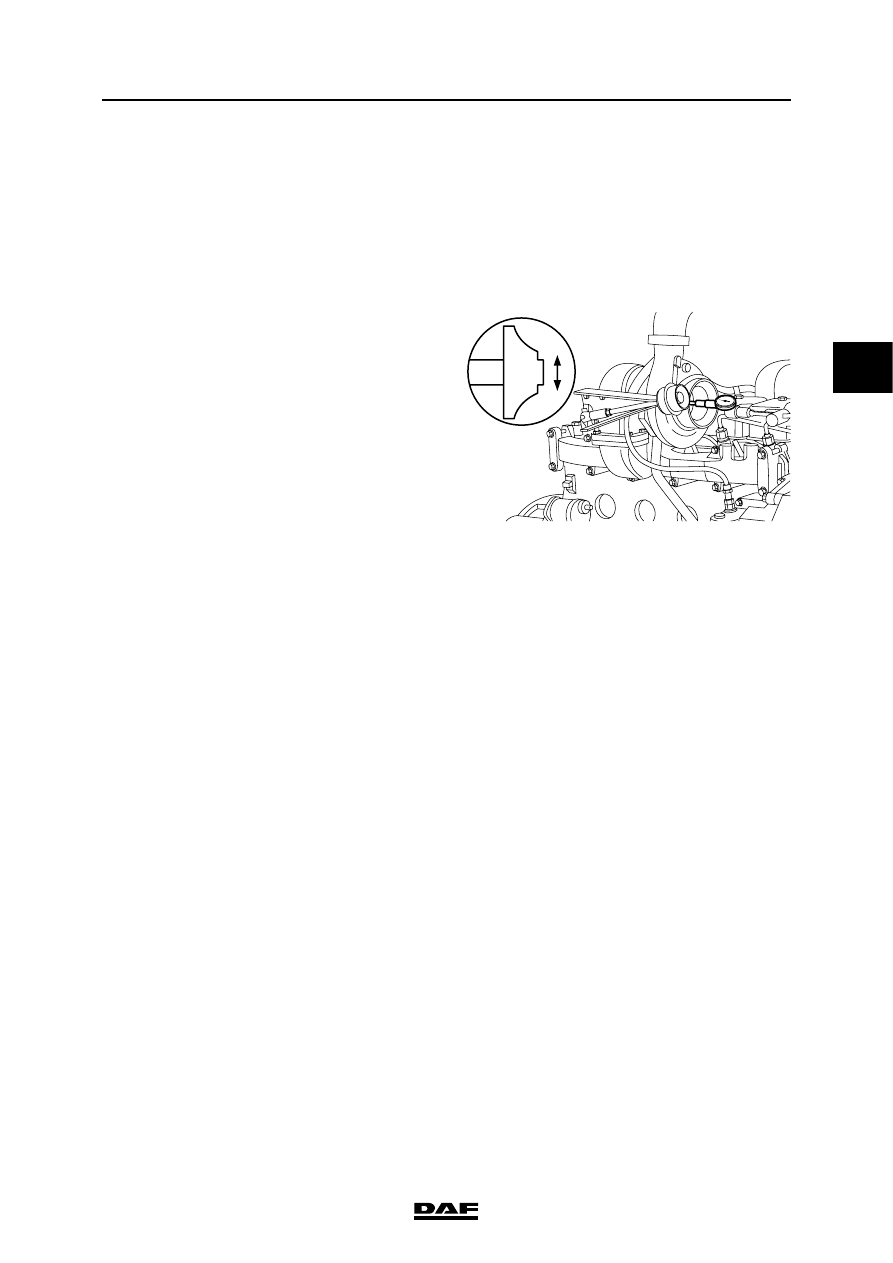

3.3 INSPECTING TURBOCHARGER RADIAL BEARING PLAY

Note:

The turbocharger radial bearing play should only

be checked when the engine is cold.

1.

Remove the turbocharger from the exhaust

manifold. See "Removal and installation".

2.

Fit a pressure gauge to the turbocharger

housing and measure the radial play.

Compare the reading with the specified

value; see "Technical data". Replace the

turbocharger if necessary.

3.

Fit the turbocharger. See "Removal and

installation".

i400650

BE ENGINE INLET/EXHAUST SYSTEM

3-4

©

200416

Inspection and adjustment

3

ΛΦ45/55 series

4

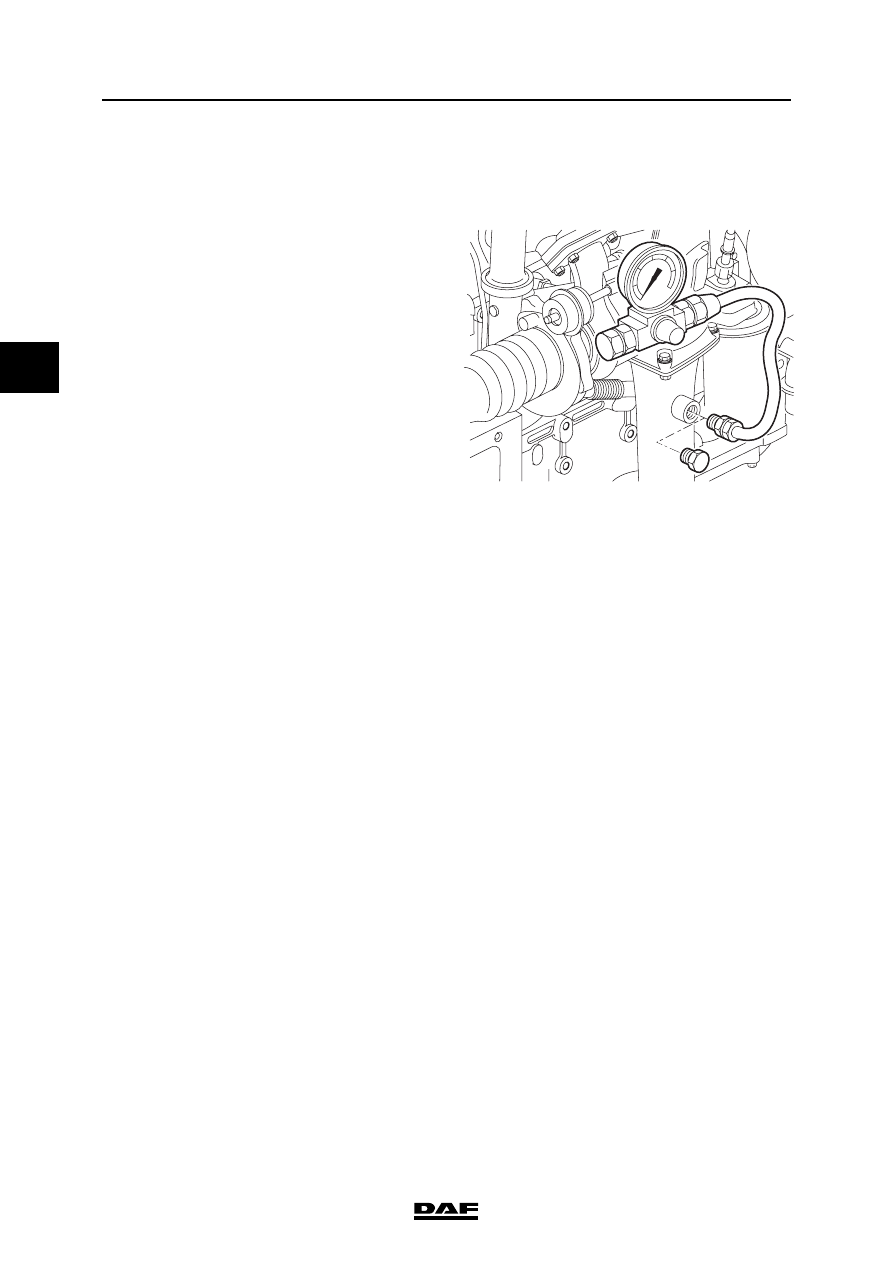

3.4 CHECKING EXHAUST GAS BACK PRESSURE

Checking exhaust gas back pressure

1.

Remove the plug from the exhaust elbow

attachment or bore a hole and install a

suitable coupling with a pipe. The first part of

the pipe must be made of metal, to withstand

the high temperatures.

Note:

Use an attenuated gauge to prevent

excessive shaking of the gauge needle.

2.

Connect a pressure gauge to the pipe, with a

range of at least 0.1 - 0.2 bar (10 - 20 kPa).

Note:

The engine brake must not be used during

measurements. This is to protect the

pressure gauge.

3.

Measure the exhaust gas back pressure at

full-load engine speed and compare the

measurements to the specified value. See

"Technical data". Check the exhaust system

if the exhaust gas back pressure is too high.

4.

Remove the pressure gauge and the

coupling and fit the plug.

i400513

©

200416

3-5

Inspection and adjustment

BE ENGINE INLET/EXHAUST SYSTEM

ΛΦ45/55 series

4

3

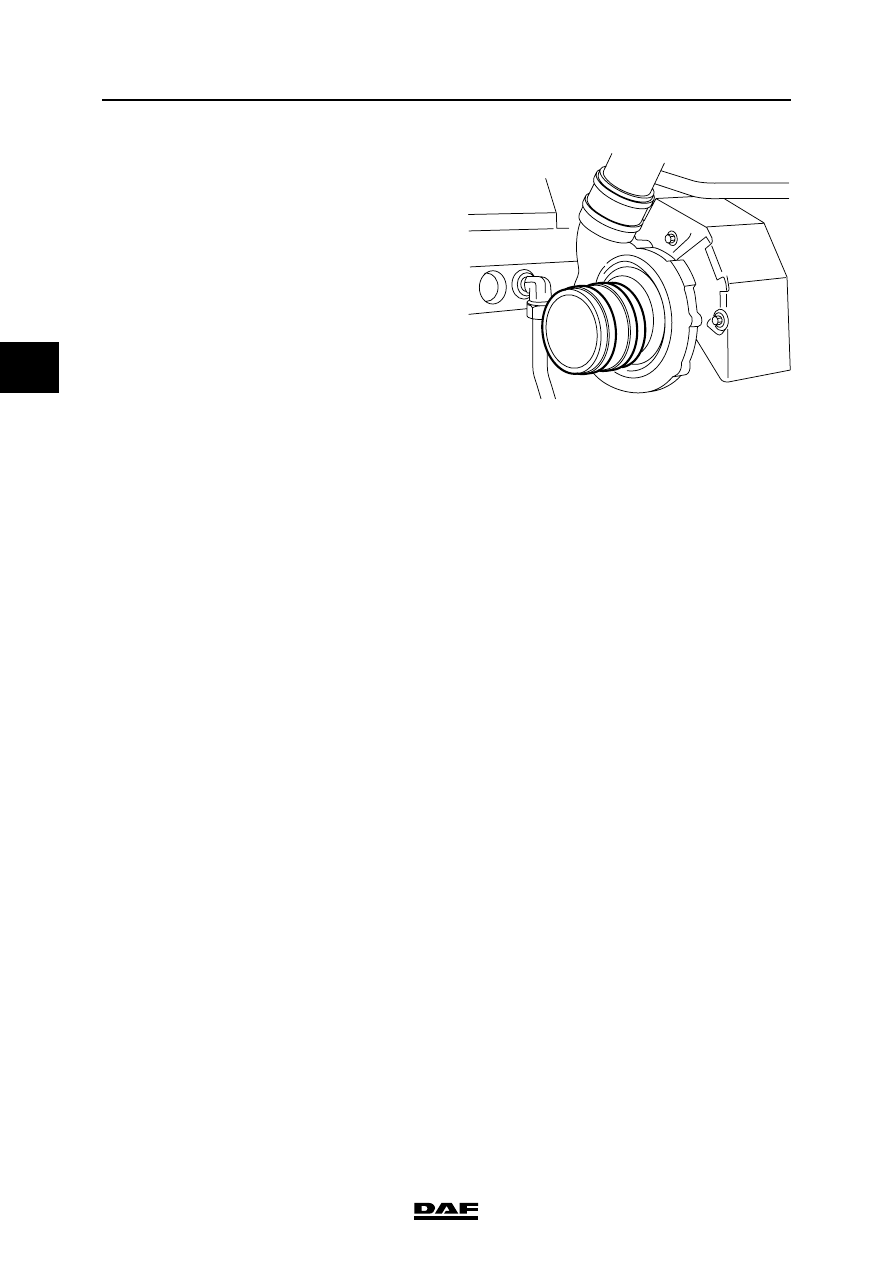

3.5 INSPECTION AND PRESSURE-TESTING, AIR INLET SYSTEM

When pressure-testing the air inlet

system, the plugs may spring off if

they are not properly secured. It is

therefore important to check the

attachment of the plugs before

pressure-testing and keep people

away from the area.

1.

Check the condition and mounting of the air

inlet channels/pipes of the air intake system.

Note:

In case of doubt as to the proper sealing of

the air inlet system, which is indicated by the

following:

- loss of power

- high fuel consumption

- unusual noises

- lit engine fault symbol on the instrument

panel, ???carry out a pressure test to check

the air inlet system for leakage.

2.

Remove the right-hand and rear engine

encapsulations.

3.

Loosen the inlet hose between the air cooler

and the inlet manifold at the inlet manifold

side.

4.

Fit the special tool (DAF no. 1453171) in the

hose.

}

A

i400856

BE ENGINE INLET/EXHAUST SYSTEM

3-6

©

200416

Inspection and adjustment

3

ΛΦ45/55 series

4

5.

Loosen the plastic pipe between the air filter

housing and the rubber suction hose on the

turbocharger.

6.

Install special tool (DAF no. 1453172) in the

rubber intake port on the turbocharger.

7.

Connect an air pipe with reducer valve to the

sealing cap (A) and charge the system to

approx. 1 bar.

8.

Use a soapy solution to check the whole inlet

system for air leaks. Also check whether the

pressure gauge of the reducer valve drops.

9.

Fit the loosened hoses of the inlet system

and the engine encapsulation.

i 400376

Нет комментариевНе стесняйтесь поделиться с нами вашим ценным мнением.

Текст