Chrysler Le Baron, Dodge Dynasty, Plymouth Acclaim. Manual — part 348

ELECTRIC MOTOR TEST

Make certain battery is in normal charged condi-

tion before circuits are tested.

To determine which motor is faulty, check each in-

dividual door for electrical lock and unlock or discon-

nect the motor connectors one at a time, while

operating the door lock switch. In the event that

none of the motors work, the problem maybe caused

by a shorted motor, or a bad switch. Disconnecting

the defective motor will allow the others to work.

The power lock motors are also equipped with a

thermal protection system which prevents the motors

from burning out. The motors may chatter if they are

continuously activated.

To test an individual door lock motor, disconnect

the wire connector at the motor (Fig. 2 and 3). Test

at the connector for 12 volts while applying door lock

switch. If no voltage repair wire. Apply 12 volts to

the motor terminal, and a known good ground to the

other terminal to check motor operation.

Should the motor defect be a result of a broken

wire, it should have no effect on the operation of the

other motors.

POWER DOOR LOCKS

When AC, AG, AJ or AY Body vehicles are

equipped with power door locks, the system includes

an automatic door locking feature which is actuated

through the vehicle’s body controller.

When this system is enabled the automatic door

locks will work automatically. When the system is

disabled the door locks will work by use of the door

lock switches only.

The body controller controls the power locks when

the door lock switch is activated. If the door lock

switch is pressed for longer than eight consecutive

seconds, the body controller will de-energize the door

lock relay. Also, the body controller will automati-

cally lock all doors when all of the conditions below

are met:

• All doors are closed

• The vehicle speed exceeds 15 6 1 MPH

• The throttle position sensor tip-in is greater than

10

6 2 degrees

The DRB II must be used to enable/disable the au-

tomatic door lock system. Refer to the Body Diagnos-

tic Procedures Manual for the procedure.

The body controller will automatically re-lock all

doors if the above conditions are met and if any of

the doors become ajar. The body controller does not

control the door unlock function. The switch is wired

directly to the lock relay.

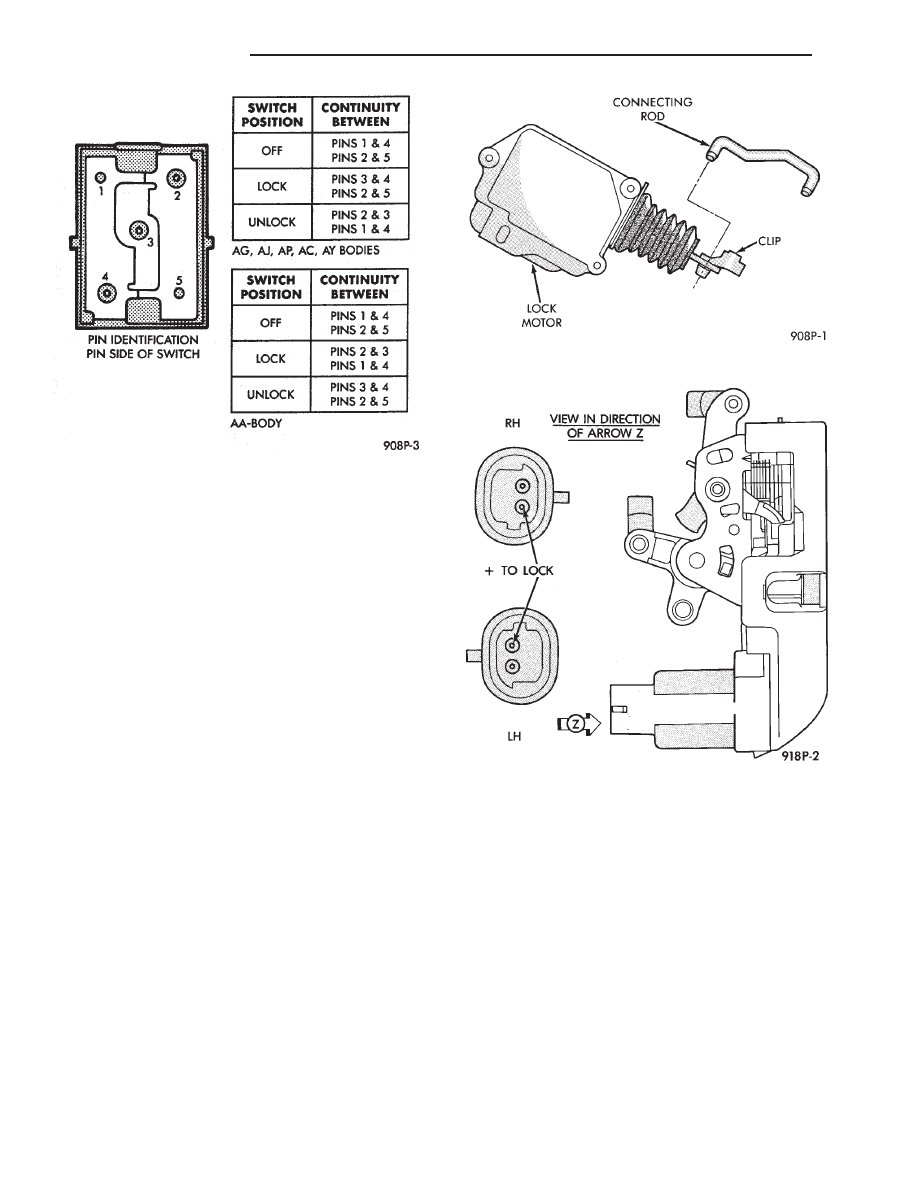

Fig. 1 Door Lock Switch Continuity

Fig. 2 Door Lock Motor

Fig. 3 Door Latch with Lock Motor—AC and AY

Bodies

8P - 2

POWER LOCKS

Ä

DOOR LOCK SYSTEM TEST

For complete testing of the AC, AG, AJ and AY

body automatic door lock systems, refer to the Body

Diagnostic Procedures Manual.

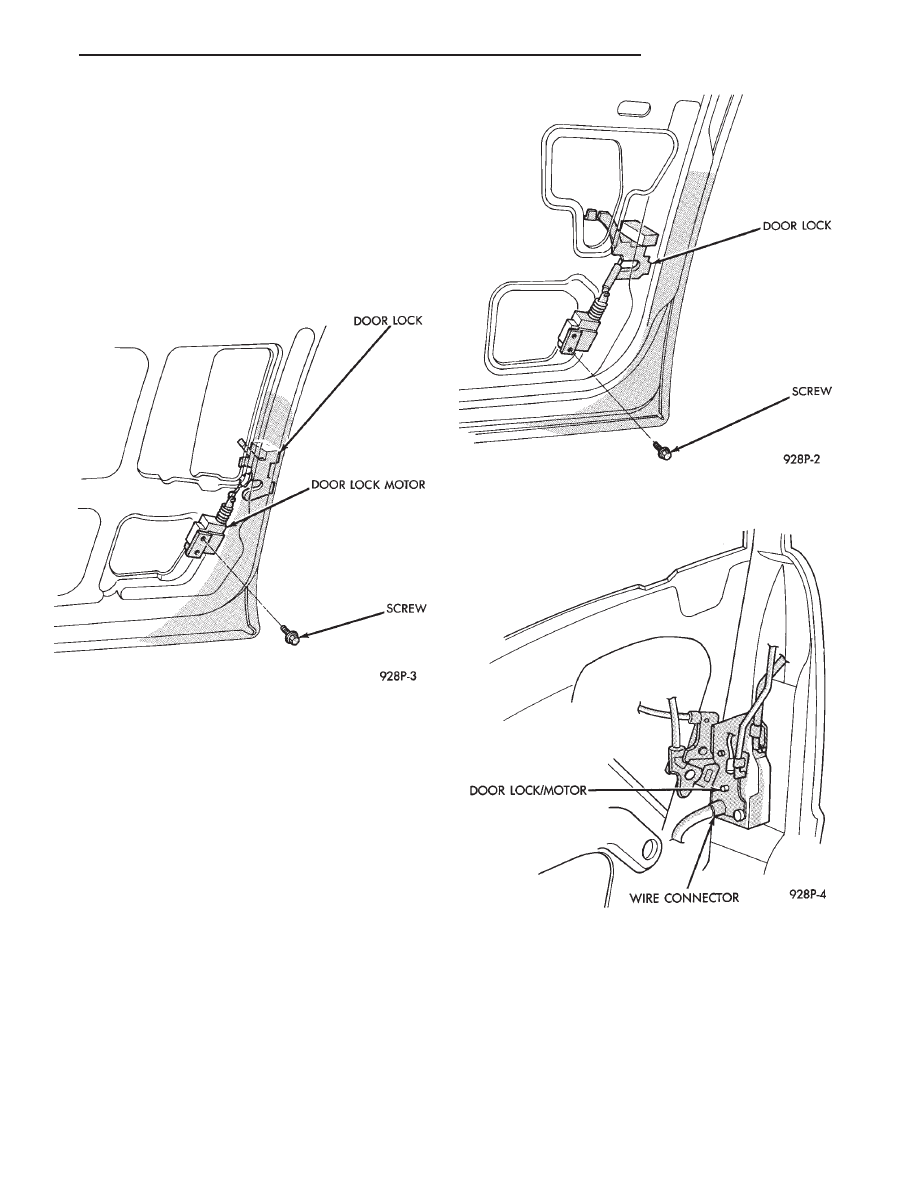

DOOR LOCK MOTOR REPLACEMENT

(1) Remove inside door release handle, window

regulator handle, if equipped and door trim panel.

(2) Roll door watershield away from lower rear cor-

ner of door to reveal inside panel access opening.

(3) Disconnect link at the motor as required (Fig. 4

through 7).

(4) Disconnect motor lead wires.

(5) Remove motor or latch attaching screws and re-

move motor assembly.

(6) For installation reverse above procedures.

DECK LID OPERATION

For vehicles equipped with electric deck lid release.

TEST

(1) Confirm solenoid lead wire is connected and 10

volts or more are available at solenoid.

(2) Provide proper ground through latch mounting

screws.

(3) Remove latch and examine plunger. Plunger

should spring back when pressed.

(4) Insure that solenoid plunger travel is adequate

approximately 16 mm (5/8 inch).

ADJUSTMENT

Adjust deck lid latch and striker so that deck lid

latches with a moderate slam. With ignition switch

in On or Accessory position, push deck lid unlock

switch. Should latch fail to lock or unlock replace

latch assembly.

DECK LID PULL-DOWN SYSTEM—AC and AY

BODIES

C-body vehicles have, as an option, a deck lid

power pull-down mechanism which latches and pulls

the deck lid down the last 25 mm (1 in.) of travel.

The system incorporates a combination latch/deck lid

Fig. 4 Front Power Door Lock Motors—AA, AG, AJ

and AP Bodies

Fig. 5 Rear Power Door Lock Motors—AA and AP

Bodies

Fig. 6 Front Power Door Lock Motors—AC and AY

Bodies

Ä

POWER LOCKS

8P - 3

release mechanism and a power pull-down motor as-

sembly (Fig. 8 through 10).

When the deck lid is closed, very light pressure is

required to cause the latch to grab the pull down bar.

The pull down motor will automatically take the

deck lid to its completely closed position.

POWER PULL DOWN

(1) Latch testing:

(a) With the deck lid open and the latch switch

released. There should be continuity between the

black with the red tracer (BK/RD*) and the black

(BK) wire (Fig. 10).

(b) With the latch switch depressed (as if the

deck lid was closed), there should be continuity be-

tween the black (BK) and the black with white

tracer (BK/WT*) wire terminals.

(c) If these results are not obtained, replace the

pull down latch.

(2) Pull down motor testing:

(a) With the pull down motor connector wiring

removed, connect a 12 volt positive source to the

red (RD) wire terminal of the motor and ground

the tan (TN) wire terminal. This will cause the

pull down bar to retract.

(b) With the positive source still connected to the

red (RD) wire terminal, ground the grey (GY) wire

terminal. This will cause the pull down bar to raise

Fig. 7 Rear Power Door Lock Motors—AC and AY

Bodies

Fig. 8 Deck Lid Pull Down Latch—AC and AY

Bodies

Fig. 9 Deck Lid Power Pull Down Motor—AC and AY

Bodies

Fig. 10 Deck Lid Power Pull Down Assembly—AC

and AY Bodies

8P - 4

POWER LOCKS

Ä

to the deck lid open position. If the pull down limit

switch is depressed at this time, the motor should

stop.

(c) If these results are not obtained, replace the

pull down motor assembly.

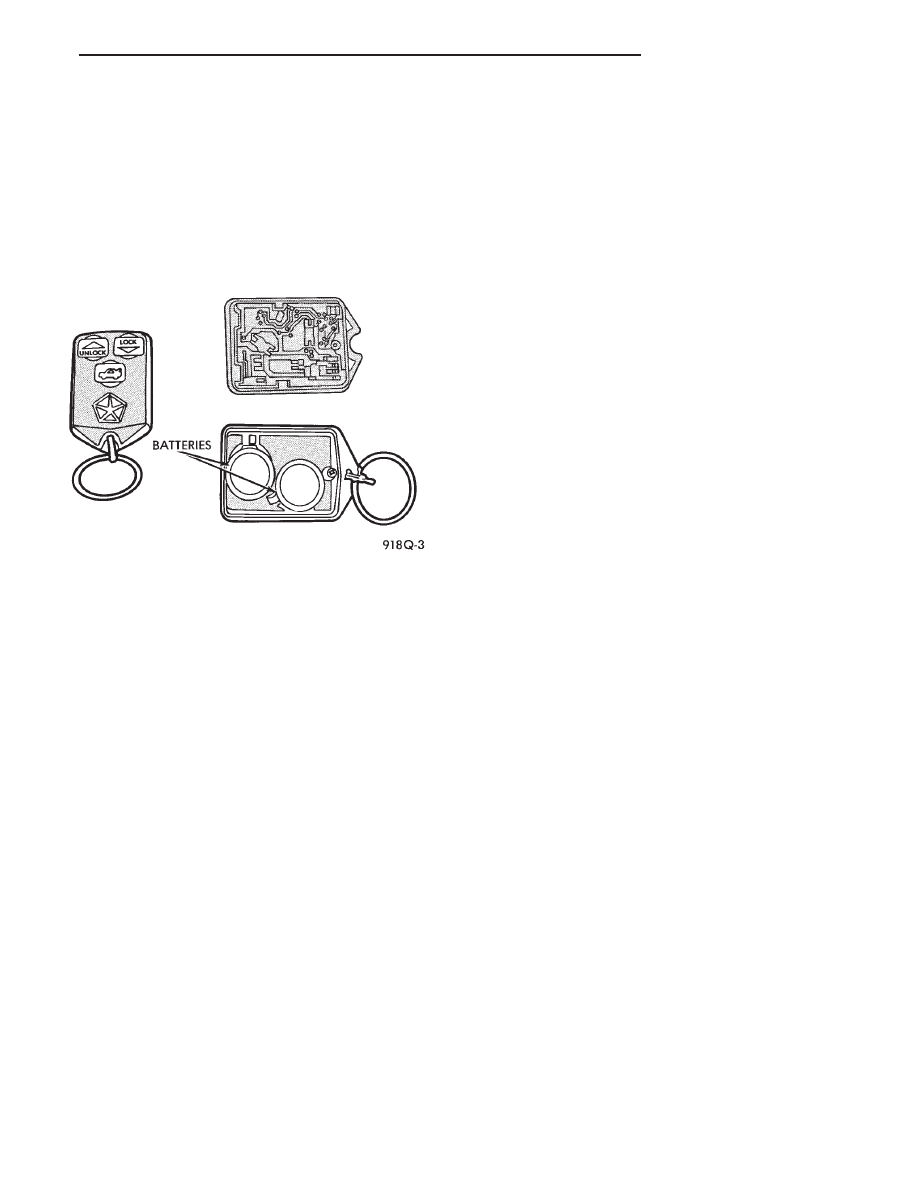

REMOTE KEYLESS ENTRY

OPERATION

The transmitter has three buttons for operation

(Fig. 11).

• UNLOCK driver’s door, enable illuminated entry,

and disarm the Theft Security System. Pushing and

releasing the button once will unlock the driver’s

door. Two times within five seconds all doors will un-

lock.

• LOCK all doors, set Theft Security System and

chirp horn. Chirp of horn is a short toot to notify

that the alarm system is set and the indicator lamp

on the instrument panel will flash for about 15 sec-

onds.

• Unlock Trunk Lid

• The receiver is capable of retaining VAC even

when power is removed.

• Each receiver must have at least one and no more

than two transmitters.

CONTROL RANGE

Operation range is within 7 meters (23 ft.) of the

receiver.

TRANSMITTER BATTERY

The battery can be removed without special tools

and are readily available at local retail stores. The

recommended battery is Duracell DL 2016 or equiv-

alent. Battery life is about one to two years.

PROGRAM REMOTE KEYLESS ENTRY

(1) Remove trim cover or floor console as needed

that may be covering the Air Bag System Diagnostic

Module (ASDM).

(2) Pull floor carpeting back between the accelera-

tor peddle and ASDM.

(3) Locate program line a dark green wire with a

insulator on the end. Located between the accelerator

and (ASDM).

(4) Turn ignition switch to the ON position.

(5) Connect the program line from the Remote

Keyless Entry Module to ground. The door locks will

lock and unlock to indicate the receiver is ready to

receive transmitter code. Trunk solenoid will not cy-

cle.

(6) Press any button on the transmitter to set code.

If there is a second transmitter it has to be set at

this time. The locks will cycle to confirm program-

ming.

(7) Disconnect the program line from ground. This

returns the system to its normal operation mode.

(8) Replace trim cover or floor console as neces-

sary.

HORN CHIRP CANCELLATION

During the programming operation the horn chirp

can be disabled using the following procedures:

(1) Remove trim cover or floor console as needed

that may be covering the Air Bag System Diagnostic

Module (ASDM).

(2) Pull floor carpeting back between the accelera-

tor peddle and ASDM.

(3) Locate program line a dark green wire with a

insulator on the end. Located between the accelerator

and (ASDM).

(4) Turn ignition switch ON.

(5) Connect the program line from the Remote

Keyless Entry Module to ground. The door locks will

lock and unlock to indicate the receiver is ready to

receive transmitter code. Trunk solenoid will not cy-

cle.

(6) Press any button on the transmitter to set code.

If there is a second transmitter it has to be set at

this time. The locks will cycle to confirm program-

ming.

(7) Press LOCK then UNLOCK transmitter but-

tons repeat three times.

(8) Door locks and rear release will cycle three

times as feedback of Horn Chirp lockout.

(9) Remove ground from program line to restore

normal system operation.

(10) To reinstate the Horn Chirp feature refer to

Program Remote Keyless Entry.

TESTING

CONDITION: When trying to program the receiver

module in the vehicle with a new transmitter and

there is no response from the module, Example: the

door locks do not cycle through a lock/unlock routine.

Refer to Fig. 12 for a block wiring diagram or to

Group 8W, Wiring Diagrams.

Fig. 11 Transmitter

Ä

POWER LOCKS

8P - 5

Нет комментариевНе стесняйтесь поделиться с нами вашим ценным мнением.

Текст