Chrysler Le Baron, Dodge Dynasty, Plymouth Acclaim. Manual — part 31

once the system has entered closed loop. Refer to

Modes of Operation in this section for an explanation

of closed loop operation.

NON-MONITORED CIRCUITS

The PCM does not monitor the following circuits,

systems and conditions that could have malfunctions

that result in driveability problems. Diagnostic trou-

ble codes may not be displayed for these conditions.

However, problems with these systems may cause di-

agnostic trouble codes to be displayed for other sys-

tems. For example, a fuel pressure problem will not

register a fault directly, but could cause a rich or

lean condition. This could cause an oxygen sensor

fault to be stored in the PCM.

Fuel Pressure - Fuel pressure is controlled by the

fuel pressure regulator. The PCM cannot detect a

clogged fuel pump inlet filter, clogged in-line fuel fil-

ter, or a pinched fuel supply or return line. However,

these could result in a rich or lean condition causing

an oxygen sensor fault.

Secondary Ignition Circuit - The PCM cannot

detect an inoperative ignition coil, fouled or worn

spark plugs, ignition cross firing, or open spark plug

cables.

Engine Timing - The PCM cannot detect an incor-

rectly indexed timing chain, camshaft sprocket and

crankshaft sprocket. The PCM also cannot detect an

incorrectly indexed distributor. However, these could

result in a rich or lean condition causing an oxygen

sensor fault to be stored in the PCM.

Cylinder Compression - The PCM cannot detect

uneven, low, or high engine cylinder compression.

Exhaust System - The PCM cannot detect a

plugged, restricted or leaking exhaust system.

Fuel Injector Malfunctions - The PCM cannot

determine if the fuel injector is clogged, the pintle is

sticking or the wrong injector is installed. However,

these could result in a rich or lean condition causing

an oxygen sensor fault to be stored in the PCM.

Excessive Oil Consumption - Although the PCM

monitors the exhaust stream oxygen content through

the oxygen sensor when the system is in closed loop,

it cannot determine excessive oil consumption.

Throttle Body Air Flow - The PCM cannot detect

a clogged or restricted air cleaner inlet or filter ele-

ment.

Evaporative System - The PCM will not detect a

restricted, plugged or loaded evaporative purge can-

ister.

Vacuum Assist - Leaks or restrictions in the vac-

uum circuits of vacuum assisted engine control sys-

tem devices are not monitored by the PCM. However,

these could result in a MAP sensor fault being stored

in the PCM.

PCM System Ground - The PCM cannot deter-

mine a poor system ground. However, a diagnostic

trouble code may be generated as a result of this con-

dition.

PCM Connector Engagement - The PCM cannot

determine spread or damaged connector pins. How-

ever, a diagnostic trouble code may be generated as a

result of this condition.

HIGH AND LOW LIMITS

The powertrain control module (PCM) compares in-

put signal voltages from each input device with es-

tablished high and low limits that are programmed

into it for that device. If the input voltage is not

within specifications and other diagnostic trouble

code criteria are met, a diagnostic trouble code will

be stored in memory. Other diagnostic trouble code

criteria might include engine RPM limits or input

voltages from other sensors or switches that must be

present before a fault condition can be verified.

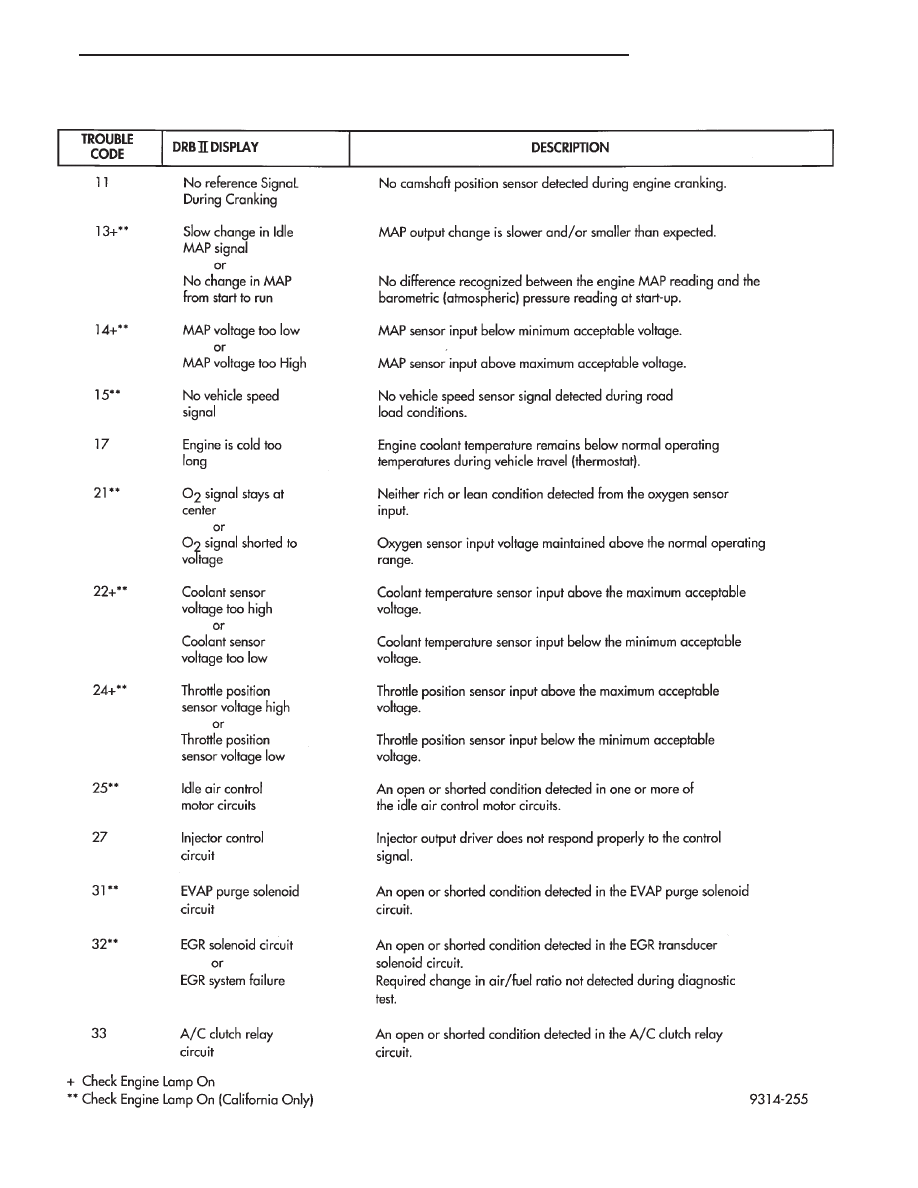

DIAGNOSTIC TROUBLE CODE DESCRIPTION

When a diagnostic trouble code appears, it indi-

cates the powertrain control module (PCM) has rec-

ognized

an

abnormal

condition

in

the

system.

Diagnostic trouble codes can be obtained from the

malfunction indicator lamp (instrument panel Check

Engine lamp) on the Instrument Panel or from the

DRBII scan tool. Diagnostic trouble codes indicate

the results of a failure but do not identify the failed

component directly.

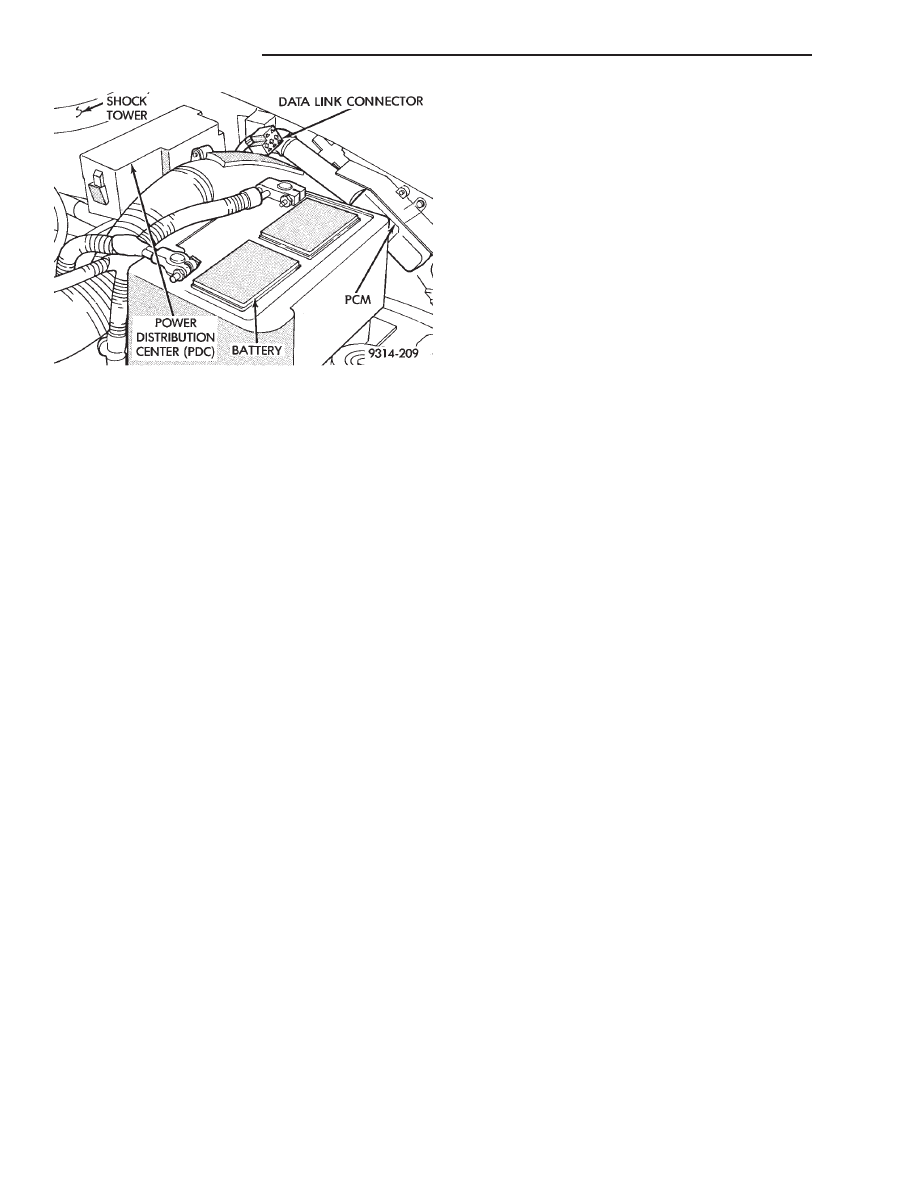

Fig. 3 Data Link Connector Location—AG and AJ

Vehicles

14 - 42

FUEL SYSTEMS

Ä

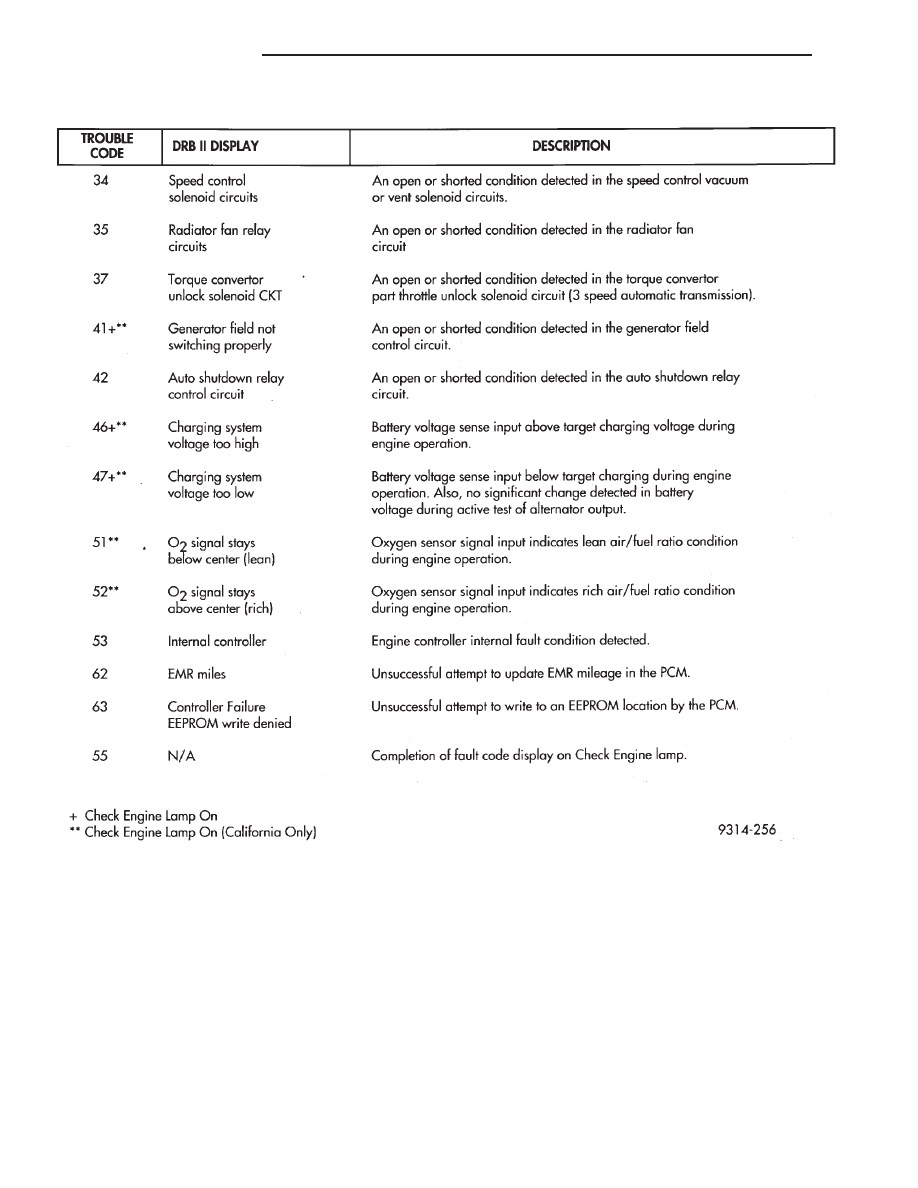

DIAGNOSTIC TROUBLE CODE DESCRIPTION

Ä

FUEL SYSTEMS

14 - 43

DIAGNOSTIC TROUBLE CODE DESCRIPTION

14 - 44

FUEL SYSTEMS

Ä

SYSTEMS TEST

WARNING:

APPLY

PARKING

BRAKE

AND/OR

BLOCK WHEELS BEFORE PERFORMING A TEST

WITH THE ENGINE OPERATING.

OBTAINING DIAGNOSTIC TROUBLE CODES

(1) Connect DRBII scan tool to the data link con-

nector located in the engine compartment near the

powertrain control module (PCM).

(2) Start the engine if possible, cycle the transaxle

selector and the A/C switch if applicable. Shut off

the engine.

(3) Turn the ignition switch on, access Read Fault

Screen. Record all the fault messages shown on the

DRBII scan tool. Observe the malfunction indicator

lamp (check engine lamp on the instrument panel).

The lamp should light for 3 seconds then go out (bulb

check).

STATE DISPLAY TEST MODE

The switch inputs used by the powertrain control

module (PCM) have only two recognized states,

HIGH and LOW. For this reason, the PCM cannot

recognize the difference between a selected switch po-

sition versus an open circuit, a short circuit, or a de-

fective switch. If the change is displayed, it can be

assumed that the entire switch circuit to the PCM is

functional. From the state display screen access ei-

ther State Display Inputs and Outputs or State Dis-

play Sensors.

STATE DISPLAY INPUTS AND OUTPUTS

Connect the DRBII scan tool to the vehicle and ac-

cess the State Display screen. Then access Inputs and

Outputs. The following is a list of the engine control

system functions accessible through the Inputs and

Outputs screen.

Park/Neutral Switch (automatic transaxle only)

Speed Control Resume

Brake Switch

Speed Control On/Off

Speed Control Set

A/C Switch Sense

S/C (Speed Control) Vent Solenoid

S/C (Speed Control) Vacuum Solenoid

Torque Converter Clutch Solenoid (3 speed auto-

matic transaxle)

A/C Clutch Relay

EGR Solenoid

Auto Shutdown Relay

Radiator Fan Relay

Purge Solenoid

Malfunction Indicator (Check Engine) Lamp

STATE DISPLAY SENSORS

Connect the DRBII scan tool to the vehicle and ac-

cess the State Display screen. Then access Sensor

Display. The following is a list of the engine control

system functions accessible through the Sensor Dis-

play screen.

Oxygen Sensor Signal

Coolant Temperature

Coolant Temp Sensor

Throttle Position

Minimum Throttle

Battery Voltage

MAP Sensor Reading

Idle Air Control Motor Position

Added Adaptive Fuel

Adaptive Fuel Factor

Barometric Pressure

Min Airflow Idl Spd

Engine Speed

Fault #1 Key-On Info

Module Spark Advance

Speed Control Target

Fault #2 Key-On Info

Fault #3 Key-On Info

Speed Control Status

Charging System Goal

Theft Alarm Status

Speed Control Switch Voltage

Map Sensor Voltage

Vehicle Speed

Oxygen Sensor State

MAP Gauge Reading

Throttle Opening (percentage)

Total Spark Advance

CIRCUIT ACTUATION TEST MODE

The circuit actuation test mode checks for proper

operation of output circuits or devices which the pow-

ertrain control module (PCM) cannot internally rec-

ognize. The PCM can attempt to activate these

outputs and allow an observer to verify proper oper-

ation. Most of the tests provide an audible or visual

indication of device operation (click of relay contacts,

spray fuel, etc.). With the exception of an intermit-

tent condition, if a device functions properly during

its test, it can be assumed that the device, its associ-

ated wiring, and its driver circuit are in working or-

der.

OBTAINING CIRCUIT ACTUATION TEST

Connect the DRBII scan tool to the vehicle and ac-

cess the Actuators screen. The following is a list of

the

engine

control

system

functions

accessible

through Actuators screens.

Stop All Tests

Ignition Coil #1

Fuel Injector #1

Idle Air Control Motor Open/Close

Ä

FUEL SYSTEMS

14 - 45

Нет комментариевНе стесняйтесь поделиться с нами вашим ценным мнением.

Текст