Dodge Dakota (ND). Manual — part 869

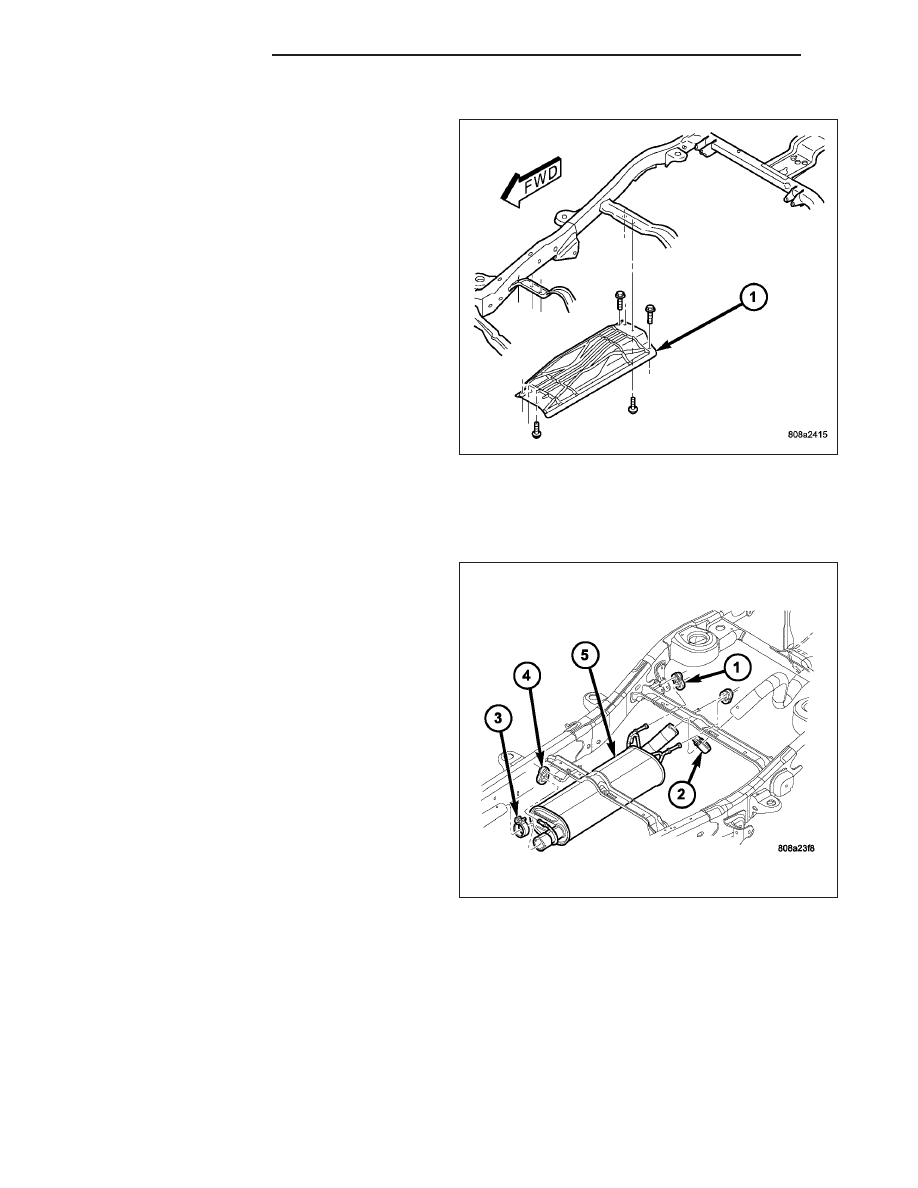

INSTALLATION

1. Position the heat shields (1) to the floor pan or the

frame and install the screws and nuts.

2. Tighten the screws/nuts to 7 N·m (60 in. lbs.)

torque. Tighten the muffler hangers (2) to 23 N·m

(200 in. lbs.)

3. Lower the vehicle.

MUFFLER

DESCRIPTION

All engines use a stainless steel muffler (1) to control

exhaust noise levels and exhaust back pressure.

OPERATION

The muffler is designed to muffle the sound of the exhaust as it leaves the engine.

11 - 6

EXHAUST SYSTEM

ND

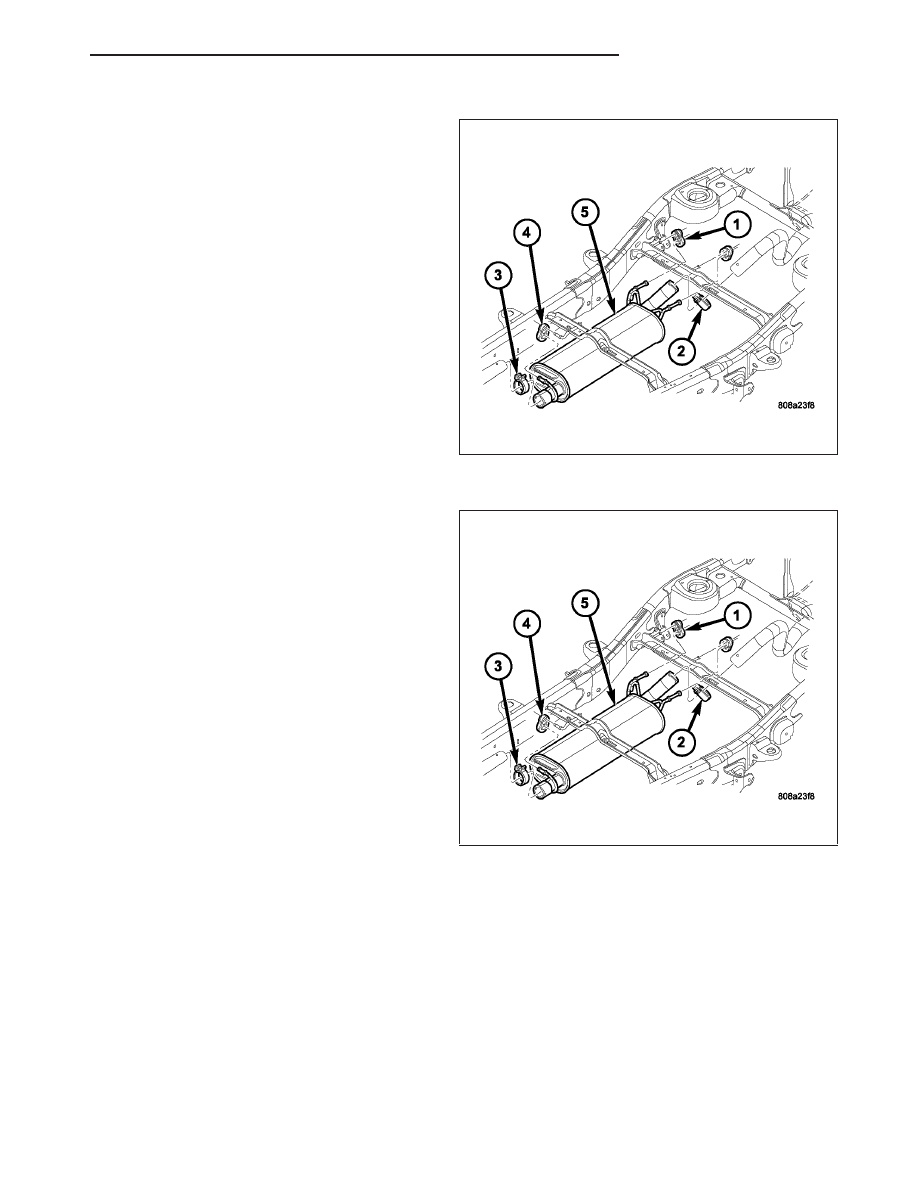

REMOVAL

1. Raise vehicle on hoist.

2. Remove the exhaust pipe (Refer to 11 - EXHAUST

SYSTEM/EXHAUST PIPE - REMOVAL).

3. Remove the muffler-to-catalytic converter clamp

(3).

4. Remove the muffler isolators (1 and 4).

5. Remove the muffler (5) from the catalytic converter.

INSTALLATION

NOTE: The band clamps are not reusable. After

removal, they must be replaced.

1. Install muffler to the catalytic converter (1).

2. Make sure the alignment tang seats in the align-

ment slot.

3. Install new exhaust clamp (4). Do not tighten at this

time.

4. Install muffler isolators.

5. Install exhaust pipe (Refer to 11 - EXHAUST SYS-

TEM/EXHAUST PIPE - INSPECTION).

6. Align muffler and exhaust pipe. Tighten exhaust

clamp nuts to 61 N·m (45 ft. lbs.).

7. Check the exhaust system for contact with the

body panels. A minimum of 25.4 mm (1.0 in.) is

required between the exhaust system components

and body/frame parts. Make the necessary adjust-

ments, if needed.

8. Lower vehicle.

9. Start engine and check for exhaust leaks. Repair exhaust leaks as necessary.

ND

EXHAUST SYSTEM

11 - 7

TAILPIPE

DESCRIPTION

The tailpipe is made of stainless steel and attaches to

the muffler.

OPERATION

The tailpipe channels the exhaust out of the muffler and out from under the vehicle to control noise and prevent

exhaust gas fumes from entering the passenger compartment.

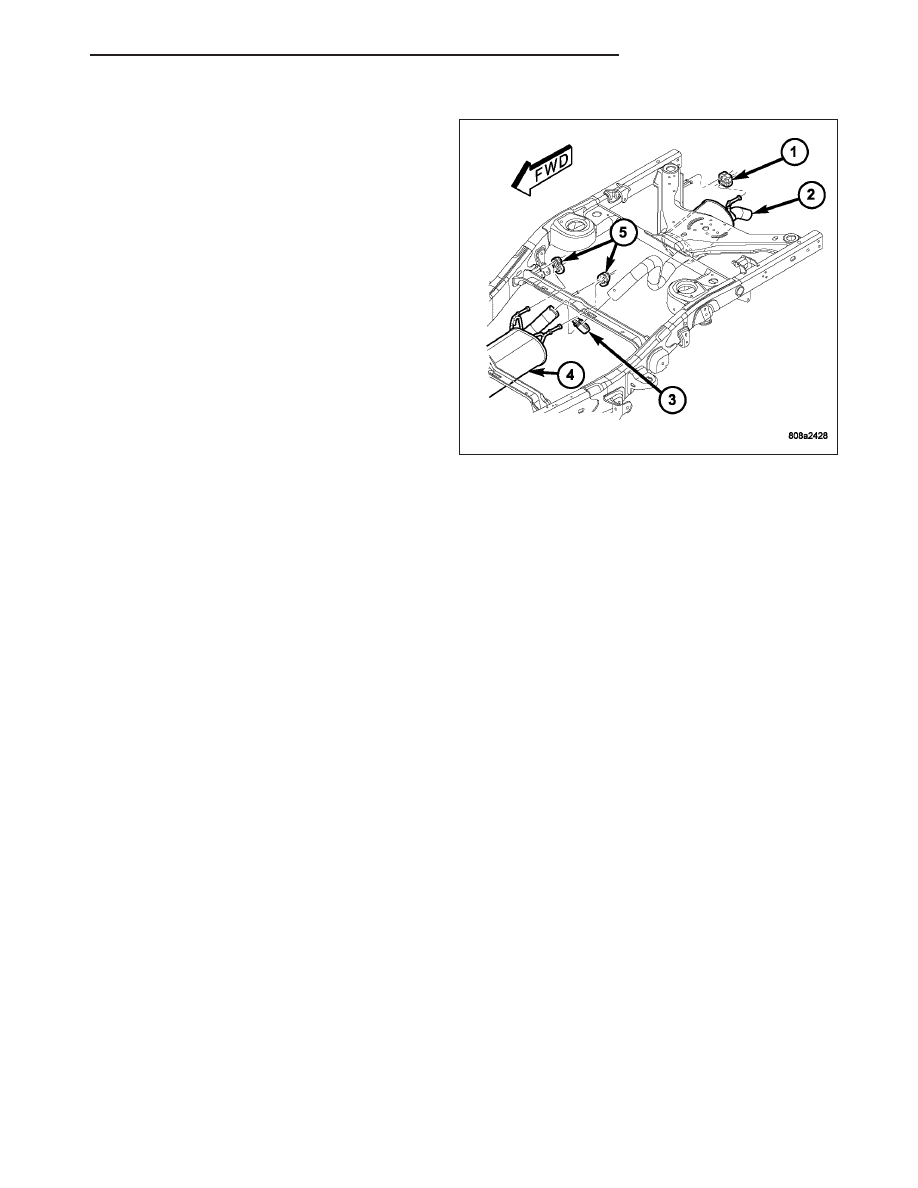

REMOVAL

WARNING: IF TORCHES ARE USED WHEN WORK-

ING ON THE EXHAUST SYSTEM, WEAR PROTEC-

TIVE EYE COVERING AND DO NOT ALLOW THE

FLAME NEAR THE FUEL LINES.

CAUTION: When servicing or replacing exhaust

system components, be sure to disconnect all

oxygen sensor connectors. Allowing the exhaust

system to hang by the harness will damage the

wiring and/or sensor.

1. Raise and support the vehicle.

2. Saturate the bolts and nuts with Mopar

T

Rust Pen-

etrant. Allow 5 minutes for penetration.

3. Remove the exhaust pipe-to-muffler clamp (3).

4. Grind any tack weld, if present.

5. Remove the exhaust pipe insulators (1).

6. Remove the rear muffler insulators (5) if necessary.

7. If necessary, heat connection with an oxygen/acetylene torch and twist tailpipe out of muffler.

8. Remove the exhaust pipe (2) from the muffler (4).

INSPECTION

Discard rusted clamps, broken or worn supports and attaching parts. Replace a component with original equipment

parts, or equivalent. This will assure proper alignment with other parts in the system and provide acceptable exhaust

noise levels.

11 - 8

EXHAUST SYSTEM

ND

INSTALLATION

NOTE: The band clamps are not reusable. After

removal, they must be replaced.

1. Remove any burrs from the exhaust pipe (2).

2. Connect the exhaust pipe (2) to the muffler (4).

3. Make sure that the alignment tang is seated in the

alignment slot.

4. Install the muffler-to-exhaust pipe clamp. Do not

tighten at this time.

5. Install the rear muffler insulators (5), if removed.

6. Install the tail pipe insulators (1)

7. Check the exhaust system for contact with the

body panels. Make the necessary adjustments, if

necessary.

8. Tighten muffler-to-exhaust pipe clamp to 61 N·m

(45 ft. lbs.).

9. Lower the vehicle.

10. Start the engine, inspect for exhaust leaks. Repair exhaust leaks as necessary.

ND

EXHAUST SYSTEM

11 - 9

Нет комментариевНе стесняйтесь поделиться с нами вашим ценным мнением.

Текст