Chrysler Le Baron, Dodge Dynasty, Plymouth Acclaim. Manual — part 30

(25) On automatic transaxle equipped vehicles,

verify the park/neutral position switch electrical con-

nector is attached to the switch (Fig. 16).

(26) On automatic transaxle equipped vehicles,

check the torque convertor lockup solenoid electrical

connection (Fig. 16).

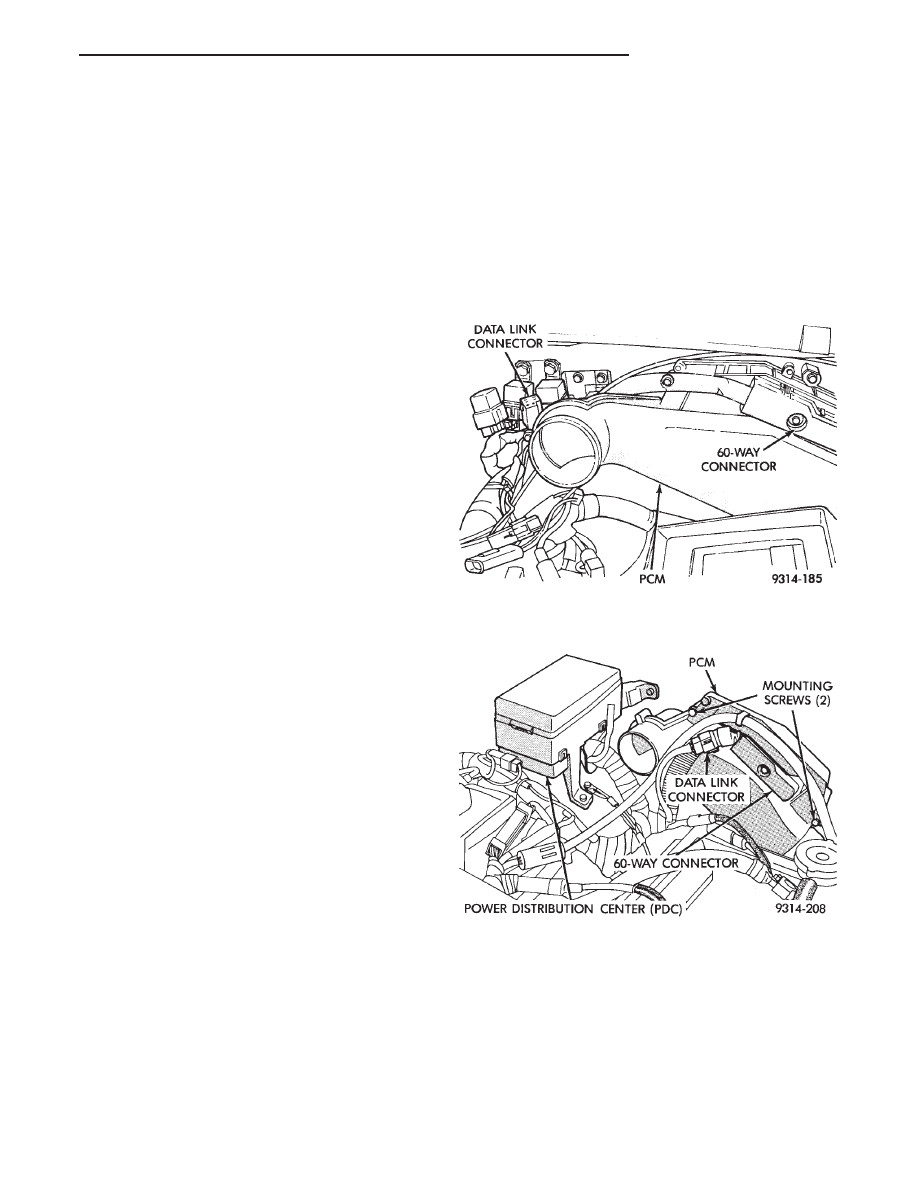

(27) Verify the 60-way connector is fully inserted

into the socket on the PCM (Fig. 17).

(28) Verify all electrical connectors are fully in-

serted into relays and that battery connections are

clean and tight (Figs. 18, 19, 20, 21, and 22).

Fig. 13 Ignition Cable Routing and Connection

Fig. 14 Coolant Temperature Sensor

Fig. 15 Distributor, Oil Pressure Switch, and

Radiator Fan Electrical Connections

Fig. 16 Automatic Transaxle Electrical Connections

Fig. 17 PCM Electrical Connector

14 - 38

FUEL SYSTEMS

Ä

(29) Verify engine harness to main harness con-

nections are fully inserted.

(30) Check the vehicle speed sensor connector (Fig.

23).

Fig. 18 Power Distribution Center (PDC) (AC Body)

Fig. 19 Relay Identification (AC Body)

Fig. 20 Relay Identification (AA and AP Bodies)

Fig. 21 Power Distribution Center (PDC) (AG and AJ

Body)

Fig. 22 Relay Identification (AG and AJ Body)

Fig. 23 Vehicle Speed Sensor Wiring Connection

Ä

FUEL SYSTEMS

14 - 39

(31) Verify engine ground strap is attached at the

engine and dash panel (Figs. 24 and 25).

(32) Verify oxygen sensor electrical connector is at-

tached to the sensor (Fig. 26).

(33) Check Hose and Wiring Connections at Fuel

Pump. Check that wiring connector is making con-

tact with terminals on pump.

Fig. 24 Engine Ground Strap at Intake Manifold

Fig. 25 Engine Ground Strap to Dash Panel

Fig. 26 Heated Oxygen Sensor Electrical

Connection

14 - 40

FUEL SYSTEMS

Ä

2.2L/2.5L SINGLE POINT FUEL INJECTION—ON-BOARD DIAGNOSTICS

INDEX

page

page

60-Way PCM Wiring Connector

. . . . . . . . . . . . . . 46

Circuit Actuation Test Mode

. . . . . . . . . . . . . . . . 45

Diagnostic Trouble Code Description

. . . . . . . . . . 42

General Information

. . . . . . . . . . . . . . . . . . . . . . . 41

High and Low Limits

. . . . . . . . . . . . . . . . . . . . . . 42

Ignition Timing Procedure

. . . . . . . . . . . . . . . . . . 46

Monitored Circuits

. . . . . . . . . . . . . . . . . . . . . . . . 41

Non-Monitored Circuits

. . . . . . . . . . . . . . . . . . . . 42

State Display Test Mode

. . . . . . . . . . . . . . . . . . . 45

Systems Test

. . . . . . . . . . . . . . . . . . . . . . . . . . . 45

Throttle Body Minimum Air Flow Check Procedure

GENERAL INFORMATION

The powertrain control module (PCM) has been

programmed to monitor many different circuits of the

fuel injection system. If a problem is sensed with a

monitored circuit often enough to indicate an actual

problem, the PCM stores a fault. If the problem is re-

paired or ceases to exist, the PCM cancels the Diag-

nostic Trouble Code after 50 to 100 vehicle key on/off

cycles.

Certain criteria must be met for a diagnostic trou-

ble code to be entered into powertrain control module

(PCM) memory. The criteria may be a specific range

of engine RPM, engine temperature, and/or input

voltage to the PCM.

It is possible that a diagnostic trouble code for a

monitored circuit may not be entered into memory

even though a malfunction has occurred. This may

happen because one of the diagnostic trouble code

criteria for the circuit has not been met. For exam-

ple, assume that one of the diagnostic trouble code

criteria for a certain sensor circuit is that the engine

must be operating between 750 and 2000 RPM to be

monitored for a diagnostic trouble code. If the sensor

output circuit shorts to ground when engine RPM is

above 2400 RPM (resulting in a 0 volt input to the

PCM) a diagnostic trouble code will not be entered

into memory. This is because the condition does not

occur within the specified RPM range.

There are several operating conditions for which

the PCM does not monitor and set diagnostic trouble

codes. Refer to Monitored Circuits and Non-Moni-

tored Circuits in this section.

Stored diagnostic trouble codes can be displayed by

cycling the ignition key On - Off - On - Off - On.

Also, the technician can display fault information us-

ing the DRB II scan tool. The DRBII scan tool con-

nects to the data link connector in the vehicle (Fig.

1, 2 or 3).

MONITORED CIRCUITS

The powertrain control module (PCM) can detect

certain fault conditions in the fuel injection system.

Open or Shorted Circuit - The PCM can deter-

mine if the sensor output (input to PCM) is within

proper range, and if the circuit is open or shorted.

Output Device Current Flow - The PCM senses

whether the output devices are hooked up. If there is

a problem with the circuit, the PCM senses whether

the circuit is open, shorted to ground, or shorted

high.

Oxygen Sensor - The PCM can determine if the

oxygen sensor is switching between rich and lean

Fig. 1 Data Link Connector Location—AA and AP

Vehicles

Fig. 2 Data Link Connector Location—AC Vehicles

Ä

FUEL SYSTEMS

14 - 41

Нет комментариевНе стесняйтесь поделиться с нами вашим ценным мнением.

Текст