Chrysler Le Baron, Dodge Dynasty, Plymouth Acclaim. Manual — part 323

COMPACT DISC PLAYER

WARNING: USE OF THE CONTROLS, ADJUST-

MENTS, OR SERVICE PROCEDURES NOT SPECI-

FIED HERE OR IN THE OWNER MANUAL MAY

RESULT IN HAZARDOUS RADIATION EXPOSURE.

REPAIR PROCEDURES SHOULD ONLY BE PER-

FORMED BY A TRAINED TECHNICIAN.

DIAGNOSIS TEST

Power to the compact disc player is supplied by the

radio through the CD interface cable. The compact

disc player will only work with the radio system

turned ON. When a compact disc is inserted with the

label side facing up, the disc is automatically loaded

and will begin to play.

The CD player may eject the disc with a display of

E under the following conditions:

• The surface of the disc is dirty or wet

• The disc was inserted with the label side facing

down

• The disc is defective

• The CD player may skip or mute while playing a

disc under severe vibration conditions example pot

holes, railroad tracks, etc.

• If the CD player becomes too hot at temperatures

above 60°C (140 °F) the CD player will shut down

with a display of HOT until it cools down. Refer to

the Audio Diagnostic Charts.

COMPACT DISC PLAYER REPLACEMENT

With intergral compact disc player refer to Radio

Removal.

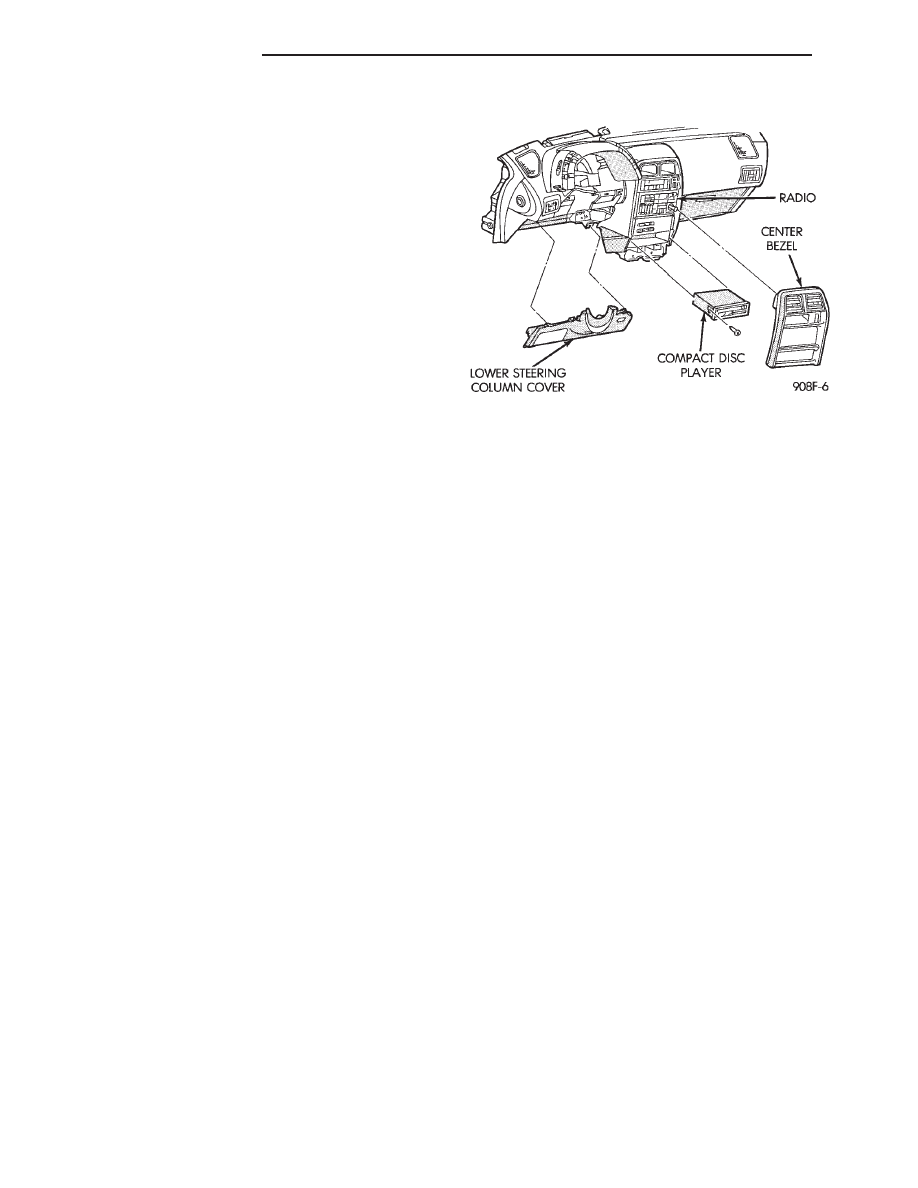

AJ BODY

(1) Remove center instrument panel bezel by pull-

ing toward the rear of the car.

(2) Remove two screws attaching disc player to

console (Fig. 36).

(3) Pull disc player out of console and disconnect

interface cable.

(4) To install compact disc player, above the re-

moval procedures.

Fig. 36 Compact Disc Player

8F - 30

AUDIO SYSTEM

Ä

HORNS

CONTENTS

page

page

GENERAL INFORMATION . . . . . . . . . . . . . . . . . . 1

HORN SWITCH REPLACEMENT

. . . . . . . . . . . . 3

TESTING HORN SYSTEM

. . . . . . . . . . . . . . . . . 1

GENERAL INFORMATION

WARNING: ON VEHICLES EQUIPPED WITH AIR

BAG, SEE GROUP 8M, RESTRAINT SYSTEMS FOR

STEERING WHEEL OR COLUMN REMOVAL PROCE-

DURES.

The horn circuit consists of a horn switch, horn re-

lay, and horns. The horn circuit feed is from the fuse

box to the number 1 terminal on the horn relay.

When the horn switch is depressed, this completes

the circuit to ground. This activates the horn relay

and an set of contacts in the relay to close, which al-

lows current to flow to the horn(s). The horn ground

wire is attached to the headlamp ground screw (Fig.

1).

TESTING HORN SYSTEM

HORNS WILL NOT SOUND

If the horns do not sound, check for a blown horn

fuse in the fuse block. If the fuse is blown, replace it

with the same fuse type. If the horns fail to sound

and the new fuse blows when depressing the horn

switch, a short circuit in the horn or the horn wiring

between the fuse terminal and the horn is responsi-

ble.

If the fuse is good, disconnect wire connector at

horn. Using an test lamp, connect one lead to the

negative terminal and the other to the positive ter-

minal (Fig. 2). Depress the horn switch, the test

lamp should illuminate. If not connect the test lamp

wire to a good ground and depress the horn switch. If

test lamp lights inspect ground wire circuit and re-

pair as needed.

If the test lamp fails to illuminate, check for a de-

fective horn relay. Substituting a known good horn

relay in the circuit. If the test lamp illuminates

when depressing the horn switch, the original relay

is defective. If the test lamp fails to illuminate with

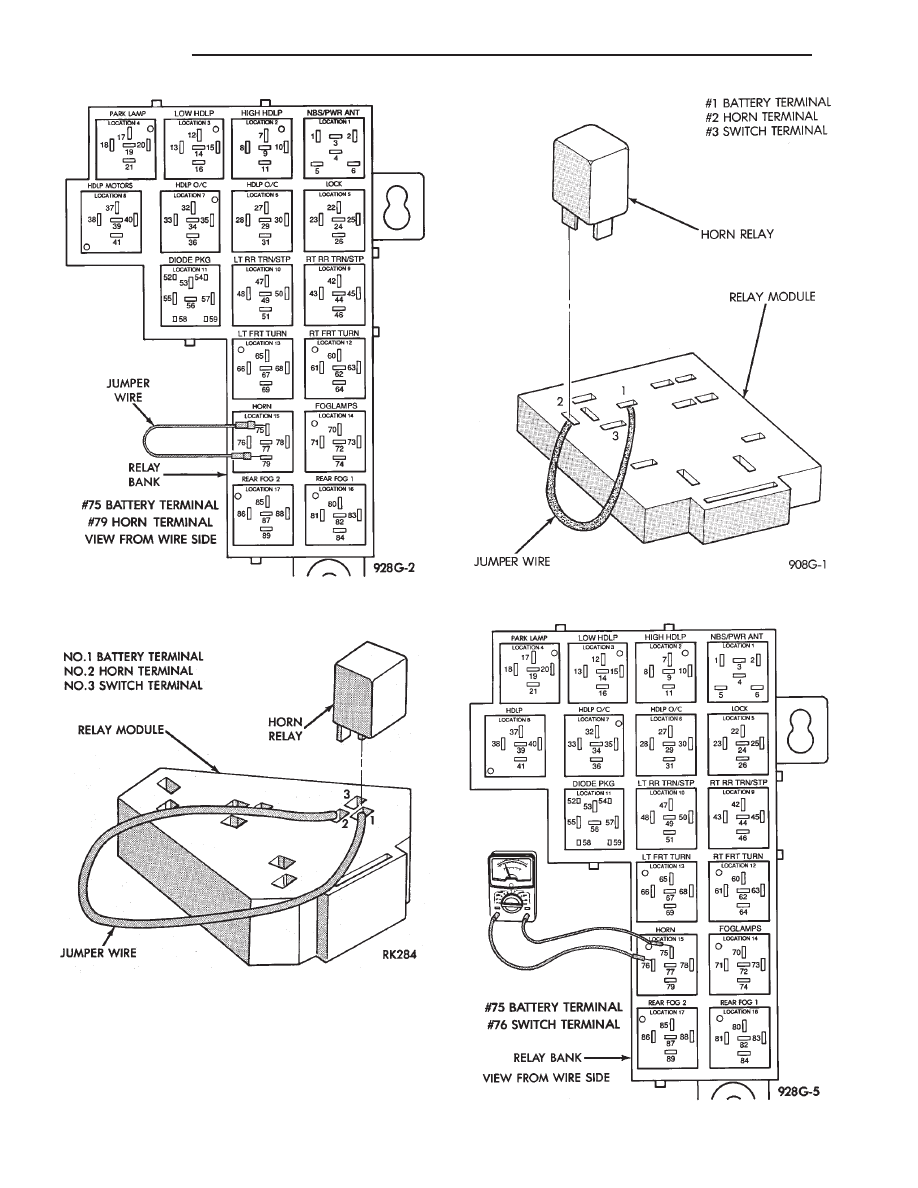

a known good relay, unplug that relay. Connect a

jumper wire from the battery terminal to the horn

terminal on the relay terminal board (Fig. 3, 4, or 5).

If the test lamp connected in place of the horns, fails

to illuminate an open circuit in the wiring between

the relay terminal and the horn switch is at fault re-

pair as necessary.

HORNS SOUND CONTINUOUSLY

CAUTION: Continuous sounding of horns may

cause relay to fail.

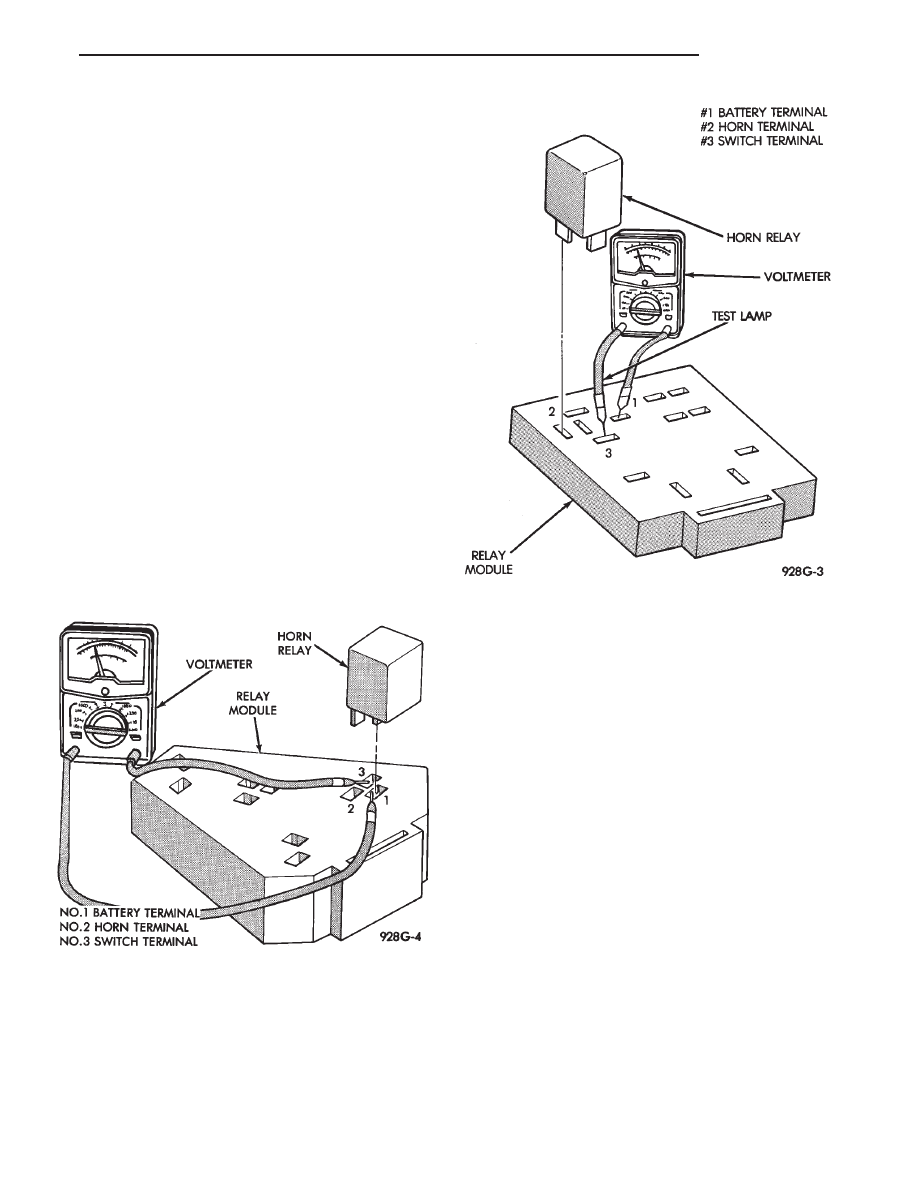

Should the horns sound continuously, unplug the

horn relay from the terminal board inside the pas-

senger compartment. Plug in a known good relay. If

the horns stop blowing, relay is defective and must

be replaced. Should the horns still sound, proceed as

follows: Connect one voltmeter lead to battery termi-

nal on relay board and the other lead to switch ter-

minal. Refer to Figs. 6, 7, or 8. Voltmeter will

Fig. 1 Conventional Horn System

Fig. 2 Horn and Connector

Ä

HORNS

8G - 1

register battery voltage when the wire to the horn

switch is shorted to ground or the horn switch is de-

fective.

Fig. 3 Testing for an Open Circuit—AG and AJ Bodies

Fig. 4 Testing for an Open Circuit—AP and AA Bodies

Fig. 5 Testing for an Open Circuit—AC and AY Bodies

Fig. 6 Testing for Short to Ground—AG and AJ Bodies

8G - 2

HORNS

Ä

Remove steering wheel horn pad and disconnect

wire from horn switch. Repeat the above test and if

the test lamp still illuminates, wire is shorted and

should be repaired. If test lamp does not illuminate,

horn switch is defective and must be replaced.

DIAGNOSIS TESTING

Horn does not sound, horn sounds intermittently,

or horn sounds continuously go to Horn Diagnosis

Chart (Fig. 9).

HORN SWITCH REPLACEMENT

WARNING: BEFORE BEGINNING ANY AIR BAG

SYSTEM REMOVAL OR INSTALLATION PROCE-

DURES, REMOVE AND ISOLATE THE NEGATIVE (-)

BATTERY CABLE (GROUND) FROM THE VEHICLE

BATTERY. THIS IS THE ONLY SURE WAY TO DIS-

ABLE THE AIR BAG SYSTEM. FAILURE TO DO

THIS COULD RESULT IN ACCIDENTAL AIR BAG

DEPLOYMENT AND POSSIBLE PERSONAL INJURY.

(1) Disconnect and isolate negative battery cable

in engine compartment.

(2) Remove four retaining nuts from back of steer-

ing wheel. Remove air bag module (Fig. 10 and 11).

(a) Disconnect wire from rear of air bag module.

(b) Place air bag module on a clean level surface

with pad facing upward.

(3) Remove horn switch assembly from steering

wheel.

(a) On luxury steering wheel (Fig. 10), pry out

two trim cover buttons on back of steering wheel to

access retaining screws for the horn switch. The

sport steering wheel (Fig. 11) the horn screws are

accessible after the Air Bag is removed.

(b) Remove two screws and disconnect horn wires

located in the lower portion of steering wheel. Feed

wires through the access ports and remove horn

switch.

(4) For installation reverse the above procedures.

Use caution not to pinch wires.

Fig. 8 Testing Horn for Continuous Sound— AP and

AA Bodies

Fig. 7 Testing for Short to Ground—AC and AY Bodies

Ä

HORNS

8G - 3

Нет комментариевНе стесняйтесь поделиться с нами вашим ценным мнением.

Текст