DAF LF45, LF55 Series. Manual — part 304

©

200416

3-7

Inspection and adjustment

BE ENGINE INLET/EXHAUST SYSTEM

ΛΦ45/55 series

4

3

3.6 CHECKING INLET UNDERPRESSURE

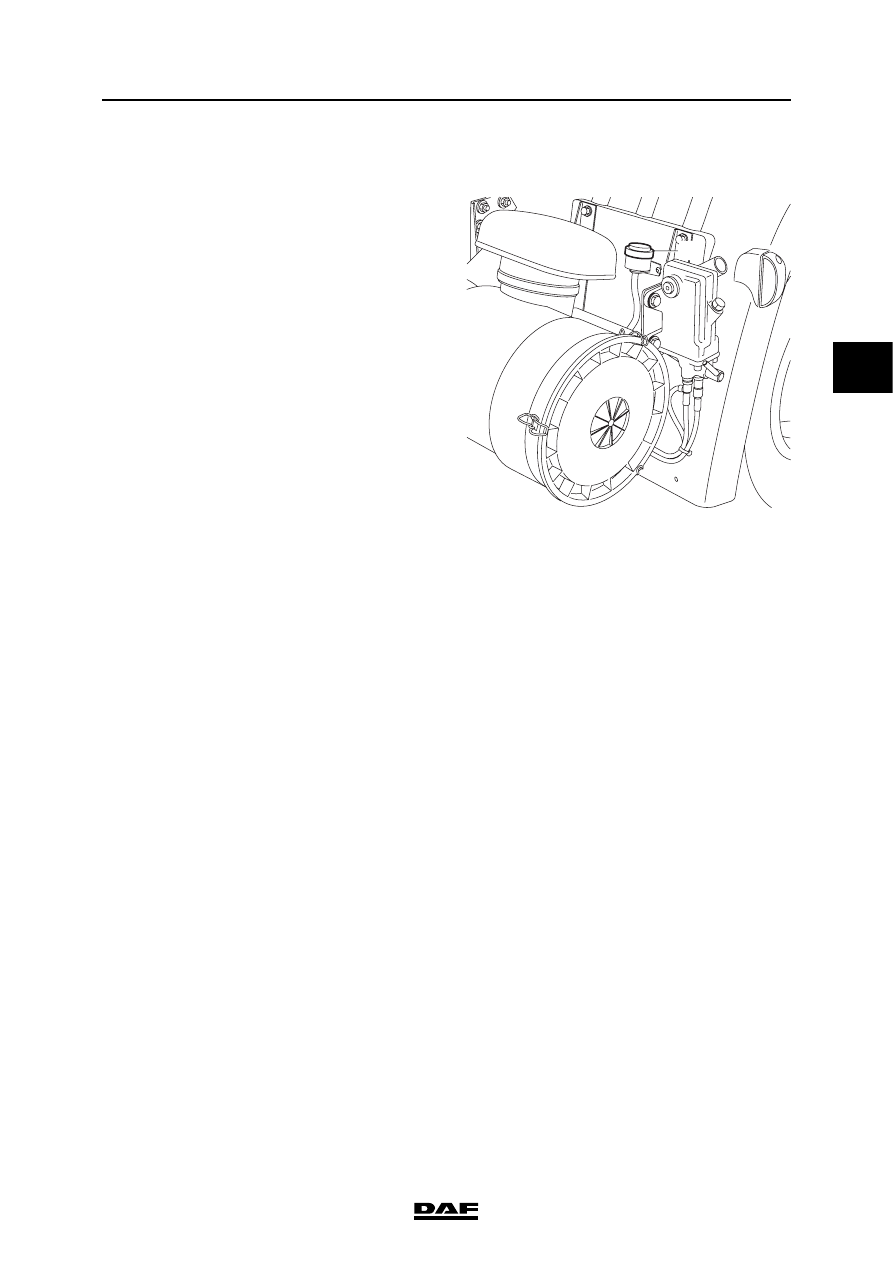

1.

Remove the connection of the air intake pipe

underpressure indicator (1) from between

the air filter housing and turbocharger.

2.

Connect a pressure gauge with a maximum

rating of -100 mbar (-10 kPa) to the

connection of the underpressure indicator.

3.

Measure the inlet underpressure at full-load

engine speed and compare the

measurement to the specified value. See

"Technical data".

4.

Fit the connection of the air intake pipe

underpressure indicator (1) between the air

filter housing and turbocharger.

i400514

1

BE ENGINE INLET/EXHAUST SYSTEM

3-8

©

200416

Inspection and adjustment

3

ΛΦ45/55 series

4

©

200416

4-1

Removal and installation

BE ENGINE INLET/EXHAUST SYSTEM

ΛΦ45/55 series

4

3

4. REMOVAL AND INSTALLATION

4.1 REMOVAL AND INSTALLATION, TURBOCHARGER

If the turbocharger to be replaced

has been damaged to such an extent

that parts of it are missing or

lubricating oil has entered the inlet

system, the inlet and exhaust

systems must be checked and

cleaned thoroughly in order to

prevent serious damage to the

engine.

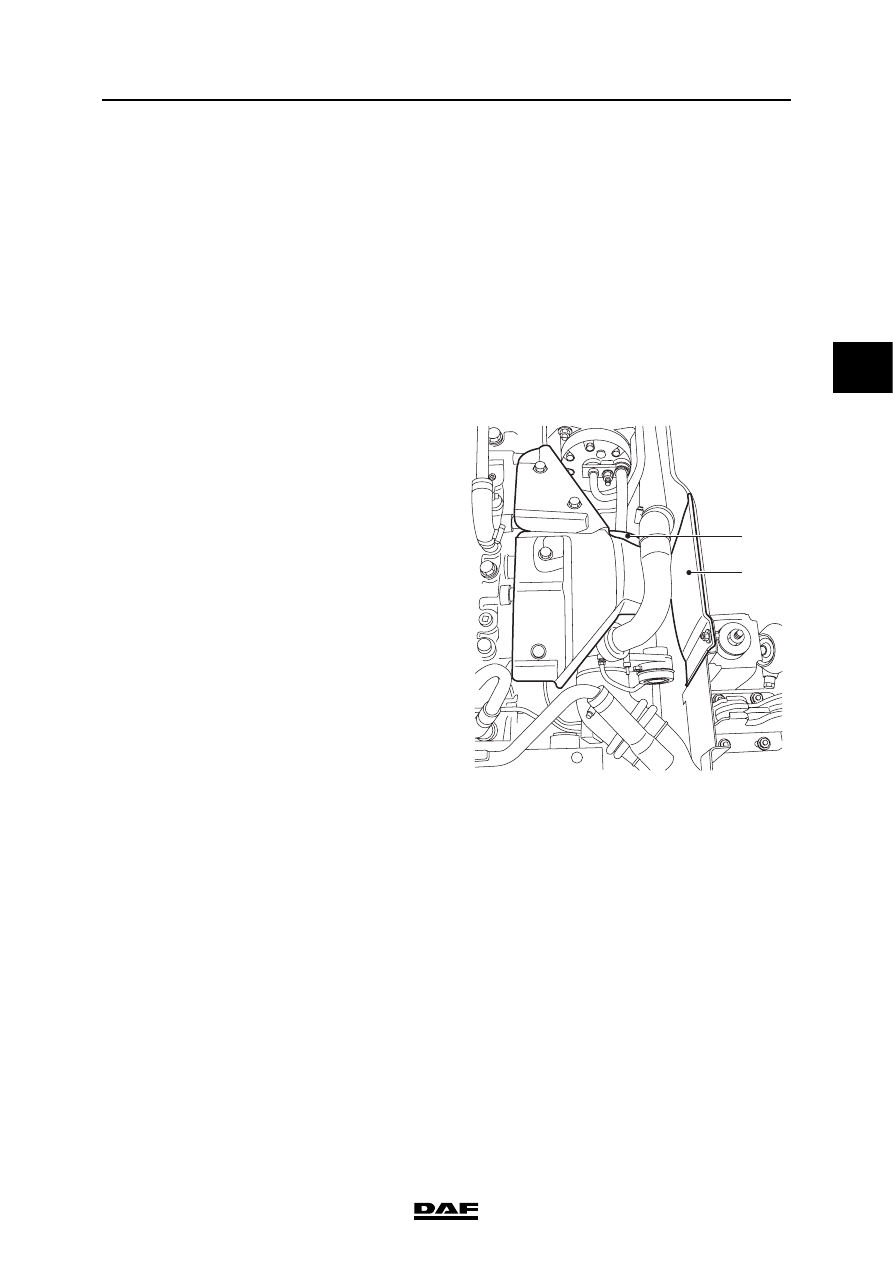

Removing the turbocharger

1.

Remove the right-hand engine

encapsulation (2).

2.

Remove the heat shield (1) from the oil filter.

3.

Remove each charge pipe and the

turbocharger exhaust pipe.

4.

Remove the oil discharge pipe from the

turbocharger.

5.

Detach the entire oil supply pipe from the oil

filter housing to the turbocharger.

6.

Remove the attachment bolts from the

turbocharger.

7.

Remove the turbocharger.

8.

Immediately plug the openings.

Installing the turbocharger

1.

Clean the turbocharger and the oil supply

and discharge pipes.

2.

Before installing the turbocharger, check the

following:

-

the turbocharger housing and connector

flange for cracks. See "Technical data"

for rejection standards;

-

the turbocharger shaft must be able to

rotate freely;

-

the turbocharger shaft must not run out

of true;

-

the turbocharger pump and turbine

wheels must not be damaged;

-

there must not be an excessive amount

of oil in the compressor side of the

turbocharger. A small amount of oil on

the inside walls of the compressor side

is allowed.

}

1

i400857

2

BE ENGINE INLET/EXHAUST SYSTEM

4-2

©

200416

Removal and installation

3

ΛΦ45/55 series

4

3.

Check the adjustment of the turbocharger

wastegate. See "Inspection and adjustment".

4.

Check the axial bearing play of the

turbocharger; see "Inspection and

adjustment".

5.

Check the radial bearing play of the

turbocharger; see "Inspection and

adjustment".

6.

Clean the sealing surfaces.

Note:

Always use new gaskets when installing the

turbocharger.

7.

Apply a layer of Copaslip to the exhaust

manifold studs.

8.

Fit the turbocharger to the exhaust manifold.

9.

Fit the attachment nuts and tighten them to

the specified torque. See "Technical data".

10. Check that the oil supply and discharge

pipes are clean and not blocked, kinked or

cracked. Replace the pipes if necessary.

Note:

If the turbocharger oil supply and/or

discharge does not function properly, this

may result in serious damage to the

turbocharger and/or engine.

11. Fit new O-rings to the oil discharge pipe and

apply a thin layer of engine oil to them. Fit the

oil discharge pipe. For the specified

tightening torque, see "Technical data".

12. Pour clean engine oil into the oil supply of the

turbocharger and fit the oil supply pipe, after

fitting a new copper ring, on the oil filter

housing and the turbocharger. Tighten the

pipe to the specified tightening torque; see

"Technical data".

Нет комментариевНе стесняйтесь поделиться с нами вашим ценным мнением.

Текст